OSHA revised Subpart S to reflect updated industry practices and technology and to incorporate the 2000 edition of NFPA 70E, Electrical Safety Requirements for Employee Workplaces, and the 2002 revision of the National Electric Code (NEC). NFPA 70E applies to all personnel working on energized equipment greater than 50 volts or equipment that could produce an arc flash, which means virtually every industry has employees at risk. Under the newly revised Subpart S—Electrical (effective Aug. 13, 2007), OSHA has not adopted NFPA 70E in its entirety, specifically excluding some personal protective equipment and clothing requirements in regard to arc flash.

Also Read: E-Books: THE WORKPLACE GUIDE TO ARC FLASH SAFETY

What Is an Arc Flash?

The arc flash is the resulting discharge of energy caused by an arcing fault. An arcing fault is the unintended flow of current through a medium not intended to carry the current. That just means that the electricity is flowing through something it should not be; in most cases that result in injury, the medium was the air. The air becomes like a piece of copper, conducting the electricity; only with the air, you can see the massive discharge of the electrons from the discharging element. This is the arc flash. It is lightning on a smaller, yet still deadly, scale.

What causes an arcing fault? The most common causes of an arcing fault are equipment failure, human error (improper placement of tools or improper use of equipment), or the conduction of electricity due to foreign particles in the air (usually metal shavings).

Wearing personal protective equipment is necessary for reducing injury from electrical arc flash accidents, but it is no substitute for proper safety training, among other best practices in arc safety.

Every day, electrical arc flash accidents injure or kill, but wearing proper personal protective equipment (PPE) minimizes accident frequency and severity. PPE alone, however, is no substitute for thorough safety training, consistently following Lockout/Tagout procedures, keeping electrical equipment well-maintained, and applying engineering controls. Burns are not the only risk. A high-amperage arc produces an explosive pressure wave blast that can cause severe fall-related injuries.

Four-step hazard calculations: First, establish the job’s hazard risk category. Second, determine what clothing and equipment the hazard risk category requires. Third, identify what arc thermal performance value (ATPV) rating is necessary. Finally, select personal protective equipment that meets or exceeds the designated ATPV rating.

Also Read: High-Voltage Electrical Safety

Arc Flash Clothing

Arc flash clothes are critically important to keep workers safe. Because of the violent nature of an arc flash exposure when an employee is injured, the injury is serious—even resulting in death. It’s not uncommon for an injured employee to never regain their past quality of life. Extended medical care is often required, sometimes costing in excess of $1,000,000.

Need for Protective Clothing

What steps can be taken to reduce the risk? NFPA 70E, Standard for Electrical Safety Requirements for Employee Workplaces, sets standards and regulations for workers working around energized equipment. NFPA 70E defines necessary steps to be taken to properly prevent serious injury in the event of an arc flash accident. NFPA 70E interprets that workers within the flash protection boundary (the area where discharged energy is greater than 1.2 cal/cm2) must be qualified and wearing thermally resistant and arc flash protective clothing.

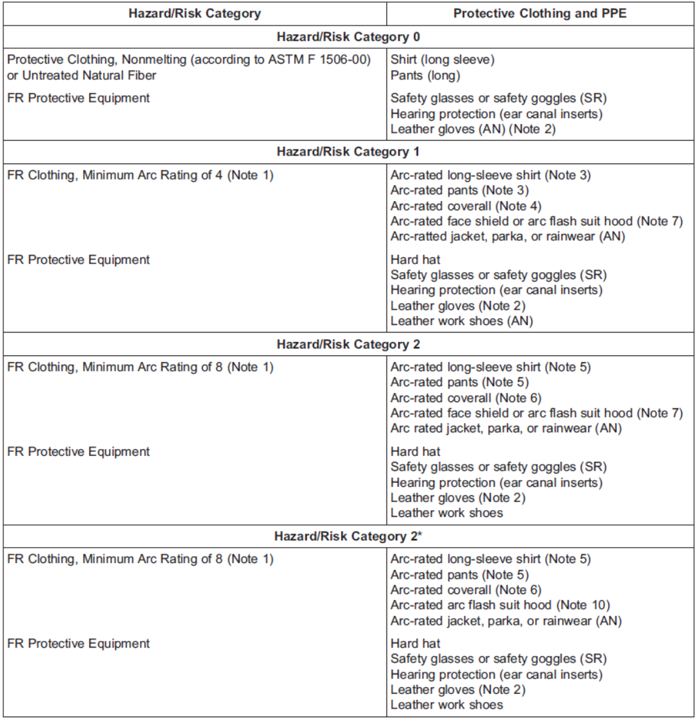

Arc Flash Clothing Selection

Picking the right type of arc flash protective clothing is easy. First, consult NFPA 70E, Table 130.7(C)(9), to determine to which category of risk a particular activity belongs. Second, consult Table 130.7(C)(10) to determine what type of clothing/equipment is required based on the category of risk determined. Third, consult Table 130.7(C)(11) to determine the ATPV (arc thermal performance value) rating needed. Once you have done all this, just go out and find the protective

gear that meets or exceeds this rating.3 One thing to remember when picking protective workwear is to try and ensure that no skin is exposed. Ensure that the pant legs (if not connected to boots) completely go down to the boot. Also ensure that the sleeves of the protective work wear go down to the hand, leaving none of the arm exposed. And lastly, remember that the head is the most vulnerable part of the body. Do not forget to complete the arc flash protective clothing with suitable headgear of the same ATPV rating as the rest of the work-wear plus high-voltage gloves.

Protective Clothing and Personal Protective Equipment (PPE)

Protective Clothing and Personal Protective Equipment (PPE) (continued)

AN = As needed

AR = As required

SR = Selection required

X = Minimum required

Notes:

- See Table 130.7(C)(11). Arc rating for a garment or system of garments is expressed in cal/cm2.

- If rubber-insulating gloves with leather protectors are required by Table 130.7(C)(9), additional leather or arc-rated gloves are not required. The combination of rubber-insulating gloves with leather protectors satisfies the arc flash protection requirement.

- The FR shirt and pants used for Hazard /Risk Category 1 shall have a minimum arc rating of 4.

- The alternative is to use FR coveralls (minimum arc rating of 4) instead of FR shirts and FR pants.

- FR shirt and FR pants used for Hazard/Risk Category 2 shall have a minimum arc rating of 8.

- The alternative is to use FR coveralls (minimum arc rating of 8) instead of FR shirts and FR pants.

- A face shield with a minimum arc rating of 4 for Hazard/Risk Category 1 or a minimum arc rating of 8 for Hazard/Risk Category 2, with wrap-around guarding to protect not only the face, but also the forehead, ears, and neck (or, alternatively, an arc-rated arc flash suit hood), is required.

- An alternate is to use a total FR clothing system and hood, which shall have a minimum arc rating of 25 for Hazard/Risk Category 3.

- The total clothing system consisting of FR shirt and pants and/or FR coveralls and/or flash coat and pants and hood shall have a minimum arc rating of 40 for Hazard/Risk Category 4.

- An Alternate is to use a face shield with a minimum arc rating of 8 and a balaclava (sock hood) with a minimum arc rating of 8 and which covers the face, head, and neck except for the eye and nose areas.

Table 130.7(C)(10) lists the requirements for protective clothing and other protective equipment based on Hazard/Risk Category numbers 0 through 4. This clothing and equipment shall be used when working within the Arc Flash Protection Boundary.

Also read: FR Clothing for Cold Weather

Protective Clothing Characteristics

Note: Arc rating is defined in Article 100 and can be either ATPV or EBT. ATPV is defined in ASTM F 1959, Standard Test Method for Determining the Arc Thermal Performance Value of Materials for Clothing, as the incident energy on a material or a multilayer system of materials that results in a 50% probability that sufficient heat transfer through the tested specimen is predicted to cause the onset of a second-degree skin burn injury based on the Stoll curve, cal/cm2. EBT is defined in ASTM F 1959 as the incident energy on a material or material system that results in a 50% probability of breakopen. Arc rating is reported as either ATPV or EBT, whichever is the lower value.

When nothing can be done about working within a flash protection boundary, proper arc flash protective clothing needs to be worn. Workers need to remember that arc flash accidents do not only occur with equipment at high voltage. The majority of arc flash accidents occur with low (120V) and medium voltage (480V) equipment. Workers who wear the proper arc flash protective clothing will significantly reduce the risk of injury or death should an arc flash accident occur.

also Read:Arc Flash Protection -Safety Moment #3(

Summary (Flash Hazard Analysis)

A complete electrical hazard analysis must also contain a Flash Hazard Analysis. NFPA 70E Article 130.3 requires this analysis to be performed. “A Flash Hazard Analysis shall be done in order to protect personnel from the possibility of being injured by an Arc-Flash. The analysis shall determine the Flash Protection Boundary and the personal protective equipment that people within the Flash Protection Boundary shall use.” NFPA 70E (2009 Edition) lists an exception in Article 130.3 that an arc flash hazard analysis is not required where all of the following conditions exist: (1) The circuit is rated 240 volts or less. (2) The circuit is supplied by one transformer. (3) The transformer supplying the circuit is rated less than 125 kVA).

Appropriate safety-related work practices must be determined before any person is exposed to the electrical hazards involved by using both shock hazard analysis and arc flash hazard analysis independently. Ensure a flash hazard analysis is performed where appropriate and acquire appropriate flash retardant clothing (FRC). Care and laundering of FRC should be performed carefully in accordance with garment instructions. Employers or employees must follow safe work practices. Employees must be adequately trained in electrical safety and first aid/CPR where needed. Lock out all equipment during maintenance and servicing whenever possible.

Also Read: Electrical Risk Assessments(

Also Read: Working with Electricity Electrical Accidents Guide for Electrical Workers

For more safety Resources Please Visit Safetybagresources