Working with Electricity-Electrical Safety Program

9 min readEmployers must implement and document an overall electrical safety program that directs activity appropriate for the voltage, energy level, and circuit conditions. The Electrical Safety Program (ESP) was created to comply with electrical systems regulatory requirements to ensure that energized electrical work at site facilities is performed safely by qualified electrical workers who are provided with appropriate safe work procedures, protective equipment, and other controls. It is intended to protect employees against electricity-related hazards. These hazards include electrical shock and burns; arc flash burns; arc-blast impacts; falls; and other potential electrical safety hazards. Working on equipment in a de-energized state is required unless de-energizing introduces an increased hazard or is infeasible (e.g., voltage testing to troubleshoot).

Also Read: E-Books: THE WORKPLACE GUIDE TO ARC FLASH SAFETY

General Categories of Electrical Hazards

There are three general categories of electrical hazards: electrical shock, arc flash, and arc blast.

1- Electric Shock

Approximately 30,000 nonfatal electrical shock accidents occur each year. The National Safety Council estimates that about 1,000 fatalities each year are due to electrocution, more than half of them while servicing energized systems of less than 600 volts. Electrocution is the fourth leading cause of industrial fatalities, after traffic, homicide, and construction accidents. The current required to light a 71⁄2 watt, 120-volt lamp, if passed across the chest, is enough to cause a fatality. The most damaging paths through the body are through the lungs, heart, and brain.

2- Arc-Flash

When an electric current passes through air between ungrounded conductors or between ungrounded conductors and grounded conductors, the temperatures can reach 35,000°F. Exposure to these extreme temperatures burns the skin directly and causes the ignition of clothing, which adds to the burn injury. The majority of hospital admissions due to electrical accidents are from arc-flash burns, not from shocks. Each year more than 2,000 people are admitted to burn centers with severe arc-flash burns. Arc flashes can and do kill at distances of 10 feet (3 m).

Also Read: Arc Flash Protection -Safety Moment #3

Arc-Blast

The tremendous temperatures of the arc cause the explosive expansion of both the surrounding air and the metal in the arc path. For example, as stated in NFPA 70E (2009 edition), copper expands by a factor of 67,000 times when it turns from a solid to a vapor. The danger associated with this expansion is one of high pressure, sound, and shrapnel. The high pressures can easily exceed hundreds or even thousands of pounds per square foot, knocking workers off ladders, rupturing eardrums, and collapsing lungs. The sounds associated with these pressures can exceed 160 dB. Finally, material and molten metal is expelled away from the arc at speeds exceeding 1,600 km/hr (700 mph), fast enough for shrapnel to completely penetrate the human body.

Also Read: Electrical Substation Safe Accessibility and Required PPE

NFPA 70E Requirements

- Arc flash boundaries must be known

- Safe approach distances established and maintained

- Marking equipment relative to hazards

- Electrically safe (voltage-rated) tools

- PPE (arc thermal performance value APTV)

- Training

Also Read: Working with Electricity Arc Flash-NFPA 70E

Electrical Hazard Analysis

If the energized electrical conductors or circuit parts operating at 50 volts or more are not placed in an electrically safe work condition, other safety-related work practices shall be used to protect employees who might be exposed to the electrical hazards involved. Appropriate safety-related work practices must be determined before any person is exposed to the electrical hazards involved by using both shock hazard analysis and arc flash hazard analysis.

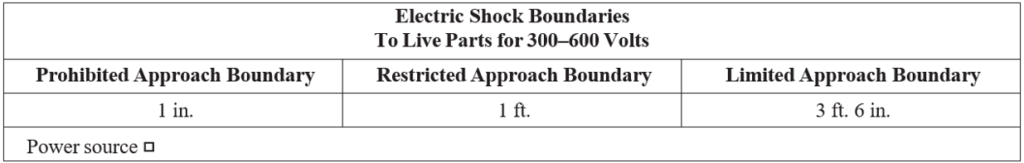

Shock Hazard Analysis

A shock hazard analysis must determine the voltage to which personnel will be exposed, boundary requirements, and the personal protective equipment necessary in order to minimize the possibility of electrical shock to personnel.

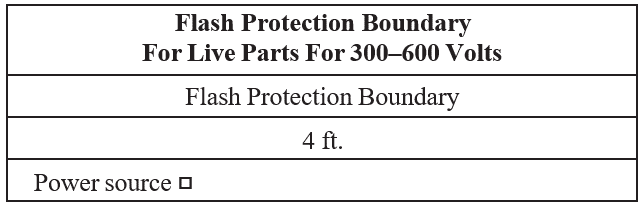

Arc Flash Hazard Analysis

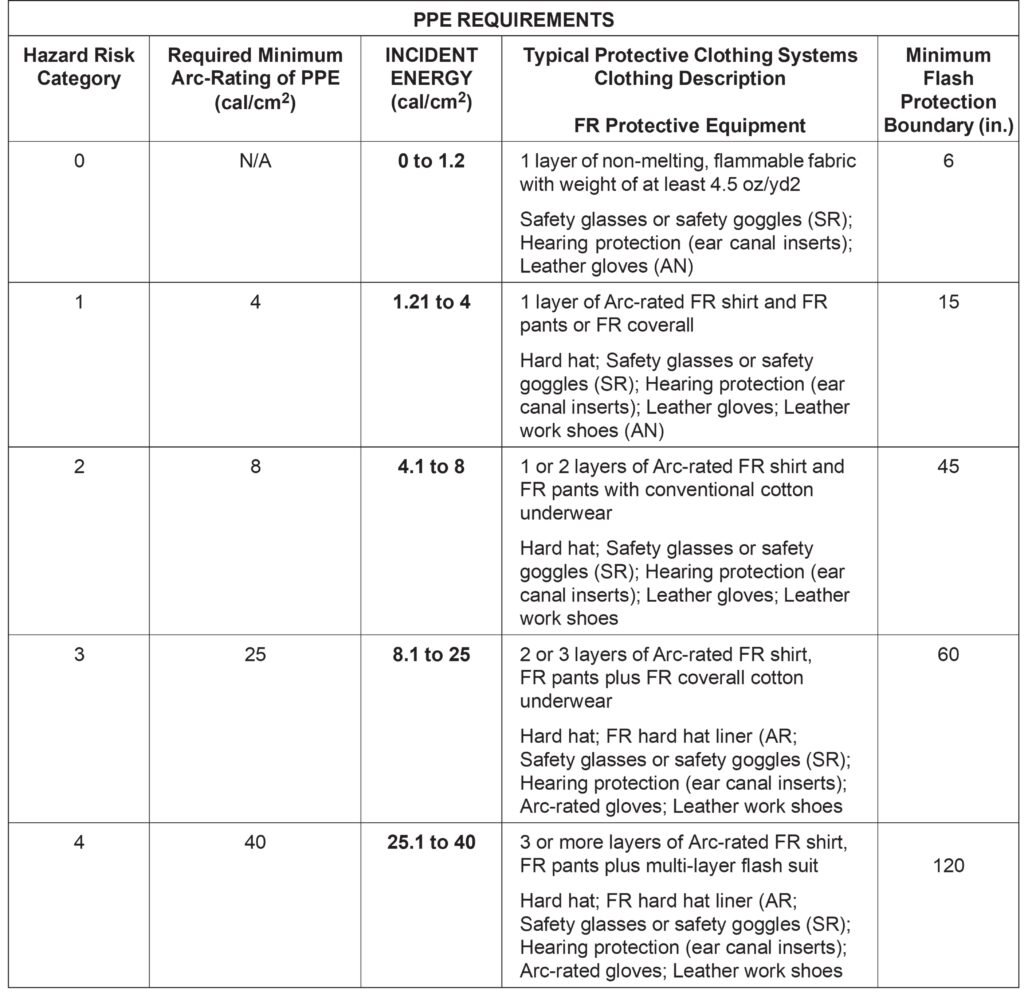

An arc flash hazard analysis must determine the Arc Flash Protection Boundary and the personal protective equipment that people within the Arc Flash Protection Boundary shall use.

The arc flash hazard analysis must be updated when a major modification or renovation takes place. It must be reviewed periodically, not to exceed five years, to account for changes in the electrical distribution system that could affect the results of the arc flash hazard analysis. The arc flash hazard analysis must take into consideration the design of the overcurrent protective device and its opening time, including its condition of maintenance.

Exception #1: An arc flash hazard analysis is not required where all of the following conditions exist:

- The circuit is rated 240 volts or less.

- The circuit is supplied by one transformer.

- The transformer supplying the circuit is rated less than 125 kVA.

Exception #2: The requirements of 130.7(C)(9), 130.7(C)(10), and 130.7(C)(11) must be permitted to be used in lieu of a detailed incident energy analysis.

Also Read: E-Books: Electrical Safety of Low Voltage Systems

Arc Flash Protection Boundary

- Voltage Levels Between 50 Volts and 600 Volts. In those cases where detailed arc flash hazard analysis calculations are not performed for systems that are between 50 volts and 600 volts, the Arc Flash Protection Boundary must be 4.0 ft, based on the product of clearing time of 2 cycles (0.033 sec) and the available bolted fault current of 50 kA or any combination not exceeding 100 kA cycles (1667 ampere seconds). When the product of clearing times and bolted fault current exceeds 100 kA cycles, the Arc Flash Protection Boundary must be calculated.

- Voltage Levels Above 600 Volts. At voltage levels above 600 volts, the Arc Flash Protection Boundary shall be the distance at which the incident energy equals 5 J/cm2 (1.2 cal/cm2). For situations where fault-clearing time is equal to or less than 0.1 sec, the Arc Flash Protection Boundary must be the distance at which the incident energy level equals 6.24 J/cm2 (1.5 cal/cm2).

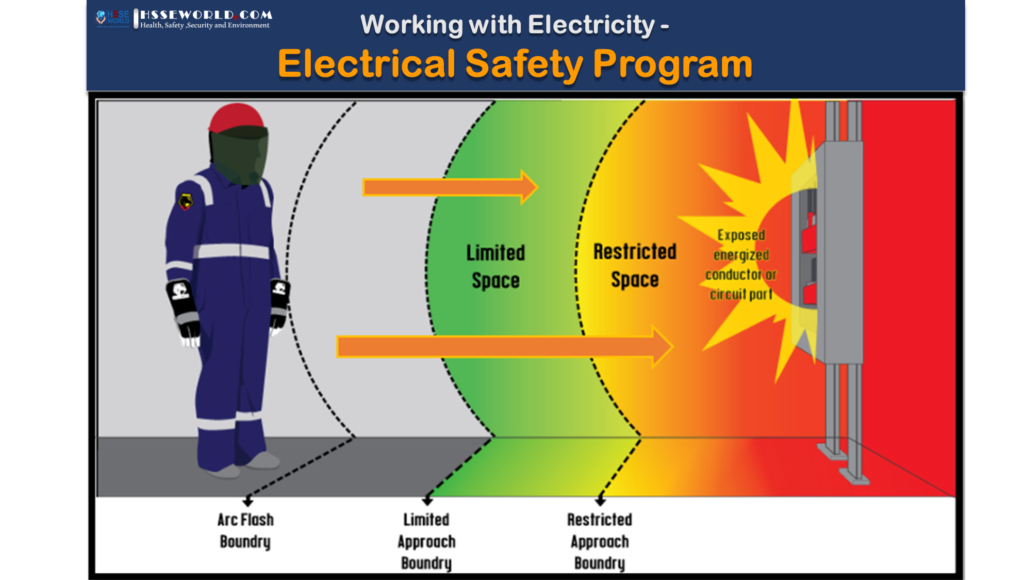

Approach Boundaries

NFPA 70E has established three shock protection boundaries:

- Limited Approach Boundary

- Restricted Approach Boundary

- Prohibited Approach Boundary

Limited Approach Boundary

The limited approach boundary is an approaching boundary to protect personnel from shock. A boundary distance is established from an energized part based on system voltage. To enter this boundary, unqualified persons must be accompanied by a qualified person and use PPE.

Restricted Approach Boundary

The restricted approach boundary is an approaching boundary to protect personnel from shock. A boundary distance is established from an energized part based on system voltage. Only qualified persons are allowed in this boundary and they must use PPE.

Prohibited Approach Boundary

The prohibited approach boundary is an approaching boundary to protect personnel from shock. Work in this boundary is considered the same as making direct contact with an energized part. Only qualified persons are allowed to enter this boundary and they must use PPE.

Shock protection boundaries are based on system voltage and whether the exposed energized components are fixed or movable.

Flash Hazard Analysis

A complete electrical hazard analysis must also contain a Flash Hazard Analysis. NFPA 70E Article 130.3 requires this analysis to be performed: “A Flash Hazard Analysis shall be done in order to protect personnel from the possibility of being injured by an Arc-Flash. The analysis shall determine the Flash Protection Boundary and the personal protective equipment that people within the Flash Protection Boundary shall use.”

Unlike the Shock Hazard Protection Boundaries that are based solely on system voltage, the Flash Protection Boundary is not fixed. In order to determine the potential Arc-Flash hazard, Flash Protection Boundaries must be calculated at every point where service on energized equipment, devices, or conductors may be required.

also Read: Photo of the day: Substation Safety Equipment

Summary of Approach Boundaries

The risk from exposed live parts depends on your distance from the parts. Three “boundaries” are key to protecting yourself from electric shock and one to protect you from arc flashes or blasts. These boundaries are set by the National Fire Protection Association (NFPA 70E).

The limited approach boundary is the closest an unqualified person can approach unless a qualified person accompanies you. A qualified person is someone who has received mandated training on the hazards and on the construction and operation of equipment involved in a task.

The restricted approach boundary is the closest to exposed live parts that a qualified person can go without proper PPE (such as flame-resistant clothing) and insulated tools. When you are this close, if you move the wrong way, you or your tools could touch live parts.

The prohibited approach boundary—the most serious—is the distance you must stay from exposed live parts to prevent flashover or arcing in the air. Get any closer and it is like direct contact with a live part.

To protect against burns, there is one more boundary: The flash protection boundary is where PPE is needed to prevent incurable burns, if there is an arc flash

OSHA Standards related to employee protection from hazards of arc flash

1910.333—Selection and use of work practices

(a) General. Safety-related work practices shall be employed to prevent electric shock or other injuries resulting from either direct or indirect electrical contacts when work is performed near or on equipment or circuits which are or may be energized. The specific safety-related work practices shall be consistent with the nature and extent of the associated electrical hazards.

(2) Energized parts. If the exposed live parts are not de-energized (i.e., for reasons of increased or additional hazards or infeasibility), other safety-related work practices shall be used to protect employees who may be exposed to the electrical hazards involved. Such work practices shall protect employees against contact with energized circuit parts directly with any part of their body or indirectly through some other conductive object. The work practices that are used shall be suitable for the conditions under which the work is to be performed and for the voltage level of the exposed electric conductors or circuit parts. Specific work practice requirements are detailed in paragraph (c) of this section.

[1910.333(b) “Working on or near exposed de-energized parts.”]

(C) Working on or near exposed energized parts.

(1) Application. This paragraph applies to work performed on exposed live parts (involving either direct contact or by means of tools or materials) or near enough to them for employees to be exposed to any hazard they present.

(2) Work on energized equipment. Only qualified persons may work on electric circuit parts or equipment that have not been de-energized under the procedures of paragraph (b) of this section. Such persons shall be capable of working safely on energized circuits and shall be familiar with the proper use of special precautionary techniques, personal protective equipment, insulating and shielding materials, and insulated tools.

1910.335—Safeguards for personnel protection

(a) Use of protective equipment.

(1) Personal protective equipment.

(i) Employees working in areas where there are potential electrical hazards shall be provided with and shall use, electrical protective equipment that is appropriate for the specific parts of the body to be protected and for the work to be performed. Note: Personal protective equipment requirements are contained in Subpart I of this part.

(ii) Protective equipment shall be maintained in a safe, reliable condition and shall be periodically inspected or tested, as required by §1910.137.

(2) General protective equipment and tools.

(i) When working near exposed energized conductors or circuit parts, each employee shall use insulated tools or handling equipment if the tools or handling equipment might make contact with such conductors or parts. If the insulating capability of insulated tools or handling equipment is subject to damage, the insulating material shall be protected.

The General Duty Clause

General Duty Requirement. NCGS 95-129(1) requires that “Each employer will furnish to each of his employee’s conditions of employment and a place of employment that are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees.”

Derived from NFPA 70E Table 130.7(C)(10) & (C)(11)

AN = As needed (optional) / AR = As required / SR = Selection required

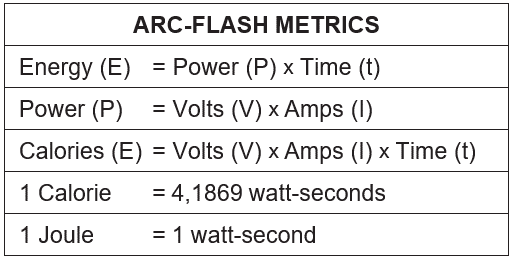

A Calorie is the amount of heat energy needed to raise the temperature of one gram of water by one degree Celsius.

Also Read: Electrical Risk Assessments(

Also Read: Working with Electricity Electrical Accidents Guide for Electrical Workers

For more safety Resources Please Visit Safetybagresources