This book contains information obtained from authentic and highly regarded sources. Reasonable efforts have been made to publish reliable data and information, but the author and publisher cannot assume responsibility for the validity of all materials or the consequences of their use. The authors and publishers have attempted to trace the copyright holders of all material reproduced in this publication and apologize to copyright holders if permission to publish in this form has not been obtained. If any copyrighted material has not been acknowledged, please write and let us know so we may rectify it in any future reprint.

The petrochemical industry had its modern origins in the later years of the 19th century. However,

the production of products from naturally occurring bitumen is a much older industry. There is evidence that the ancient Bronze Age towns of Tuttul (Syria) and Hit (also spelled Heet, Iraq) used bitumen from seepages as a caulking material and mastic. Also, Arabian scientists knew that attempts to distill the bitumen caused it to decompose into a variety of products. By the time that the 19th century had dawned, it was known that kerosene, fuel for heating and cooking, was the primary product of the petroleum industry in the 1800s. Rockefeller and other refinery owners considered gasoline a useless by-product of the distillation process. But all of that changed around 1900 when electric lights began to replace kerosene lamps, and automobiles came on the scene. New petroleum fuels were also needed to power the ships and airplanes used in World

War I. After the war, an increasing number of farmers began to operate tractors and other equipment powered by oil. The growing demand for petrochemicals and the availability of petroleum and natural gas caused the industry to quickly expand in the 1920s and 1930s. During World War II, vast amounts of oil were produced and made into fuels and lubricants. The United States supplied more than 80% of the aviation gasoline used by the allies during the war. American oil refineries also manufactured synthetic rubber, toluene (an ingredient in TNT), medicinal oils, and other key military supplies.

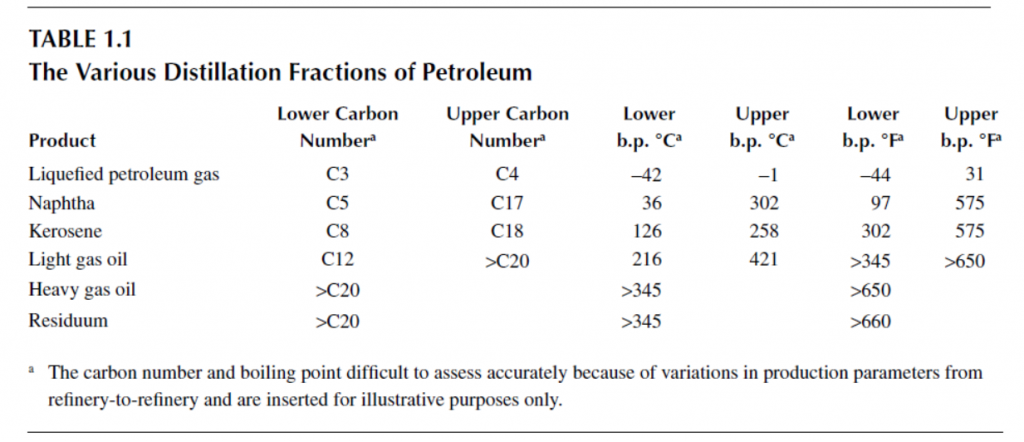

The constant demand for hydrocarbon products such as liquid fuels is one of the major driving forces behind the petroleum industry. However, the other driving force is a major group of hydrocarbon products (petrochemicals) that are the basis of a major industry. There is a myriad of products that have evolved through the short life of the petroleum industry, either as bulk fractions or as single hydrocarbon products (Tables 1.1 and 1.2). And the complexities of product composition have matched the evolution of the products. In fact, it is the complexity of product composition that has served the industry well and, at the same time, had an adverse effect on product use.

Petrochemical is a chemical product developed from petroleum that has become an essential part of the modern chemical industry (Table 1.3) (Speight, 1987; Parkash, 2003; Gary et al., 2007; Speight, 2014; Hsu and Robinson, 2017; Speight, 2017). The chemical industry is, in fact, the chemical process industry by which a variety of chemicals are manufactured. The chemical process the industry is, in fact, subdivided into other categories that are:

(i) the chemicals and allied product industries in which chemicals are manufactured from a variety of feedstocks and may then be put to further use,

(ii) the rubber and miscellaneous product industries which focus on the manufacture of rubber and plastic materials, and

(iii) petroleum refining and related industries which, on the basis of the following chapters in this text, is now self-explanatory. Thus, the petrochemical industry falls under the subcategory of petroleum and related industries.

In the context of this book, the definition of petrochemicals excludes fuel products, lubricants, asphalt, and petroleum coke but does include chemicals produced from other feedstocks such as coal, oil shale, and biomass, which could well be the sources of chemicals in the future. Thus, petrochemicals are, in the strictest sense, different from petroleum products insofar, as the petrochemicals are the basic building blocks of the chemical industry. Petrochemicals are found in products as diverse as plastics, polymers, synthetic rubber, synthetic fibers, detergents, industrial chemicals, and fertilizers (Table 1.3). Petrochemicals are used for the production of several feedstocks and monomers and monomer precursors. The monomers after the polymerization process create several polymers,

which ultimately are used to produce gels, lubricants, elastomers, plastics, and fibers.

By way of definition and clarification, as it applies to the petrochemical and chemical industry, primary raw materials are naturally occurring substances that have not been subjected to chemical

Contents

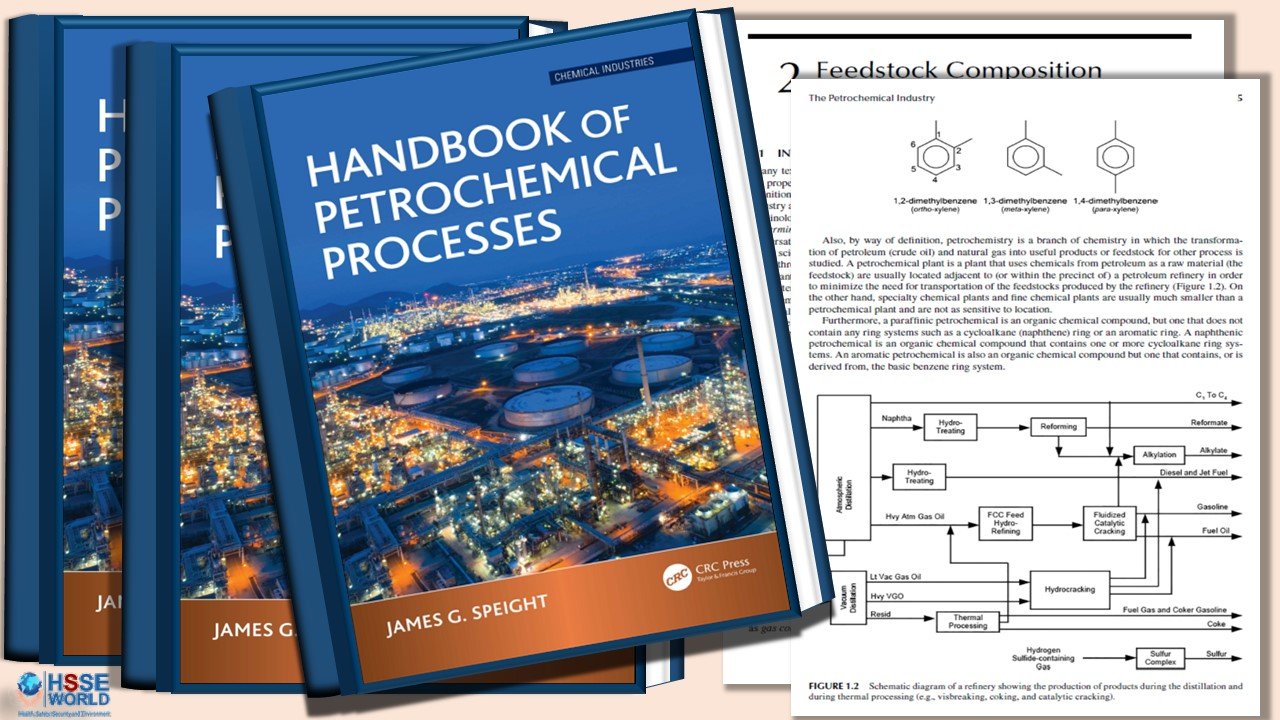

Table of Contents of the Handbook of Petrochemical Processes

- Preface

- About the Author

- Chapter 1 The Petrochemical Industry

- Chapter 2 Feedstock Composition and Properties

- Chapter 3 Other Feedstocks Coal, Oil Shale, and Biomass

- Chapter 4 Feedstock Preparation

- Chapter 5 Feedstock Preparation by Gasification

- Chapter 6 Chemicals from Paraffin Hydrocarbons

- Chapter 7 Chemicals from Olefin Hydrocarbons

- Chapter 8 Chemicals from Aromatic Hydrocarbons

- Chapter 9 Chemicals from Non-hydrocarbons

- Chapter 10 Chemicals from the Fischer–Tropsch Process

- Chapter 11 Monomers, Polymers, and Plastics

- Chapter 12 Pharmaceuticals

- References

- Conversion Tables

- Glossary

- Index

Download the book

More Downloads

- E-Books: Healthcare Hazard Control & Safety Management

- E-Books: Safety, Health and Working Conditions Training Manual

- E-Books: Energy Efficiency in Water and Wastewater Facilities

- E-Books: Fire Service Features of Buildings and Fire Protection Systems

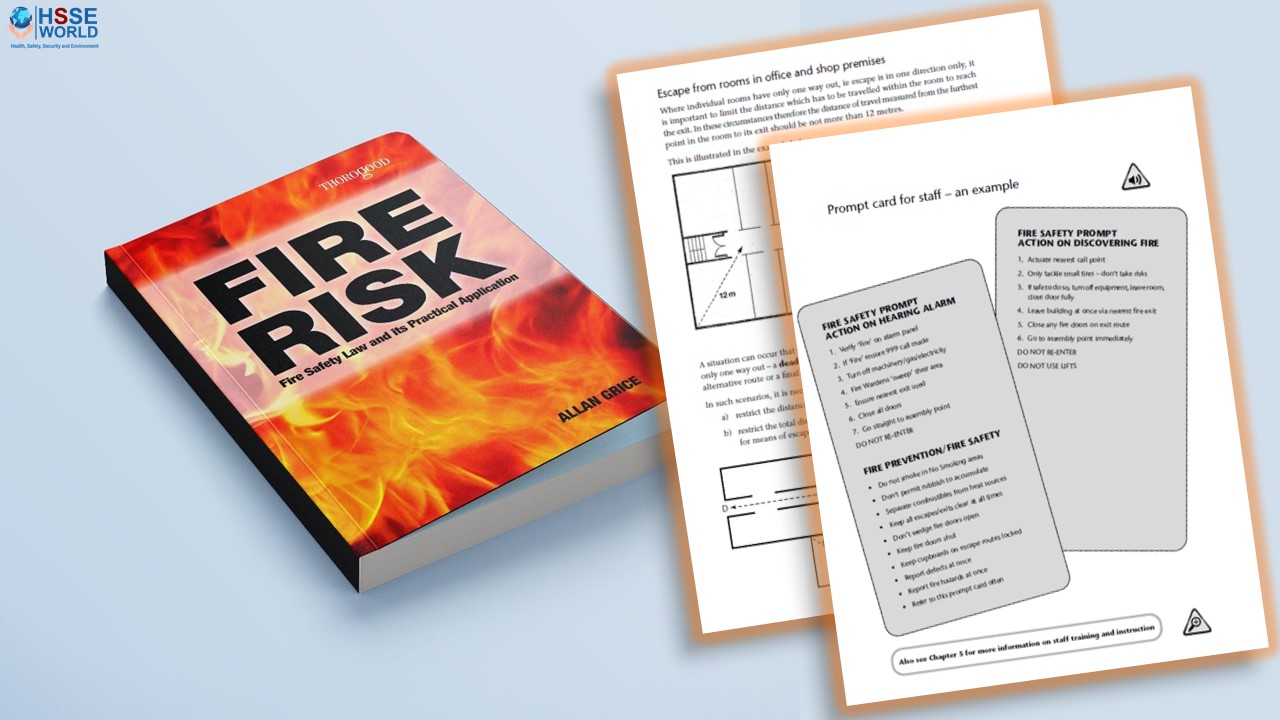

- E-Books: Evaluation of Fire Safety free download

- E-Books: PPE for Chemical, Biological, and Radiological Hazards free

- E-Books: Changing the Workplace Safety Culture free download

- E-Books: Site Emergency Planning Workbook

- E-Books: Load Restraint Guide

- E-Books: Essential Practices for Creating, Strengthening, and Sustaining Process Safety Culture

- E-Books: System Safety Engineering and Risk Assessment

- E-Books: Permit-Required Confined Spaces

- E-Books: Is it Safe to Enter Confined Space?

- E-Books: 5-Minute Workplace Safety Talks

- E-Books: Safety Culture and High-Risk Environments

- E-Books: Practical Guide to Industrial Safety

- E-Books: Slip, Trip, and Fall Prevention for Healthcare Workers

- E-Books: Health and Safety at Work Key Terms

- E-Books: Fundamentals of Process Safety Engineering

- E-Books: Gas Detection Hand Book

- E-Books: Occupational health and safety management systems ANSI-AIHA-z10-2012

- E-Books: Hot Work on Drums and Tanks

- E-Books: Human Fatigue Risk Management

- E-Books: Guidelines for the provision of facilities and general safety in the construction industry

- E-Books: Handbook of Training in Mine Rescue and Recovery Operations ( 2021)

- E-Books: Code of Practice for the Safe Use of Lifting Equipment – Edition 9 (Nov 2019)

- E-Books: Free Forklift Health and Safety Best Practices Guideline

- E-Books: Handbook of Hazardous Chemical Properties

- E-Books: Human Performance Improvement through Human Error Prevention

- E-Books: Principles Of Fire Risk Assessment In Buildings

- E-Books: Investigation of Occupational Accidents and Diseases

- E-Books: Radiation Protection and Safety in Industrial Radiography

- E-Books: Basic Guide to System Safety, Third Edition

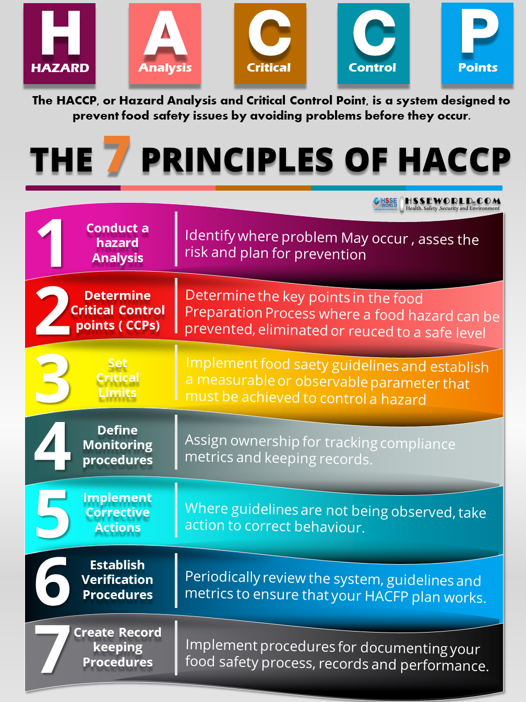

- E-Books: Food Safety Management-A Practical Guide for the Food Industry

- E-Books: Safety identification: Escape and evacuation plan signs- ISO 23601

- E-Books: Safety at Work

- E-Books: The Safety-Critical Systems Handbook 4th edition

- E-Books: Fundamental principles of occupational health and safety

- E-Books: Fire Safety Risk assessment Guide – Sleeping Accommodation

- E-Books: Mental health at work series

- E-Books: Live Fire Training: Principles and Practice

- E-Books: Pre-Startup Safety Review Guide

- E-Books: Fire and Emergency Drill Manual and Building Inspection Guide

- E-Books: Health and Safety: Risk Management 5th edition

- E-Books: Fire Protection systems -Third edition 2021

- E-Books: Fire Safety Logbook templates

- E-Books: From Accidents to Zero

- E-Books: Electric Safety Practice and Standards

- Your steps to chemical safety

- E-Books: Ergonomics and Psychology Developments in Theory and Practice

- E-Books: HAZOPS Should BE fun-The Stream-Based HAZOP

- E-Books: Safety Health and Environmental Auditing

- E-Books: A Quick Guide to Health and Safety

- E-Books: Occupational Ergonomics A Practical Approach

- E-Books: Job Hazard Analysis A Guide for Voluntary Compliance and Beyond

- E-Books: Electrical Safety of Low Voltage Systems