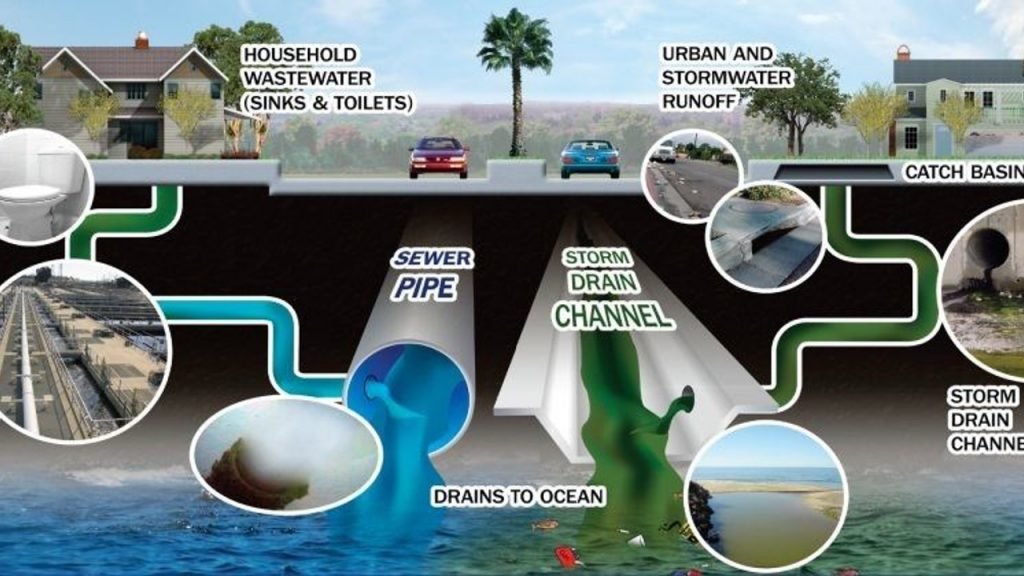

When stormwater flows through parking lots, chemical storage areas, areas of outside industrial activity, waste management areas material loading and unloading operations, and similar areas, it can pick up debris such as chemicals, fertilizers, fecal bacteria, pollutants, and other hazardous materials. This now-contaminated stormwater can then flow untreated directly into nearby bodies of water used for swimming, drinking, recreation, and farming. Pollution spread by contaminated stormwater is a real problem and understanding your organization’s stormwater pollution prevention plan is the purpose of this Article.

Topics include :

- What the National Pollution Discharge Elimination System (NPDES) & Multi-Sector / Industrial General Permits (MSGP / IGP) are.

- How the stormwater pollution prevention team functions.

- What activities should be considered when conducting a site assessment of potential sources of stormwater pollution.

- What are the various methods for minimizing the exposure of pollutants are?

- How facilities respond to spills and leaks effectively.

- How routine facility inspections, visual stormwater assessments, and comprehensive annual site inspections should be conducted to monitor stormwater discharge.

The national pollution discharge elimination system

- In the united states, the environmental protection agency, the EPA, is the controlling authority tasked with reducing stormwater pollution. As part of the federal clean water act, the EPA has developed the national pollution discharge elimination system or NPDES.

- The NPDES requires permits for various types of “point source” discharges into the environment. The EPA’s definition of “point source” discharge includes stormwater discharges associated with industrial activity.

- The EPA’s regulation 40 CFR 122.26 specifically lists 10 categories of industrial activities which fall under the regulations. When facilities in these categories also have a stormwater discharge associated with industrial activity, a stormwater discharge permit will be required.

- What this means is that stormwater pollution is a big deal and is regulated by the environmental protection agency as a matter of law. The EPA regulates stormwater pollution by regulating and controlling the issuance of stormwater discharge permits.

- Chances are, you work for an organization that either has, is renewing, or is applying for a stormwater discharge permit.

- You may think this process doesn’t apply to your specific job function; however, all employees need to understand the overall scope of your organization’s stormwater pollution prevention plan and the role each person plays in its success.

- Stormwater runoff is water from rain or snowmelt that does not immediately infiltrate into the ground and flows over or through natural or manmade storage or conveyance systems.

- These various conveyances from which stormwater is or may be discharged are considered by the EPA to be a “point source” of stormwater discharge. The conveyances for discharge are also called “outfalls.”

- Most states are authorized by the EPA to manage their own stormwater permit systems, which must be equally as stringent as the federal EPA’s regulations. Keep in mind that some of the details of any particular state regulation may be different from those mentioned in this program; however, the general intent will be the same.

The multi-sector general permit & stormwater pollution prevention plan

- There are two types of stormwater permits: an individual permit or a general permit. The general permit is called the multi-sector general permit for industrial activities, sometimes called the MSGP. Some state plans refer to it as the industrial general permit or IGP.

- To obtain coverage under the multi-sector general permit, facilities must submit a “notice of intent” or NOI to the appropriate permitting authority.

- The EPA has established an electronic version of the notice of intent called the E-NOI; however, before a notice of intent can be submitted, your facility must have developed a comprehensive stormwater pollution prevention plan or SWPPP.

- The process of developing a site-specific stormwater pollution prevention plan can be divided into the following four steps: step one: creating a pollution prevention team; step two: conducting a site assessment of potential sources of stormwater pollution; step three: selecting the appropriate pollution control measures for each potential source of stormwater pollution; and step four: developing procedures for conducting the monitoring and inspection activities required by the permit.

The stormwater pollution prevention team

- The pollution prevention team should be “cross-functional” and include members from various departments who are most familiar with the facility’s operations.

- Team members will be assigned responsibilities related to their area of operation. For example, a maintenance supervisor may be tasked with stormwater-related upkeep of buildings and grounds; a material handling supervisor may be asked to ensure proper placement of stored materials; the hazardous waste coordinator may be assigned the duty to routinely inspect all chemical storage areas; while the safety and environmental manager may be given the duty of overseeing the sampling of stormwater runoff for contaminants.

- Your facility’s stormwater pollution prevention plan will specifically name members of the pollution prevention team either by name or job title.

- No matter how big or small the pollution prevention team may be, there must be one person who has overall responsibility for the stormwater pollution prevention plan and is the main point of contact during an inspection.

- The completed plan must be signed by a member of management who has authority for the facility’s operation and can certify the plan meets all the requirements of the permit.

Conducting a site assessment of potential sources of stormwater pollution

- Once the stormwater pollution prevention team is assembled, the next step is conducting a site assessment of potential sources of stormwater pollution.

- Be sure to consider the following common activities identified by the EPA as major sources of industrial stormwater pollution.

- Loading and unloading operations: there are a wide variety of ways materials may be loaded, unloaded, and moved about a facility. Material spills or leaks during these operations may accumulate and be washed away during a storm event.

- Outdoor storage: many facilities’ operations require the outdoor storage of materials. These storage areas, when exposed to rainfall or runoff, can become a source of stormwater pollution if precautions aren’t taken.

- Outdoor process activities: when industrial activity occurs outdoors, the various liquid spills and dispersement of material solids associated with the processing activity can also be a source of pollutants exposed to stormwater.

- Dust and particulate generating processes: this includes industrial activities with stack emissions or processes which generate dust. These particulates can settle on exposed surfaces and be exposed to rain or runoff, allowing pollutants to enter the stormwater runoff.

- Waste management: all facilities are involved in some type of waste management. Trash, recyclables, hazardous waste, discarded equipment, and other waste streams must be properly controlled to prevent pollution discharge into stormwater.

- non-stormwater discharge: non-stormwater discharge is any discharge from your facility that is not entirely composed of runoff from rain or snowmelt. With few exceptions, non-stormwater discharges are prohibited and must be eliminated or permitted separately under a different NPDES discharge permit.

- Inspection for non-stormwater runoff should be conducted in dry weather.

- In addition to creating a detailed list of the site-specific industrial activities which are exposed to stormwater, a detailed material inventory is another essential element of the stormwater pollution prevention plan that should be compiled during the initial site assessment.

- This material inventory should include the various types of materials stored, handled, or processed at the facility as well as their purpose and proper storage location.

- Included in this material inventory will be the amount of these materials which have been exposed to stormwater during the past three years. This is important to help identify areas of high pollution potential so control measures can be designed to reduce exposure.

- For example, the assessment may find that in the past, pallets contaminated with oils and grease may have been stored outside and exposed to rainfall. To correct this problem, the new stormwater prevention plan may now require inspecting all used pallets for visual contaminants and ensuring dirty pallets are stored in a covered area.

- This type of change is referred to as a “corrective action.” Documenting the corrective actions taken to prevent stormwater pollution is an important part of the plan.

- Finally, the site assessment should include a listing of any spills or leaks of toxic or hazardous materials which were in excess of reportable quantities during the past three years.

The detailed site map

- After the site assessment is completed, the items found which will impact stormwater discharge should be included on a detailed site map.

- This detailed site map is a critical part of the stormwater pollution prevention plan and should include the locations of all points of stormwater discharge, sometimes called “outfalls,” the surface runoff pattern and direction, and the location of structural control measures such as storm drains, ditches, gates, vegetative buffers, swales and holding ponds.

- Also included on the site map should be the location of the material storage areas and locations of industrial activity identified in the site assessment as having a potential impact on stormwater runoff.

Structural & non-structural control measures

- Once the pollution prevention team is in place and the potential sources of stormwater pollution have been identified, the next step is to develop and implement the control measures which will be used to reduce or prevent the discharge of pollutants into stormwater runoff.

- Some types of control measures are “structural” in nature. For example, vegetative swales, collection and re-use devices, wet retention areas, gates, dykes and sluices, and other structures designed to control discharges.

- Other types of control measures are “non-structural” in nature. These measures often called “best management practices” include practices and procedures which reduce or eliminate the exposure of pollutants to stormwater.

- One such principle is recognizing that the best way to control stormwater pollution is to prevent the runoff from becoming polluted in the first place. This is commonly referred to as “minimizing exposure.”

Minimizing exposure

- One method of minimizing exposure includes relocating industrial activities and material handling operations to be under covered areas or to areas where any runoff is contained and controlled.

- Ensuring employees understand that certain activities and materials must be located in designated areas is an important part of the best management practices necessary to minimize exposure.

- For example, material handlers must be trained to understand which materials may be placed outside for storage and which may not.

- Improperly stored materials and equipment are a major source of polluted stormwater runoff. For example, a common pollution prevention control measure is to clean and thoroughly drain any obsolete equipment or vehicles of oils and other contaminants before storing them outdoors.

Good housekeeping & maintenance programs

- Minimizing the exposure of pollutants to stormwater also depends on good housekeeping, especially in the following areas: dumpsters and waste containers, outdoor material storage areas, vehicle, and equipment maintenance areas, and loading docks and material handling areas.

- Another important control measure to minimize exposure is to implement a good maintenance program.

- A maintenance program designed to reduce stormwater pollution will not only be designed to keep all structural control measures in proper operating condition but will also keep industrial equipment, machines, and vehicles in proper good condition. Good condition includes minimizing or preventing equipment and vehicles from leaking oil and other pollutants.

- The maintenance program should be outlined in the stormwater pollution prevention plan and will include regular inspections, testing, preventive maintenance, and repairs.

- Remember, the best way to minimize polluted stormwater is to prevent pollutants from being exposed to stormwater in the first place.

( Download: Workplace-housekeeping-checklist/)

Spill & leak response

- The control methods we have discussed so far are designed to help minimize exposure; however, in the event that a spill or leak does occur, your facility’s stormwater pollution prevention plan must include procedures to ensure an effective response.

- Employees should be trained on how to respond and whom they should contact in the event of a leak or spill.

- Spill kits should be maintained near areas where spills or leaks are likely to occur.

- Designated employees should be trained in the proper use of the spill response kit and procedures must be developed to stop, contain and clean up leaks and spills.

- Promptly deploying a spill response kit can limit the spread of a spill by blocking access to storm drains and other discharge routes, preventing the pollutant from entering the receiving waters downstream.

- Any employee who notices potential stormwater problems such as clogged storm drains, improperly stored materials, indications of leaks or spills, non-stormwater discharges, poor housekeeping, or other potential problems should report them right away to their supervisor or a member of the stormwater pollution prevention team.

( learn more: Prevention-tips-to-reduce-the-incidence-of-chemical-spills/)

Routine facility inspections

- The stormwater pollution prevention plan will also include procedures for inspecting the site and monitoring the stormwater discharge. Inspecting and monitoring procedures are critically important in determining whether the pollution control methods are working as intended.

- The industrial general permit typically requires three types of inspections: routine facility inspections, visual stormwater assessments, and comprehensive annual site inspections.

- A routine facility inspection of all industrial materials and activities exposed to stormwater should be conducted at least quarterly by a qualified member of the pollution prevention team or a qualified contractor accompanied by a member of the team.

- The stormwater pollution prevention plan should include an inspection plan and checklist to ensure all areas are inspected consistently.

- Inspect all areas visited for good housekeeping and proper preventive maintenance operations.

- Walk the perimeter of your facility and look for any evidence of polluted stormwater discharge such as stains from chemicals, oil or grease. Be sure to observe each outfall where stormwater leaves the facility.

- Some visual indications of poor stormwater control measures include a rainbow-colored sheen on the surface of stormwater, which indicates the presence of oil or similar pollutants; dark-colored streaks inflowing stormwater, which can indicate soil erosion; foam on top of standing or running water, which can indicate a potential chemical pollutant; and, evidence of trash and other debris being carried off-site, which indicates poor housekeeping practices.

- Be sure to record and document your routine facility inspections.

Visual assessments

- The second type of inspection required by the permit is a visual assessment of the stormwater discharge. The visual assessment is conducted on stormwater samples taken during a storm event.

- If possible, the sample should be collected during the first 30 minutes of the actual discharge. If this is not possible, the reason must be documented as part of the written report.

- The sample should be collected in a clean, clear jar and examined in a well-lit area.

- Collect samples from stormwater discharges that occur at least 72 hours from the previous discharge event.

- A sample should be taken from each stormwater discharge associated with industrial activity.

- If the sample appears tainted or otherwise objectionable, the tester should backtrack upstream and attempt to identify the source of potential pollutants.

- The visual assessment should be conducted by a qualified member of the stormwater pollution prevention team or a qualified contractor accompanied by a member of the team.

- The sample should be assessed for the following water quality characteristics: color, odor, clarity, floating solids, settled solids, suspended solids, foam, oil sheen, and any other obvious indicators or pollution.

- The results of the visual assessment must be documented in a written report. A blank copy of the visual assessment report should be included in the stormwater pollution prevention plan.

Annual comprehensive site inspections

- The third type of required inspection is the annual comprehensive site inspection. This annual inspection evaluates the condition of all control measures and takes into account any trends observed in the routine inspections and visual assessments conducted during the year.

- This inspection must be conducted by at least one member of the stormwater pollution prevention team.

- The procedures for conducting the annual inspection, any standard forms used, the documents which will be inspected, the person responsible for the inspection, and the schedule for conducting the inspection should all be included in your facility’s stormwater pollution prevention plan.

- Also, any methods and procedures used to carry out any required sector-specific benchmark or discharge monitoring must be described and documented in the stormwater pollution prevention plan.

- Once the facility’s plan is put into action, the various inspections, assessments, monitoring, and corrective actions taken will generate documents and records. Be sure to maintain this documentation on site along with a copy of the written plan. Upon inspection, these documents will help demonstrate full compliance with your facility’s multi-sector general permit.