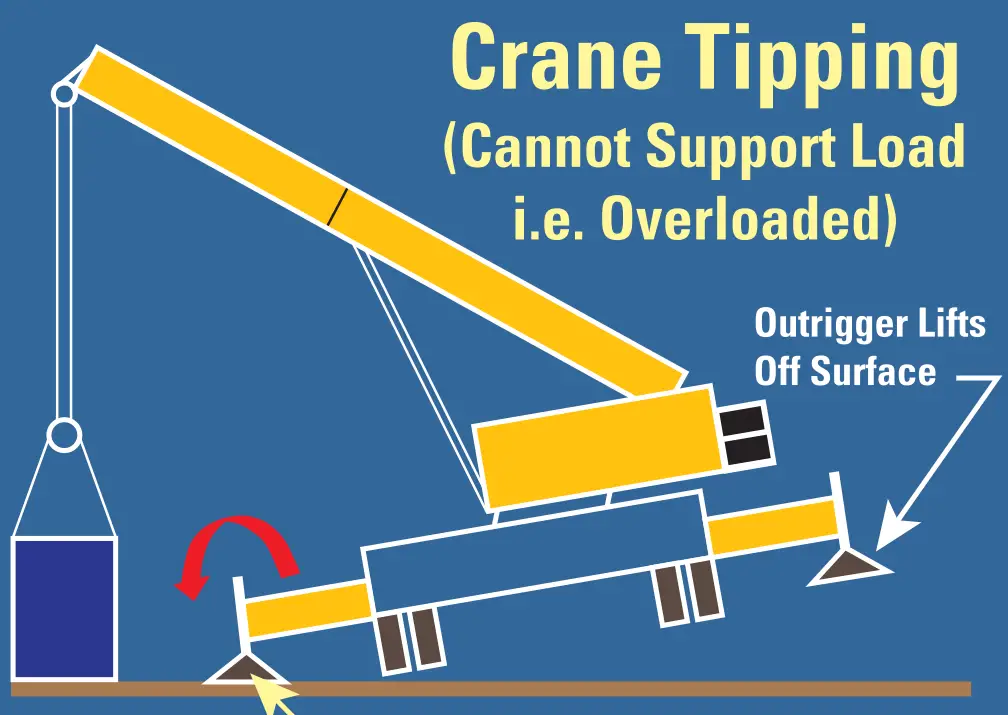

Of all crane-related accidents, tipping accidents are the most common. Crane operators who fail to follow the manufacturer’s guidelines regarding crane ratings are sure to suffer a tipping incident sooner or later. Possibly you have experienced a tipping incident where you felt the crane come up behind you (such as the feeling in the seat of the pants). Maybe you have had someone tell you that you had lifted one or more of the outriggers behind the crane or maybe you have been less fortunate, and your crane has turned over, changing the incident into an accident. In each of these cases, a loss of crane stability has come into play.

Studies show that one crane accident occurs for every 10,000 hours of use in the United States.

The easiest way to prevent a tipping accident is to never lift more load than what’s stated on the load chart and make sure your crane is set up properly. But, people do make mistakes.

Stability of Cranes

The suitability of ground conditions is the responsibility of the Contractor, who must ensure that all crane standing positions are prepared in accordance with the loading provided by the Company Representative. The stability of mobile cranes relies on the following factors:

- That the ground is suitably compacted and leveled. Underground services or constructions may suffer damage or collapse due to a crane passing over or nearby, which in turn may lead to the crane overturning. Arrangements must be made to avoid underground services and constructions, basements, and embankments.

- That the outrigger beams on the crane are extended to the required lengths or positions in accordance with the crane manufacturer’s specified duties and dimensions.

- That the outrigger jacks are extended to raise the crane wheels off the ground and free of weight.

- That adequate support material has been positioned under the outrigger jacks to prevent them from sinking into the ground whilst lifting loads.

- That the crane carries out lifting strictly in accordance with the manufacturer’s tables of Safe Working Loads, i.e. Duty Charts.

- The outrigger jack loading tables are for guidance only and show the maximum theoretical loads for a selection of various cranes in each category. Loadings for other crane models and specific outrigger loadings are available from the Crane Owner.

- The Crane Supervisor and Crane Operator must monitor ground conditions during the course of erection, paying attention to deterioration as a result of usage and adverse weather.

- If there is doubt about the ground condition, the Crane Operator should be instructed to fully retract the main boom derrick to minimize radius and then slew the counterweight in the direction of each outrigger in turn for two minutes to simulate actual lift.

Tipping of Cranes

The crane could tip over if:

- The crane is set up on the soft, unstable, or unsuitable ground.

- The crane is not set up level.

- The crane is positioned above underground services.

- Insufficient counterweights are used.

- There is wind.

- The weight of the load is calculated incorrectly.

- The outriggers of a mobile crane are not fully extended or used as directed in the manufacturer’s instructions.

Before the Lift:

- Inspect the crane ( Find out:crane-inspection-report).

- Complete a plan & Hazard assessment ( Find out: lift plan form/).

- Discuss the lift plan with the operator, dogman, and other persons involved in the lift. Make sure you understand the hazards and you are satisfied that they have been appropriately controlled.

- Ensure that the hazards and controls are communicated to all workers and anyone else in the vicinity that may be affected. Communication methods include:

- Work start/toolbox talks

- Permit to work systems

- Hazard boards

- Hazard signs

- Barriers

- Spotters.

- Follow the plan- Far too often accidents happen when the agreed-upon plan is not followed or enforced.

(Find out: critical lifts/ ).

During the Lift:

Ensure:

- Safety zones are maintained

- Workers are following safety instructions

- The lift plan is being followed.

After the Lift:

- Provide feedback to the operator and dogman

- Cancel any permits to work

- Raise any health and safety or operating concerns with the controller

- Discuss any areas for improvement with site workers at the next site meeting.

What Are We Going to Do Today?

What will we do at the worksite to prevent injuries while working with cranes?

More Safety Moments

- 15 Home Insurance Safety Tips to Lower Premiums

- 66 Safety Tips at work-Safety Moment#17

- Abrasive blasting: Know the hazards -Safety Moment #7

- Annual inspection and certification requirements for mobile cranes and boom trucks-Safety Moment#18

- Arc Flash Protection -Safety Moment #3

- Cleaning chemicals Tips: Know the risks -Safety Moment #9

- Common Causes of the workplace incident: Safety Moment#32

- Cranes Stability and Tipping: Safety Moment#29

- Don’t ignore shoulder pain-Safety Moment #11

- Electrical Safety Tips -Safety Moment #6

- Electrical Safety While Working From Home: Safety Moment#30

- Explain chemical Data Sheets For Non-Technical People-Safety Moment #10

- Exposure Limit Terms -Safety Moment#21

- Falls from heights :Video-Safety Moment #14

- Flammable Liquid Storage -Safety Moment #1

- Gasoline Safety Tips

- Hidden Hazards:25 steps to a safer office -Safety Moment #15

- How to use Plate Clamps Safely: Safety Moment#34

- Keeping Warehouse Personnel Safe 6 Key Tips -Safety Moment#20

- Know how to handle a hammer -Safety Moment #4

- Machinery Guarding: Safety Moment#31

- Oil & extraction: hazards, controls & resources -Safety Moment#22

- Photo of the day: 10 Scaffold Safety Essentials

- Photo of the day: Flood Safety Tips

- Photo of the day: Incident Investigations

- Practice caution when handling fuel-Safety Moment #13

- Quick Tips for Avoiding Pinch Point Injuries: Safety Moment#27

- Risk of Explosion during Removal of Split Rim/Multi Piece Wheels from Vehicles-Safety Moment #8

- Safety Net Regulations: Safety Moment#28

- Scaffolding Safety Tips

- The Golden safety rules :Video-Safety Moment #12

- Tick’s Threats when working outdoors -Safety Moment #16

- Tips to Avoid Standstill Accidents: Safety Moment#33

- Tips to prevent heat illness -Safety Moment #5

- Understanding RF radiation-Safety Moment#19

- Vehicle Backing Safety Facts

- Video: Aerial Work Platform Safety: Safety Moment#35

- Video: Avoiding line of Fire: Safety Moment#36

- Video: Electrical Safety Awareness -Safety Moment#23

- Video: Isocyanates Exposure -Safety Moment#24

- Video: Winter’s Hidden Hazard -Safety Moment#25

- Video: Working safely Near powerlines -Safety Moment#26

- Working safely with cement -Safety Moment #2