Aerial work platforms are powerful machines that help us in many maintenance and construction projects. If used correctly, these pieces of equipment can provide quick and easy access to work areas that were once almost impossible to reach. While there are several types of these vehicles, they all have one thing in common: they must be operated safely to prevent accidents, property damage, injuries, and death.

The live-action video below demonstrates safe work practices for operating aerial work platforms. Topics include pre-operational inspection of vehicle and work area, fueling and battery charging, and mounting the lift. Safe procedures for driving, raising/lowering platforms, and parking the lift are also covered.

Watch the Video

Characteristics of the equipment

- Many types of aerial work platforms can be found in our workplaces today: articulating boom lifts, telescopic boom lifts, and scissor lifts.

- Scissor lifts use a scissor assembly to raise the work platform to the desired elevation.

- Boom lifts have an articulating or telescopic boom that is used to maneuver the work platform in place.

- While each type of lift has several of its own unique safety precautions, the basic safe operating procedures for all of this equipment are the same.

Training & authorization

- Before operating any type of lift, you must be trained and authorized.

- Your training will cover the model you will be operating or one that has similar operating characteristics.

- Make sure you understand all of the instructions in the operato®s manual and all safety rules put in place by your company before operation.

- Make sure you know the location of the manual on your vehicle.

- Also, be sure you understand and follow all warning and caution signs on your machine.

- Never use this type of equipment under the influence of alcohol or drugs. If you are on prescription medication, ask your physician how it may affect your ability to operate a lift safely.

- If you have a history of dizziness or seizures or are uncomfortable working above ground, you should not operate aerial lifts.

Pre-operational inspection

- As a trained and authorized operator, you must inspect your equipment before you begin work each day.

- If you find any problems, report them to the proper authority. Do not operate the unit until all malfunctions have been corrected.

- Begin your inspection with a walk-around check of the platform. Look for structural damage, loose parts, leaks, and other unsafe conditions.

- As part of the inspection you should also:

- make sure safety signs and warnings are legible and in good condition.

- Check for damaged, missing, or loose parts.

- inspect the tires for cuts and bulges and makes sure they maintain the approved tire pressure. Make sure the wheel rims are not damaged and that there are no missing lug nuts.

- check the fuel and hydraulic systems for leaks.

- if the unit is equipped with outriggers, stabilizers, or extending axles, be sure they are in good condition.

- check all controls for proper operation, including the emergency controls.

- make sure all guardrails, gates, and all other protective devices are in place and secure.

Inspecting the work area

- Before you operate the lift, you should inspect the areas where you will travel and work.

- Look for holes, bumps, and drop-offs as well as obstructions and slippery surfaces.

- Make sure you can clear any overhead obstructions.

- If the path of your equipment may cross the motion of a crane in the area, take the necessary precautions to prevent a collision.

- Be especially wary of high voltage power lines in the area and maintain distances from them as specified in the operator’s manual.

Fueling and battery charging

- The platform of the vehicle must be lowered and the engine shut off before fueling.

- Never overfill the tank. If fuel is spilled, clean it up immediately.

- Fueling should be done in well-ventilated, smoke-free areas away from flames, sparks, or other fire hazards.

- If the lift is battery-powered, charge the battery in a well-ventilated area free of open flames.

- Refer to the operator’s manual for proper charging procedures.

Mounting the lift

- Before mounting, make sure you are wearing the proper protective clothing and other equipment required by your company.

- This equipment may include hard hats, safety shoes, and work gloves. Some environments may require special equipment, such as respirators.

- Before you begin your climb to the platform, make sure co-workers are not under or around the machine. Let others in the area know that you are preparing to start up.

- When entering the platform, face the machine and always maintain three-point contact.

- Never use the control levers as handholds when climbing on or off. Also, be sure to stay clear of any foot controls when mounting.

- Make sure that all handrails, gates, toe boards, and chains are in place and secured.

- If you are operating a boom lift, you must wear the proper fall protection equipment. An adequate protection device with a lanyard attached to a platform lanyard attachment handle must be worn by everyone that occupies the platform.

- Be aware that fall protection on any lift is designed to keep you inside the working area of the vehicle, not to break a fall. If you actually were to fall off the unit while tied off, the lift could possibly tip over.

- Make sure that the total weight of personnel and equipment does not exceed the manufacturer’s rated capacity.

Starting the lift

- When starting the vehicle, follow the starting procedures in the operator’s manual. It will include instructions for starting in cold weather.

- Do not start the machine in confined areas where flammable gases may be present.

- After starting, recheck all gauges and lights. If the lift is equipped with alarms, make sure they are working properly.

- Check all of the control functions, including the emergency stop mechanism.

- Also, make sure the steering and brake work properly and that you can control the travel and elevating functions.

- If any of the controls do not work properly or there is any other malfunction, have the machine repaired before you continue operation.

Operating the controls

- After you have determined that the controls are safe to operate, make sure that you operate them smoothly. Avoid sudden stops, starts or changes in direction.

- Never attempt to operate the controls when you are outside of the operator’s control station.

- Never override any safety device on the vehicle.

- Keep co-workers on the ground clear of an operating lift and don’t position any part of the unit over anyone. Never allow anyone to stand or pass under a raised platform.

- If you discover any problems while operating the lift or encounter any potentially hazardous locations, report them to your supervisor immediately. Make sure any problems are rectified before proceeding with your work.

Safe driving procedures

- Whenever possible, drive the unit in the stowed position to maintain maximum stability.

- Avoid sharp turns and sudden stops, especially when traveling at high speeds.

- When encountering a ramp or a slope, make sure the grade does not exceed your vehicle’s rating for traveling on these types of surfaces.

- If you must drive while elevated, make sure your view is clear and maintain a safe distance from overhead obstacles and other hazards.

- Maintain a travel speed that will allow you to safely avoid congestion, co-workers, and other hazards.

- Use extreme caution when traveling in confined areas.

- Keep your attention in the direction of travel and be sure to check clearance around, above, and below you. Have a co-worker serve as a lookout if your view is obstructed.

- On a boom lift, don’t drive the machine too close to an obstacle when placing it in a work position. Place your machine in a safe parking area and then use the boom functions to maneuver in close to the work area.

- In all driving situations, remember that stunt driving and horseplay are prohibited.

- If for any reason you must stop the vehicle and leave it unattended, lower the platform, shut off the engine, engage the parking brake. Follow your company’s procedures for preventing unauthorized use of the lift.

Raising & lowering platforms

- When preparing to elevate the platform, make sure the lift is on a firm, flat surface within 5 degrees of level.

- The lift must have a tilt alarm that activates when it is more than 5 degrees out of level.

- Be sure to position outriggers, stabilizers, extending axles or other stabilizing features according to instructions in the operator’s manuals.

- Before raising the platform, make sure the load is dispersed evenly.

- Always check clearances above, below, and on all sides before raising, lowering, or rotating the platform.

- While you are raising the platform, remember it is unsafe to position it against another object to steady it.

- When the platform has reached the working position, make sure to secure items that could shift and strike the operating controls or fall from the platform.

- If the platform or elevating assembly of a boom lift gets caught or snagged by another object and cannot be moved by the reverse control, all workers on the platform must be removed before attempts are made to free the platform.

- Never attach wire, rope, or cable to the platform. If they were to get tangled or caught on an obstacle, the vehicle could tip over. Also, remember that an aerial platform should never be used as a crane.

- Keep the floor of the platform clear of debris that could cause a slip or trip. Make sure rope, electrical cords, and other equipment will not affect your footing in any way.

- Never use ladders, planks, or other devices to gain additional reach or height or lean over, sit or climb on the platform railings. Keep both feet on the platform floor at all times.

- When lowering the platform, make sure that the surrounding area is free of personnel and other equipment.

- If you are lowering the platform of a boom lift from the lower controls, make sure you are clear of the platform’s path and other movable parts.

Parking/dismounting

- Park the lift in an area designated by your company. Make sure to park the unit on level ground.

- After you have parked the vehicle, place the platform in the stowed position.

- When you have come to a complete stop, place the controls in neutral.

- Allow the engine to idle for a moment so it will cool down. Then shut it off or kill the electrical power.

- Follow your company’s procedures for preventing unauthorized use of the lift by other employees.

- Dismount carefully using three-point contact while facing the machine. Never jump off the machine or dismount while it is moving.

More Safety Moments

- 15 Home Insurance Safety Tips to Lower Premiums

- Scaffolding Safety Tips

- Vehicle Backing Safety Facts

- Gasoline Safety Tips

- Photo of the day: Flood Safety Tips

- Video: Avoiding line of Fire: Safety Moment#36

- Video: Aerial Work Platform Safety: Safety Moment#35

- How to use Plate Clamps Safely: Safety Moment#34

- Photo of the day: Incident Investigations

- Photo of the day: 10 Scaffold Safety Essentials

- Tips to Avoid Standstill Accidents: Safety Moment#33

- Common Causes of the workplace incident: Safety Moment#32

- Machinery Guarding: Safety Moment#31

- Electrical Safety While Working From Home: Safety Moment#30

- Cranes Stability and Tipping: Safety Moment#29

- Safety Net Regulations: Safety Moment#28

- Quick Tips for Avoiding Pinch Point Injuries: Safety Moment#27

- Video: Working safely Near powerlines -Safety Moment#26

- Video: Winter’s Hidden Hazard -Safety Moment#25

- Video: Isocyanates Exposure -Safety Moment#24

- Video: Electrical Safety Awareness -Safety Moment#23

- Oil & extraction: hazards, controls & resources -Safety Moment#22

- Exposure Limit Terms -Safety Moment#21

- Keeping Warehouse Personnel Safe 6 Key Tips -Safety Moment#20

- Understanding RF radiation-Safety Moment#19

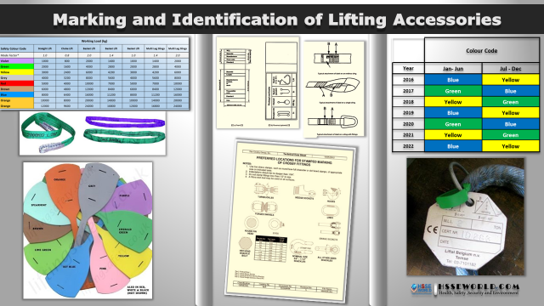

- Annual inspection and certification requirements for mobile cranes and boom trucks-Safety Moment#18

- 66 Safety Tips at work-Safety Moment#17

- Tick’s Threats when working outdoors -Safety Moment #16

- Hidden Hazards:25 steps to a safer office -Safety Moment #15

- Falls from heights :Video-Safety Moment #14

- Practice caution when handling fuel-Safety Moment #13

- The Golden safety rules :Video-Safety Moment #12

- Don’t ignore shoulder pain-Safety Moment #11

- Explain chemical Data Sheets For Non-Technical People-Safety Moment #10

- Cleaning chemicals Tips: Know the risks -Safety Moment #9

- Risk of Explosion during Removal of Split Rim/Multi Piece Wheels from Vehicles-Safety Moment #8

- Abrasive blasting: Know the hazards -Safety Moment #7

- Electrical Safety Tips -Safety Moment #6

- Tips to prevent heat illness -Safety Moment #5

- Know how to handle a hammer -Safety Moment #4

- Arc Flash Protection -Safety Moment #3

- Working safely with cement -Safety Moment #2

- Flammable Liquid Storage -Safety Moment #1