Forklifts are very useful but also dangerous machines. The most common causes of forklift fatalities are:

- Crushed by tipped vehicle (42%)

- Crushed between the vehicle and a surface (25%)

- Crushed between two vehicles (11%)

- Struck or run over by forklift (10)

- Struck by falling material (8%)

- Fall from platforms on the forks (4%)

All but the last one can be attributed in one way or another to a lack of situational awareness. Having another set of eyes (a spotter) and making use of proper signaling, then, are great ways to control for these hazards (learn about 4 Common Forklift Accidents and How to Prevent Them).

Since forklift work tends to happen in noisy worksites and warehouses where the operator and the spotter are likely wearing hearing protection, using hand signals is the most reliable and direct method of communication for operators and spotters.

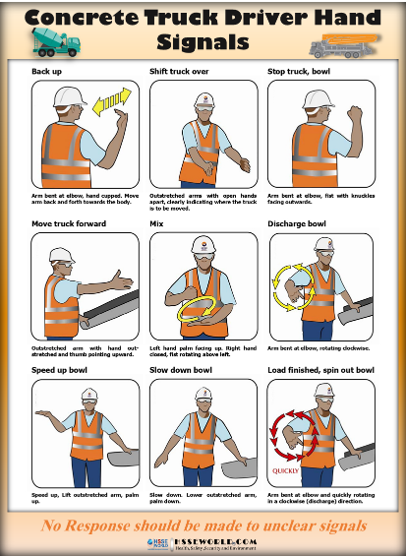

Use Standardized Hand Signals

Spotters need to use a standardized set of hand signals that the operator can easily recognize and interpret. To ensure consistency, both the operator and the spotter should learn and memorize the OSHA-approved signals for directing forklifts. This will not only prevent miscommunication between these employees but will also provide consistency when working in situations involving multiple employers or when hiring new (and trained) employees.

It is good practice to ensure posters or cards demonstrating the hand signals are posted on site. Some companies have these cards stuck on the forklift, in the operator’s line of sight, while others prefer posters placed in the areas where forklifts operate (learn How to choose floor marking tape for your facility/).

Spotters

There should always be an agreement about who is the designated spotter. Only one spotter should attempt to direct the operator and the operator should take direction from that spotter only. The only exception is the STOP signals. The operator should respond to this signal regardless of who is giving it, under the assumption that further action might result in material damage or somebody being hurt.

The spotter should be positioned in such a way that their hand signals are clearly seen by the forklift operator and the operator should confirm that they have seen and understood the signal.

The spotter should always keep their sight on the load and the proximity to structures, not on the operator.

The Seven Basic Forklift Hand Signals

The signals used to direct forklifts are somehow similar to the ones used for directing cranes. These are the seven basic forklift hand signals that are commonly used in work environments around the globe.

Raise the Tines

With the forearm of your right hand vertical to the ground and the forefinger pointing up, move the hand in a small horizontal circle. Continue the circular motion for as long as you want the operator to continue to raise the tines.

Lower the Tines

With the right arm extended out and parallel to the ground, point the palm down and lower the arm repeatedly until the tines are lowered at the appropriate level for directing the next sequence of motions.

Tilt the Mast Back

With the forearm of the right arm vertical to the ground and the thumb extended, jerk the thumb over the right shoulder. Do the motion slowly so the operator can mirror you and stop at the same moment you stop making this signal.

Tilt the Mast Forward

With the right arm extended and the thumb pointing down toward the ground, lower the arm repeatedly, until the mast reaches the desired angle.

Move the Tines in the Direction I’m Pointing

With the left or right arm extended out and parallel to the ground, with the palm down, point the forefinger in the desired direction.

Dog Everything

Clasp the hands in front of the body in front of the navel. The signal is usually given in a risky situation or in response to an unplanned event, like someone entering the work area who could potentially walk in the path of the load or forklift, or the load/pallet not fitting in the location where they were intended to go.

Stop

Extend both arms out from the body so they are parallel to the ground. This signal is usually associated with an immediate hazard and for this reason, the operator should follow this signal no matter who is giving it.

Training and Risk Assessment

Using a spotter and proper signals can help reduce the number and severity of forklift accidents, but these should always be used in conjunction with proper training, equipment operation that falls within the manufacturer’s limitations, and proper work procedures. Forklift operators and their assistants should receive retraining every three years.

Also, regardless of training and how long the operator and spotter have been in the job, knowledge of proper hand signals does not replace the need for a pre-job hazard assessment and a conversation between the two before starting work.

Conclusion

There are approximately 855,900 forklifts in U.S. workplaces, and according to OSHA, there are nearly 100,000 employees who suffer injuries due to forklifts annually. That means that about one out of every ten forklifts will be involved in an accident this year. Do what you can to make sure one of them isn’t yours, starting with the use of proper hand signals.