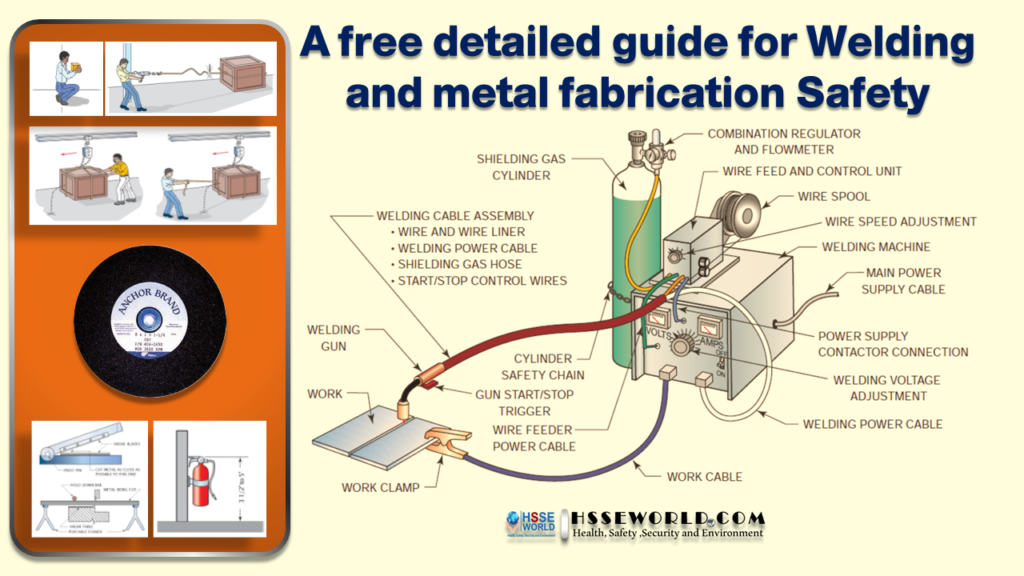

Accident prevention is the main intent of the welding safety guide. The safety information included in this text is intended as a guide. There is no substitute for caution and common sense. A safe job is no accident; it takes work to make the job safe. Each person working must do their own part to make the job safe.

Welding fabrication is a very large and diverse industry. This guide concentrates on only that portion

of welding fabrication safety related to the areas of light metal. You must read, learn, and follow all safety rules, regulations, and procedures for those areas.

Light welding fabrication, like all other areas of welding work, has a number of potential safety hazards. These hazards need not result in anyone being injured. Learning to work safely is as important as learning to be a skilled welding fabrication worker. You must approach new jobs with your safety in mind. Your safety is your own responsibility, and you must shoulder that responsibility. It is not possible to

anticipate all of the possible dangers in every job. This text may not cover some dangers. You can get specific safety information from welding equipment manufacturers and their local suppliers, your local college and university, and the World Wide Web.

If an accident does occur on a welding site, it can have consequences far beyond just the person being injured. Serious accidents can result in local, state, or national investigations. For example, if the federal office of the Occupational Safety and Health Administration (OSHA) becomes involved, the jobsite may be

closed for hours, days, weeks, months, or even permanently. While the jobsite is closed for the investigation, you may be off without pay. If it is determined that your intentional actions contributed to the accident, you may lose your job, be fined, or worse. Always follow the rules; never engage in horseplay or play practical jokes while at work.

After completing this guide, the reader should be able to:

- Explain how to work safely.

- Identify each degree of burn and describe how to provide first aid.

- List the types of protective clothing a welder should wear.

- Explain the importance of proper ventilation and respiratory protection.

- Describe how to safely lift, climb, and handle materials.

- Demonstrate electrical safety.

THE GUIDE CONTENTS

Burns is one of the most common and painful injuries that occur in welding fabrication. Burns can be caused by ultraviolet light rays as well as by contact with hot welding material. The chance of infection is high with burns because of the dead tissue that results. It is important that all burns receive proper medical treatment to reduce the chance of infection. Burns are divided into three classifications, depending upon the degree of severity. The three classifications include first-degree, second-degree, and third-degree burns.

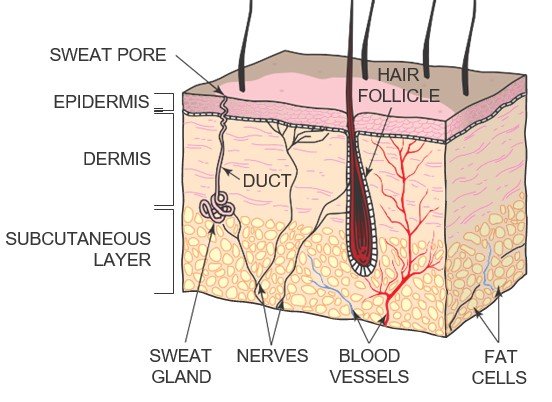

First-Degree Burns

First-degree burns have occurred when the surface of the skin is reddish in color, tender, and painful; they do not involve any broken skin, Figure 1-1. The first step in treating a first-degree burn is to immediately put the burned area under cold water (not iced) or apply cold water compresses (clean towel, washcloth, or handkerchief soaked in cold water) until the pain decreases. Then cover the area with sterile bandages or a clean cloth. Do not apply butter or grease, or any other home remedies or medications, without a doctor’s recommendation.

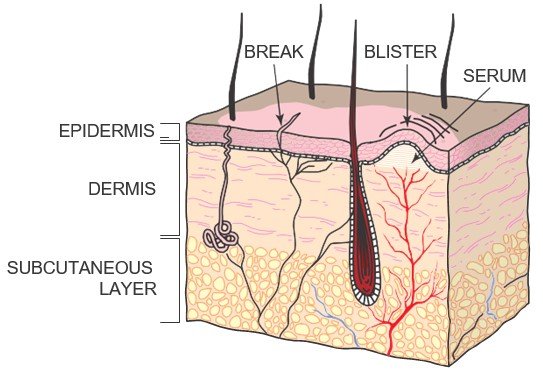

Second-Degree Burns

Second-degree burns have occurred when the surface of the skin is severely damaged, resulting in the formation of blisters and possible breaks in the skin, Figure 1-2. Again, the most important first step in treating a second-degree burn is to put the area under cold water (not iced) or apply cold water compresses until the pain decreases. Gently pat the area dry with a clean towel, and cover the area with a sterile bandage or clean cloth to prevent infection. Seek medical attention. If the burns are around the mouth or nose or involve singed nasal hair, breathing problems may develop. Do not apply ointments, sprays, antiseptics, or home remedies. Note: In an emergency, any cold liquid you drink, for example, water, cold tea, soft drinks, or milk shake, can be poured on a burn. The purpose is to lower the skin temperature as quickly as possible to reduce tissue damage.

Third-Degree Burns

Third-degree burns have occurred when the surface of the skin and possibly the tissue below the skin appear white or charred. There may be cracks or breaks in the skin, Figure 1-3. Initially, little pain is present because the nerve endings have been destroyed. Do not remove any clothes that are stuck to the burn. Do not put ice water or ice on the burns; this could intensify the shock reaction. Do not apply ointments, sprays, antiseptics, or home remedies. If the victim is on fire, smother the flames with a blanket, rug, or jacket. Breathing difficulties are common with burns around the face, neck, and mouth; be sure that the victim is breathing. Place a cold cloth or cool water on burns of the face, hands, or feet to cool the burned areas. Cover the burned area with thick, sterile, nonfluffy dressings. Call for an ambulance immediately if needed; people with even small third-degree burns need to consult a doctor.

Burns Caused by Light

Some types of light can cause burns. There are three types of light—ultraviolet, infrared, and visible. Ultraviolet and infrared are not visible to the unaided human eye but can cause burns. During welding, one or more of the three types of light may be present.

Arc welding and arc cutting produce all three kinds of light, but gas welding produces only the less hazardous visible and infrared lights. The light from the welding process can be reflected from walls, ceilings, floors, or any other large surface. This reflected light is as dangerous as the direct welding light. To reduce the danger from reflected light, welding shops, if possible, should be

painted flat black. Flat black reduces the reflected light

by absorbing more of it than any other color. If the welding cannot be moved away from other workers, screen off the welding arc with welding curtains that will absorb the welding light, Figure 1-4. These special portable welding curtains may be either transparent or opaque. Transparent welding curtains are made of a special high-temperature, flame-resistant plastic that prevents harmful light from passing through.

CAUTION– Welding curtains must always be used to protect other workers in an area that might be exposed to the welding light.

Ultraviolet Light (UV)

Ultraviolet light waves are the most dangerous. They can cause first-degree and second-degree burns to the eyes or to any exposed skin. Because you cannot see or feel ultraviolet light while being exposed to it, you must stay protected when in the area of any arc welding process. The closer a person is to the arc and the higher the current, the quicker a burn may occur.

The ultraviolet light is so intense during some welding processes that the eyes can receive a flash burn within seconds, and the skin can be burned within minutes.

Ultraviolet light can pass through loosely woven clothing, thin clothing, light-colored clothing, and a damaged or poorly maintained arc welding helmet.

Infrared Light

Infrared light is the light wave that is felt as heat. Although infrared light can cause burns, a person will immediately feel this type of light. Therefore, burns can easily be avoided.

Visible Light

Visible light is the light that we see. It is produced in varying quantities and colors during welding. Too much visible light may cause temporary night blindness (poor eyesight under low light levels). Too little visible light may cause eyestrain, but visible light is not hazardous.

Whether burns are caused by ultraviolet light or hot material, they can be avoided if proper clothing and other protection are worn.

Also Read: Photo of the day: First Aid for Electrical Burns-Infographic free

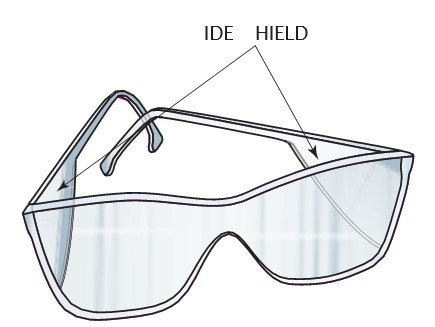

Face and Eye Protection

Eye protection must be worn in the shop at all times. Eye protection can be safety glasses with side shields, Figure 1-5; goggles; or a full face shield. For better protection when working in brightly lit areas or outdoors, some welders wear flash glasses, which are special, lightly tinted safety glasses. These safety glasses provide protection from both flying debris and reflected light.

Suitable eye protection is important because you cannot immediately detect excessive exposure to an arc light. Welding light damage occurs often without warning, like a sunburn’s effect that is felt the following day. Therefore, welders must take appropriate precautions in selecting filters or goggles that are suitable for the process being used. Selecting the correct shade lens is also important because both extremes of too light or too dark can cause eyestrain. New welders often select a lens that is too dark, assuming it will give them better protection, but this results in eyestrain in the same manner as if they were trying to read in a poorly lit room. In reality, any approved arc welding lens filters out harmful ultraviolet light. Select a lens that lets you see comfortably. At the very least, the welder’s eyes must not be strained by excessive glare from the arc.

Ultraviolet light can burn the eye in two ways. It can injure the retina, which is the back of the eye. Burns on the retina are not painful but may cause some loss of eyesight. Ultraviolet light can also burn the whites of the eyes, Figure 1-6. The whites of the eyes are very sensitive, and burns are very painful.

The eyes are easily infected because, as with any burn, many cells are killed. These dead cells in the moist environment of the eyes promote the growth of bacteria that cause infection. When the eye is burned, it feels as though there is something in the eye, but without a professional examination, it is impossible to know. Because there may be something in the eye and because of the high risk of infection, home remedies or other medicines should never be used for eye burns. Any time you receive an eye injury, you should see a doctor.

white or on the retina by ultraviolet light.

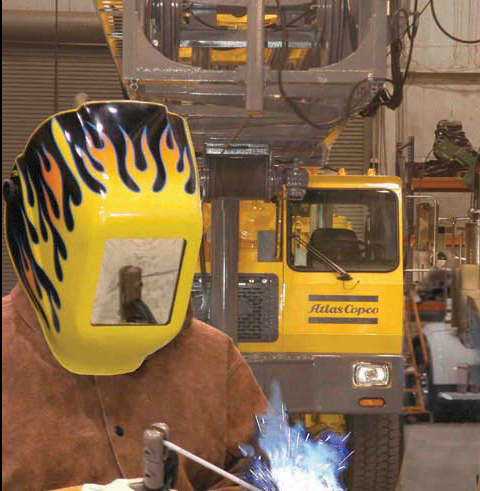

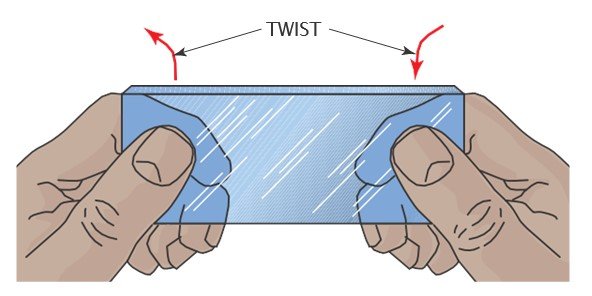

Even with quality welding helmets, like the one shown in Figure 1-7, the welder must check for potential problems that may occur from accidents or daily use. Small, undetectable leaks of ultraviolet light in an arc welding helmet can cause a welder’s eyes to itch or feel sore after a day of welding. To prevent these leaks, make sure that the lens gasket is installed correctly, Figure 1-8. The outer and inner clear lens must be plastic. As shown in Figure 1-9, the lens can be checked for cracks by twisting it between your fingers. Worn or cracked spots on a helmet must be repaired. Tape can be used as a temporary repair until the helmet can be replaced or permanently repaired.

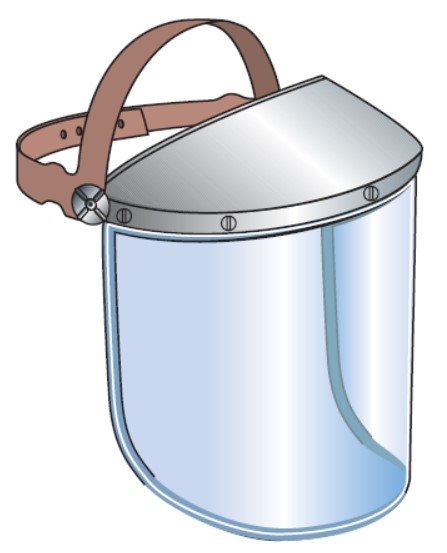

Safety glasses with side shields are adequate for general use, but if you are doing heavy grinding, chipping, or overhead work, you should wear goggles or a full face shield in addition to safety glasses, Figure 1-10. Safety glasses are best for general protection because they must be worn under an arc-welding helmet at all times.

Ear Protection

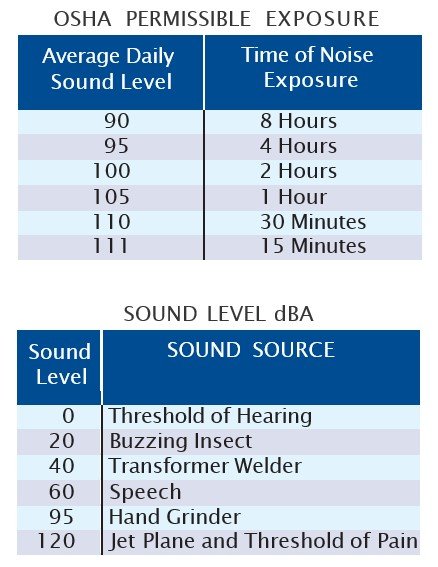

The welding environment can be very noisy. The sound level is at times high enough to cause pain and some loss of hearing if the welder’s ears are unprotected, Table 1-2. Hot sparks can also drop into an open ear, causing severe burns. Ear protection is available in several forms. One form of protection is earmuffs that cover the outer ear completely, Figure 1-11. Another form of protection is earplugs that fit into the ear canal, Figure 1-12. Both of these protect a person’s hearing, but only the earmuffs protect the outer ear from burns.

only.

All welding and cutting processes produce undesirable by-products, such as harmful dust, fumes, mists, gases, smoke, sprays, or vapors. For your safety and the safety of others, your primary objective is to prevent these contaminants from forming and collecting in the area’s atmosphere. This can be accomplished as much as possible by thorough cleaning of surface contaminants before starting work, and confinement of the operation to outdoor or open spaces.

Production of welding fumes and vapor by-products cannot be avoided. They are created when the temperature of metals and fluxes is raised above the temperatures at which they boil or decompose. Most of the by-products are recondensed in the weld. However, some do escape into the atmosphere, producing the haze that occurs in improperly ventilated welding shops.

Some fluxes used in welding electrodes produce fumes that may irritate the welder’s nose, throat, and lungs.

When welders must work in an area where effective controls to remove airborne welding by-products are not feasible, employers must provide equipment such as respirators when necessary to protect workers’ health. The respirators must be applicable and suitable for the purpose intended. The welding shop will establish and implement a written respiratory protection program with work site-specific procedures indicating where respirators are necessary to protect welders’ health or whenever respirators are required by the shop. Welders are responsible for following the welding shop’s established written respiratory protection program. Guidelines for the respiratory protection

program are available here

Training must be a part of the welding shop’s respiratory protection program. This training should include instruction in the following procedures:

- Proper use of respirators, including techniques for putting them on and removing them.

- Schedules for cleaning, disinfecting, storing, inspecting, repairing, discarding, and performing other aspects of maintenance of the respiratory protection equipment.

- Selection of the proper respirators for use in the workplace, and any respiratory equipment limitations. ( Photo of the day: Choosing the Right Face Mask and the difference between a respirator and face mask )

- Procedures for testing for tight-fitting respirators.

- Proper use of respirators in both routine and reasonably foreseeable emergency situations.

- Regular evaluation of the effectiveness of the program. All respiratory protection equipment used in a welding shop should be certified by the National Institute for Occupational Safety and Health (NIOSH).

Some of the types of respiratory protection equipment that may be used include the following: - Air-purifying respirators have an air-purifying filter, cartridge, or canister that removes specific air contaminants by passing ambient air through the air-purifying element.

- Atmosphere-supplying respirators supply breathing air from a source independent of the ambient atmosphere; this includes both the supplied-air respirators and self-contained breathing apparatus-type units.

- Demand respirators are atmosphere-supplying respirators that admit breathing air to the facepiece only when negative pressure is created inside the facepiece by inhalation.

- Positive pressure respirators are respirators in which the pressure inside the respiratory inlet covering exceeds the ambient air pressure outside the respirator.

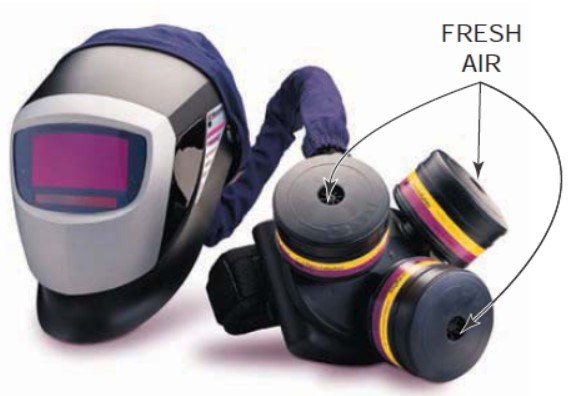

- Powered air-purifying respirators (PAPRs) are air-purifying respirators that use a blower to force the ambient air through air-purifying elements to the

inlet covering, Figure 1-13. - Self-contained breathing apparatuses (SCBAs) are atmosphere-supplying respirators for which the breathing air source is designed to be carried by the user.

- Supplied-air respirators (SARs), or airline respirators, are atmosphere-supplying respirators that have air piped in through a flexible hose from a large central air supply.

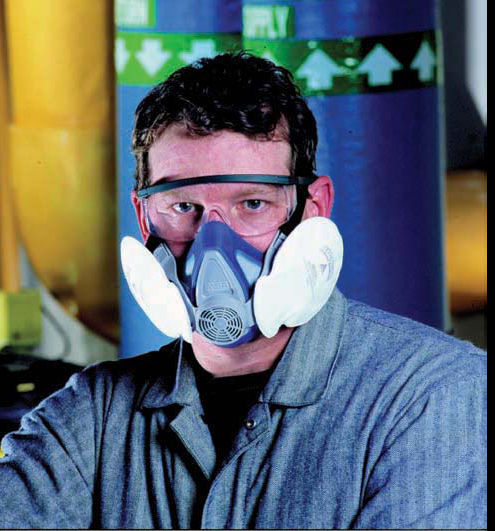

Respiratory protection equipment used in many welding applications is of the filtering facepiece (dust mask) type, Figure 1-14. These mask types use the negative pressure as you inhale to draw air through a filter, which is an integral part of the facepiece. In areas of severe contamination, you may use a hood-type respirator, which covers your head and neck and may also cover portions of your shoulders and torso.

Some materials used as paint, coating, or plating on metals to prevent rust or corrosion can cause respiratory problems. Other potentially hazardous materials include alloys used in metals to give them special properties.

Before it is welded or cut, any metal that has been painted or has any grease, oil, or chemicals on its surface must be thoroughly cleaned. This cleaning may be done by grinding, sandblasting, or applying an approved solvent.

Most paints containing lead have been removed from the market. But some industries, such as marine or ship applications, still use these lead-based paints. Often, old machinery surfaces may have lead-based paint coatings. Old solder often contains lead alloys.

The welding and cutting of lead-bearing alloys or metals whose surfaces have been painted with lead-based paint can generate lead oxide fumes. Inhalation and ingestion of lead oxide fumes and other lead compounds cause lead poisoning. Symptoms include a metallic taste in the mouth, a loss of appetite, nausea, abdominal cramps, and insomnia. In time, anemia and general weakness, chiefly in the muscles of the wrists, develop.

Both cadmium and zinc are plating materials used to prevent iron or steel from rusting. Cadmium is often used on bolts, nuts, hinges, and other hardware items, and it gives the surface a yellowish-gold appearance.

Acute exposure to high concentrations of cadmium fumes can produce severe lung irritation. Long-term exposure to low levels of cadmium in the air can result in emphysema (a disease affecting the lung’s ability to absorb oxygen) and can damage the kidneys.

Zinc galvanizing may be found on pipes, sheet metal, water tanks, bolts, nuts, and many other types of hardware. Zinc plating that is thin may appear as a shiny, metallic patchwork or crystal pattern; thicker, hot-dipped zinc appears rough and may look dull. Zinc is used in large quantities in the manufacture of brass and is found in brazing rods. Inhalation of zinc oxide fumes can occur when you are welding or cutting on these materials. Exposure to these fumes is known to cause metal fume fever; its symptoms are very similar to those of common influenza.

Concern has been expressed about the possibility of lung cancer being caused by some of the chromium compounds that are produced when stainless steels are welded.

Rather than take chances, welders should recognize that fumes of any type, regardless of their source, should not be inhaled. The best way to avoid problems is to provide adequate ventilation. If this is not possible, breathing protection should be used. ( Introduction to industrial ventilation )

Potentially dangerous gases can also be present in a welding shop. Proper ventilation or respirators are necessary when welding in confined spaces, regardless of the welding process being used. Ozone is a gas that is produced by ultraviolet radiation in the air in the vicinity of arc welding and cutting operations.

Ozone is very irritating to all mucous membranes, with excessive exposure producing pulmonary edema. Other effects of exposure to ozone include headache, chest pain, and dryness in the respiratory tract.

Phosgene is formed when ultraviolet radiation decomposes chlorinated hydrocarbon. Fumes from chlorinated hydrocarbons can come from solvents such as those used for degreasing metals and from refrigerants from air-conditioning systems. They decompose in the arc to produce a potentially dangerous chlorine acid compound. This compound reacts with the moisture in the lungs to produce hydrogen chloride, which in turn destroys lung tissue.

For this reason, any use of chlorinated solvents should be well away from welding operations in which ultraviolet radiation or intense heat is generated. Any welding or cutting on refrigeration or air-conditioning piping must be done only after the refrigerant has been completely removed in accordance with Environmental Protection Agency (EPA) regulations.

Care also must be taken to avoid the infiltration of any fumes or gases, including argon or carbon dioxide, into a confined working space, such as when welding in tanks or cylinders. The collection of some fumes and gases in a work area can go unnoticed by the welders. Concentrated fumes or gases can cause a fire or explosion if they are flammable, asphyxiation if they replace the oxygen in the air, or death if they are toxic.

Despite these fumes and other potential hazards in welding shops, welders have been found to be as healthy as workers employed in other industrial occupations.

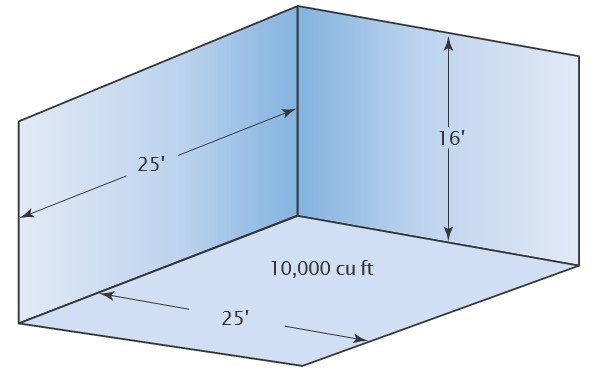

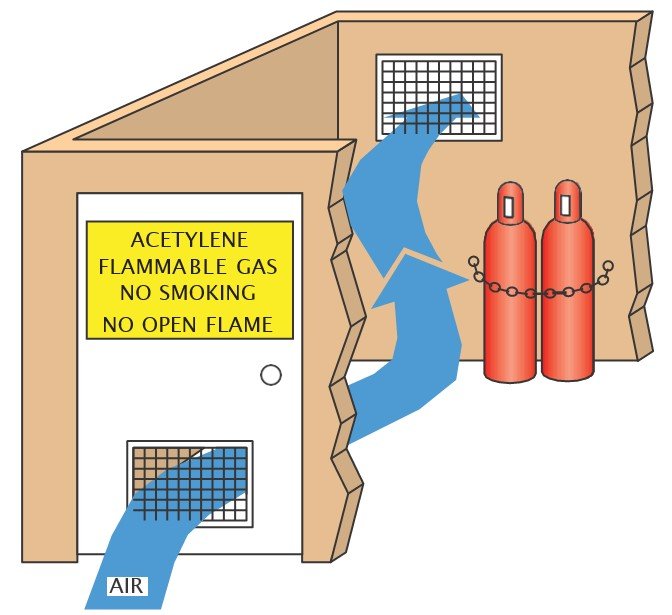

The actual welding area should be outside or well-ventilated. Excessive fumes, ozone, or smoke may collect in the welding area; ventilation should be provided for their removal. Natural ventilation is best, but forced ventilation may be required. Areas that have 10,000 cu ft (283 m3) or more per welder, or that have ceilings 16 ft (4.9 m) high or higher, Figure 1-15, may not require forced ventilation unless fumes or smoke begins to collect.

Forced Ventilation

Small shops or shops with large numbers of welders require forced ventilation. Forced ventilation can be general or localized using fixed or flexible exhaust pickups, Figure 2-16. General room ventilation must be at a rate of 2000 cu ft (56 m3) or more per person welding. Localized exhaust pickups must have a suction strong enough to pull welding fumes away from the welder at a velocity of 100 linear feet (30.5 m) per minute, Figure 1-17. Local, state, or federal regulations may require that welding fumes be treated to remove hazardous components before they are

released into the atmosphere.

Any system of ventilation should draw the fumes or smoke away before rising past the level of the welder’s face.

Forced ventilation is always required when welding on metals that contain zin

All manufacturers of potentially hazardous materials must provide the users of their products with detailed information regarding possible hazards resulting from the use of their products. These material specification data sheets are often called SDSs. They must be provided to anyone using the product or anyone working in the area where the products are in use. Often companies will post these sheets on a bulletin board or put them in a convenient place near the work area.

Some states have right-to-know laws that require specific training for all employees who handle or work in areas with hazardous materials.

( Also Read : E-Books: Preparation safety data sheets for hazardous chemicals )

Welding shops generate waste materials. Much of the waste is scrap metal. All scrap metal, including electrode stubs, can be easily recycled. Recycling metal is good for the environment and can be a source of revenue for the welding shop.

Some of the other waste, such as burned flux, cleaning solvents, and dust collected in shop air filtration systems, may be considered hazardous materials. Check with the material manufacturer or an environmental consultant to determine if any waste material is considered hazardous. Throwing hazardous waste material into the trash, pouring it on the ground, or dumping it down the drain is illegal. Before you dispose of any welding shop waste that is considered hazardous, you must first consult local, state, and federal regulations. Protecting our environment from pollution is everyone’s responsibility.

( Also Read: RCRA Hazardous Waste Final Rule: The E-Manifest System & Other Key Revisions )

Falls are a major cause of injury and death. Improper use of ladders is often a factor in these falls. Always keep in mind when erecting a ladder that even short step stools can pose a potential fall hazard. Never approach a climb assuming that because it is not high, it cannot be that dangerous. All ladder usage poses a danger to your safety. Some students think that if a ladder starts to fall they will just “jump clear.” You cannot jump clear if the ladder under you has given way because there is nothing solid under your feet for you to jump from. When a ladder falls, you fall.

Keep the area around the base of the ladder clear so if you do fall, it will not be onto debris or equipment.

Types of Ladders

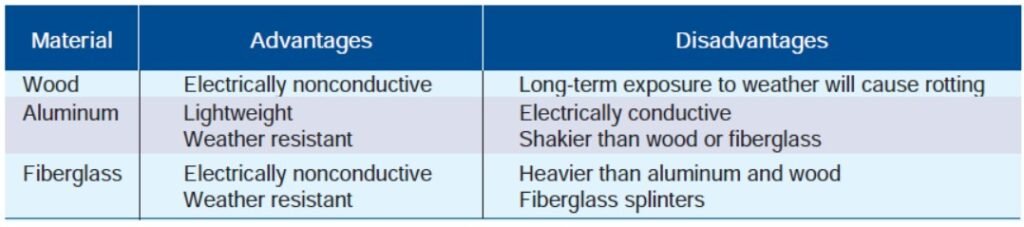

Both stepladders and straight ladders are used extensively in welding fabrication. Straight ladders may be single-section or extension-type ladders. Most ladders are made from wood, aluminum, or fiberglass, and each type has its advantages and disadvantages, Table 1-2. All ladders used in welding fabrication should be listed with the American National Standards Institute (ANSI) or Underwriters Laboratories (UL) to ensure they are constructed to a standard of safety.

Also, Read: Portable Ladder Safety

Ladder Inspection

Over time, ladders can become worn or damaged and should be inspected each time they are used. Look for loose or damaged steps, rungs, rails, braces, and safety feet. Check to see that all hardware is tight, including hinges, locks, nuts, bolts, screws, and rivets.

Wooden ladders must be checked for cracks, rot, or wood decay. Never use a defective ladder. Make any necessary repairs before it is used or, if it cannot be repaired, replace it. ( Also Read: Ladder Inspection Form )

Rules for Ladder Use

Read the entire ladder manufacturer’s list of safety rules before using the ladder for the first time. Stepladders must be locked in the fully opened position with the spreaders. Straight or extension ladders must be used at the proper angle; either too steep or too flat is dangerous, Figure 1-18.

The following are general safety and usage rules for ladders:

- Follow all recommended practices for safe use and storage.

- Do not exceed the manufacturer’s recommended maximum weight limit for the ladder.

- Before setting up a ladder, make certain that it will be erected on a level, solid surface.

- Never use a ladder in a wet or muddy area where water or mud will be tracked up the ladder’s steps or rungs. Only climb or descend ladders with clean, dry shoes.

- Tie the ladder securely in place.

- Climb and descend the ladder cautiously.

- Do not carry tools and supplies in your hand as you climb or descend a ladder. Use a rope to raise or lower the items once you are safely in place.

- Never use ladders around live electrical wires.

- Never use a ladder that is too short for the job, requiring you to reach or stand on the top step.

- Wear well-fitted shoes or boots.

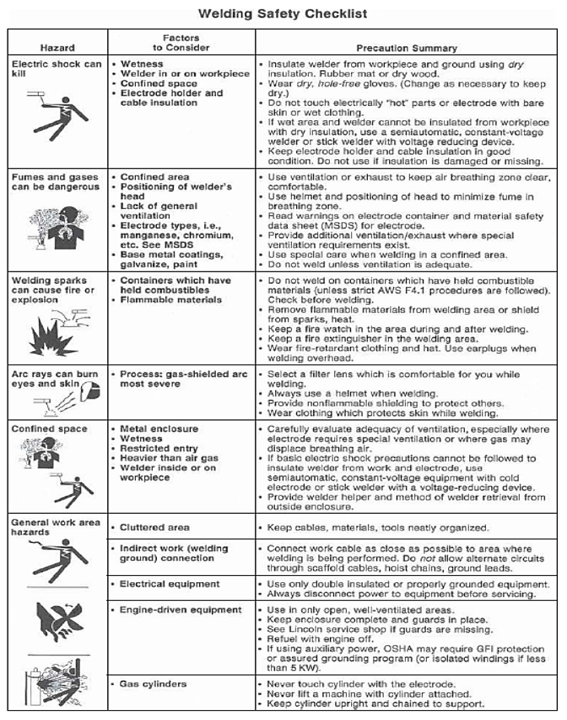

Electric shock can cause injuries and even death unless proper precautions are taken. Most welding and cutting operations involve electrical equipment in addition to arc welding power supplies. Grinders, electric motors on automatic cutting machines, and drills are examples. Most electrical equipment in a welding shop is powered by alternating-current (AC) sources having input voltages ranging from 115 to 460 volts. However, fatalities have occurred when working with equipment operating at less than 80 volts. Most electric shocks in the welding industry do not occur from contact with welding electrode holders but as a result of accidental contact with bare or poorly insulated conductors. Electrical resistance is lowered in the presence of water or moisture, so welders must take special precautions when working under damp or wet conditions, including perspiration. Figure 2-19 shows a typical warning label shipped with the welding equipment

Cables must be checked periodically to be sure that they have not become frayed, and if they have, they must be replaced immediately. Never allow the metal parts of electrodes or electrode holders to touch the skin or wet coverings on the body. Dry gloves in good condition must always be worn. Rubber-soled shoes are advisable. Precautions against accidental contact with bare-conducting surfaces must be taken when the welder is required to work in cramped kneeling, sitting, or prone positions. Insulated mats or dry wooden boards are desirable protection from the earth.

Welding circuits must be turned off when the workstation is left unattended. The main power supply must be turned off and locked or tagged to prevent electrocution when you are working on the welder, welding leads, electrode holder, torches, wire feeder, guns, or other parts. Since the electrode holder is energized when coated electrodes are changed, the welder must wear dry gloves.

The workpiece being welded, and the frame or chassis of all electrically powered machines must be connected to a good electrical ground. The work lead from the welding power supply is not an electrical ground and is not sufficient. A separate lead is required to ground the workpiece and power source.

Electrical connections must be tight. Terminals for welding leads and power cables must be shielded from accidental contact by personnel or by metal objects. Cables must be used within their current-carrying and duty-cycle capacities; otherwise, they will overheat and break down the insulation rapidly. Cable connectors for lengthening leads must be insulated.

Electrical Safety Systems

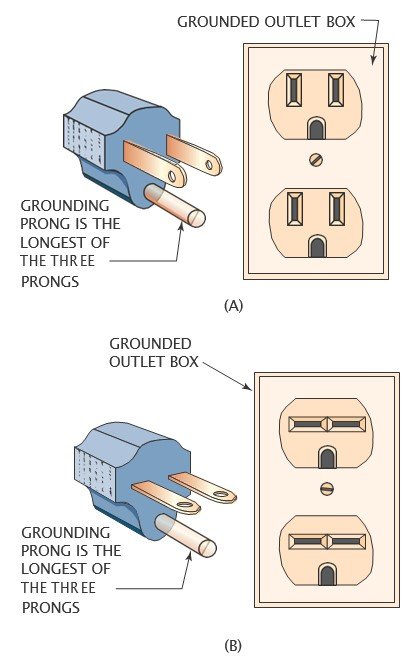

For protection from electrical shock, the standard portable tool is built with either of two equally safe systems: external grounding or double insulation. A tool with external grounding has a wire that runs from the housing through the power cord to a third prong on the power plug. Wflen tflis tflird prong is connected to a grounded, tflree-flole electrical outlet, tfle grounding wire will carry any current tflat leaks past tfle electrical insulation of tfle tool away from tfle user and into tfle ground. In most electrical systems, the three-prong plug fits into a three-prong, grounded receptacle. If the tool is operated at less than 150 volts, it has a plug-like that is shown in Figure 1-20A. If it is used at 150 to 250 volts, it has a plug like that shown in Figure 1-20B

Also, Read: Free Guidelines for Working with Electricity-Ground Fault Circuit Protection

In either type, the green (or green and yellow) conductor in the tool cord is the grounding wire. Never connect the grounding wire to a power terminal.

All electrical plugs must be grounded, and it is against many local, state, and national electrical safety codes to remove or disable the ground plug on a power cord. However, some older buildings may have old ungrounded, two-prong electrical outlets, so an adapter must be used. If there is any uncertainty about whether a receptacle is properly grounded, have it checked by a qualified electrician.

A double-insulated power tool has an extra layer of electrical insulation that eliminates the need for a three-prong and grounded outlet. Double-insulated tools do not require grounding and therefore have a two-prong plug. In addition, double-insulated tools are always labeled as such on their nameplate or case, Figure 1-21.

Before connecting a tool to a power supply, be sure that the voltage supplied is the same as that specified on the nameplate of the tool. A power source with a voltage greater than that specified for the tool can lead to serious injury to the user as well as damage to the tool. Using a power source with a voltage lower than the rating on the nameplate is harmful to the motor.

Tool nameplates also bear a figure with the abbreviation amps (for amperes, a measure of electric current). Tflis refers to the current-drawing requirement of the tool. The higher the input current, the more powerful the motor.

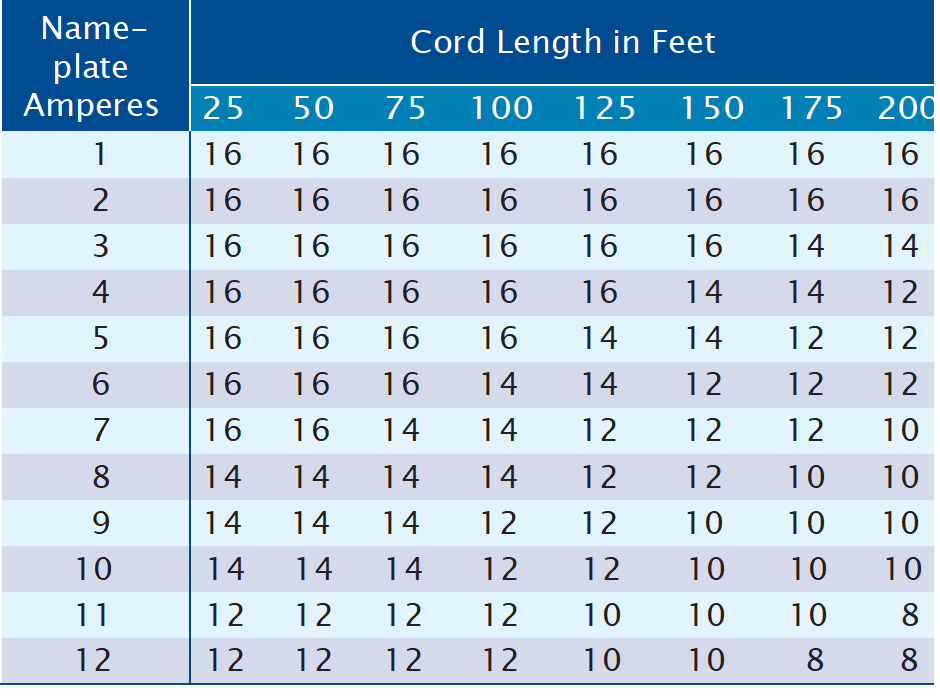

Extension Cords

When there is some distance from the power source to the work area or if the portable tool is equipped with a stub power cord, an extension cord must be used. When using extension cords on portable power tools, the size of the conductors must be large enough to prevent an excessive drop in voltage. A voltage drop is the lowering of the voltage at the power tool from that of the voltage at the supply. This occurs because of resistance flow in the wire. A voltage drop causes loss of power, overheating, and possible motor damage. Table 1-3 shows the correct size extension cord to use based on cord length and nameplate amperage rating. If in doubt, use the next larger size. The smaller the gauge number of an extension cord, the larger the cord.

Only three-wire, grounded extension cords connected to properly grounded, three-wire receptacles should be used. Two-wire extension cords with two-prong plugs should not be used. Current specifications require outdoor receptacles to be protected with ground-fault circuit interpreter (GFCI) devices. These safety devices are often referred to as GFIs.

with Portable Electric Tools

When using extension cords, keep the following safety tips in mind:

- Always connect the cord of a portable electric power tool to the extension cord before the extension cord is connected to the outlet.

- Always unplug the extension cord from the receptacle before unplugging the cord of the portable power tool from the extension cord.

- Extension cords should be long enough to make connections without being pulled taut, creating unnecessary strain or wear.

- Be sure that the extension cord does not come in contact with sharp objects or hot surfaces. The cords should not be allowed to kink, nor should they be dipped in or splattered with oil, grease, or chemicals.

- Before using a cord, inspect it for loose or exposed wires and damaged insulation. If a cord is damaged, replace it. This also applies to the tool’s power cord.

- Extension cords should be checked frequently while in use to detect unusual heating. Any cable that feels more than slightly warm to a bare hand placed outside the insulation should be checked immediately for overloading.

- See that the extension cord is positioned so that no one trips or stumbles over it.

- To prevent the accidental separation of a tool cord from an extension cord during operation, make a knot as shown in Figure 1-22A, or use a cord connector as shown in Figure 1-22B.

- Use an extension cord that is long enough for the job but not excessively long.

- Extension cords that go through dirt and mud must be cleaned before storing.

Safety Rules for Portable Electric Tools

In all tool operations, safety is simply the removal of any element of chance. Following are a few safety precautions that should be observed. These are general rules that apply to all power tools. They should be strictly obeyed to avoid injury to the operator and damage to the power tool.

- Know the tool. Learn the tool’s applications and limitations as well as its specific potential hazards by reading the manufacturer’s literature.

- Ground the portable power tool unless it is double insulated. If the tool is equipped with a tflree-prong plug, it must be plugged into a tflree-flole electrical receptacle. If an adapter is used to accommodate a two-pronged receptacle, the adapter wire must be attached to a known ground. Never remove the third prong.

- Do not expose the power tool to rain. Do not use a power tool in wet locations.

- Keep the work area well-lighted. Avoid chemical or corrosive environments.

- Because electric tools spark, portable electric tools should never be started or operated in the presence of propane, natural gas, gasoline, paint thinner, acetylene, or other flammable vapors that could cause a fire or explosion.

- Do not force a tool. It will do the job better and more safely if operated at the rate for which it was designed.

- Use the right tool for the job. Never use a tool for any purpose other than that for which it was designed.

- Wear eye protectors. Safety glasses or goggles protect the eyes while you operate power tools.

- Wear a face or dust mask if the operation creates dust.

- Take care of the power cord. Never carry a tool by its cord or yank it to disconnect it from the receptacle.

- Secure your work with clamps. It is safer than using your hands, and it frees both hands to operate the tool.

- Do not overreach When operating a power tool. Keep proper footing and balance at all times.

- Maintain power tools. Follow the manufacturer’s instructions for lubricating and changing accessories. Replace all worn, broken, or lost parts immediately.

- Disconnect the tools from the power source When they are not in use.

- Form the habit of checking to see that any keys or wrenches are removed from the tool before turning it on.

- Avoid accidental starting. Do not carry a plugged-in tool with your finger on the switch. Be sure the switch is off When plugging in the tool.

- Be sure accessories and cutting bits are attached securely to the tool.

- Do not use tools with cracked or damaged housings.

- When operating a portable power tool, give it your full and undivided attention; avoid dangerous distractions.

Because of the amount and temperature of hot sparks, metal, and slag produced during welding, cutting, or brazing; and the fact that special protective clothing cannot be worn at all times, it is important to choose general work clothing that minimizes the possibility of getting burned.

Wool clothing (100% wool) is the best choice but is difficult to find. All-cotton (100% cotton) clothing is a good second choice, and it is the most popular material used. Synthetic materials, including nylon, rayon, and polyester, must be avoided because they are easily melted, they produce hot, sticky ash (because it sticks, burns can be more severe), and some produce poisonous gases. The clothing must also stop ultraviolet light from passing through it. Tflis is accomplished if the material chosen is a dark color, thick, and tightly woven.

The following are some guidelines for selecting work clothing:

- Shirts must be long-sleeved to protect the arms, have a high-buttoned collar to protect the neck, be long enough to tuck into the pants to protect the waist, and have flaps on the pockets to keep sparks out (or have no pockets), Figure 1-23. Pants must have legs long enough to cover the tops of the boots and must be without

- cuffs that would catch sparks.

- Boots must have high tops to keep out sparks; have steel toes to prevent crushed toes, Figure 1-24; and have smooth tops to prevent sparks from being trapped in seams.

- Caps should be thick enough to prevent sparks from burning the top of a welder’s head.

All clothing must be free of frayed edges and holes. The clothing must be relatively tight-fitting to prevent excessive folds or wrinkles that might trap sparks.

Butane lighters and matches may catch fire or explode if they are subjected to welding heat or sparks. There is no safe place to carry these items When welding. They must always be removed from the welder’s pockets and placed a safe distance away before any work is started.

Each person must wear general work clothing in the shop. In addition to this clothing, extra protection is needed for each person who is in direct contact with hot materials. Leather is often the best material to use, as it is lightweight, flexible, resists burning, and is readily available. Synthetic insulating materials are also available. Ready-to-wear leather protection includes capes, jackets, aprons, sleeves, gloves, caps, pants, kneepads, and spats, among other items.

Hand Protection

All-leather, gauntlet-type gloves should be worn when doing any welding, Figure 1-25. Gauntlet gloves that have a cloth liner for insulation are best for hot work. Noninsulated gloves give greater flexibility for fine work. Some leather gloves are available with a canvas gauntlet top, which should be used for light work only.

When a great deal of manual dexterity is required for gas tungsten arc welding, brazing, soldering, oxyfuel gas welding, and other delicate processes, soft leather gloves may be used, Figure 1-26. All-cotton gloves are sometimes used when doing very light welding.

Also Read: Q & A: What kind of gloves are best for stick welding?

Body Protection

Full leather jackets and capes protect a welder’s shoulders, arms, and chest, Figure 1-27. A jacket, unlike the cape, protects a welder’s back and complete chest. A cape is open and much cooler but offers less protection. The cape can be used with a bib apron to provide some additional protection while leaving the back cooler. Either the full jacket or the cape with a bib apron should be worn for any out-of-position work.

Also, Read: Photo of the day: Types of Hand Protection

Waist and Lap Protection

Bib aprons or full aprons protect a welder’s lap. Welders especially need to protect their laps if they squat or sit while working and When they bend over or lean against a table.

Arm Protection

For some vertical welding, a full- or half-sleeve can protect a person’s arm, Figure 1-28. The sleeves work best if the work level is not above the welder’s chest. Work levels higher than this usually require a jacket or cape to keep sparks off the welder’s shoulders.

Leg and Foot Protection

When heavy cutting or welding is being done and a large number of sparks are falling, leather pants and spats should be used to protect the welder’s legs and feet. If the weather is hot and full leather pants are uncomfortable, leather aprons with leggings are available. Leggings can be strapped to the legs, leaving the back open. Spats prevent sparks from burning through the front of lace-up boots.

Also, Read: Photo of the day: Types of Foot Protection

Oxygen and fuel gas cylinders or other flammable materials must be stored separately. The storage areas must be separated by 20 ft (6.1 m), or by a wall 5 ft (1.5 m) high with at least a 1/2-flour (hr) burn rating, Figure 1-29. The purpose of the distance or wall is to keep the heat of a small fire from causing the oxygen

cylinder safety valve to release. If the safety valve were to release the oxygen, a small fire would become a raging inferno.

Inert gas cylinders may be stored separately or with oxygen cylinders. Empty cylinders must be stored separately from full cylinders, although they may be stored in the same room or area. All cylinders must be stored vertically and have the protective caps screwed on firmly.

Securing Gas Cylinders

Cylinders must be secured with a chain or other device so that they cannot be knocked over accidentally.

Storage Areas

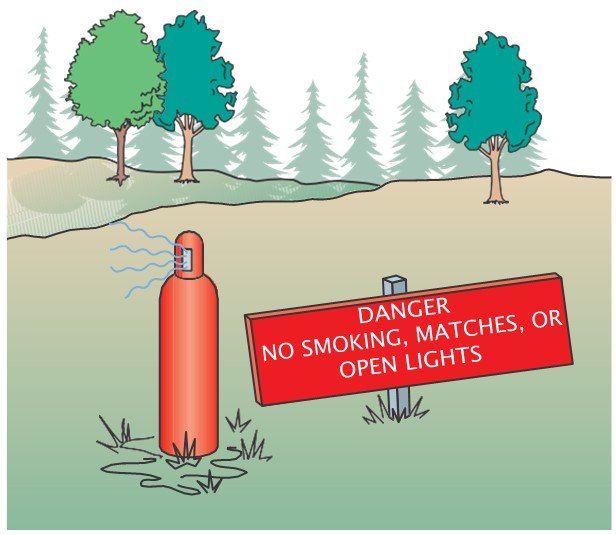

Cylinder storage areas must be located away from halls, stairwells, and exits so that in case of an emergency they will not block an escape route. Storage areas should also be located away from heat, radiators, furnaces, and welding sparks. Storage areas should be situated so that unauthorized people cannot tamper with the cylinders. A warning sign that reads “Danger—No Smoking, Matcfles, or Open Ligflts,” or similar wording, should be posted in the storage area, Figure 1-30.

Cylinders with Valve Protection Caps

Cylinders equipped with a valve protection cap must have the cap in place unless the cylinder is in use. The protection cap prevents the valve from being broken off if the cylinder is knocked over. If the valve of a full high-pressure cylinder (argon, oxygen, C02, and mixed gases) is broken off, the cylinder can fly around the shop like a missile if it has not been secured properly.

Never lift a cylinder by the safety cap or the valve.

The valve can easily break off or be damaged.

When you are moving cylinders, the valve protection cap must be on, especially if the cylinders are mounted on a truck or trailer for out-of-shop work. The cylinders must never be dropped or handled roughly.

General Precautions

Use warm water (not boiling) to loosen cylinders that are frozen to the ground. Any cylinder that leaks, has a bad valve, or has gas-damaged threads must be identified and reported to the supplier. A piece of soapstone is used to write the problem on the cylinder. If the leak cannot be stopped by closing the cylinder valve, the cylinder should be moved to a vacant lot or an open area. The pressure should then be slowly released after a warning sign is posted, Figure 1-31.

Acetylene cylinders that have been lying on their sides must stand upright for four flours or more before they are used. The acetylene is absorbed in acetone, and the acetone is absorbed in the filler material. The filler does not allow the liquid to settle back away from the valve very quickly, Figure 1-32. If the cylinder has been in a horizontal position, using it too soon after it is placed in a vertical position may draw acetone out of the cylinder. Acetone lowers the flame temperature and can damage the regulator or torch valve settings.

Also Read: Photo of the day: Safe handling of Gas Cylinders and lecture bottles

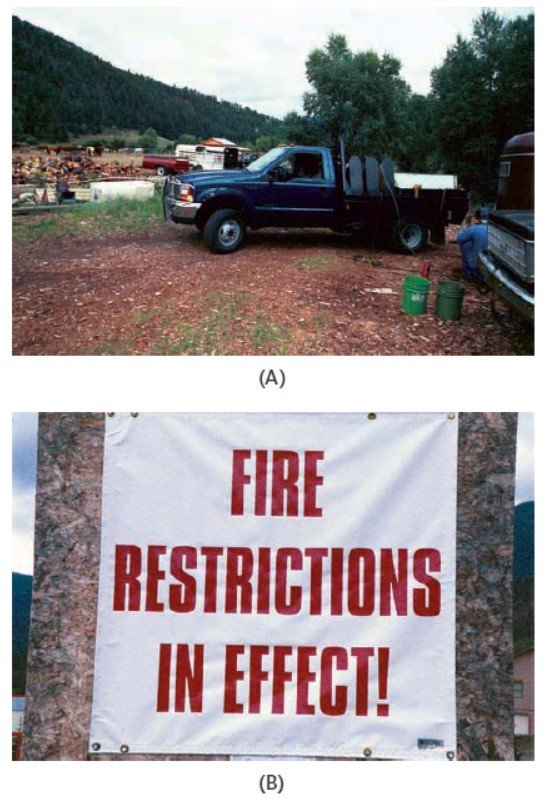

Fire is a constant danger to the welder. The possibilities of fire cannot always be removed, but they should be minimized. Highly combustible materials like paint, fuel, oil, and any large quantity of material that might start more than a small fire must be moved 35 ft (10.7 m) from any welding or cutting.

However, in welding fabrication, it is not always possible to weld or cut 35 ft (10.7 m) or more away from some combustible materials. When welding outside or at a remote job site, there may be dry grass, wood chips, or numerous other items that will burn around your work areas. If you must work around combustible materials, wet the area first and then keep a bucket of water and a fire extinguisher handy and use a fire watch, Figure 1-33A.

Fire Watch

A fire watch can be provided by any person who knows the flow to sound the alarm and use a fire extinguisher. The fire extinguisher must be the type required to put out a fire of the type of combustible materials near the welding. Combustible materials that cannot be removed from the welding area should be soaked with water or covered with sand or noncombustible insulating blankets, whichever is available.

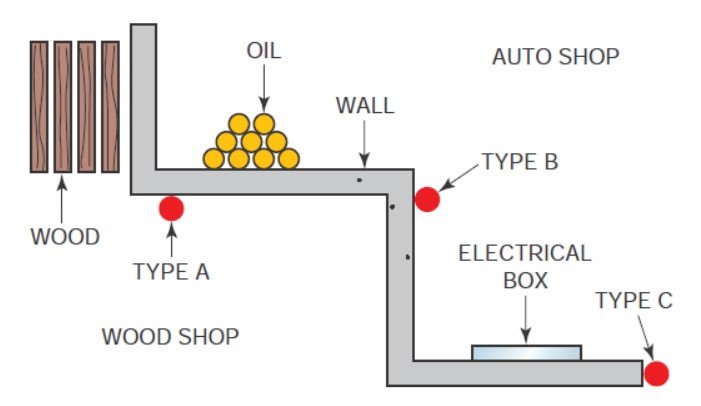

Fire Extinguishers

The four kinds of fire extinguishers are type A, type B, type C, and type D. Each is designed to put out fires on certain types of materials. Some fire extinguishers can be used on more than one type of fire. However, using the wrong kind of fire extinguisher can be dangerous, causing the fire to spread, causing electrical shock, or causing an explosion.

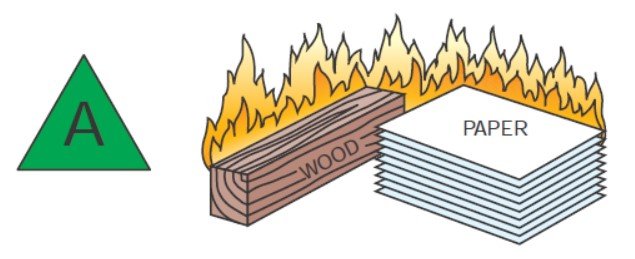

Type A Extinguishers

Type A fire extinguishers are used for combustible solids (articles that burn), such as paper, wood, and cloth. The symbol for a type A extinguisher is a green triangle with the letter A in the center, Figure 1-34.

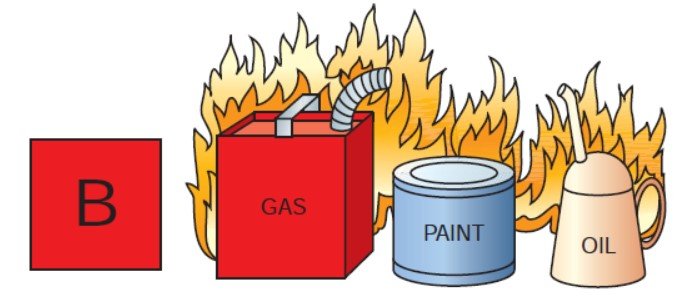

Type B Extinguishers

Type B fire extinguishers are used for combustible liquids, such as oil, gas, and paint thinner. The sym- bol for a type B extinguisher is a red square with the letter B in the center, Figure 1-35.

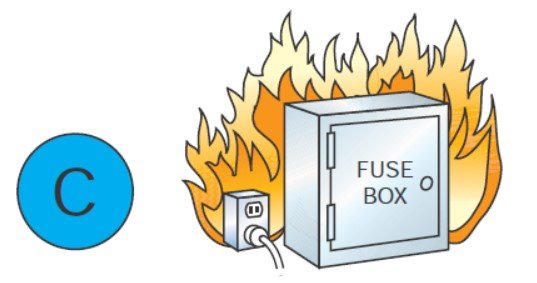

Type C Extinguishers

Type C fire extinguishers are used for electrical fires. For example, they are used on fires involving motors, fuse boxes, and welding machines. The sym- bol for a type C extinguisher is a blue circle with the letter C in the center, Figure 1-36.

Type D Extinguishers

Type D fire extinguishers are used on fires involving combustible metals, such as zinc, magnesium, and titanium. The symbol for a type D extinguisher is a yellow star with the letter D in the center, Figure 1-37.

Location of Fire Extinguishers

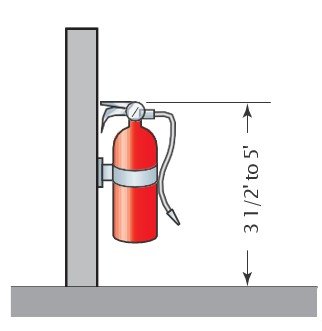

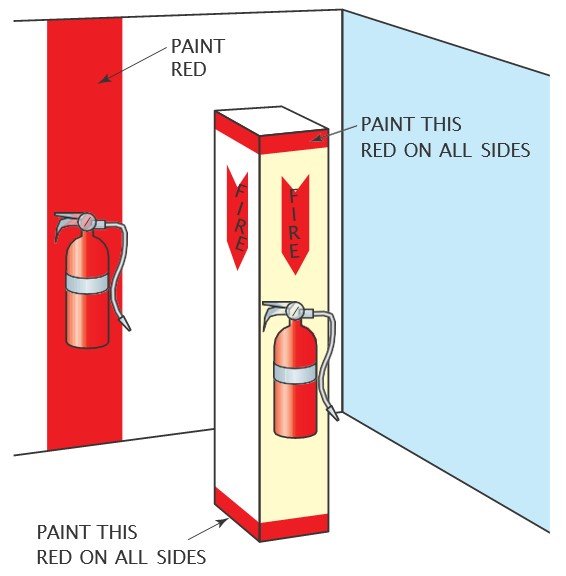

Fire extinguishers should be of a type that can be used on the combustible materials located nearby, Figure 1-38. The extinguishers should be placed so that they can be easily removed without reaching over combustible material. They should also be placed at a level low enough to be easily lifted off the mounting, Figure 1-39. The location of fire extinguishers should be marked with red paint and signs, high enough so that their location can be seen from a distance over people and equipment. The extinguishers should also be marked near the floor so they can be found even if a room is full of smoke, Figure 1-40.

Use

A fire extinguisher works by breaking the fire triangle of heat, fuel, and oxygen. Most extinguishers both cool the fire and remove the oxygen. They use a variety of materials to extinguish the fire. The majority of fire extinguishers found in welding shops use foam, carbon dioxide, a soda-acid gas cartridge, a pump tank, or dry chemicals.

When using a foam extinguisher, do not spray the stream directly into the burning liquid. Allow the foam to fall lightly on the base of the fire.

When using a carbon dioxide extinguisher, direct the discharge as close to the fire as possible, first at the edge of the flames and gradually to the center.

When using a soda-acid gas cartridge extinguisher, place your foot on the footrest and direct the stream at the base of the flames.

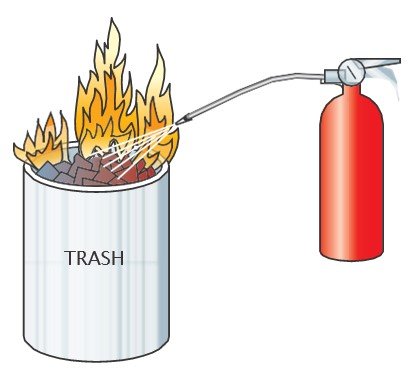

When using a dry chemical extinguisher, direct the extinguisher to the base of the flames. In the case of type A fires, follow up by directing the dry chemicals at the remaining material still burning. There- fore, the extinguisher must be directed at the base of the fire where the fuel is located, Figure 1-41.

Also Read: Workplace Fire Safety Program

A routine schedule of equipment maintenance aids in detecting potential problems such as leaking coolant, loose wires, poor grounds, laid insulation, or split hoses. Small problems, if fixed in time, can prevent the loss of valuable time due to equipment breakdown or injury.

Any maintenance beyond routine external maintenance should be referred to a trained service technician.

In most areas, it is against the law for anyone but a licensed electrician to work on arc welders and anyone but a factory-trained repair technician to work on regulators. Electrical shock and exploding regulators can cause serious injury or death.

Hoses

Hoses must be used only for the gas or liquid for which they were designed. Green floses are to be used only for oxygen, and red floses are to be used only for acetylene or other fuel gases. Using unnecessarily long lengths of floses should be avoided. Never use oil, grease, lead, or other pipe-fitting compounds for any joints. Hoses should also be kept out of the direct line of sparks. Any leaking or bad joints in gas hoses must be repaired.

Also Read: Templates:Fire Sprinkler Maintenance Program

The work area should be kept picked up and swept clean. Collections of steel, welding electrode stubs, wires, hoses, and cables are difficult to work around and easy to trip over. An electrode caddy can be used to hold the electrodes and stubs, Figure 1-42. Hooks can be made to hold hoses and cables, and scrap steel should be thrown into scrap bins.

Also Read: Hot Work Controls and its Permit to work Form

If a piece of hot metal is going to be left unattended, write the word hot on it before leaving. This procedure can also be used to warn people of hot tables, vises, firebricks, and tools.

Also, Read: Workplace Safety Inspections Forms

The welder uses hand tools to do the necessary assembly and disassembly of parts for welding as well as to per- form routine equipment maintenance.

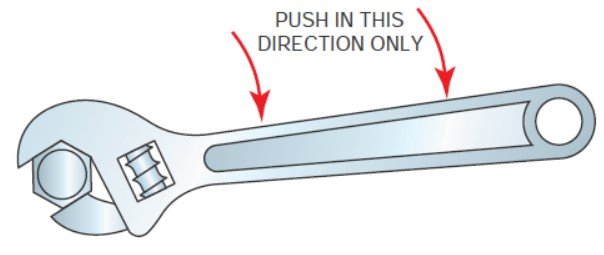

The adjustable wrench is the most popular tool used by the welder. During use, this wrench should be adjusted tightly on the nut and pushed so that most of the force is on the fixed jaw, Figure 1-43. When a wrench is being used on a tight bolt or nut, the wrench should be pushed with the palm of an open hand or pulled to prevent injuring the hand. If a nut or bolt is too tight to be loosened with a wrench, obtain a longer wrench. A cheater bar should not be used. The fewer points a box end wrench or socket has, the stronger it is and the less likely it is to slip or damage the nut or bolt, Figure 1-44.

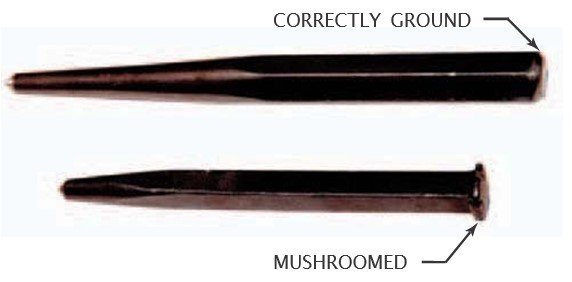

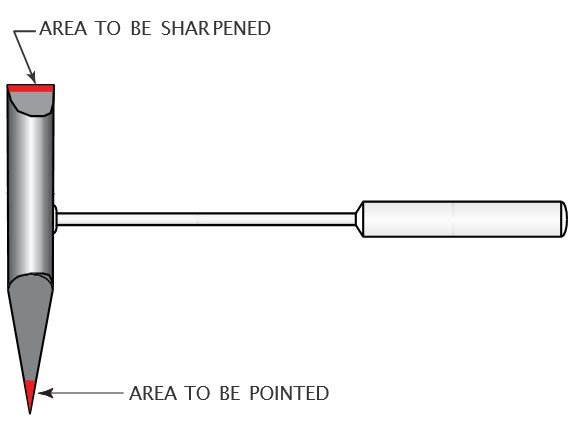

Striking a hammer directly against hard surfaces such as another hammer face or anvil may result in chips flying off and causing injury The mushroomed heads of chisels, punches, and the faces of hammers should be ground off, Figure 1-45.

Chisels and punches that are going to be hit harder than a slight tap should be held in a chisel holder or with pliers to eliminate the danger of injuring your hand. A handle should be placed on the tang of a file to avoid injuring your hand, Figure 1-46. A file can be kept free of chips by rubbing a piece of soapstone on it before it is used.

It is important to remember to use the correct tool for the job. Do not try to force a tool to do a job that it was not designed to do.

Hand Tool Safety

Hand tools used in welding fabrication should be treated properly and not abused. Many accidents can be avoided by using the right tool for the job. For instance, use a tool that is the correct size for the work rather than one that is too large or too small.

Keep hand tools clean to protect them from corrosion. Wipe off any accumulated dirt, mud, and grease. Occasionally dip the tools in cleaning fluids or solvents and wipe them clean. Lubricate adjustable and other moving parts to prevent wear and misalignment.

Make sure that hand tools are sharp, Figure 1-47. Sharp tools make work easier, improve the accuracy of the work, save time, and are safer than dull tools. When sharpening, redressing, or repairing tools; shape, grind, flone, file, fit, and set them properly using other tools suited to each purpose. For sharpening tools, either an oilstone or a grindstone is preferred. If grinding on an abrasive wheel is required, grind only a small amount at a time. Hold the tool lightly against the wheel to prevent overheating, and frequently dip the part being ground in water to keep it cool. Tflis will protect the hardness of the metal and help to retain the sharpness of the cutting edge. Be sure to wear safety goggles When sharpening or redressing tools.

Also Read: hand and portable powered tools guideline

When carrying tools, protect the cutting edges and carry the tools in such a way that you will not endanger yourself or others. Carry pointed or sharp-edged tools in pouches or holsters.

Hammer Safety

Keep hammer handles secure and safe. Check wedges and handles frequently. Be sure heads are wedged tightly on handles. Keep handles smooth and free of rough or jagged edges. Do not rely on friction tape to secure split handles or to prevent handles from splitting. Replace handles that are split or chipped or that cannot be refitted securely.

When swinging a hammer, be absolutely certain that no one is within range or can come within range of the swing or be struck by flying material. Always allow plenty of room for arm and body movements When hammering on anything.

The following safety precautions generally apply to all hammers:

- Check to see that the handle is tight before using any hammer. Never use a hammer with a loose or damaged handle.

- Always use a hammer of a suitable size and weight for the job.

- Discard or repair any tool if the face shows excessive wear, dents, chips, mushrooming, or improper redressing.

- Rest the face of the hammer on the work before striking to get the feel or aim; then, grasp the handle firmly with the hand near the end of the handle. Move the fingers out of the way before striking with force.

- A hammer blow should always be struck squarely, with the hammer face parallel to the surface being struck. Always avoid glancing blows and over-and-under strikes.

- For striking another tool (cold chisel, punch, wedge, etc.), the face of the hammer should be proportionately larger than the head of the tool. For example, a 1/2-in. (13-mm) cold chisel requires at least a 1-in. (24-mm) hammer face.

- Never use one hammer to strike another hammer.

- Do not use the end of the handle of any tool for tamping or prying; it might split.

All power tools must be properly grounded to prevent accidental electrical shock. If even a slight tingle is felt while using a power tool, stop and have the tool checked by an electrical technician. Power tools should never be used with force or allowed to overheat from excessive or incorrect use. If an extension cord is used, it should have a large enough current rating to carry the load, Table 2-4. An extension cord that is too small will cause the tool to overheat.

Safety glasses must be worn at all times When using any power tools.

Grinders

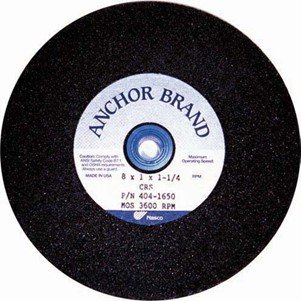

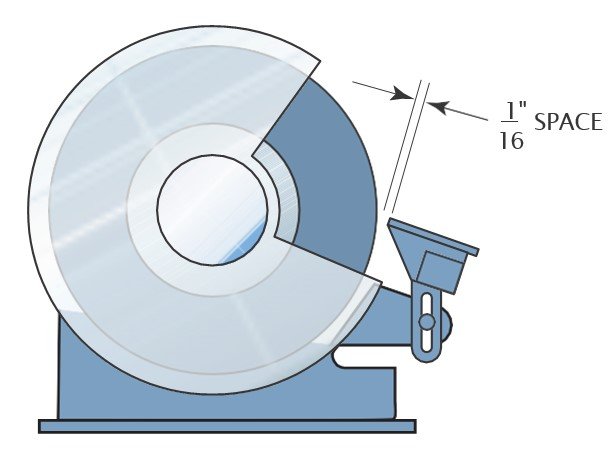

Grinding using a pedestal grinder or a portable grinder is required to do many welding jobs correctly. Often it is necessary to grind a groove, remove rust, or smooth a weld. Grinding stones have the maximum revolutions per minute (RPM) listed on the paper blotter, Figure 1-48. They must never be used on a machine with a higher-rated RPM. If grinding stones are turned too fast, they can explode.

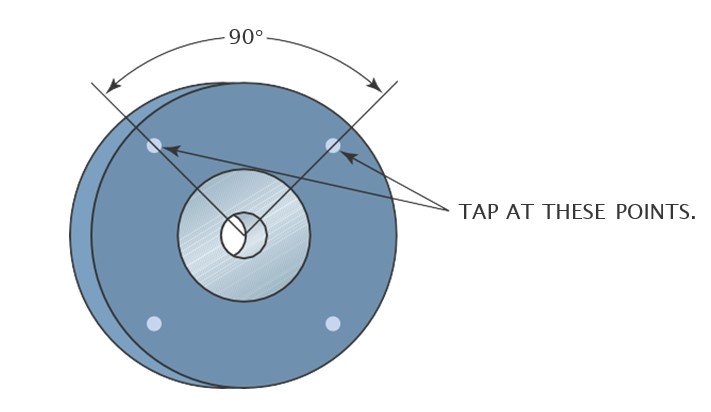

Grinding Stone

Before a grinding stone is put on the machine, the stone should be tested for cracks. You can do this by tapping the stone in four places and listening for a sharp ring, which indicates it is good, Figure 1-49. A dull sound indicates that the grinding stone is cracked and should not be used. Once a stone has been installed and has been used, it may need to be trued and balanced by using a special tool designed for that purpose, Figure 1-50. Truing keeps the stone face flat and sharp for better results.

Types of Grinding Stones: Each grinding stone is made for grinding specific types of metal. Most stones are for ferrous metals, meaning iron, cast iron, steel, and stainless steel, among others. Some

stones are made from nonferrous metals such as aluminum, copper, and brass. If a ferrous stone is used to grind nonferrous metal, the stone becomes glazed (the surface clogs with metal) and may explode due to frictional heat building up on the surface. If a nonferrous stone is used to grind ferrous metal, the stone is quickly worn away.

When the stone wears down, keep the tool rest adjusted to within 1/16 in. (2 mm), Figure 2-51, so that the metal being ground cannot be pulled between the tool rest and the stone surface. Stones should not be used When they are worn down to the size of the paper blotter. If small parts become hot from grinding, pliers can be used to hold them. Gloves should never be worn When grinding. If a glove gets caught in a stone, the whole hand may be drawn in.

The sparks from grinding should be directed down and away from other welders or equipment.

Drills

Before starting to drill, secure the workpiece as necessary and fasten it in a vise or clamp. Holding a small item in your hand can cause injury if it is suddenly seized by the bit and whirled from your grip. This is most likely to happen just as the bit breaks through the hole at the back side of the work. All sheet metal tends to cause the bit to grab as it goes through This can be controlled by reducing the pressure on the drill just as the bit starts to go through the workpiece.

Carefully center the drill bit in the jaws of the chunk and securely tighten it. Do not insert the bit off-center because it will wobble and probably break When it is used. Drill bits that are 1/4 in. (6 mm) may be hand tightened in the drill chuck to prevent them from snapping if they are accidentally grabbed. Hand-tightening the small bits allows them to spin in the chuck if necessary, thus reducing bit breakage. This technique does not always work because some chunks cannot hold the bits securely enough to prevent them from spinning during normal use. In these cases, the chunk must be tightened securely with a chuck key.

When possible, center-punch the workpiece before drilling to prevent the drill bit from moving across the surface as the drilling begins. After centering the drill bit tip on the exact point at which the hole is to be drilled, start the motor by pulling the trigger switch. Never apply a spinning drill bit to the work. With a variable-speed drill, run it at a very low speed until the cut has begun. Then gradually increase to the optimum drill speed.

Except When it is desirable to drill a hole at an angle, hold the drill perpendicular to the face of the work. Align the drill bit and the axis of the drill in the direction that the hole is to go and apply pressure only along this line, with no sideways or bending pressure. Changing the direction of pressure will distort the dimensions of the hole and might snap a small drill bit.

Use just enough steady, even pressure to keep the drill cutting. Guide the drill by leading it slightly, if needed, but do not force it. Too much pressure can cause the bit to break or overheat. Too little pressure will keep the bit from cutting and dull its edges due to the friction created by sliding over the surface.

If the drill becomes jammed in the hole, release the trigger immediately, remove the drill bit from the work, and determine the cause of the stalling or jamming. Do not squeeze the trigger on or off in an attempt to free a stalled or jammed drill. When using a reversing-type model, the direction of the rotation may be reversed to help free a jammed bit. Be sure the direction of the rotation is reset before trying to continue the drilling.

Reduce the pressure on the drill just before the bit cuts through the work to avoid stalling in metal. When the bit has completely penetrated the work and is spinning freely, withdraw it from the work while the motor is still running, and then turn off the drill.

Many types of metal cutting machines are used in the welding shop—for example, shears, punches, cut-off machines, and band saws. Their advantages include little or no post-cutting cleanup, a wide variety of metals that can be cut, and the fact that the metal is not heated.

Shears and Punches

Welders frequently use shears and punches in the fabrication of metal for welding. These machines can be operated either by hand or by powerful motors. Hand-operated equipment is usually limited to thin sheet stock or small bar stock. Powered equipment can be used on a material an inch or more in thickness and several feet wide, depending on the equipment’s rating. Their power can be a potential danger if these machines are not used correctly. Botfl shears and punches are rated by the thickness, width, and type of metal that can be used to work with safely. Failure to follow these limitations can result in damage to the equipment, damage to the metal being worked, and injury to the operator.

Sflears work like powerful scissors. The metal being cut should be placed as close to the pivoting pin as possible, Figure 1-52. The metal being sheared must be securely held in place by the clamp on the shear before it is cut. If you are cutting a long piece of metal that is not being supported by the shear table, then portable supports must be used. As the metal is being cut, it may suddenly move or bounce around; if you are holding on to it, this can cause a serious injury. Power punches are usually either hydraulic or fly-wheel operated. Botfl types move quickly, but only the hydraulic type can usually be stopped midstroke.

the flywheel-type punch has been engaged, in contrast, it will make a complete cycle before it stops. Because punches move quickly or may not be stopped, it is very important that the operator’s two hands be clear of the machine and that the metal be held firmly in place by the machine clamps before starting the punching operation.

Cut-Off Machines

Cut-off machines may use abrasive wheels or special saw blades to make their cuts. Most abrasive cut-off wheels spin at high speeds (high RPMs) and are used dry (without a coolant). Most saws operate much more slowly and with a liquid coolant. Botfl types of machines produce quality cuts in a variety of bar- or structural-shaped metals. The cuts require little or no post-cut cleanup. Always wear eye protection When operating these machines. Before a cut is started, the metal must be clamped securely in the machine vise. Even the slightest movement of the metal can bind or break the wheel or blade. If the machine has a manual feed, the cutting force must be applied at a smooth and steady rate. Apply only enough force to make the cut without dogging down the motor. Use only reinforced abrasive cut-off wheels that have an RPM rating equal to or lighter than the machine-rated speed.

Band Saws

Band saws can be purchased as vertical or horizontal, and some can be used in either position. Some band saws can be operated with a cooling liquid and are called wet saws, but most operate dry. The blade guides must be adjusted as closely as possible to the metal being cut. The cutting speed and cutting pressure must be low enough to prevent the blade from overheating. When using a vertical band saw with a manual feed, you must keep your hands away from the front of the blade so that if your hand slips, it will not strike the moving blade. If the blade breaks, sticks, or comes off the track, turn off the power, lock it off, and wait for the band saw drive wheels to come to a complete stop before touching the blade. Be careful of hot-flying chips.

Portable band saws can be used to make cuts through pipes, angles, and other similarly shaped materials up to approximately 6 in. (152 mm) in size. These portable saws can make quick work of cutting small-diameter material; however, the cut may not be as square as those made with a fixed band saw. In most cases, the slight out-of-square cut is made well within the tolerance needed for general fabrication work.

Also, Read:

Proper lifting, moving, and handling of large, heavy-welded assemblies are important to the safety of the workers and the weldment. Improper work habits can cause serious personal injury as well as cause damage to equipment and materials.

Lifting

When you are lifting a heavy object, the weight of the object should be distributed evenly between both hands, and your legs (not your back) should be used to lift, Figure 1-53. Do not try to lift a large or bulky object without help if the object is heavier than you can lift with one hand.

Hoists or Cranes

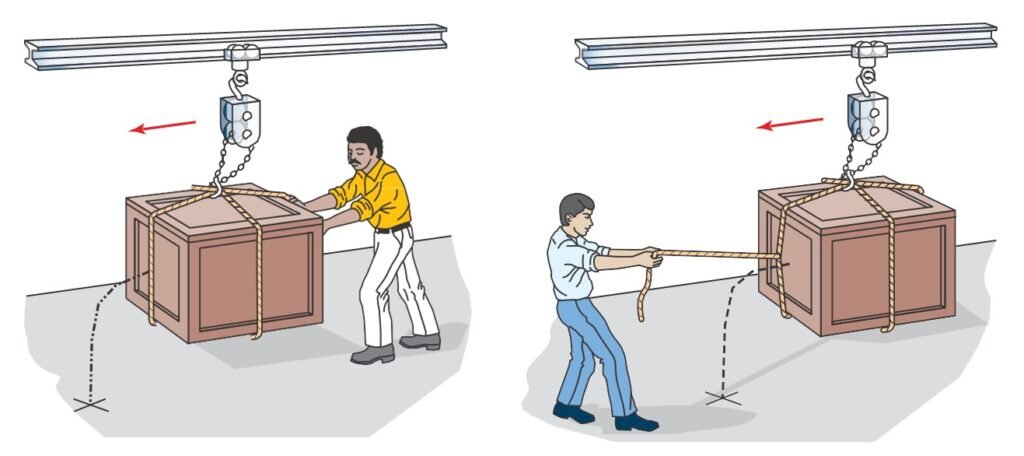

Hoists or cranes can be overloaded with welded assemblies. The capacity of the equipment should be checked before trying to lift a load. Keep any load as close to the ground as possible while it is being moved. Pusfling a load on a crane is better than pulling a load. It is advisable to stand to one side of ropes, chains, and cables that are being used to move or lift a load, Figure 1-54. If they break and snap back, they will miss flitting you. If it is necessary to pull a load, use a rope, Figure 1-55

Hauling

Much of the fabrication work may be done away from the buildings or shops. This means that the equipment used for weldings, such as torches, grinders, gas cylinders, and portable welders, has to be hauled out to the job in the work area. Keeping everything together makes it safer and easier to haul. Depending on the operation’s needs, a truck or trailer can be set up for welding.

To secure the safety of oxyacetylene cylinders, a special cylinder holder can be built in the vehicle. It is important that fuel and oil for the engine generator welder not be stored in the toolboxes. If fuel or oil gets on the oxygen and acetylene regulators, they can explode When connected to the cylinders for use. Even a small amount of liquid or vapors from fuel and oil can ruin welding electrodes. Electrodes contaminated with fuel or oil produce porous, weak welds.

Often the tie-downs in a truck bed are connected high along the bed rail, which makes it difficult to secure small items like fuel and oil containers. Magnetic strap connectors, like Magna-TiesTM, make it easier to safely secure small items in the bed of weld- ing vehicles

SUMMARY

Safety in all aspects of welding fabrication is of utmost importance. When done correctly, welding and fabrication are safe. You are responsible for your own safety. If you do not think a job can be done safely, do not start the job. If you have safety concerns about a job, get help.

You must read and follow all of the manufacturer’s operation and safety literature on any equipment. Do not assume that any new equipment has the exact same operating instructions or safety rules. As equipment changes, even slightly, manufacturers update the literature; you must read it to know that you are working in the safest manner.

Periodically performing maintenance, servicing, and doing a safety check of equipment makes doing every job safer. In addition to maintaining safety, keeping equipment well-maintained reduces operating costs. Equipment that is in good working order makes the job go better, faster, and safer.

REVIEW QUESTIONS

- What are the most common and painful injuries that occur in welding fabrication?

- What three classifications are burns divided into?

- Wflat burns are reddish in color, tender, and painful and do not involve any broken skin?

- Why is it important to cool the burned area?

- Why should you not put ice or ice water on a burn?

- What are the two types of light that can cause burns?

- What problems can reflected welding light cause?

- What should be done if welding cannot be moved away from other workers in the area?

- How long might it take to burn your eyes with UV light?

- What problem might visible light cause?

- When must eye protection be worn?

- Why can an injured (burned) eye become infected?

- What type of eye and face protection should be worn for heavy grinding?

- According to Table 2-2, what is the maximum number of flours a welder can grind without wearing ear protection?

- Which welding and cutting processes may produce undesirable respiratory by-products that might require some type of protection?

- List some of the items that should be included in a respirator-protection training program.

- Which type of respirator uses a blower to force the ambient air through air-purifying elements to the inlet covering?

- What is a possible way of telling if a bolt, nut, or hinge is plated with cadmium?

- How is ozone produced by welding?

- Why must welding be done outside or in a well-ventilated area?

- List some of the metals that may give off dangerous fumes and always require forced ventilation When being welded.

- Ladders used for welding fabrication should be listed with what organizations?

- List the general safety rules for ladder use.

- Why must welding cables be checked periodically?

- What is a double-insulated power tool?

- Refer to Table 2-4 to find the wire gauge needed for an extension cord if it is going to be 100 ft (30.5 m) long and supply 9 amps to the power tool.

- What is the correct term for a device sometimes referred to as a GFI?

- Clothing made from what materials must be avoided in the welding shop?

- Why must butane lighters and matches not be carried in a welding shop?

- List the types of ready-to-wear leather-protective clothing for welding.

- Why must fuel gas cylinders or other flammable materials be stored separately from oxygen cylinders?

- When must the valve protection cap be on a cylinder?

- Why must an acetylene cylinder stand upright for four flours after it has been stored on its side?

- Who can stand fire watch for a welder?

- List the four types of fire extinguishers and tell what type of fire each can be used to fight.

- Why should a wrench be pushed with the palm of an open hand or pulled?

- How can hand tools be cleaned?

- How should a hammer blow be made?

- How can you tell what the maximum RPMs a grinding stone can be used at?

- Why might small drill bits be hand tightened?

- What should you do before operating any power equipment for the first time?

- What can happen if fuel or oil gets on oxygen and acetylene regulators?

Also Read: E-Books:Welding safety Guide

For many Free Safety resources please visit SAFETYBAGRESOURCES