A pre-startup safety review (PSSR) is carried out to confirm that all appropriate elements of process safety management have been addressed satisfactorily and that the facility is safe to startup.

The objective of this position paper is to define the key attributes that would be rated by Marsh as very good for a PSSR in the oil, gas, and petrochemical industry. The attributes demonstrated in this Position Paper can be used to support and define risk improvement recommendations and can also provide detailed advice to clients seeking to improve their management systems.

VALUE OF THE PSSR PROCESS

The startup of new or modified equipment is a particularly vulnerable time for safety incidents and other unplanned events which can cause significant loss, both financial loss and damage to human life and health. A number of elements of good process safety management practice and capital project design include measures to reduce the risk of loss on startup. Such losses include, but are not limited to, incidents involving fire, explosion, environmentally damaging spill or gaseous release, or incidents involving injury to employees or members of the public. Poorly planned or executed startups can result in loss or wastage of materials, and other inefficiencies which can damage profitability.

Good management practices in this context include front-end engineering design (FEED), construction practices, quality assurance, process hazard analysis (PHA), management of change (MoC), and PSSR.

The PSSR provides a final checkpoint to confirm all appropriate elements of process safety management have been addressed satisfactorily and that the facility is safe to startup.

This includes checking that all the action items from other design and construction processes are complete.

Some projects may necessitate a number of PSSRs where different modules of process and utilities are brought into operation at different stages of commissioning.

WHAT ARE THE KEY STEPS IN A PSSR?

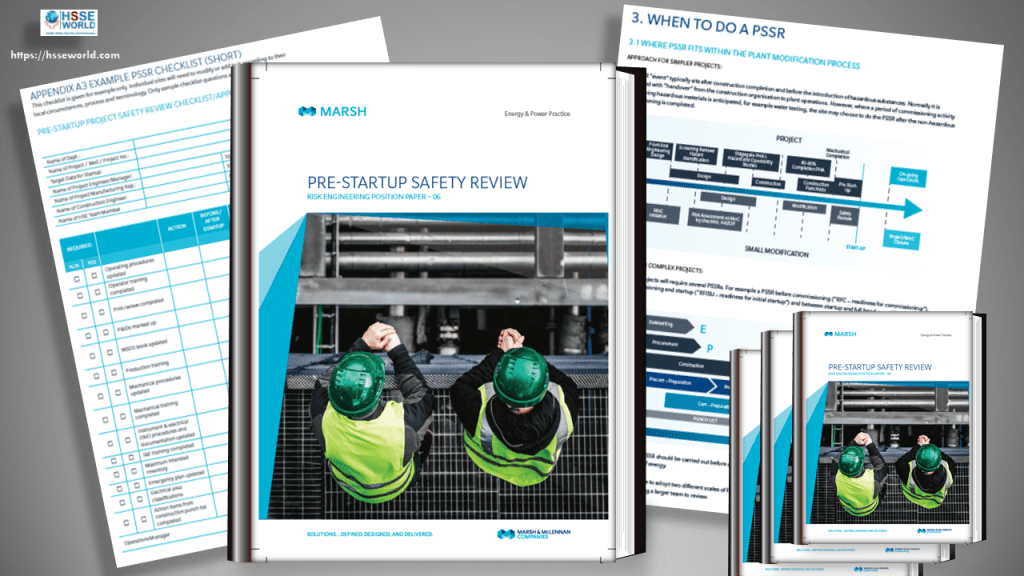

An organization should develop a written PSSR procedure requiring the following steps:

- Identification of the need for a PSSR, sometimes referred to as the trigger event, as identified in section 3.2 above.

- Assignment of a PSSR leader and team as indicated in sections 4.1 and 4.2.

- The PSSR team meeting to discuss the purpose of the PSSR, and review all the items on the PSSR checklist. This meeting is the core of the PSSR process and leads to:

- A review of the status of documentation on physical completion, procedures, training, piping and instrumentation diagrams (P&IDs), etc., as indicated in the example checklist in the appendices.

- A visit of the PSSR team to the actual installation to get visual confirmation of readiness for a startup.

- A visit to the control room to get visual confirmation of the readiness of the control room for the startup of the new parts of the installation.

- Completion of the PSSR checklist by the team (see section 7).

- Listing of action items that need correction before or potentially after startup.

- Team sign-off for one of the following scenarios:

- The facility is ready to startup, or move to the next phase.

- The facility may be started up but there are some issues that need to be dealt with after startup. These issues will be listed in the PSSR checklist, with responsibilities.

- The facility may not be started up until some issues are dealt with. These issues will be listed in the PSSR checklist with responsibilities.

- A managerial sign-off that the plant is ready to startup, or move to the next phase. The manager may or may not be part of the PSSR team, but the input from the PSSR team will be his/her primary source of advice that the facility is not ready to startup (see appendix A1 for suggested form).

- Action tracking with regards to issues that need to be dealt with after the PSSR. For organizations with central action tracking systems, this central action tracking system should also be used for the PSSR actions.

Contents

The Contents of Pre-Startup Safety Review Guide

- Objective 3

- Background 3

- When to do a pre-startup safety review (PSSR)? 5

- Who carries out the PSSR? 7

- What are the steps in a PSSR? 7

- Stewardship of the PSSR? 8

- Use of PSSR forms and checklists 8

- References 8

- Appendix A 10

- Example PSSR form 10

- Example PSSR checklist (long) 10

- Example PSSR checklist (short) 16

- Appendix B 18

- Self-assessment checklist 18

Download the book

Pre-Startup Safety Review Guide

(Download and read: pre-startup-safety-review-checklist-PSSR/)

More Downloads

- E-Books: Healthcare Hazard Control & Safety Management

- E-Books: Safety, Health and Working Conditions Training Manual

- E-Books: Energy Efficiency in Water and Wastewater Facilities

- E-Books: Fire Service Features of Buildings and Fire Protection Systems

- E-Books: Evaluation of Fire Safety free download

- E-Books: PPE for Chemical, Biological, and Radiological Hazards free

- E-Books: Changing the Workplace Safety Culture free download

- E-Books: Site Emergency Planning Workbook

- E-Books: Load Restraint Guide

- E-Books: Essential Practices for Creating, Strengthening, and Sustaining Process Safety Culture

- E-Books: System Safety Engineering and Risk Assessment

- E-Books: Permit-Required Confined Spaces

- E-Books: Is it Safe to Enter Confined Space?

- E-Books: 5-Minute Workplace Safety Talks

- E-Books: Safety Culture and High-Risk Environments

- E-Books: Practical Guide to Industrial Safety

- E-Books: Slip, Trip, and Fall Prevention for Healthcare Workers

- E-Books: Health and Safety at Work Key Terms

- E-Books: Fundamentals of Process Safety Engineering

- E-Books: Gas Detection Hand Book

- E-Books: Occupational health and safety management systems ANSI-AIHA-z10-2012

- E-Books: Hot Work on Drums and Tanks

- E-Books: Human Fatigue Risk Management

- E-Books: Guidelines for the provision of facilities and general safety in the construction industry

- E-Books: Handbook of Training in Mine Rescue and Recovery Operations ( 2021)

- E-Books: Code of Practice for the Safe Use of Lifting Equipment – Edition 9 (Nov 2019)

- E-Books: Free Forklift Health and Safety Best Practices Guideline

- E-Books: Handbook of Hazardous Chemical Properties

- E-Books: Human Performance Improvement through Human Error Prevention

- E-Books: Principles Of Fire Risk Assessment In Buildings

- E-Books: Investigation of Occupational Accidents and Diseases

- E-Books: Radiation Protection and Safety in Industrial Radiography

- E-Books: Basic Guide to System Safety, Third Edition

- E-Books: Food Safety Management-A Practical Guide for the Food Industry

- E-Books: Safety identification: Escape and evacuation plan signs- ISO 23601

- E-Books: Safety at Work

- E-Books: The Safety-Critical Systems Handbook 4th edition

- E-Books: Fundamental principles of occupational health and safety

- E-Books: Fire Safety Risk assessment Guide – Sleeping Accommodation

- E-Books: Mental health at work series

- E-Books: Live Fire Training: Principles and Practice

- E-Books: Pre-Startup Safety Review Guide

- E-Books: Fire and Emergency Drill Manual and Building Inspection Guide

- E-Books: Health and Safety: Risk Management 5th edition

- E-Books: Fire Protection systems -Third edition 2021

- E-Books: Fire Safety Logbook templates

- E-Books: From Accidents to Zero

- E-Books: Electric Safety Practice and Standards

- Your steps to chemical safety

- E-Books: Ergonomics and Psychology Developments in Theory and Practice

- E-Books: HAZOPS Should BE fun-The Stream-Based HAZOP

- E-Books: Safety Health and Environmental Auditing

- E-Books: A Quick Guide to Health and Safety

- E-Books: Occupational Ergonomics A Practical Approach

- E-Books: Job Hazard Analysis A Guide for Voluntary Compliance and Beyond

- E-Books: Electrical Safety of Low Voltage Systems