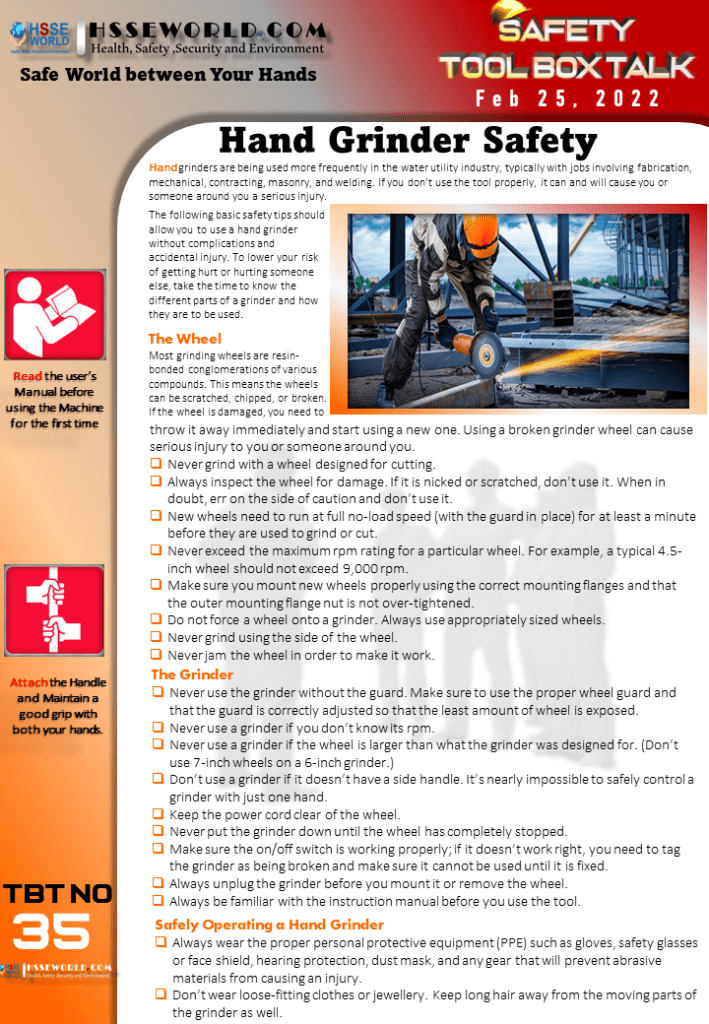

Hand grinders are being used more frequently in the water utility industry, typically with jobs involving fabrication, mechanical, contracting, masonry, and welding. If you don’t use the tool properly, it can and will cause you or someone around you a serious injury.

This Tool Box Talk outlines basic Hand Grinder safety tips that should allow you to use a hand grinder without complications and accidental injury. To lower your risk of getting hurt or hurting someone else, take the time to know the different parts of a grinder and how they are to be used.

(Read More: Machinery Guarding: Safety Moment#31 )

The Wheel

Most grinding wheels are resin-bonded conglomerations of various compounds. This means the wheels can be scratched, chipped, or broken. If the wheel is damaged, you need to throw it away immediately and start using a new one. Using a broken grinder wheel can cause serious injury to you or someone around you.

- Never grind with a wheel designed for cutting.

- Always inspect the wheel for damage. If it is nicked or scratched, don’t use it. When in doubt, err on the side of caution and don’t use it.

- New wheels need to run at full no-load speed (with the guard in place) for at least a minute before they are used to grind or cut.

- Never exceed the maximum rpm rating for a particular wheel. For example, a typical 4.5-inch wheel should not exceed 9,000 rpm.

- Make sure you mount new wheels properly using the correct mounting flanges and that the outer mounting flange nut is not over-tightened.

- Do not force a wheel onto a grinder. Always use appropriately sized wheels. qNever grind using the side of the wheel. Never jam the wheel in order to make it work.

The Grinder

- Never use the grinder without the guard. Make sure to use the proper wheel guard and that the guard is correctly adjusted so that the least amount of wheel is exposed.

- Never use a grinder if you don’t know its rpm. qNever use a grinder if the wheel is larger than what the grinder was designed for. (Don’t use 7-inch wheels on a 6-inch grinder.)

- Don’t use a grinder if it doesn’t have a side handle. It’s nearly impossible to safely control a grinder with just one hand.

- Keep the power cord clear of the wheel. qNever put the grinder down until the wheel has completely stopped.

- Make sure the on/off switch is working properly; if it doesn’t work right, you need to tag the grinder as being broken and make sure it cannot be used until it is fixed.

- Always unplug the grinder before you mount it or remove the wheel.

- Always be familiar with the instruction manual before you use the tool.

Safely Operating a Hand Grinder Safety

- Always wear the proper personal protective equipment (PPE) such as gloves, safety glasses or face shield, hearing protection, dust mask, and any gear that will prevent abrasive materials from causing an injury.

- Don’t wear loose-fitting clothes or jewellery. Keep long hair away from the moving parts of the grinder as well.

- Don’t reach too far with a grinder. You need to have solid footing and balance. If you can’t fully reach what you’re working on, turn off the tool and reposition yourself.

- Make sure you are to the side of the grinder opposite of the wheel and wheel guard. Keep bystanders at a safe distance from the work area.

- Keep a firm grip on the grinder and be ready to resist a kickback.

- Only use accessories designed for the grinder that you’re using. Never mix accessories.

- Never use any electrical tools in rain or wet conditions. This increases your chance of electrocution. Never use the unplugged cord to pull or carry the grinder.

Photo of the day: Eyes on the Road The challenges of safe driving

Use common sense when it comes to using and working with power tools

Download Hand Grinder Safety Tool Box Talk

More Toolbox Talks

- Death of Oregon forestry worker prompts new toolbox talk

- Tool Box Talk: Securing a construction Site

- Tool Box Talk: Basic Electrical

- Tool Box Talk: Hazardous Chemicals- Four Routes of Entry

- Tool Box Talk: Excavation

- Tool Box Talk: Shift Work Dangers

- Tool Box Talk: Hearing Protection

- Tool Box Talk: Hydraulic Excavators: Lifting with Slings

- Tool Box Talk: Pneumatic tools

- Tool Box Talk: Oil Spill Response

- Tool Box Talk: Heart Risks: AEDs and CPR in the Workplace

- Tool Box Talk: Aerial Lift Safety

- Tool Box Talk: Aerogel Nanoporous Insulation Products

- Tool Box Talk: Arc Welding and Fire Safety

- Tool Box Talk: Asphalt Fumes: Roofing Operations

- Tool Box Talk: Biohazard Safety

- Tool Box Talk: Boom Truck Safety

- Tool Box Talk: Carbon Monoxide Poisoning

- Tool Box Talk: Rotary Hammers-Hammer Drills

- Tool Box Talk: Working Around Heavy Equipment

- Tool Box Talk: Winter Driving Safety Tips

- Tool Box Talk: Lockout and Tagging

- Tool Box Talk: Hand Grinder Safety

- Tool Box Talk: Don’t Let Chemicals Get to You

- Tool Box Talk: Rough Terrain Fork Truck Scaffolds

One thought on “Tool Box Talk: Hand Grinder Safety”