The purpose of this Article is to establish minimum safety requirements for safe concrete and masonry construction operations on the execution of construction projects and aimed to provide guidelines for form work and concrete shoring design, erection, supports, and bracing, to ensure its ability to safely support all vertical and lateral loads that may be imposed upon it during placement of concrete

GENERAL

Reinforcing Steel

- Personnel working 1.8 meters (6ft.) and above any adjacent working surfaces, placing and tying reinforcing steel in walls, piers, columns, etc.; shall be provided with proper work platforms with a guardrail system

- When work is to be accomplished outside a work platform, a full body safety harness be worn and at least one of the two lanyards shall be securely fixed to a vertical life line or suitable anchorage. Chain re-bar positioning systems are permitted, but shall not be used as a personal fall protection device.

- The exposed ends of all reinforcing steel shall be capped or otherwise protected. Caps shall meet OSHA standards (29 CFR

Part 1926). Personnel shall not be permitted to work above vertically protruding reinforcing steel unless it has been bent over or capped. - Wire mesh rolls shall be secured at each end to prevent dangerous recoiling action.

- Guying: reinforcing steel for walls, piers, columns, and similar vertical form work structures shall be guyed and supported to prevent collapse and to guard against possible wind pressures.

Post-Tensioning Operations

- No personnel shall be permitted to be behind the jack during posttensioning operations.

- Signs and barriers shall be erected to limit access to the posttensioning area.

- Contractors shall follow manufacturer’s recommendations when using post-tensioning equipment.

Personal Protective Equipment

- Personnel applying concrete through a pneumatic hose, as well as other personnel potentially exposed to splashing shall wear a face shield, or other eye and face protection equipment.

- Personnel shall wear gloves, boots and protective clothing that reduces potential skin exposure to cement.

- Where cement dust cannot be eliminated personnel shall wear approved dust respirators. All respirators shall be NIOSH approved.

Hygiene

- Personnel working with cement, wet concrete and similar materials shall be provided washing facilities.

- Portable eye-wash stations shall be provided where cement dust is not adequately controlled.

Bulk Concrete Handling

- Bulk storage bins, containers, or silos shall have conical or tapered bottoms with mechanical or pneumatic means of starting the flow of material.

- Personnel shall be prohibited from entering storage containers unless the ejection system has been shut-down, locked-out and tagged to indicate that the ejection system is not to be operated. Entry shall be controlled through the use of a Confined Space

Entry Permit Concrete Mixers

Concrete mixers equipped with 0.8 meter3 (1 yd3) capacity or greater shall be equipped with a mechanical device to clear the skip of concrete.

Concrete Mixers of 0.8 meter3 (1 yd3) capacity or greater shall be quipped with protective guardrails installed on each side of the skip.

All powered concrete mixers, including portable mixers shall have all guards in place. Hopper grates shall be kept closed while the equipment is energized.

Tools and Equipment

- Bull Floats: Handles on bull floats, used where they may contact energized electrical conductors, shall be constructed of non-conductive

material. - Powered Concrete Trowels: Powered and rotating-type concrete troweling machines that are manually guided shall be equipped with a control switch that will automatically shut off the power when ever the operator removes his hands from the equipment handles. The rotating blades shall be guarded at the top and outer perimeter.

- Concrete Buggies: Handles of buggies shall not extend beyond the wheels on either side of the buggy. Installation of knuckle guards on buggy handles is recommended to protect the hands.

- Concrete Buckets

- Personnel shall not ride concrete buckets.

- Concrete buckets shall have a positive safety latch installed to prevent accidental dumping. The bucket’s latch and bail shall be cleaned periodically and maintained in good operating condition.

- Concrete buckets shall not be lifted over personnel working below.

- When hoisted, concrete buckets shall be provided with a “safety-line” which consists of a wire rope sling secured to the bucket and above the crane hook that is rated 6 times the anticipated load.

- A tag-line shall be used to control the concrete bucket as it is being positioned. Care is needed so the tag-line isnot caught on adjacent structures.

Aggregate and loose material shall not be permitted to accumulate on the top and sides of the bucket. - Tremies: Sections of tremies and similar pipe/hoses used to transfer concrete shall be secured with wire rope in addition to the regular couplings or connections.

- Ready-Mix Trucks:

- When discharging on a slope, the wheels of the truck shall be blocked, and the brakes set to prevent movement.

- Where there is a potential for the truck to back into an excavation, stop-logs shall be used and the brakes set.A flagman/spotter shall be used to back ready-mix trucks.

Concrete Truck washout shall be performed in a designated area prepared especially for that purpose. - Concrete Pumping Systems

Concrete pumping systems using discharge pipes shall be provided with pipe supports designed for 100 percent overload. - Compressed air hoses in such systems shall be provided with positive fail-safe joint connectors to prevent separation of sections when pressurized.

- Concrete pump trucks, while in use shall have all outriggers fully extended and supported by adequate base-plates.

- Base plates shall be on sills. The truck shall be level and used on compacted soil.

- Concrete pump trucks shall be provided with means to prevent any discharge of oils and grease onto the ground. Concrete pump truck washout shall be performed in a designated area prepared especially for that purpose.

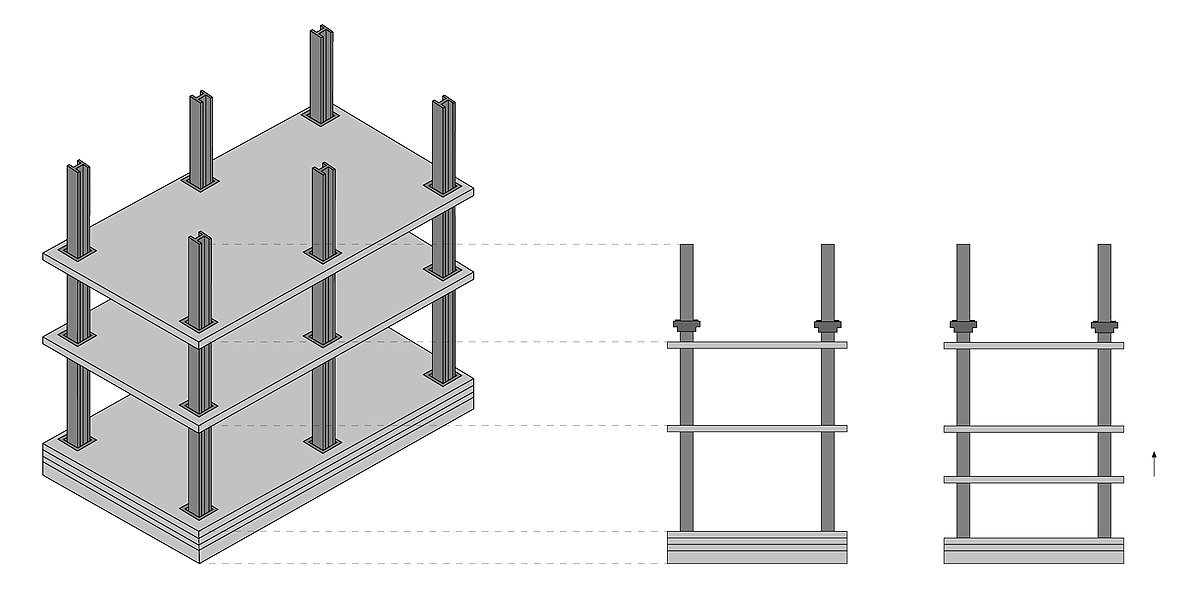

SHORING

General Requirements

- Formwork and shoring shall be designed, erected, supported, braced and maintained so that it will safely support all vertical and lateral loads that may be imposed during concrete placement.

- Drawings or plans showing the jack layout, formwork, shoring, working decks and scaffolding shall be available.

- When temporary storage of reinforcing steel, material or equipment on top of formwork becomes necessary, these areas shall be strengthened, or shored to meet intended loads.

- Contractors shall pay particular attention to stored material on shoring and shall not place more than can be used in one shift unless documentation verifying the structure’s integrity is provided and approved

- All shoring and formwork material shall be inspected prior to erection to determine that it is as specified in the shoring layout.

Damaged equipment shall not be used for shoring. - Erected shoring equipment shall be inspected immediately prior to and immediately after the placement of concrete. Equipment that is found to be damaged or weakened shall be immediately reinforced or re-shored.

- Re-shoring shall be provided when necessary to safely support slabs and beams after stripping, or where such members are subjected to superimposed loads.

- The sills for shoring shall be sound, rigid, and capable of carrying the maximum intended load.

- Personnel shall not be allowed under or in close proximity of the form work during pour operations. Personnel not engaged in the pour operation shall stay clear of the pour area. A clear area shall be maintained at 1-1/2 times the highest point of the form work.

- Stripped forms and shoring shall be removed and stockpiled promptly after stripping, in all areas in which persons are required to work or pass. Protruding nails, wire ties, and other form accessories not necessary to subsequent work shall be pulled, cut, or other means taken to eliminate the hazard.

Tubular Welded Frame Shoring - Metal tubular frames used for shoring shall not be loaded beyond the safe working load recommended by the manufacturer

- All locking devices on frames and braces shall be in good working order. Coupling pins shall align the frame or panel legs, pivoted cross braces shall have their center pivot in place, and all components shall be in a condition similar to that of original manufacture.

- When checking the erected shoring frames with the shoring layout, the spacing between towers and cross brace spacing shall not exceed that shown on the layout, and all locking shall be in the closed position.

- Devices for attaching the external lateral stability bracing shall be securely fastened to the legs of the shoring frames

- All base plates, shore heads, extension devices, or adjustment screws shall be in firm contact with the footing sill and the form.

Vertical Slip Forms - The steel rods or pipe on which the jacks climb or by which the forms are lifted shall be specifically designed for the purpose. Such rods shall be adequately braced where not encased in concrete.

- Jacks and vertical supports shall be positioned in such a manner that the vertical loads are distributed equally and do not exceed the capacity of the jacks.

- The jacks or other lifting devices shall be provided with mechanical dogs or other automatic holding devices to provide protection in case of failure of the power supply of the lifting mechanism.

- Lifting shall proceed steadily and uniformly and shall not exceed the predetermined safe rate of lift or concrete cure.

- Lateral and diagonal bracing of the forms shall be provided to prevent excessive distortion of the structure during the jacking operation.

- During jacking operations, the form structure shall be maintained in line and plumb. All vertical lift forms shall be provided with scaffolding or work platforms completely encircling the area of placement with intermittent tie breaks to ensure that superimposed loads on the scaffold /work platforms cannot pull down the entire scaffold works.

Tube and Coupler Shoring - Couplers (clamps) shall not be used if they are deformed, broken, or have defective or missing threads on bolts, or other defects.

- The material used for the couplers (clamps) shall be of a dropforged steel, malleable iron, or structural grade aluminum. Gray cast iron shall not be used

- When checking the erected shoring towers with the shoring layout, the spacing between posts shall not exceed that shown on the layout, and all interlocking of tubular members and tightness of couplers shall be checked.

- All base plates, shore heads, extension devices, or adjustment screws shall be in firm contact with the footing sill, the form material; and shall be snug against the posts.

Single Post Shores - For stability, single post shores shall be horizontally braced in both longitudinal and transverse directions, and diagonal bracing shall also be installed. Such bracing shall be installed as the shores are being erected.

- All base plates or shore heads of single post shores shall be in firm contact with the footing sill and the form materials.

- Whenever single post shores are used in more than one tier, the layout shall be designed by a qualified designer and inspected by an engineer qualified in structural design.

- When form work is at an angle, or sloping, or when the surface shored is sloping, the shoring shall be designed for such loading.

- Adjusting devices shall not be used if heavily rusted, bent, dented, re-welded, or having broken weldments or other defects.

- Adjustment of single post shores to raise form work shall not be made after concrete is in place.

- Fabricated single post shores shall not be used if heavily rusted, bent, dented, re-welded; or has broken welds, or other defects.

- All timber and adjusting devices to be used for adjustable timber single post shores shall be inspected before erection.

- Timber shall not be used if it is split, cut, has sections removed, is rotted; or is otherwise structurally damaged.

- All nails used to secure bracing or adjustable timber single post shores shall be driven home and the point of the nail bent over if exposed.

Also Read:Excavation and Trenching Safety Guideline

Removal of Formwork

- Forms and shores shall not be removed until it is determined that the concrete has gained sufficient strength to support its weight and any superimposed loads. Such determination shall be based on:

- Plans and specifications stipulate conditions for removal of forms and shores, and such conditions are followed; or

- The concrete has been tested with a appropriate ASTM standard test method, and the test results indicate that the concrete has gained sufficient strength to support its weight and superimposed loads.

- Re-shoring shall not be removed until the concrete has gained adequate strength to support its weight and all loads placed upon it.

MASONRY CONSTRUCTION

General

- Contractor shall establish a limited access zone whenever a masonry wall is being constructed. The limited access zone shall:

- Be equal to the height of the wall to be constructed plus 1.2 meters (4 ft.) and shall run the entire length of the wall;

- Be on the un-scaffolded side of the wall;

- Be restricted to those persons actively engaged in constructing the wall; and

- Shall remain in place until the wall is adequately supported to prevent overturning or collapse.

- Masonry walls exceeding 2.4 meters (8 ft.) shall be braced to prevent overturning or collapse. The bracing shall remain in place until permanent supporting elements of the structure are in place.

Masons’ Scaffolds - When working form cantilevers, install a handrail/midrail and toeboards at the ends of a continuous run of scaffold to keep masons from falling when working their way backwards. Additional detailed scaffolding requirements are Scaffold Manual of the project

- Do not stack or store blocks more than 24 inches (60 centimeters) high on the scaffold deck except during the initial placement of the stock on the scaffold.

- To disperse the load, immediately break down stacks once they are placed on the scaffold.

- Do not set scaffolds on foundations of cement block.

- Ensure that materials are placed over the strongest point of the scaffold frame; not at the center of the platform/decking span.

Storage and Handling - Stockpile masonry materials on a solid, even grade, out of the way of high-activity areas.

- Use caution when removing metal banding materials from brick and block stacks. Use only strap or side cutters.

- Properly dispose of used banding materials. Before accumulating scrap banding becomes a safety hazard.

Housekeeping and Cleanup - Masonry contractors shall maintain good housekeeping in their work areas. This shall include:

- Gathering up broken masonry pieces at least once per day into a central pile or container for disposal:

- Gathering up waste mortar / mortar spills at least once per day into a central pile or container for disposal and gathering up scrap paper and other trash;

- Removing the nails from form boards and the placing used nails into a container for disposal, stacking the reusable boards and stakes so that they are out-or-the-way of other workers on the site, and placing all un-usable boards and stakes in a container for disposal.

- Masonry contractors shall remove and properly dispose of their accumulated debris from the job site at least once per week.

- At the completion of their work, masonry contractors shall remove and properly dispose of their accumulated debris from the job site

before leaving the job site.

Also Read: Workplace Housekeeping Checklist

LIFT-SLAB OPERATIONS

- Lift-slab operations shall be designed and planned by a professional engineer who has experience in lift-slab construction.

- Jacks or lifting units shall be marked to indicate their rated capacity.

- Jacks or lifting units shall not be loaded beyond the rated capacity established by the manufacturer.

- All jacking equipment shall be capable of supporting at least 2½ times the load being lifted.

- Jacks or lifting equipment shall be designed and installed so that they will not lift when they are loaded in excess of their capacity, and shall have a safety device installed that will cause the equipment to support the load in the event of a malfunction or lose of lifting ability.

- Slabs shall be lifted so that all lift points are kept within 12.7 millimeters (0.5 in.) of that needed to maintain the slab in a level position.

- No personnel, except those essential to the jacking operation, shall be permitted in the structure while any jacking operation is taking place.

- When making temporary connections to support slabs, wedges shall be secured by tack welding. Lifting rods may not be released until the wedges at that column have been secured.

- All welding on temporary and permanent connections shall be performed by a certified welder.

- Load transfers from jacks to building columns shall not be executed until all welds on column shear plates are cooled to air temperature.

- Jacks or lifting units shall be secured to building columns so that they do not become dislocated. Equipment shall be designed and installed so that lifting rods cannot slip out of position.

Also Read: Guideline for Crane Stability and Ground Pressure

PRECAST CONCRETE

- Wall units, structural framing and tilt-up wall panels shall be adequately supported to prevent overturning or collapse until permanent connections

are completed. - Lifting inserts that are embedded or otherwise attached to precast concrete member shall be capable of supporting at least 4 times the maximum intended load applied to them. Reinforcing steel shall not be

permitted as lifting inserts. - Lifting hardware shall be capable of supporting at least 5 times the maximum intended load applied to the lifting hardware.

- Personnel or any part of their body shall not be permitted under pre-cast concrete members being lifted or tilted into position.

Also Read: Photo of the day: Concrete Truck Driver Hand Signals

For More Safety Resources Please visit Safetybagresources