Walking and Working Surfaces can be stairs, platforms, ramps, floors, and other surfaces where you may be required to conduct your work. These surfaces may have hazards due to various conditions. This article outlines the Walking and Working Surfaces (WWS) program and program requirements. All sites must implement this to successfully manage WWS concerns and to ensure compliance with regulatory and company requirements. also provides the requirements for the walking and working surfaces program to reduce physical hazards in the workplace by ensuring that all walking and working surfaces are free of known hazards. implements feasible engineering controls and combines work practices and procedures to achieve this objective.

Also Read: What is the difference between fall protection and fall prevention(Opens in a new browser tab)

General Requirements

These outlines provide the general requirements of walking-working surfaces, proper guarding of floor and wall openings and holes, fixed industrial stairs, and other working surfaces, at worksite facilities. Ladders and scaffolds, although part of the walking-working surfaces Subpart are also covered in different articles

Provide stairways and ladders for the following conditions:

- When there is a break in elevation of 19 inches (48 cm) or more and no ramp, runway, embankment, or personnel hoist is available.

- When there is only one point of access between levels, keep the area clear of obstacles to permit free passage. If this point becomes restricted, provide a second point of access.

Housekeeping

- Keep the following places clean, orderly and in a sanitary condition: work areas, passageways (access and egress routes), stairs, storerooms, service rooms, and in and around buildings.

- Keep storage areas free from the accumulation of materials that constitute hazards from fire, explosion, or pests.

- Keep floors clean and dry.

- Where wet processes are used, maintain drainage and provide false floors, platforms, mats, or other dry-standing places.

- Keep all work areas free from protruding nails, splinters, holes, or loose boards.

- Remove combustible scrap and debris regularly to designated waste areas.

- Control vegetation when necessary.

Also Download: Workplace Housekeeping Checklist

Aisles and Passageways

- Where mechanical handling equipment is used, allow sufficient safe clearances for aisles, at loading docks, through doorways, and wherever turns or passages must be made.

- Keep aisles and passageways clear and in good repair, with no obstructions that could create a hazard.

- Mark permanent aisles and passageways appropriately.

- Demarcate aisles and passageways with paint, striping, marking pillars, powder stripping, flags, traffic cones or barrels.

also Read: Five Steps to Improve Ergonomics in the Office

Material Storage

- Post maximum safe load limits of floors within buildings in all storage areas except for slab on grade.

- Maintain proper loading procedures. Do not load floors and roofs beyond the posted load rating.

- Store and handle all materials with caution for their fire characteristics and compatibilities.

- Keep storage areas free from the accumulation of unnecessary combustible materials.

- Control weeds and grass in outside storage areas.

- When a difference in road or working levels exist, use ramps, blocking, or grading to ensure the safe movement of vehicles between the two levels.

- Do not store materials inside buildings under construction within 6 feet (1.8 m) of any hoistway or inside floor openings, nor within 10 feet (3 meters) of an exterior wall, which does not extend above the top of the material stored.

- Do not store materials on scaffolds or runways in excess of supplies needed for immediate operations.

- Materials stored in tiers must be stacked, racked, blocked, interlocked, or otherwise secured to prevent sliding, falling or collapsing.

- Stack bagged materials by stepping back the layers and cross-keying the bags at least every 10 bags high.

- Bound brick stacks must not exceed 7 feet (2 meters) in height. Loose brick stacks must not exceed 4 feet (1.2 meters) in height.

- Remove nails from used lumber before stacking. Stack used lumber on a level and solidly supported sills.

- Lumber piles must be accessible and in stacks not exceeding 16 feet (4.8 meters) in height. Structural steel, poles, pipe, bar stock, and other cylindrical materials, unless racked, must be stacked and blocked so as to prevent spreading or tilting

Guarding Floor and Wall Openings and Holes

- Every stairway and ladderway floor opening or platform must be guarded by a standard railing on all exposed sides (except at the entrance to the stairway).

- For infrequently used stairways where traffic across the opening prevents the use of a fixed standard railing, provide a guard consisting of a hinged floor opening cover of standard strength and construction and removable standard railings on all exposed sides.

- Hatchways and chutes must be guarded by one of the following items:

- A hinged floor opening cover of standard strength and construction equipped with standard railings or permanently attached so as to leave only one side exposed. When not in use, close the cover or guard it.

- A removable railing with a toeboard on not more than 2 sides of the opening and fixed standard railings with toeboards on all other exposed sides.

- Removable railings must be in place when the opening is not in use.

- Where work requires the feeding of material into an opening, provide protection to prevent a person from falling through it.

- Guard skylight floor openings and holes with a standard skylight screen or a fixed standard railing on all exposed sides. The screens must withstand a load of at least 200 pounds (90.7 kg) applied perpendicularly at any one area on the screen. The screen must be constructed so that under ordinary loads or impacts it will not deflect downward sufficiently to break the glass below it. The screen must be constructed of grillwork with openings not more than 4 inches (10.16 cm) long or of slatwork with openings not more than 2 inches (5.08 cm) wide with length unrestricted.

- Guard pit and trap door floor openings with floor opening covers.

- When the cover is not in place, protect the pit or trapdoor on all exposed sides by removable railings or by an employee acting as a lookout.

- Guard manhole floor openings with a standard manhole cover. Manhole covers and their supports, when located in plant roadways, must comply with local highway requirements or be designed to carry a truck rear-axle load of at least 20,000 lbs (9,072 kg).

- When the cover is not in place, protect the pit or trapdoor on all exposed sides by removable railings or by an employee acting as a lookout.

- Temporary floor openings must have either standard railings or be constantly attended by an employee. The opening must have a cover constructed of any material that meets strength requirements. Use covers that project more than 1 inch (2.5 cm) above the floor level providing that the edges are chamfered to an angle with a horizontal of not over 30 degrees. Set handles, hinges, bolts, or other parts flush with the floor or cover surface.

- Guard floor holes into which a person could accidentally walk with:

- A standard railing with toeboard on all exposed sides, or

- A cover protected by a removable railing.

- When the cover is not in place, the opening must be protected on all exposed sides by removable railings or by an employee acting as a lookout.

- Protect floor holes into which a person could not accidentally walk (on account of fixed machinery, equipment or walls) by a cover that leaves no openings greater than one inch (2.54 cm) wide and that is securely held in place.

- Trench or conduit covers and their supports, when located in plant roadways, must be designed to carry a truck-rear-axle load of at least 20,000 pounds (9,072 kg).

- Where doors or gates open directly onto a stairway, provide a platform. The swing of the door must not reduce the width of the stairway to less than 20 inches (50.8 cm)

- Guard wall openings from which there is a drop of more than 4 feet (1.2 m) by one of the following:

- An extension platform onto which materials can be hoisted for handling. This platform must have side rails or equivalent guards.

- A railing, roller, picket fence, half door, or equivalent barrier with a grab handle on each side of the opening with the center of the handle located approximately 4 feet (1.2 m) above floor level. The handle must withstand a load of at least 200 lbs (440 kg) applied in any direction (except upward) at any point on the top rail or corresponding member.

- Wall opening grab handles must not be less than 12 inches (30.48 cm) in length and must be mounted to provide 3 inches (7.62 cm) of clearance from the side frame of the wall opening.

- If there is an exposure to falling material, provide a removable toeboard.

- Wall opening grab handles must not be less than 12 inches (30.48 cm) in length and must be mounted to provide 3 inches (7.62 cm) of clearance from the side frame of the wall opening.

- Window openings at a stairway landing, floor, platform, or balcony, from which there is a drop of more than four feet (1.2 m) and where the bottom of the opening is less than 3 feet (0.9 m) above the platform or landing, must be guarded by standard slats, grill or railing.

- Provide toeboards where the window opening is below the landing.

- Guard runways by a standard railing on all open sides 4 feet (1.2 m) or more above floor or ground level.

- Temporary wall openings must have adequate guards.

- All open-sided floors or platforms 4 feet (1.2 m) or more above an adjacent floor or ground level must be guarded by a standard railing on all open sides except where there is an entrance to a ramp, stairway, or fixed ladder. The railing must include a toeboard, wherever, beneath the open sides a person can pass, there is moving machinery or equipment with which falling materials could create a hazard.

- Guard runways by a standard railing on all open sides 4 feet (1.2 m) or more above floor or ground level.

- Runways used for special purposes, such as oiling, shafting, or filling tank cars, may omit the railing on one side as required for performing work, provided that the runway is at least 18 inches (46 cm) wide. Review each condition and complete the proper paperwork before beginning work.

- Provide toeboards wherever tools, machine parts or materials are used.

- Open-sided floors, walkways, platforms or runways above dangerous equipment must be guarded with a standard railing and toeboard.

- Hand Rails

- Railings must meet the following criteria:

- For wood railings, the posts must be made from 2-inch (5.08 cm) by 4-inch (10.2 cm) stock and spaced no more than 6 feet (1.8 m) apart.

- If the top rail is made of two right-angle pieces of 1-inch (2.54 cm) by 4-inch (10.2 cm) stock, posts may be spaced on 8-foot (2.4 m) centers, with a 2-inch (5.08 cm) by 4-inch (10.2 cm) intermediate rail.

- For pipe railings, the posts and top and intermediate rails must have a diameter greater than 1 ½ inch (3.8 cm) and be spaced no more than 8 feet (2.4 m) on center.

- For structural steel railings, the posts and top and intermediate rails must be of 2-inch (5.08 cm) by 2-inch (5.08 cm) by 3/8 inch (0.95 cm) angles or other metal shapes of equivalent bending strength with posts spaced not more than 8 feet (2.4 m) on center.

- Other types of railing are acceptable if the top rail is smooth; located 42-inches (1.07 m) above the floor, platform, runway or ramp; has the strength to withstand 200 lbs (440 kg) of pressure at any point on the top rail; and protection between the top rail and the floor, platform, runway or ramp is equal to that of a standard intermediate rail.

- For all railing types, anchor the posts and frame the members so that the structure can withstand a 200 lbs (440 kg) load applied in any direction on the top rail.

- For wood railings, the posts must be made from 2-inch (5.08 cm) by 4-inch (10.2 cm) stock and spaced no more than 6 feet (1.8 m) apart.

- Locate toe boards at least 4 inches (10.16 cm) from the top edge to the level of the floor, platform, runway or ramp. Fasten toe boards in place with not more than ¼ inch (0.64 cm) clearance above floor level. Toe boards can be made of any substantial material either solid or with openings not over 1 inch (2.54 cm) in greatest dimension.

- When the material is piled to a height so that a standard toe board does not provide protection, provide paneling from the floor to the intermediate rail, or to the top rail.

- Mount handrails directly on the wall or partition with brackets attached to the lower side of the handrail no more than 8 feet (2.4 m) apart. There should be no obstruction to a smooth surface along the top and both sides of the handrail and the brackets should allow at least a 3-inch (7.62 cm) clearance between the handrail and the wall or any projection of the wall. The handrail must be round or another cross-sectional shape that allows an adequate handhold. Turn the ends of the handrail into the supporting wall or arrange them to prevent a projection hazard.

- The height of the handrails must not be more than 34 inches (0.86 m) or less than 30 inches (0.76 m) from the upper surface of the handrail to the tread in line with the face of the riser or to the surface of the ramp. Wooden handrails must be at least 2-inches (5.08 m) in diameter. Metal pipe handrails must be at least 1 ½ inches (3.8 cm) in diameter. The handrails must withstand a load of at least 200 lbs (440 kg) applied in any direction at any point on the rail, and must be at least 3-inches (7.62 cm) from any other object.

- Railings must meet the following criteria:

Also Read: Scaffolding Safety Tips

Fixed Industrial Stairs

- Provide fixed stairs for:

- Access from one level to another where operations require regular travel between levels.

- Access to operating platforms at the equipment that requires attention routinely during operations.Access to elevations which must be accessed daily or at each shift for gauging, inspection, or regular maintenance.

- Work that may expose employees to acids, caustics, gases or other harmful substances or work tasks that require carrying tools or equipment by hand.

- Access from one level to another where operations require regular travel between levels.

- Spiral stairways are not permitted except for limited use and secondary access where a conventional stairway is not practical.

- Winding stairways may be installed on tanks and similar round structures where the diameter of the structure is not less than five (5) feet (1.5 m).

- Fixed stairways must be designed and constructed to carry a load of 5 times the normal live load anticipated but never less than a concentrated load of 1000 pounds (454 kg).

- Fixed stairways must have a minimum width of 22 inches (0.56 m). The stair treads must be slip-resistant and the nosings must be of nonslip finish.

- Welded bar grating treads without nosings are acceptable when the leading edge is noticeable by personnel descending the stairway and the tread is serrated or nonslip.

- Stairway platforms must be no less than the width of a stairway and a minimum of 30 inches (0.76 m) in length measured in the direction of travel.

Permissible Range Rise/Tread Dimensions For Fixed Stairs

| Angle to horizontal | Rise in inches( cm) | Tread run in inches ( cm ) |

|---|---|---|

| 30º 35’ | 6½ (16.9 cm) | 11 (27.9) |

| 32º 08’ | 6¾ (17.1) | 10¾ (27.3) |

| 33º 41’ | 7 (17.8) | 10½ (26.7) |

- Provide standard railings on the open sides of all exposed stairways and stair platforms. Provide handrails on at least one side of closed stairways preferably on the right side descending.

- Flights of stairs having four or more risers must be equipped with standard stair railings or standard handrails. The width of the stair must be clear of all obstructions except handrails.

- On stairways, less than 44 inches (1.12m) wide, with both sides enclosed, provide at least one handrail, preferably on the right side descending.

- On stairways, less than 44 inches (1.12 m) wide with one side open, provide at least 1 stair railing on the open side.

- On stairways, less than 44 inches (1.12 m) wide with both sides open, provide a stair railing on each side.

- On stairways, more than 44 inches (1.12 m) wide but less than 88 inches (2.24 m) wide, provide one handrail on each enclosed side and one stair railing on each open side.

- On stairways, 88 inches (2.24 m) or wider, provide one handrail on each enclosed side, one stair railing on each open side, and one intermediate stair railing located in the middle of the stairway.

- Winding stairs must have a handrail that is offset to prevent walking on portions of the tread that are less than 6 inches (15.24 cm) wide.

- Standard railings must consist of a top rail, an intermediate rail, and posts. Railings must have a vertical height of 42 inches (1.07 m) nominal from the upper surface of the top rail to the floor, platform, runway, or ramp level. The intermediate rail must be halfway between the top rail and the floor, platform, runway, or ramp level.

- The top rail must be smooth.

- The ends of the rails must not overhang the terminal posts except were not result in a projection hazard

- Stair railings must be constructed like standard railings, but the vertical height shall be no more than 34 inches (86 cm) nor less than 30 inches (76.2 cm) from the upper surface of the top rail to the point where the surface of the stair meets the riser below.

- Vertical clearance above any stair tread to an overhead obstruction must be at least 7 feet (2.1 m) measured from the leading edge of the tread.

- Install fixed stairs at angles to the horizontal of between 30 and 50 degrees. Use any uniform combination of rise/tread dimensions that result in a stairway at an angle to the horizontal within the permissible range. Ensure that the rise height and tread width are uniform throughout any flight of stairs including any foundation structure used as one or more treads of the stairs and shall not exceed ¼ inch (0.64 cm) in variation. The following table gives examples of rise/tread dimensions that produce a stairway within the permissible range, however, the combinations are not limited to those listed below.

- Except during construction, stairways should not have metal pan landings and treads that have not been filled with concrete or other materials.

- Do not use skeleton metal frame structures and steps unless the stairs are fitted with secured temporary treads and landings.

Also Read: Stairways as a fall prevention measure

Other Working Surfaces

- Secure portable dock boards (bridge plates) in position or use devices which prevent their slipping.

- Provide handholds on portable dock boards when the dock board must be repositioned or relocated.

- Do not move railroad cars while dock boards or bridge plates are in position.

- Machine Areas

- Locate the machines with enough clearance between them so that operators do not interfere with each other, and provide ample room for cleaning machines and handling the work, including material and scrap. Arrange the machines so that operators do not stand in aisles. Aisles must be wide enough to allow room for employees transporting material, which must be independent of working and storage space.

- Use well-constructed wood platforms on the floor in front of machines.

- Use anti-slip coating or tape if the presence of oils or other substances could create a slip hazard

Also Read: Photo of the day: 5 ways to reduce the risk of Slipping and Tripping

Illumination

- Work areas must be well-lit while work is in progress. Measure illumination intensities with a light meter. If existing illumination intensities are not sufficient, provide supplemental lighting to meet the minimum intensities required as per the table below

| FOOT CANDLES | AREA OR OPERATION |

|---|---|

| 5 | General construction area lighting. |

| 3 | General construction areas, concrete placement, excavation and waste areas, accessways, active storage areas, loading platforms, refueling, and field maintenance areas. |

| 5 | Indoor: warehouses, corridors, hallways, and exit ways. |

| 5 | Tunnels, shafts, and general underground work areas: (Exception: minimum of 10 foot-candles is required at tunnel and shaft heading during drilling, mucking, and scaling. Cap lights approved by the Mine Safety and Health Administration are acceptable for use in the tunnel heading). |

| 10 | General construction plants and shops, such as batch plants, screening plants, mechanical and electrical equipment rooms, carpenter shops, rigging lofts, active storerooms, mess halls, indoor toilets, and workrooms. |

| 30 | First aid stations, infirmaries, and offices. |

- Poorly illuminated areas can be hazardous. Even moderate deficiencies can result in a significant loss of visual efficiency and in fatigue.

- Access and egress routes must be adequately lit always.

Training

- All employees must be trained in the hazards associated with walking on working surfaces.

- Training must ensure the employee’s understanding of the hazards associated with walking and working surfaces.

- Conduct training before any new job, before the introduction of new equipment or material that may present walking and working surfaces hazards, per the company Training Matrix, or as needed to ensure proficiency.

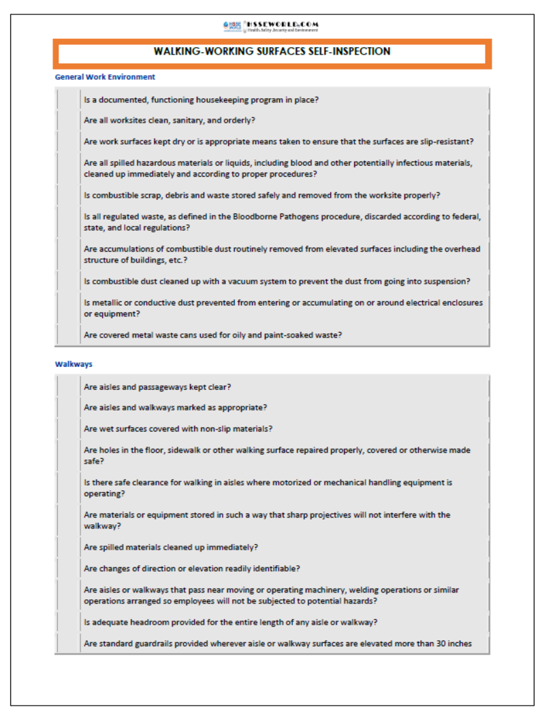

Download the Walking and Working Surfaces Self-Inspection checklist

For many Resources please visit safetybagresources