The Occupational Health and Safety Act ‐ Fall Protection Regulations outline the instances and requirements for employers to provide a means of fall protection where a worker is exposed to a fall hazard. This guide is intended to provide clarification on the acceptable use of warning line systems used on flat roofing as “another means of fall protection”

This guide does not apply to work on types of roofs other than flat roofing. If a worker works on types of roofs other than flat roofing, then another means of fall protection must be used, as required by the Occupational Health and Safety Act Fall Protection Regulations.

Control Zones

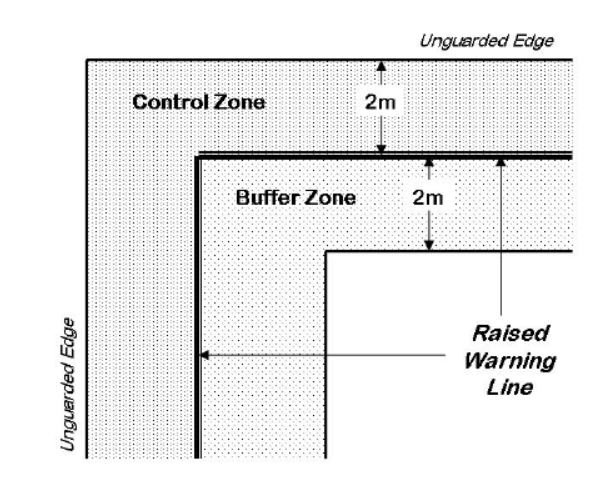

A control zone is a distance between an unguarded edge of a building or structure and a line that is set back a safe distance (2 meters). The use of a control zone is an approach to fall protection for workers performing work on a level working surface within 2 meters of an unguarded edge above a surface or thing that could cause injury to the worker if the worker were to fall on the surface or thing.

If a worker works within 2 meters of the control zone, i.e. within 4 meters of the unguarded edge, a raised warning line is required (see Figure 1).

A control zone cannot be used if the level working surface where work is being performed is less than 4 meters wide. In such circumstances, one of the other means of fall protection must be used, as required by the Occupational Health and Safety Act ‐ Fall Protection Regulations.

Defining the Control Zone

If a worker works within 2 meters of the control zone, i.e. within 4 meters of the unguarded edge, a raised warning line is required (see Figure 2). The raised warning line must be placed at least 2 meters from the unguarded edge. The purpose of the warning line is not to prevent access to the control zone but to provide a visual and physical reminder of the presence of the hazard.

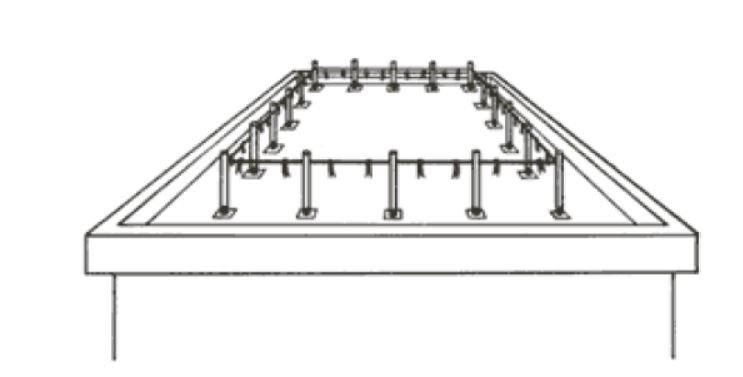

For compliance purposes, a raised warning line can consist of ropes, wires or chains, and supporting stanchions, and:

a. Be flagged or marked with highly visible materials at intervals that do not exceed 2 meters,

b. Be rigged and supported so that the lowest point (including sag) is not less than 0.9 meters (34 inches) from the walking or working surface and its

the highest point is not more than 1.2 meters (45 inches) from the walking or working surface,

c. Be so attached to each stanchion in such a way that pulling on one section of the line between stanchions will not result in slack being taken up in the adjacent section before the stanchion tips over, and

d. The rope, wire, or chain must have a minimum tensile strength of 2.2 kN (500 lbs).

Working within the Control Zone

If a worker works within the control zone, then another means of fall protection must be used, as required by the Occupational Health and Safety Act ‐ Fall Protection Regulations.