Wood is used to create products from fine furniture to the home that you live in. While many people may admire the workmanship in these items, how many of us take the time to consider the hazards a worker undergoes to build these products? Wood is a complex biological and chemical material, which creates a variety of hazards when used to build a product. One hazardous byproduct created when using wooden building materials is wood dust.

In This article, you will have a Quick Guide to controlling the wood dust hazards at work and you will be familiar with:

- Types of wood products

- How can wood dust harm you?

- Chemical exposure from wood products

- Who is at risk?

- Workplace exposure standards for wood products

- Control measures

Also Read:

Types of wood products

Wood products may be considered in three categories:

- softwoods like pine and cedar;

- hardwoods like oak, teak, and jarrah; and

- engineered wood products such as particle board (‘chip’ board), medium-density fibreboard (MDF), and laminated veneered lumber (LVL).

How can wood dust harm you?

Studies have linked wood dust in workplaces to asthma, bronchitis, lung, sinus, and throat irritation, shortness of breath, and skin problems. The International Agency for Research on Cancer (IARC), after researching nasal cancer among woodworkers in Europe, has classified wood dust as a human carcinogen.

Wood dust from timbers such as beech and oak which is fine enough to be inhaled is known to cause cancer. Other species such as birch, mahogany, teak, and walnut may also be capable of causing nasal cancer. As this is a rare form of cancer, the risk is small and generally restricted to the finishing trades where the dust is fine.

Freshly cut trees contain large amounts of microbes, mainly moulds. The number of these increases if the logs are stored outside and under moist or humid conditions. The microbes can cause inflammation of the airways during debarking, sawing, and transport.

While there has been considerable research carried out on European and North American species, relatively little is known about the way dust from different Australian, African, South American, or Asian timbers affects people’s health. Each type of timber has its own chemical components and may affect people differently.

Wood dust is combustible, and build-up around the workplace can increase the risk of fire or a dust explosion.

( Also Read: Combustible dust awareness )

Chemical exposure from wood products

Engineered wood products such as plywood, fiberboards, particle boards, and laminated products contain formaldehyde, which can cause irritation of the respiratory system and eyes, a sore throat, and a runny nose.

Formaldehyde is classified as carcinogenic to humans, however, this health effect has been noted in circumstances of high exposure (such as occupational use of concentrated formaldehyde solution).

Small amounts of formaldehyde may be given off during the cutting or machining of engineered wood products, but this is seldom high enough to cause a problem. Higher levels may accumulate if products are stored in plastic or in unventilated enclosed spaces, or may be found when handling products not manufactured to meet Australian Standards for formaldehyde emission.

Many wood products have been coated with varnishes, lacquers, polishes, and other chemicals. These may cause harm to health under some circumstances, and need to be considered when working with wood.

Also Read: Formaldehyde Exposure

Dust from second-hand timbers may contain toxic paints, preservatives, or lead.

There are also many chemicals used for sealing, coating, and polishing timber that may pose a hazard to workers during their application. Refer to the material safety data sheet (MSDS) for safety information for these chemicals.

Who is at risk?

People exposed to wood dust at work are at greater risk of developing nose, sinus, throat, lung, and skin conditions.

Health problems may take a long time to develop and are most common in people who have spent many years at workplaces exposed to high concentrations of wood dust (for example, indoor workplaces with inadequate dust extraction systems).

Dust from hardwoods is usually finer and therefore more easily inhaled.

Hazardous amounts of wood dust may be generated by jobs like floor sanding, furniture sanding, wood turning, routing, sawing, sweeping, and emptying dust filters.

Dust hazards exist in varying degrees from timber felling in the forest to furniture manufacturing and cabinet making in factories and workshops.

The main hazards occur where there is poor natural or mechanical ventilation.

Workplace exposure standards for wood products

Workplace exposure standards (WES) are levels of contaminants in the air that must not be exceeded. They are set at a level that is expected to prevent health effects from occurring in most workers.

The workplace exposure standard for airborne inhalable wood dust is 1 mg/m3 for hardwoods and 5 mg/m3 for softwoods.

The standard for MDF is also 1 mg/m3 because it can contain hardwood.

The average inhalable wood dust in the breathing zone of the worker must not exceed the WES over an eight-hour working shift.

Formaldehyde exposure must be below the WES of 1 ppm when averaged over an eight-hour day. Short-term exposures should not exceed 2 ppm.

Control measures

The preferred and most effective order of control measures is:

1. Elimination

This is possible only if the wood is not machined, sawn, or sanded, or if all work that produces wood dust is outsourced to another workplace with adequate controls.

2. Substitution

Replacing more hazardous timbers with less hazardous species may be possible if reliable data on health risks is available. For most species, however, there is little data available.

Products with lower formaldehyde emissions may be substituted for products with higher formaldehyde emissions.

3. Isolation

Enclose plant or keep workers away from dusty areas.

4. Engineering

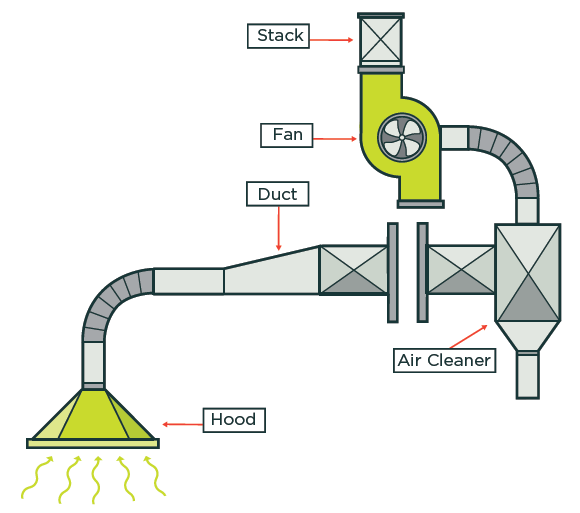

Ventilation

The best way of reducing wood dust at a workplace is by using machines that are enclosed or fitted with effective local exhaust ventilation (LEV). LEV involves locating an extraction outlet as close as possible to each identified source of dust and having sufficient air velocity to draw dust away before it becomes airborne. When buying new equipment, choose equipment with integrated dust extraction systems

On some machines with a single cutting, grinding, or sanding face, there may be several sources of dust either thrown, drawn, or blown from different parts of the machine.

Ideally, each dust source should be controlled by the LEV system.

While most wood dust is from machines, hand sanding fine furniture can be one of the dustiest jobs at the workplace. Hand sanding generally requires the use of respiratory protection.

Formaldehyde risks can be reduced by choosing engineered timber products that have been tested to confirm they comply with the relevant Australian Standards, and by using machines with appropriate LEV.

LEV systems consist of a hood to capture the dust, duct work to convey the dust, and a mechanism such as a filter or a cyclone to remove the dust. Energy to move the air and dust through the system is provided by a fan that is driven by an electric motor.

Each of these components is important and needs to be matched to the job. Specialized knowledge is needed to design an effective LEV system.

Most modern woodworking power tools and machines are fitted with one or more local exhaust ventilation hoods or outlets to capture dust.

Small portable machines such as sanders usually have a filter bag attached. These filters generally do not reduce fine dust exposure sufficiently. Larger machines are connected by a duct to a fixed or portable dust collection unit. The filters on these units are more effective. However in either case respiratory protection may need to be worn if workplace exposure standards are likely to be exceeded.

While most modern woodworking machines are designed with dust control in mind, the effectiveness of the systems available can vary considerably. Dust control should be considered when purchasing new machinery.

Detailed guidance on the design of ventilation systems Read Introduction to industrial ventilation.

Maintenance of LEV systems is as important as good design. The performance of LEV systems needs to be monitored and the system maintained in accordance with the manufacturer’s specifications.

Room exhaust ventilation, or natural ventilation such as an open roller door, is usually inadequate in controlling occupational wood dust hazards.

What about older equipment?

Exhaust ventilation attachments and improvements have also been developed that can be fitted to some earlier machines, for example, table saws, band saws, belt sanders, and orbital sanders.

Machines and power tools that are difficult to fit with local exhaust ventilation may need to be replaced.

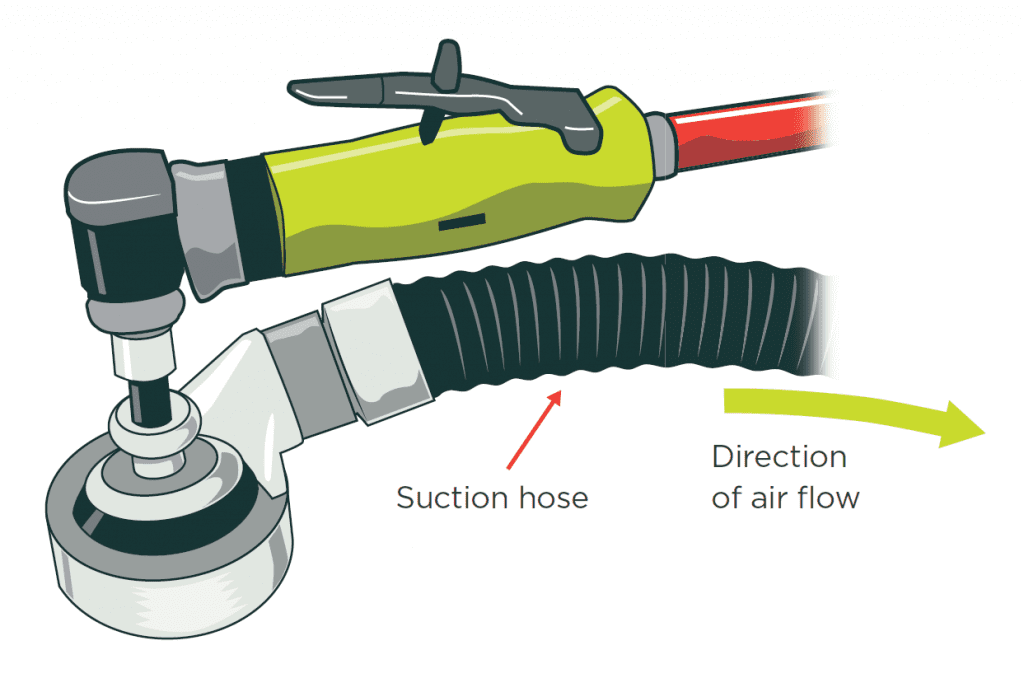

Use on-tool extraction on saws and grinders to control wood dust at the source.

5. Administrative controls

Some examples:

- Use vacuum cleaners – rather than compressed air – to remove accumulated dust from ledges, corners, pits, and floors.

- Empty filter bags outdoors, away from work areas, and where the dust will not blow back into the workplace.

- Rotate dusty tasks to reduce workers’ exposure times.

- Provide education, supervision, and training on wood dust hazards for both managers and employees.

- Monitor risks to ensure they remain as low as possible.

- Workers exposed to wood dust should wash their hands and arms before eating or smoking, especially if handling treated wood.

- Clean work areas frequently.

6. Personal protective equipment (PPE)

Personal protective equipment, such as dust masks or respirators, is a less effective control and should not be used as a substitute for local exhaust ventilation.

PPE is the last line of protection. In some circumstances it may be needed to supplement other measures, to reduce exposure to levels below the workplace exposure standard.

- Respiratory equipment should be manufactured, selected, and maintained in accordance with standards AS/NZS 1715 and 1716.

- People with skin sensitivity to certain wood dust should wear suitable protective clothing, eg. coveralls, long sleeves, and properly fitted industrial gloves.

Worker training

Educate your workers about risks from wood dust and the control measures. Regular training is important to ensure worker awareness remains high.

Training should include information on:

- The health risks from exposure to wood dust.

- Safe work practices to follow when wood dust is created.

- How to use and maintain LEV systems.

- The appropriate use and care of PPE (including protective clothing and RPE).

Also read:

Please visit our Safety Resources SAFETY BAG to have many Safety Resources