The explosion is the result of rapid combustion with a sudden, violent change of pressure involving the liberation and expansion of a large volume of gas.

Thus the release of energy in a rapid and uncontrolled manner gives rise to an explosion. The released energy may appear as heat, light, sound, or mechanical shock. Combustible dust or powders, flammable vapors, and flammable gases can explode. A combustible material, air, and source of ignition (or temperature) are the prerequisites for an explosion.

Thus explosion is a sudden and violent release of emergency. Its effect depends on the rate at which the energy is released.

The difference between fire and explosion is the rate of release of energy. In a fire, it is at a slow rate and in the explosion, it is at a high rate and sudden release.

Three types of energy can be released: Physical, chemical, or nuclear. Bursting of tire, vessel, pipe, etc. due to overpressure or brittle fracture and flushing of superheated liquid (thermal energy) are examples of physical energy. Chemical energy is released due to chemical reactions. It may be uniform as in the case of a vessel, or it may be propagating as in the case of a long pipe. Exothermic or runaway reaction, decomposition, and polymerization are also examples of a chemical explosion. Nuclear energy release can cause nuclear explosions.

Types of the explosion are deflagration and detonation. It is also classified as a confined and unconfined explosion, BLEVE, gas, and dust explosion.

Explosion Data refers to information on the explosive properties of a material and is usually given in descriptive terms, such as low, moderate, or high.

The explosion hazard of a material can be described by its:

- Sensitivity to mechanical shock or impact, which indicates whether or not the material will burn or explode on shock or friction and

- Sensitivity to static discharge, which indicates how readily the material can be ignited by an electric shock.

Explosion hazards in process plants are of many types.

- Dust explosions

- Molten Metal-water explosions (e.g induction furnace)

- Air system explosions

- Superheated liquid explosions

- Mist and Spray explosions

- Crankcase explosions

Explosion limits specify the concern fraction range of a material in the air (percentage volume) that will burn or explode in the presence of an ignition source. Explosive limits of some common chemicals are as under:

| Chemical | LEL (%) | UEL (%) |

|---|---|---|

| Acetylene | 3 | 82 |

| Benzene | 1.4 | 8 |

| Butadiene | 2 | 11.5 |

| Butane | 1.9 | 8.5 |

| Carbon disulfide | 1 | 44 |

| Hydrogen | 4 | 75 |

| Methane | 5 | 15 |

| Natural gas | 3.8 | 17 |

For other chemicals see MSDS for such explosive limits.

Explosive material is classified as high, low, and initiating as under:

High explosive is a chemical compound usually containing nitrogen that detonates as a result of shock or heat. Examples of high explosives are dynamite, ammonium nitrate slurries sensitized with TNT, acetylides of copper and silver, nitro-glycerine, mercury fulminate.

Low explosive deflagrates rather than detonates, such as black powder.

Initiating explosive is an explosive composition used as a component of blasting caps, detonators, and primers. They are highly sensitive to flame, heat, impact, or friction. Examples are lead azide, silver acetylide, mercury fulminate, diazodinitrophenol, nitrosoguanidine, lead styphnate, and pentaerythritol tetranitrate.

In an explosion caused by a high explosive, the rate of energy release is rapid and the explosion has high shattering power. The shock wave from such an explosion has a very short duration time.

Sources of ignition that may cause explosion are:

- Sparks

- Flames and hot surfaces

- Static electricity

- Compression

- Chemicals-pyrophoric material, unstable compounds, reactive compounds, and catalysts.

Effects of the explosion are:

- Blast damage primary and secondary

- Missile damage

- Thermal effects

- Ground shock

- Crater and

- Effect on people

The shock wave is a pressure wave moving through a gas. A shock wave in the open air and combined with a wind wave is called a ‘blast wave’.

Shock-waves due to explosions can cause damage to building breaking windows and ejecting missiles over distances of several hundred meters. People can be blown over or knocked down, buried under collapsed material or injured by flying fragments. People in the vicinity of over-pressure may die and injuries due to indirect effects are also serious.

The effects of explosion depend on the nature and quantity of material involved and the degree of confinement of the vapor cloud. The pressure decreases rapidly with an increase in distance. For example the explosion of a tank containing 50 tonnes of propane results in a pressure of 14 kPa at 250 mt and a pressure of 5 kPa at 500 mt from the tank.

At a pressure of 5 to 10 kPa, people can be injured, while structural demolition and doors/windows breaking are possible at a pressure of 3 to 10 kPa.

Data on fatality is given by Glasstone as under:

| Probability of fatality (%) | Peak overpressure (psi) (duration 400 milliseconds) |

|---|---|

| 1 | 35-45 |

| 50 | 45-55 |

| 99 | 55-65 |

- Overpressure = above the atmospheric pressure.

Explosion pressure on an object is as a result of an impacting shock wave.

Much higher overpressure is required to effect the same levels of fatality for the duration of the order of 1-15 milliseconds typical of high explosives.

Data on eardrum rupture due to direct blast effect is given by Eisenberg as under:

| Probability of eardrum rupture (%) | Peak overpressure (psi) |

|---|---|

| 1 (threshold) | 2.4 |

| 10 | 2.8 |

| 50 | 6.3 |

| 90 | 12.2 |

The extent of injury (Laceration, wound, etc.) depends on the weight of the flying fragment (g), its density (g/cm2), peak pressure (psi) and impact velocity (m/s). Based on these factors, Eisenberg considered a flying glass fragment of 10g with 2.65 g/cm2 density and gave the following data:

| Type of injury | Peak pressure (psi) | Impact velocity (m/s) |

|---|---|---|

| Skin laceration threshold | 1-2 | 15 |

| Serious wound threshold | 2-3 | 30 |

| Serious wound 50% probability | 4-5 | 55 |

| Serious wound 100% probability | 7-8 | 90 |

Some historical figures on explosion events.

| Year | Place | Chemical | Deaths | Injuries |

|---|---|---|---|---|

| 1921 | Oppau, Germany | Ammonium nitrate | 430 | – |

| 1942 | Tessenderloo, Belgium | Ammonium nitrate | 100 | – |

| 1947 | Texas city, US | Ammonium nitrate | 552 | 3000 |

| 1948 | Ludwigshafen, W. Germany | Di-methyl-ether | 245 | 3800 |

| 1954 | Bitburg, Germany | Kerosene | 32 | 16 |

| 1967 | Lake Charles | Iso-butane | 7 | 13 |

| 1972 | East St. Louis, Illinois, US | Propylene | – | 230 |

| 1974 | Decatur, Illinois, US | Propane | 7 | 152 |

| 1974 | Flixborough, UK | Cyclo-hexane | 28 | 89 |

| 1975 | Beak, Netherlands | Propylene | 14 | 107 |

Explosion Control Devices:

The main methods to prevent any type of explosion are

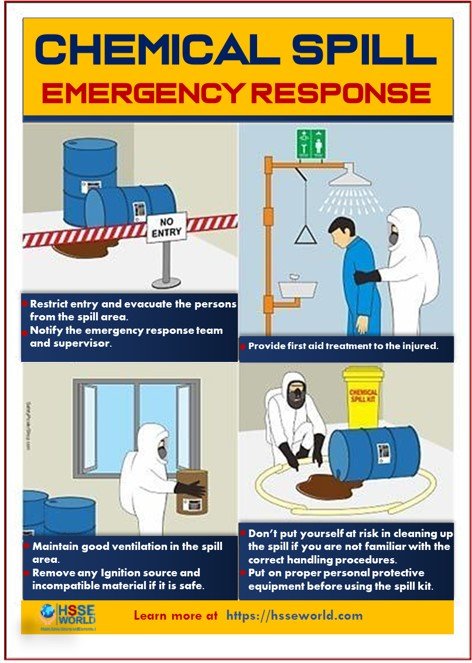

- Avoidance of flammable mixture by good ventilation, dilution, dust collection system, wet methods, etc.

- Avoidance of sources of ignition by avoiding excessive heating (temperature), elimination of spark, flame, etc., using spark/flame arrester, using explosion-proof electrical equipment and fittings and explosion-proof electrical equipment and fittings and by avoidance of static electricity, avoiding friction, etc.

Explosion Protection and relief includes the methods of

- Flame arresters and avoidance of source of ignition.

- Automatic isolation

- Automatic suppression

- Separation

- Containment

- Venting of dust and pipes

- Venting of vessels

- Venting of reactors

- Explosion relief of plant and equipment.

Despite all such methods, if the explosion is possible, control measures should be adopted such as to limit the spread and effects of an explosion by providing explosion relief devices such as rupture diaphragms or explosion doors/windows, panels, or vents, providing blast-walls or strong enclosure, etc.

Explosion venting devices:

Explosion venting device is the most widely accepted and utilized explosion protection strategy in use today. Various types of devices are used to provide explosion overpressure protection, such as certified rupture panels (explosion vents), hinged devices, shear-type fasteners, homemade (uncertified) venting panels, “blow out panels” etc. Many of these devices offer some redeeming benefits, but in the end, are not reliable as explosion protection options.

In view of the reduced efficiency, hinged enclosures and light-weight rupture diaphragms are recommended.

For an explosion venting device, there are five important performance characteristics to consider:

- Venting Efficiency – Efficient devices require less relief area and/or provide lower vented pressures.

- Certified Burst Pressure (P) – The venting device tested and warranted to open at the identified pressure every time.

- Opening Pattern – It provides the expected relief area every time.

- Fragmentation – Its operation creates dangerous projectiles, therefore less preferred.

- Reliability – It operates properly when needed.

Types of Explosion

Dust Explosion

It is possible due to flammable dust of wood, coal, food (starch, flour, sugar, cocoa, feedstuffs), chemicals, plastics (urea-formaldehyde, resin, polyethylene, polystyrene), metals (aluminum, magnesium), etc.

Its results from the rapid combustion of fire solid particles like iron, aluminum, wood, starch, etc. Many solid particles when reduced to fine powder become very flammable and explosive.

At a starch/corn plant at Ceder Rapids, Iowa in 1919, 43 people were killed and at Peking. In Illinois in 1924, 42 people were killed due to a dust explosion.

At a starch plant in Ahmedabad, 29 workers injured, and out of the 20 died due to a starch dust explosion on 19-12-1991.

Explosion characteristics of dust suspension are as under:

- Explosion-ability classification.

- Minimum explosible concentration.

- Minimum ignition temperature.

- Minimum ignition energy.

- Maximum permissible oxygen concentration to prevent ignition.

- Explosion pressure characteristics.

(a) Maximum explosion pressure.

(b) Maximum rate of pressure rise.

(c) Average rate of pressure rise.

Source of ignition for dust explosions are

- Flames, heat, or hot surfaces

- Welding and cutting

- Mechanical sparks

- Self-heating

- Static electricity

- Electrical equipment

Preventing methods for dust explosion include

- Isolation

- Containment

- Explosion suppression

- Explosion venting

Dust fires can occur in dust deposits and are of two types – flaming and smoldering fires.

Deflagration:

It is an explosion with a resulting shock wave moving at a speed less than the speed of sound in the un-reacted medium.

Deflagration is a very rapid auto combustion of particles of explosive as a surface phenomenon. It may be initiated by contact of a flame or spark but may be caused by impact or friction. It is a characteristic of low explosives.

Deflagration or detonation is a form of explosion, the former is due to low burning velocity (flame speed as 1 m/s) while the latter is due to high burning velocity (flame speed as 2000-3000 m/s). A detonation generates high pressure and is more destructive than a deflagration. The peak pressure caused by a deflagration in a closed vessel can reach up to 70-80 kPa (8 bar), whereas in the case of detonation it easily reaches up to 200 kPa (20 bar).

A deflagration can turn into a detonation while traveling through a long pipe. In that case, deflagration velocity exceeds that mentioned above.

Detonation:

It is an explosion with a resulting shock wave moving at a speed more than the speed of sound in the unreached medium.

Detonation is the extremely rapid, self-propagating decomposition of an explosive accompanied by a high pressure-temperature wave that moves from 1000-9000 m/sec. It may be initiated by mechanical impact friction or heat. It is a characteristic of high explosives that varies considerably in their sensitivity to shock, nitro-glycerine being one of the most dangerous in this regard.

Whether a deflagration or detonation takes place depends on the material involved and the conditions under which it occurs. A vapor phase explosion requires some degree of confinement for a detonation to take place.

The detonation of a gas-air mixture is possible directly by a powerful ignition source or by the transition from deflagration. Such transition requires a strong acceleration of the flame front. It is possible in pipelines but rarely possible in vessels.

A number of substances are listed which can produce detonation in a gas-air mixture. Some commonly known substances are:

Acetone, Acetylene, Benzene, Chloroform, Cyclohexane, Diethyl ether, Ethylene, Hydrogen, Methane, Methanol, Naphthalene, Trichloroethylene.

Detonation usually occurs well below the upper explosive limits. Separate Detonation Limits are available for some substances as under:

| Substance | Detonation Limits (%) | Explosive Limits (%) | ||

| Lower | Upper | LEL | UEL | |

| Acetylene | 4.2 | 50 | 3 | 82 |

| Ether | 2.8 | 4.5 | 1.8 | 48 |

| Hydrogen | 18.3 | 59 | 4 | 75 |

Though upper detonation limits are normally below upper explosive limits, exceptions have been reported.

(learn what-is-meaning-of LEL-UEL-PID).

Confined and Unconfined Vapour Cloud Explosion (VCE):

Deflagration and detonation discussed in the previous part are confined explosions, as they occur in a process vessel, building, or pipework i.e. in a confined space. The only conditions necessary are that the gas mixture should be within explosive/detonable range and there should be a source of ignition or the mixture should have been heated to its auto-ignition temperature. The transition from deflagration to detonation (mostly in the pipeline) is also possible.

An unconfined vapor cloud explosion (UVCE) occurs in open at a distance from the point of vapor release and threatens a larger area. A large release of flammable vapors and cloud formation explodes when spark or friction is available. Through it is a rare possibility but has more potential to damage.

A confined vapor cloud explosion (CVCE) occurs in a confined place (e.g. vessel, pipe, building, pit, etc.) while UVCE occurs in an open area. The peak pressures of CVCE are much higher than that of UVCE.

Some examples of UVCE are as under:

| Year | Place | Chemical | Quantity | Deaths |

|---|---|---|---|---|

| 1967 | Lake Charles, La. | Iso-butane | 46 | 7 |

| 1968 | Pernis, Netherlands | Hydrocarbon | 140 | 2 |

| 1970 | Port Hudson, Miss | Propane | 29 | 0 |

| 1974 | Flixborough, UK | Cyclo-hexane | 25 | 28 |

The date on the equipment involved in UVCE name process equipment, storage tank, transportation vehicle, and modes of release as vessel failure, piping, valves or fittings failure, release from venting facilities, etc.

(learn: Guideline for hazardous locations ).

Some issues connected with confined and un-confined VCE are as under:

- Determination of detonation limits.

- Mass of material released and partly vaporized.

- Possibility from deflagration to detonation.

- Probability of explosion or fire.

- Probability and technique of ignition of the cloud.

- Dilution due to air entrainment.

- Distance traveled by a cloud before ignition.

- Nature of flame propagation.

- Types of effects of the explosion.

UVCE due to hydrogen is unusual but did occur. Hydrogen venting should be direct to the atmosphere via multiple vents or by flare.

Methane at normal temperature burns but does not explode. Vapour cloud of LNG might explode.

BLEVE (Boiling Liquid Expanding Vapour Explosion):

Boiling liquid expanding vapor explosion (BLEVE), also referred to as a fireball, is a combination of fire and explosion with an intense radiant heat emission within a relatively short time interval.

When a tank or pressure vessel containing liquid or liquefied gas above its boiling point (so heated) fails or ruptures, the release of the contents as a turbulent mixture of liquid and gas, expanding rapidly and dispersing in the air like a cloud. When this cloud is ignited, a fireball occurs causing enormous heat radiation intensity within a few seconds. This heat is sufficient to cause severe skin burns and deaths within a few hundred meters depending on the mass of the gas involved. A BLEVE involving a 50- tonne propane tank can cause a third-degree burn at @200 mt and blisters at @ 400 mt.

Road/rail accident to a tank car/wagon or due to weakening of structure by fire or physical impact on an overstressed vessel/tank can cause a BLEVE.

Some reported major BLEVE examples are as under:

| Year | Location | Chemical | Death | Injuries |

|---|---|---|---|---|

| 1966 | Feyzin, France | LPG (Propane) | 18 | 90 |

| 1969 | Laurel, Miss | LPG | 2 | – |

| 1970 | Cresent city | LPG | 0 | 66 |

| 1971 | Houston, Tex | Vinyl chloride | 1 | – |

| 1972 | New Jersey | Propylene | 2 | – |

| 1985 | Mexico city | LPG | 650 | 2500 |

(learn: What are explosive work environment and how to select the right tools ).