Forklifts are essential pieces of equipment in various industries, including warehousing, construction, and manufacturing. However, their operation requires the utmost caution to prevent accidents and ensure the safety of operators and those working in the vicinity. In this blog post, we will delve into the importance of forklift safety while using a forklift and provide comprehensive guidelines for operators. By following these safety measures, you can significantly reduce the risk of accidents and create a secure working environment.

Read: Close calls and Near-Miss Incidents

Understanding the Risks

Before we dive into the safety guidelines, it is crucial to understand the potential risks associated with forklift operation. Some common risks include:

- Collisions with pedestrians or other vehicles

- Overturning due to unstable loads or excessive speed

- Falling objects from improperly secured loads

- Exposure to hazardous materials

- Accidents caused by inadequate training or lack of awareness

Safety Guidelines for Forklift Operators

1. Training and Certification:

An untrained forklift operator can be as dangerous as an unlicensed driver of a motor vehicle. Before operating a forklift, it is crucial to undergo proper training and obtain the necessary certification. This training should cover the safe operation of the forklift, understanding load capacities, and recognizing potential hazards. Regular refresher courses are also essential to stay updated with best practices.

The topics listed below must be covered when training a forklift operator. However, if a specific topic does not apply to the forklift in the employer’s workplace, covering it is optional.

Topics related to forklifts

- Operating instructions

- Warnings and precautions for the types of forklift the operator will be authorized to operate Differences between a forklift and an automobile

- Controls and instrumentation: Where they are located, what they do and how they work

- Engine or motor operation

- Steering and maneuvering

- Visibility (including restrictions due to loading)

- Fork and attachment adaptation, operation, and use limitations

- Forklift capacity

- Forklift stability

- Any inspection and maintenance that the operator will be required to perform

- Charging and recharging of batteries

- Operating limitations

- Any other operating instructions, warnings, or precautions listed in the operator’s manual for the types of forklift that the employee is being trained to operate

Topics related to your workplace

- Surface conditions where the forklift will be operated

- Composition of loads to be carried and load stability

- Load manipulation, stacking and un-stacking

- Pedestrian traffic in areas where the forklift will be operated

- Narrow aisles and other restricted places where the forklift will be operated

- Use of door opening and closing devices

- Hazardous (classified) locations where the forklift will be operated

- Ramps and other sloped surfaces that could affect the forklift’s stability

- Closed environments and other areas where insufficient ventilation or poor maintenance could cause a buildup of carbon monoxide or diesel exhaust

- Other unique or potentially hazardous environmental conditions in the workplace that could affect safe operation

Qualified Trainers

The employer or any other person the employer chooses who has the knowledge, training, and experience to train and evaluate forklift operators can do this training and evaluation. The trainee can operate the forklift only when directly supervised by such a person and when this would not endanger anyone.

Documenting Training

If the operator had previous forklift training, the employer must document that the training covered the required topics described above. The operator must have been evaluated in the current workplace within the last three years.

Training and Evaluation Records

The employer must keep a record that shows that each forklift operator has been trained. The record must include the name of the operator, the date of training, the date of evaluation, and the name of the person(s) giving the training and evaluation. Refresher training must be given if the operator has been involved in an accident, a near miss, or unsafe operations. Also, if an operator is assigned to a new type of forklift or if workplace conditions change and an evaluation shows they are not operating it safely, then refresher training is required.

2. Pre-Operational Checks:

Before using a forklift, conduct a thorough inspection to ensure it is in good working condition. Check the brakes, steering, tires, lights, and any other relevant parts. Report any defects or malfunctions to the appropriate personnel, and refrain from using the forklift until it is repaired.

Pre-use Inspection Checklist

The forklift must be checked for defects. daily, usually by the operator or a designated person before the beginning and after a shift. Even if you operate a forklift safely, a defect can cause or contribute to a serious accident. you can use Pre-Use Inspection and Daily checklist

3. Load Capacity:

Always adhere to the forklift’s load capacity limits. Overloading can lead to instability and increase the risk of accidents. Consult the forklift’s manual or load capacity chart to determine the maximum weight it can safely handle.

4. Proper loading and unloading:

When loading or unloading materials, ensure that the load is evenly distributed and properly secured. Use appropriate attachments, such as pallets or clamps, to secure the load. Make sure the forklift’s forks are inserted fully under the load and tilted slightly back for stability.

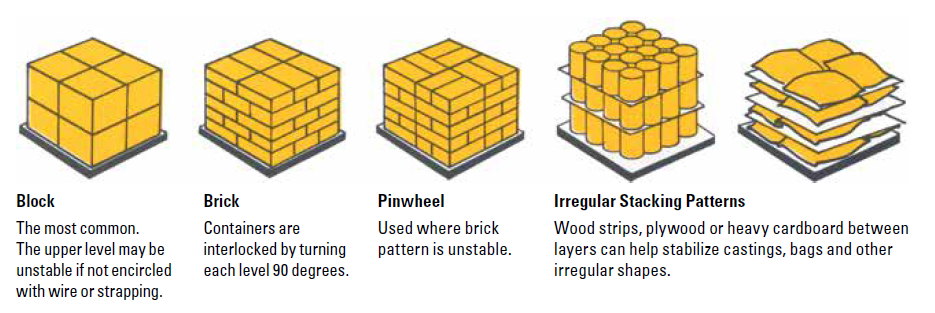

Check the load before you pick it up.

- Is it stable, or will parts slide or fall during transit? Secure it as necessary. The illustrations below show some common pallet-stacking patterns. ( Refer to Forklift Stability Triangle )

- Do the dimensions and weight of the load fall within the capacity rating of the forklift at the highest elevation and extension at which you will handle the load? If not, can you break the load into smaller parts?

When you pick up the load:

- Move squarely into position in front of the load.

- Position the forks wide apart to keep the load balanced.

- Drive the forks fully under the load.

- Tilt the mast backward slightly to stabilize the load and lift.

Check the destination before you place the load.

- Is the destination flat and stable, or will the load rock, tilt, or lean?

- Never place heavy loads on top of light loads.

- Observe maximum stacking quantities and orientation if printed on cartons.

- Do you know the load-bearing capacity of your rack or storage loft destination?

- Are rack legs or support members bent or disconnected? The load-bearing capacity of a damaged rack is unknown! Wait until the damaged component has been replaced before loading.

- Are racks arranged back to back with a stock behind where you will place the load? Someone may need to be in the next aisle to control access while you place the load.

- Are the wooden stringers or decking laid between the front and rear rack beams in good condition?

- If you are stacking, are other pallets in the stack in good condition and capable of supporting the load in addition to what they are already supporting?

- Are racks secured to the floor or other adjacent structures?

When you place the load at its destination:

- Move squarely into position in front of the rack or stack where the load will be placed.

- When ready to place the load, tilt the mast to level. Only tilt forward when the load is over the spot where it will be placed.

- Lower the forks and back away.

- Visually verify that the load is stable.

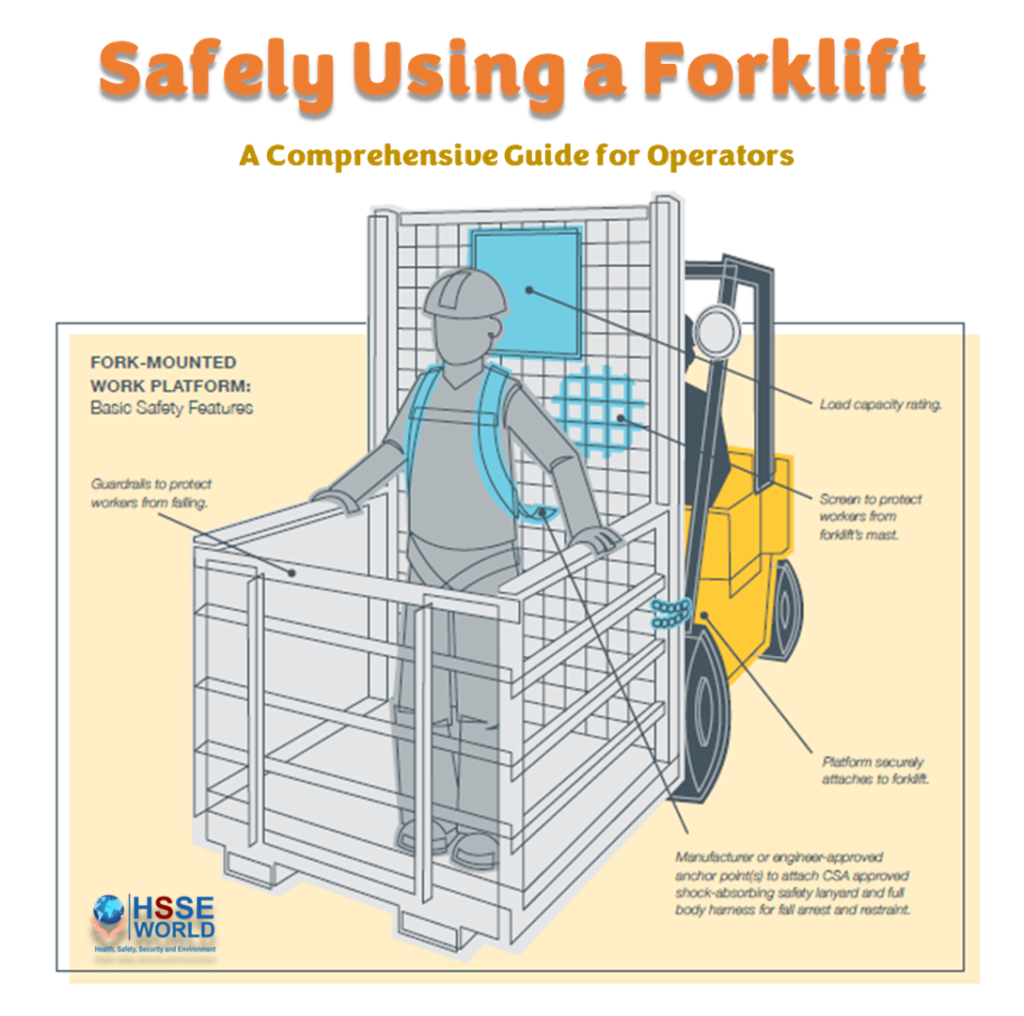

Lifting and Lowering People

Never allow anyone to be lifted while standing on the forks or on a pallet lifted by the forks! If you want to use a forklift to raise an employee to an elevated position, use a platform or structure specifically built for this purpose that meets these conditions:

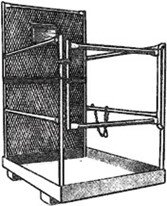

The platform must be approved by the manufacturer and have standard guardrails, which include a top rail 39 to 45 inches above the midrail and toeboard. It must also prevent contact with chains and shear points on the mast. See the illustration below for an example.

- The platform must be securely attached to the forks, such as by a clamp or chain.

- Must have a nameplate and label attached to the forklift.

- Check with the forklift manufacturer to verify that the hydraulic system will not allow the lift mechanism to drop faster than 135 feet per minute in the event of a system failure. Identify the forklift as approved for use with the platform.

- Lock or secure the tilt control to prevent the boom from tilting.

- A forklift operator must be in the normal operating position when lifting and lowering the platform. The operator must be within 25 feet of the forklift while a worker is elevated.

- Do not move the forklift between two points when a worker is on the platform.

5. Speed and maneuvering:

Always operate the forklift at a safe speed, considering the load, terrain, and visibility. Avoid sudden stops or starts, and use caution when turning or operating on inclines. Slow down when approaching corners, intersections, or congested areas. ( Read more: 4 Major Forklift Accidents and Prevention )

6. Pedestrian Safety:

Be aware of pedestrians and other vehicles in the vicinity. Use horns or audible signals when necessary, and maintain a safe distance from people or objects. Always look in the direction of travel and use mirrors to check for blind spots. ( Also Read: Pedestrian safety in the industry )

7. Hazardous Materials:

If handling hazardous materials, ensure that you are trained in the proper procedures and use the necessary personal protective equipment (PPE). Follow all relevant safety protocols and dispose of hazardous materials in accordance with regulations.

Also Read: Hazardous Chemical Storage

8. Maintenance and Inspections:

Regularly maintain and inspect the forklift to ensure it remains in good working condition. Follow the manufacturer’s guidelines for maintenance and conduct routine inspections for any signs of wear or damage. Report any issues promptly, and refrain from using the forklift until it is repaired.

Safety in the Maintenance Area

To prevent injury or illness when doing maintenance on a forklift:

- Do not do repairs in an area with a potentially flammable or combustible atmosphere (Class I, II, or III).

- Make sure there is adequate ventilation to prevent the accumulation of exhaust or gas fumes.

- Do not use flammable solvents to clean a forklift. Use a non-combustible (flash point above 100 °F) solvent.

- Never get under a forklift supported only by a jack or under any part supported only by hydraulic pressure! Install jack stands or secure block support.

- To prevent the forklift from accidentally being started, remove and keep control of the key or disconnect the battery while making repairs. If the electrical system will be serviced, you must disconnect the battery before starting repairs.

Conclusion

Operating a forklift safely is crucial to preventing accidents and maintaining a secure working environment. By following the guidelines outlined in this comprehensive guide, forklift operators can significantly reduce the risk of accidents and ensure the safety of themselves and others. Remember, safety should always be the top priority when operating a forklift.

Read and download many resources at Safetybagresources.com