Worksite traffic can be a major cause of harm to workers and other people at work sites. A well-planned and designed worksite can reduce the risks to people working near worksite traffic.

This article provides examples of ways you can control worksite traffic risks from a site design or layout perspective. This may be particularly useful when planning or setting up a new worksite, but many control measures can also be added to existing work sites as well (such as adding barriers and signage).

As a PCBU, you will need to assess your individual situation to decide what control measures will be the most effective, and reasonably practicable for your situation. This may mean adopting a combination of control measures to manage the risk.

When planning a new worksite, consideration also needs to be given to any resource consent or building consent requirements, including any traffic management requirements.

The main aim of any worksite design should be the separation of vehicles and pedestrians as much as possible.

The most effective way of making sure pedestrians and vehicles can move safely around a worksite is to provide separate pedestrian and vehicle traffic routes. You could eliminate just about all interaction by using overhead walkways (see Figure 1).

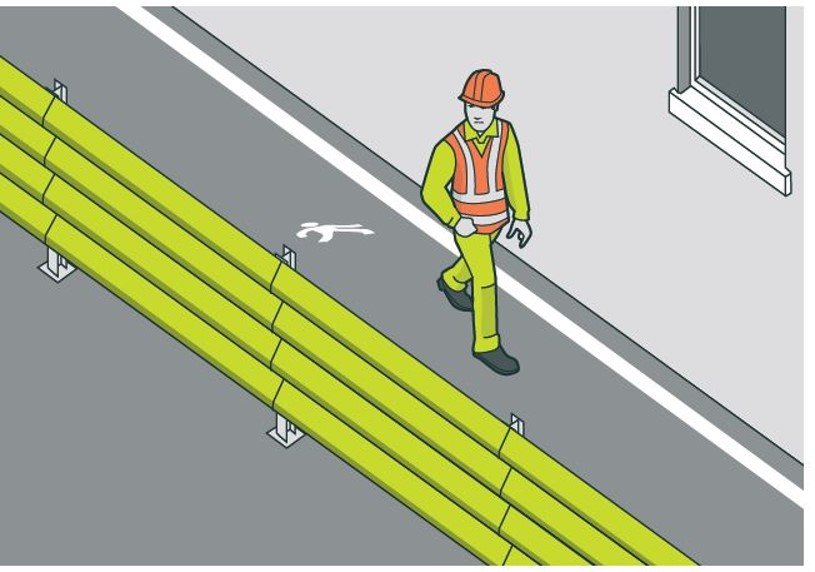

For static work sites, barriers and guard rails should be suitable for what they are providing protection from. High impact barriers could be used to stop vehicles from entering pedestrian walkways. Low impact barriers could be used to keep pedestrians within pedestrian routes.

When planning pedestrian routes, create paths pedestrians would naturally follow so they will be more likely to stay on the path and not take shortcuts.

If possible, schedule works so vehicles and pedestrians are not in the same area at the same time. For example, only accepting deliveries during certain hours, when there are no pedestrians about.

Have designated pedestrian crossings

Where pedestrian and vehicle traffic routes cross, there should be clear ground markings, lights, and signs to show that it is a crossing area. Typically vehicles will have the right of way unless the pedestrian is already on the crossing when a vehicle approaches.

Pedestrians should not cross unless all vehicles are well clear of the crossing, or the vehicle has stopped and the pedestrian and driver have positively acknowledged each other’s presence and made confirmed eye contact.

Any vehicle that has stopped at a pedestrian crossing should wait until the pedestrian is well clear of the crossing before moving again.

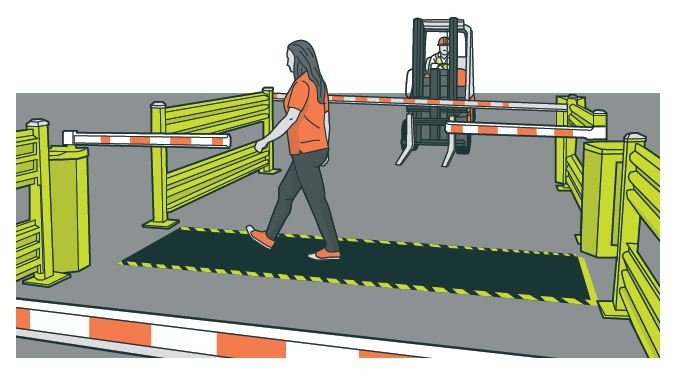

Consider control measures to stop pedestrians from accidentally stepping out into traffic areas without stopping and checking first (see Figure 8).

For example:

- install interlocked gates in front of crossing areas

- install gates that open towards the pedestrian

- install gates with warning devices

- use a traffic light system or have a competent worker direct traffic.

These methods create a stop or pause in the pedestrian’s movement before entering a vehicle area.

Alternatively, you could have pedestrian crossings where vehicles must stop behind barriers that lower when a pedestrian is crossing the vehicle route (see Figure 9).

Pedestrians and vehicles should have good visibility. Do not store goods near crossing areas in a way that could block people’s view.

Check there are no-slip or trip hazards, especially near pedestrian crossing areas.

Plan vehicle routes

Ideally, worksites should have a one-way system with separate entry and exit points. This removes the need for vehicles to reverse.

Where it is not possible to have a one-way system, traffic lanes should be

clearly-marked:

- make allowances for stopping distances

- traffic lanes should be wide enough for stationary vehicles to be passed safely and overhead clearance high enough for the largest vehicle that may use them

- create designated turning areas that are wide enough for vehicles to reverse/ turn without entering pedestrian or loading/unloading areas. See Section 5.2 Reversing vehicles

Keep vehicle routes clear of known hazard areas

Avoid putting vehicle routes and parking areas near designated hazardous substance storage areas. For more information on hazardous substances, see our hazardous substances section.

If vehicle routes come close to building columns, pipework, storage racking, or cables, install barriers to protect them from vehicle impacts.

Avoid vehicle routes that cross public parking and pedestrian areas

Where relevant, worksite traffic should have separate entry and exit points from the general public. When planning or setting up new work sites, avoid creating vehicle routes that require delivery vehicles to travel through public car parks to access loading/unloading bays.

Where historical layouts require drivers to navigate public car parks or park on public roads to unload, the additional risks this creates should be clearly addressed in a worksite traffic management plan.

Control measures may include:

- only accepting smaller delivery vehicles at that worksite

- staggering delivery times so only one vehicle is present at a time

- setting delivery hours outside of shop hours

- using a spotter to help guide the driver.

Temporary traffic routes

Dynamic work sites, for example, construction and forestry sites, often have routes for vehicles and pedestrians that change as work progresses. Where possible, these routes should follow the same basic standards as the static traffic routes listed above. Temporary physical barriers can be used to keep people out of exclusion zones (see Figure 4). Road cones or roadside edge markers could be used to indicate traffic routes.

Reviewing control measures is especially important for dynamic work sites where the risks may change often.

Maintain road surfaces

Driving surfaces should be firm, even, and flat. When planning or building new

traffic routes:

- make sure driving surfaces are able to drain well so that water cannot build-up

- avoid steep slopes and sharp bends (these can affect vehicle stability and increase the risk of rollovers)

- consider any seasonal effects on the road surface:

- temporary roads or general traffic operating areas need to have good drainage to avoid becoming muddy in wetter months

- consider if dust suppression may be required in drier months to maintain visibility for vehicles and limit dust exposure for workers.

Driving surfaces should be properly maintained and kept clear of debris. Potholes should be repaired immediately. Any line-markings should be maintained so they remain bright and clear.

Have dedicated parking areas

Parking for workers, visitors, trucks, and other vehicles should be located away from busy work areas and traffic routes.

Walkways leading to and from parking areas should be separated from vehicles and vehicle routes. Avoid layouts where workers and visitors have to walk= through worksite traffic to get to and from the car park. Use physical control measures like barriers or bollards to stop vehicles from crossing into walking areas (see Figure 10).

Provide good visibility and lighting

Worksites should be designed so drivers and pedestrians can always see each other clearly:

- avoid creating sharp bends or tight corners that could create blind spots

- make sure pedestrian crossings are clearly visible to drivers

- make sure there are no obstructions to visibility near the pedestrian crossing area

- keep all areas well lit – especially walkways, vehicle routes, maneuvering areas, truck lay down areas, junctions, and buildings

- consider the use of mirrors where blind corners cannot be avoided

- make sure that any doors opening into traffic areas have vision panels (fire-rated glass can be used in fire doors).

Install clear signage

For general worksite signage:

- Signs should be well-positioned, well lit, clean, and clear, and easy to read for pedestrians and drivers.

- Keep signage simple and uncomplicated. If more detail is required, include this in worksite induction documents.

- Signs for drivers and pedestrians should be the same as those used on public roads, wherever a suitable sign exists. Otherwise, use industry-accepted signs and colors (see Figure 11), for example:

- red for danger or prohibited activities

- yellow or amber for warnings or caution required

- blue for mandatory requirements

- green for emergency escapes, exits, and facilities

Examples of signs you should have at a worksite include:

- worksite traffic rules and all other key health and safety requirements for that worksite (at all points of entry to the worksite)

- signs to show exclusion and safety zones

- parking areas

- speed limits

- vehicle crossings

- hazards like blind corners, steep gradients, sharp turns, and where forklifts are in use

- signs stating if the worksite is using left-hand or right-hand bi-directional traffic management.

Clearly identify traffic and activity zones

Areas designated for certain activities should be clearly marked using signs, color-coded road or floor markings, and barriers. For example, loading/ unloading areas, pedestrian areas, and forklift operating areas.

Road/floor markings should be regularly maintained to remain clearly visible. Consider using reflective paint, particularly for outdoor environments.

Use temporary barriers and signs for dynamic work sites or work sites with unsealed surfaces where ground marking is not suitable.

Keep markings consistent

Color-coded zones should be consistent with industry guidelines so that the same colors mean the same type of work zone across different sites and businesses. This will help drivers who visit many sites in a day to more easily know the different areas at each site they visit.

( Learn more about construction-site-traffic-management-plan-cstmp-guidance/)