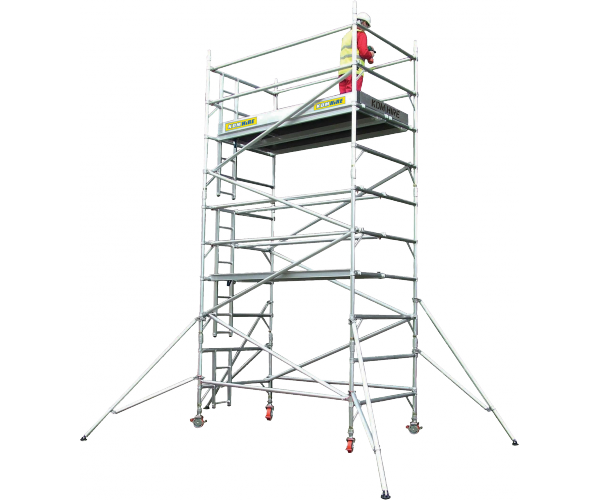

Working at height can be dangerous if the proper precautions aren’t taken. In fact, scaffolding-related accidents account for a large number of injuries in the construction industry every year. According to the Occupational Safety and Health Administration (OSHA), around 4,500 scaffolding-related injuries occur annually, which results in a whopping $90 million worth of lost workdays and other associated costs such as increased insurance premiums and potential fines.

These accidents are often preventable, thereby making a bit of preparation incredibly valuable.

There are many ways for employers to protect their employees from scaffolding-related accidents, including providing adequate training to their workers.

In this article, we will discuss ten important scaffolding safety tips, as well as the following:

- What is Scaffolding Safety?

- Scaffolding Construction

- Access and Use

- Scaffold Inspection and Tagging

- Records

- Training

- Auditing

Also Read: Photo of the day: 10 Scaffold Safety Essentials

What is Scaffolding Safety?

Scaffolding safety is a combination of practices and safety procedures that aim to prevent scaffolding-related accidents. These accidents can occur due to several reasons, such as falls, electrocution, being struck by falling objects, and more.

To avoid these accidents, employers need to provide adequate training and orientation on scaffolding safety procedures to their workers. Additionally, workers should be aware of the potential hazards associated with working on scaffolds and take the necessary precautions to avoid them.

Scaffolding Construction

- Erect scaffolds according to applicable standards and designs.

- A competent person must supervise each scaffold that is erected, altered, relocated, or dismantled. Only experienced and trained workers must perform the work. The competent person also determines the feasibility and safety of providing fall protection for workers who erect or dismantle scaffolding.

- Do not mix scaffold components from different manufacturers unless the components fit together (unmodified) without force and the structural integrity is maintained.

Also Read: What are the Types of scaffold’s load?

- Erect scaffolds on sound, rigid footing capable of carrying the maximum intended load. Do not load scaffolds and scaffold components in excess of their maximum intended load or rated capacity, whichever is less.

- Install standard railings and toe boards on all open sides and ends of platforms more than 10 feet (3 m) in height, except on needle beam scaffolds and floats. Install standard railings and toe boards on all open sides and ends of platforms on scaffolds 4 – 10 feet (1.2 – 3 m) high, having a minimum dimension in either direction of fewer than 45 inches (1.14 m).

- Erect scaffolds level and plumb on a firm base.

- Tie off scaffolding horizontally every 30 feet (9 m).

- Scaffolds and their components, except for wire or fiber rope suspension, must be capable of supporting 4 times the maximum intended load. Wire or fiber rope used to suspend scaffolds must be capable of supporting at least 6 times the maximum intended load.

- For planks, use 2-inch (5.1 cm) scaffold-grade lumber, laminated wood, or manufactured aluminum decking. Lap the planking by a minimum of 12 inches (0.3 m). Secure the planking properly to prevent displacement and sideways movement.

- Scaffold platforms and walkways must measure at least 18 inches (0.46 m) wide.

- Provide overhead protection for employees working on scaffolds who are exposed to falling objects. Where persons work or pass under a scaffold, install a screen between the toe board and top rail, extended along the entire opening, consisting of No. 18 U.S. gauge 1/2-inch (1.27 cm) mesh or equivalent.

- Restrain scaffolding with a height-to-base width (including outrigger supports, if used) ratio of more than 4:1. Place restraints vertically at the horizontal members every 20 feet (6 m) or less. Place restraints at horizontal intervals of no more than 30 feet (9 m).

- When space permits, scaffold platforms (except for float and needle beam scaffolds) must be equipped on all open sides with standard 42 inches (1.1 m) high handrails rigidly secured, standard 21-inch (0.53 m) mid rails, completely decked, and rigidly secured toe boards.

- Scaffold planks may extend over their end supports by 6 to 12 inches (0.15 to 0.3 m).

- Counterweights, if used, must be made of non-flowable material. Do not use sand, gravel, or similar materials.

- Immediately repair or replace scaffolding or defective parts in scaffolding and accessories.

- Do not erect, use, dismantle, alter, or move scaffolds such that they or any conductive material handled on them might come closer to exposed and energized power lines according to the chart below at a minimum, or in compliance with local standards. Allow the following clearance between scaffolds and power lines:

| VOLTAGE | Minimum Distance from INSULATED LINES |

| Less than 300 volts | 3 feet (0.9m) |

| 300 volts to 50 k volts | 10 feet (3 m) |

| More than 50 k volts | 10 feet (3 m) plus .4 inches (1 cm) /each 1kv |

| VOLTAGE | MINIMUM DISTANCE FROM UNINSULATED LINES |

| Less than 50 k volts | 10 feet (3 m) |

| More than 50 k volts | 10 feet (3m) plus .4 inches (1 cm) /each 1 kV |

Also Read: Major Safety Concerns for Construction Workers

Access and Use

- Provide a safe and convenient means of access to the working platform, such as a portable or fixed ladder, ramp, runway, or stairway. This does not apply to swinging scaffolds or those with safe and convenient access from adjacent floors. Do not use cross-bracing as a means of access.

- Wear personal fall protection connected to an independently secured horizontal or vertical lifeline or building structure when working from a suspended scaffold, boatswains’ chair, catenary, float, needle beam scaffold, or any scaffold platform not equipped with standard handrails, mid-rails on all open sides, or complete deck.

Also Read: Mobile Scaffold Inspection checklist

- Provide overhead protection for workers on scaffolds exposed to overhead hazards.

- Secure swinging loads lifted onto or near scaffolding by a tagline or equivalent measures to control the load.

- Do not change or remove a scaffold unless authorized by the supervisor responsible for its erection.

- Do not ride on the mobile scaffold. Remove or secure tools or materials on the deck before moving.

- Do not climb on or work from a scaffold handrail or mid-rail. Do not apply rigging to a handrail, mid-rail, or scaffold brace.

- Do not alter scaffold members by welding, burning, cutting, drilling, or bending. Do not combine parts and sections of scaffolding made by one manufacturer with those from a different manufacturer.

- Keep scaffold platforms and accessways free of tripping or slipping hazards.

- Do not use scaffolds during storms or high winds.

- Pick up rubbish on scaffolds daily and do not leave tools on scaffolds overnight.

- Do not stockpile or store material on scaffolds.

- Do not use makeshift devices such as, but not limited to, boxes and barrels on scaffold platforms to increase the work level height.

- Employees may use ladders on large area scaffolding to increase work level height if the following conditions are met:

- The ladder must be secured to prevent sideways motion.

- Ladder legs must be stabilized on the same platform.

- Protect scaffolds from trucks and other vehicles contacting them.

- Clear working platforms of ice, snow, and oil before using them.

- Keep scaffolds clean, with no scrap, loose tools, or tangled lines.

- Do not allow open fires upon or near wooden scaffolds or metal scaffolds with flammable components.

- For work from suspended scaffolds, or metal frame scaffolds greater than 30 feet (9 m) in height, contact the EHS.

Scaffold Inspection and Tagging

- The foreman responsible for erecting the scaffold must inspect the scaffold after erection and before use to determine that:

- The scaffold hardware is not defective, and the components are compatible and sufficient.

- Standard guardrails and decking are in place.

- Wheels on mobile scaffolds are locked.

- Ladder is in place for proper access.

- Locking pins are in place at each joint.

- Toeboards are in place.

- No damage to hooks on manufactured platforms.

- Wooden planks are free of splints, knots, and dry rot.

- No de-lamination of laminated veneer planks.

- Scaffolds are sturdy, level, and properly placed on support surfaces.

- After the inspection, the foreman completes and attaches one of the following tags as appropriate: “COMPLETE SCAFFOLD” (Green), “CAUTION, INCOMPLETE SCAFFOLD”, “CAUTION” (Yellow), or “DANGER – DO NOT USE” (Red). Figure 2 for examples of tags.

- Before each shift, or after any occurrence, which could affect a scaffold’s structural integrity, a competent person must inspect all scaffolds and scaffold components for visible defects as. Any part of the scaffold that fails inspection must be immediately withdrawn from service, tagged out, and repaired.

Records

Any written inspection or documentation generated for specific scaffolds shall be maintained for the duration the scaffolding is in use. Note this does not apply to reusable daily-use scaffold tags.

Also Read: Scaffold Register and Inspection Checklist

Training

- Persons performing work on a scaffold must be trained by a qualified person to recognize the hazards associated with the type of scaffold being used and to understand the procedures to control or minimize those hazards. Training must include, as applicable:

- Electrical hazards.

- Fall hazards.

- Proper use and material handling on scaffolds.

- Load and load-carrying capabilities of scaffolds.

- A competent person must train employees who erect, disassemble, move, operate, repair, maintain, or inspect a scaffold to recognize hazards associated with the work. Training must include, as applicable:

- The nature of scaffold hazards.

- The correct procedures for erecting, disassembling, moving, operating, repairing, inspecting, and maintaining the type of scaffold in use.

- The design criteria, maximum intended load-carrying capacity, and intended use of the scaffold.

- Conduct retraining at a minimum, whenever the following situations apply:

- Employees’ work with scaffolds indicates they have not retained the requisite proficiency.

- The worksite presents a hazard in which the employee has not been previously trained.

- Changes in scaffolding, fall protection, falling object protection, or other equipment present a hazard in which the employee has not been previously trained.

Also Read : Video: Supported Scaffolding Safety

Auditing

Review the Scaffolding Safety program annually to ensure the continued effectiveness of the policy and procedures. Update the program, as needed, to reflect any changes in policy or procedure.

Also Read: Scaffold Safety self Audit and checklist

Please visit our Safety Resources SAFETY BAG to have many Safety Resources