Stairways as a fall prevention measure

5 min readIf you work in a multi-floored building and walk up stairways, you’re using a form of fall prevention. Whether or not you’re working on a construction site, if you have to move between floors, you use stairways. Stairways are considered a fall prevention measure by standards set forth by the Occupational Safety and Health Administration (OSHA).

Stairways are required anytime there are level separations of more than 19”. Depending on their formation, including spiral, narrow, wide, etc., each stairways system has unique dimensions within the OSHA standards.

In this article, you’ll learn about:

- Importance of fall prevention

- Stairways as a fall prevention measure

- OSHA standards for stairways

- Stairways and OSHA-mandated dimensions

- Additional requirements in the OSHA 1910.25 standard

Importance of Fall Prevention

According to OSHA Publication 2056, there are nearly 6,000 workplace fatalities in the United States and 50,000 deaths due to workplace-related illnesses each year. Also, there are 5.7 million non-fatal workplace injuries, and those injuries alone cost U.S. businesses over $125 billion annually.

Falls are the leading cause of death in the construction industry, and most fatalities happen when employees fall from open-sided floors and through floor openings. Falls from as little as 4’ to 6’ can cause long-term time away from work or death, which means all open-sided floors and platforms 6’ or more in height must be guarded.

Stairways as Fall Prevention Measure

Like guardrails, stairways are a fall prevention system designed to minimize the risk of falling while working at height. They help workers stay safe when there’s a break in the evaluation of at least 19”.

When a flight of stairs has at least four risers, the stairway must have at least one handrail. This is to provide support for workers as they climb up or down. Stairs wider than 44” need handrails on both sides, and those wider than 88” need a handrail down the middle, and on both sides of the staircase.

What Standards Govern Stairways Usage?

Stairways are governed by OSHA 1910.25, which includes standard, spiral, ship, and alternating tread-type stairs. However, there are exceptions that aren’t held to this standard, including stairs:

- For floating roof tanks

- On scaffolds

- Designed into machines or equipment

- On self-propelled motorized equipment

According to this standard, the employer must ensure handrails, stair rail systems, and guardrail systems are provided in accordance with OSHA 1910.28.

Vertical clearance above any stair tread to an overhead obstruction is at least 6’8” (203 cm), as measured from the leading edge of the tread.

Stairs have uniform riser heights and tread depths between landings. Stairway landings and platforms are at least the widths of the stair and at least 30” (76 cm) in-depth, as measured in the direction of travel.

Each stair can support at least five times the normal anticipated live load, but never less than a concentrated load of 1,000 lbs. (454 kg) applied at any point.

Standard stairs are used to provide access from one walking-working surface to another when operations necessitate regular and routine travel between levels, including access to operating platforms for equipment. Winding stairways may be used on tanks and similar round structures when the diameter of the tank or structure is at least 5’ (1.5 m).

Spiral, ship, or alternating tread-type stairs are used only when the employer can demonstrate that it’s not feasible to provide standard stairs.

Stairways and OSHA-mandated Dimensions

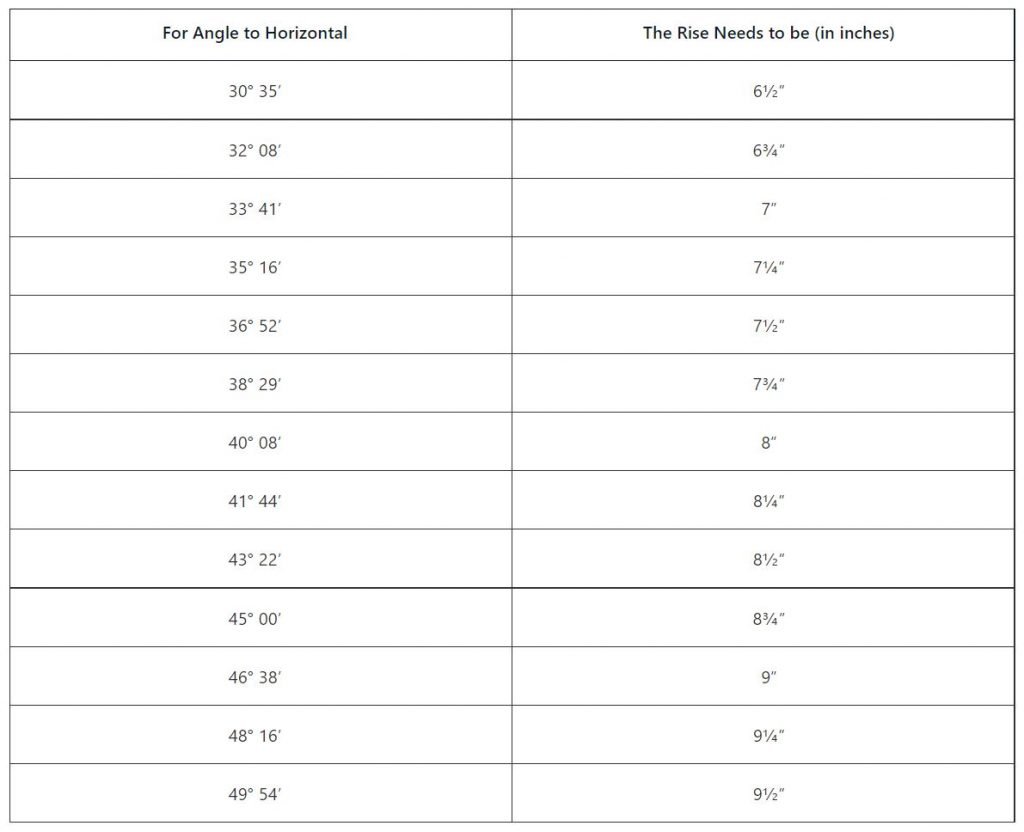

OSHA defines Stairway Rise and Tread Dimensions as follows:

Dimensions for Non-Standard Stairs

Spiral Stairs

Employers must ensure spiral stairs have:

- The minimum clear width of 26” (66 cm)

- Maximum riser height of 9½” (24 cm)

- Minimum headroom above spiral stair treads of at least 6’6” (2 m), measured from the leading edge of the tread

- Minimum tread depth of 7½” (19 cm), measured at a point 12” (30 cm) from the narrower edge

- Uniform tread size

Ship stairs

The employer must ensure ship stairs have:

- Been installed at a slope of 50° to 70° from the horizontal

- Open risers with a vertical rise between tread surfaces of 6½” to 12” (17 to 30 cm)

- Minimum tread depth of 4” (10 cm)

- Minimum tread width of 18” (46 cm)

Alternating Tread-Type Stairs

The employer must ensure alternating tread-type stairs have a:

- Series of treads installed at a slope of 50° to 70° from the horizontal

- Distance between handrails of 17” to 24” (51 to 61 cm)

- Minimum tread depth of 8½” (22 cm)

- Open risers if the tread depth is less than 9½” (24 cm)

- Minimum tread width of 7” (18 cm), measured at the leading edge of the tread

Doors or Gate Openings on Stairways

The OSHA 1910.25(c) standard has special requirements for door or gate openings on stairways.

The employer must ensure standard stairs:

- Must be installed at angles between 30° to 50° from the horizontal

- Have a maximum riser height of 9.5” (24 cm)

- Need a minimum width of 22” (56 cm) between vertical barriers

Additional OSHA Standards

The OSHA 1910.25(a) standard governs all stairways (including standard, spiral, ship, and alternating tread-type stairs), except for articulated stairs (stairs that change pitch due to change in height at the point of attachment).

Articulated stairs serve several purposes, including on:

- Floating roof tanks

- Scaffolds

- Designed into machines or equipment

- Self-propelled motorized equipment

Employers must ensure handrails, stair rail systems, and guardrail systems are provided in accordance with the OSHA 1910.28 standard, which outlines all of the duties required to have adequate fall protection in place for workers at height.

Vertical clearance above any stair tread to an overhead obstruction is at least 6’8” (203 cm). This is measured from the leading edge of the tread. Spiral stairs must meet the vertical clearance requirements in paragraph (d)(3) of this section.

OSHA 1910.25(b)(3)

Stairs must have uniform riser heights and tread depths between landings. Also, OSHA outlines that stairway landings and platforms are at least the width of the stair and at least 30” (76 cm) in-depth, as measured in the direction of travel.

OSHA 1910.25(b)(5)

When a door or a gate opens directly on a stairway, a platform is provided, and the swing of the door or gate does not reduce the platform’s effective usable depth to:

- Less than 20” (51 cm) for platforms installed before January 17, 2017

- Less than 22” (56 cm) for platforms installed on or after January 17, 2017

OSHA 1910.25(b)(8)

Spiral, ship, or alternating tread-type stairs are used only when the employer can demonstrate that it is not feasible to provide standard stairs.

OSHA 1910.25(b)(9)

When paragraph (b)(8) of this section allows the use of the spiral, ship, or alternating tread-type stairs, they are installed, used, and maintained in accordance with the manufacturer’s instructions.