It is our goal and primary responsibility to establish and maintain a healthy and safe work environment for all work employees. This is a shared goal that requires constructive efforts of employees, supervisors, and management. To help nurture this goal, an Overhead and Gantry Cranes Program has been established as part of our overall safety effort. This program, which complies with 29 CFR 1910.179, covers all employees at this location. Our Overhead and Gantry Cranes Program provides appropriate measures, including training and education, to ensure that safety requirements are maintained.

Training Guidelines

Training will be provided to employees designated to operate overhead and gantry cranes. Training will include but not be limited to:

- Handling the load

- Frequent inspections

- Periodic inspections

- General requirements for operating equipment

Handling the Load

- Only designated personnel will be allowed to operate overhead and gantry cranes

- The hoist shall not be loaded beyond its rated load capacity

- The hoist chain or rope shall be free from kinks or twists

- The hoist chain or rope shall not be wrapped around the load

- The load shall be well secured and properly balanced in the lifting device before it is lifted more than a few inches

- There will be no sudden acceleration or deceleration of the moving load

- No loads will be carried over people

- The operator must not leave the controls of the hoist while it is suspended

Frequent Inspections

A frequent inspection is an inspection that is performed daily to monthly intervals. The following items must be inspected as defined below:

- Daily Inspections

- All functional operating mechanisms

- Leakage or deterioration in lines, tanks, valves, drain pumps, and other parts of air or hydraulic systems

- Visual inspection of hooks for deformation or cracks

- Visual inspection of hoist chains for excessive wear, twist, or distorted links that would interfere with proper function or stretch beyond the manufacturer’s recommendation

- All functional operating mechanisms for excessive wear of components

- Weekly Inspections

- Maintenance will perform their weekly PM on all electric hoists which include:

- Measuring latch hook openings, replace hook when opening is greater than 1”

- Verify latch is working correctly on hook. Latch gate must close tightly on hook, replace as needed

- Verify electrical control functions work correctly

- Inspect external covers for loose screws, bolts or nuts. Tighten as needed.

- Inspect trolley track wheels for wear, inspect flange for wear and loose bolts, Tighten or replace as needed

All monthly inspections must be documented with the following information:

- The date of inspection

- The signature of the person performing the inspection

Periodic Inspections

A periodic inspection is an inspection that is performed between one (1) and twelve (12) month intervals. These inspections shall include all items in the monthly inspection as well as the following:

- Deformed, cracked, or corroded members

- Loose bolts or rivets

- Cracked or worn sheaves and drums

- Excessive wear of chain drive sprockets and excessive chain stretch

- Excessive wear on brake systems parts

- Electrical controls for signs of pitting or any deterioration of controller contactors, limit switches, and pushbutton stations

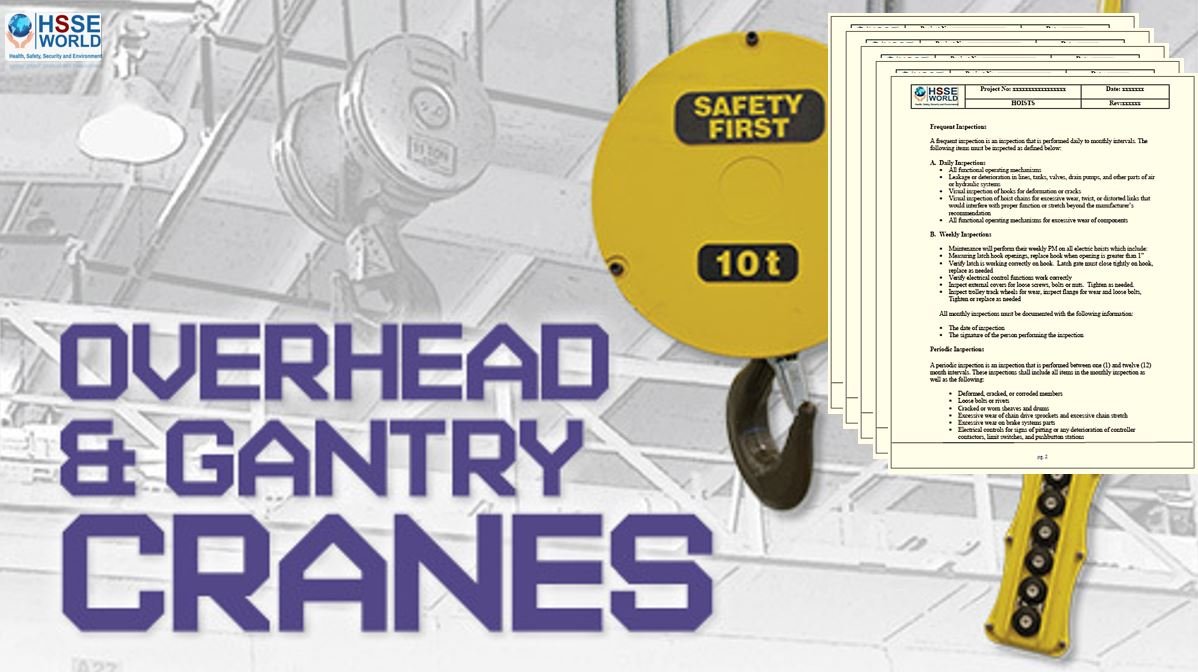

The following template can be used to help your organization develop a written Overhead and Gantry Crane Program. This template cannot be used as is – you must customize the template to meet the needs of your organization. We have made this template easier for you to customize by adding visual prompts that identify some areas where your input is needed. These are identified by Red highlighted, red text in the template. You may also change any of the text in the template to meet your organization’s needs – for example, Company department names, job titles, listed responsibilities and audiologist.

Disclaimer. This sample written SOverhead and Gantry Crane Program Blank template cannot be used as is. You must customize the template to meet the needs of your organization. HSSE WORLD does not guarantee that this template is or can be relied on for compliance with any law or regulation, assurance against preventable losses, or freedom from legal liability. We make no representations or warranties of any kind whatsoever, either express or implied, in connection with the use of this template. HSSE WORLD will not be liable for your use of the template as customized by you. All safety programs and policies, including this template and the information you supply to complete it, should be reviewed by your legal counsel and/or risk management staff.