Exposure to the gases, dust, mists, and fumes of hazardous chemicals can cause lung damage, cancer, and other serious conditions of the respiratory and central nervous systems as well as other organs. Your organization has implemented a written respiratory protection program to protect workers from the adverse health effects of airborne contaminants while performing your job. A key component of this is training and that’s the purpose of this program, to provide employees with an understanding of the respiratory hazards they may encounter in their work areas and how to use the proper respiratory protection to prevent exposures to such hazards.

This article includes medical evaluations, fit testing, employee responsibility to wear respiratory protection, particulate filter respirators, chemical cartridge respirators, PAPRs, SCBAs and SARs, user seal checks and cleaning, disinfecting, and storing respirators.

The written respiratory protection program

Your organization has implemented a written respiratory protection program to protect you from the adverse health effects of airborne contaminants while performing your job. A key component of this program is employee training and that’s the purpose of this program, to provide you with an understanding of the respiratory hazards you may encounter in your work area and how to use the proper respiratory protection to prevent exposures to such hazards.

Another element of the respiratory program is reducing employee exposure to respiratory hazards through the use of engineering and work practice controls. Examples of methods most companies utilize to reduce exposure include the use of ventilation and exhaust hoods, enclosing operations that release dangerous fumes and gases, and substituting hazardous chemicals with less hazardous substances.

Quite often, these practices cannot adequately reduce the number of respiratory hazards to acceptable levels in a given work area. When this is the case, employees must wear respirators to achieve the necessary protection.

Medical evaluations

Before wearing respiratory protection, you must undergo a medical evaluation by a licensed physician to determine if you can safely wear a respirator. During the evaluation, you will complete a questionnaire or similar survey that collects data on your medical history, including past and current health conditions such as respiratory or cardiovascular problems.

X-rays or pulmonary function tests may also be administered to determine if you have any respiratory or cardiovascular issues.

Keep in mind that your cooperation during the medical evaluation is critical in determining whether you can wear a respirator safely.

Fit testing

In addition to the medical evaluation, you must also undergo a fit test procedure before being permitted to wear a respirator. A fit test ensures a proper fit and must be performed at least once a year while you are in the respiratory program.

The fittest will be conducted while you are wearing the same type, style, and size of respirator that you will don while performing your job. A respirator must fit properly to provide the required protection from respiratory hazards.

During a fit test, you will be asked to perform several exercises to simulate common body movements that occur while working. These exercises may vary depending on the specific type of test being conducted.

Responsibility to wear respiratory protection

As part of the written respiratory protection program, your organization has evaluated various areas of the workplace for respiratory hazards and selected the appropriate respirator that provides the necessary protection for each location.

In most situations, your employer will determine which type of respirator is required for your specific work environment.

While the company may select the appropriate device for you to wear, it is ultimately your responsibility to wear that protection in all required situations.

Assigned protection factors (APF’s)

Various governmental agencies have established exposure limits for various contaminants. When the concentration of a given substance exceeds these exposure limits in a work zone, respiratory protection must be worn.

Protection factors have been assigned to common respirator styles and classes. The assigned protection factor, also known as an apf, indicates the ability of a respirator to reduce the user’s level of exposure compared to the level of ambient air.

These numbers, which are crucial in determining the proper respirator for a given job, can range from 10 to 10,000.

A half-mask air purifying respirator only has an APF of 10; a full face respirator has an APF of 50, while a full face piece self-contained breathing apparatus in pressure-demand mode has an APF of 10,000.

Be aware that wearing a respirator with a lower APF than the one assigned to you may not provide adequate protection from the level of airborne contaminants.

If you have any questions about the proper protection for a specific assignment, ask your supervisor.

Particulate filter respirators

One common type of respirator is a particulate filter respirator. These come in a variety of styles.

Filters are rated according to the efficiency a filter has when capturing airborne particles. This efficiency rating is either 95 percent, 99 percent, or 100 percent. The higher the rating, the more protection the filter provides.

Also, be aware that the higher the rating, the more difficult it is to breathe through the filter. Selecting a higher efficiency than needed can cause unnecessary strain while breathing, while choosing too low an efficiency may not provide adequate protection.

There are three classes, or series, of negative-pressure particulate filter respirators, based on the types of particles they are designed to remove.

N-series filters are not resistant to oil, therefore, only provide protection against non-oil-based liquids and non-oil-based solid particulates such as dust created during the processing of coal, iron ore, flour, metal, and wood.

R-series filters are resistant to oil, meaning they protect against solid and liquid aerosol particulates that may contain oil. This type of filter is designed to be used for only one shift or eight hours then replaced. Due to this service life restriction, they are the least common type of particulate filters.

P-series filters also provide protection against both solid and liquid aerosol particulates that may contain oil, but they have a recommended service life of 40 hours or one month, whichever comes first.

NIOSH-approved dust masks

One type of filter respirator is a NIOSH-approved dust mask. NIOSH-approved dust masks are effective when used around dust, but they do not provide protection against gases or vapors.

For this reason, they should not be worn while spray painting. In addition, this type of respirator is not appropriate for working with asbestos or lead.

Keep in mind that single-strap dust masks are not NIOSH-approved and provide no protection against hazardous substances.

When wearing any type of dust mask, it should be replaced when it becomes clogged with dust or debris.

Face-masks with replaceable filters

Another type of filter respirator is the “half” or “full” face mask which supports replaceable filters. These face masks provide a better seal than a dust mask and should be used when additional protection is required.

No matter what type of particulate filter is used, they should be replaced whenever noticeable breathing resistance is detected.

Chemical cartridge respirators

Another type of filter respirator provides protection from the gases and vapors of hazardous chemicals. Known as chemical cartridge respirators, their cartridges remove harmful chemical irritants from the air the user breathes.

It’s critical that you remember that there is no single cartridge that protects against all chemical hazards you may encounter.

Each cartridge is designed for a specific purpose. Some protect against one single chemical, while others provide protection from several different substances.

Using the wrong cartridge can have disastrous consequences.

Your company has established a schedule for changing out chemical cartridges. This ensures they are replaced before the end of their service life and before a “breakthrough” occurs.

Breakthrough has occurred when sorbent material in the cartridge has become overly saturated and allows gas and vapors to enter the face mask. In most breakthrough cases, you will be able to detect the odor of gas in your respirator.

Become familiar with your organization’s change-out policies and make sure to change out cartridges as scheduled.

Powered-air purifying respirator (PAPRs)

In addition to chemical cartridge respirators, a respirator is known as the powered-air purifying respirator, or PAPR also uses cartridges and filters to capture airborne contaminants. These have become popular in recent years due to their flexibility and comfort.

What separates these devices from traditional respirators is the addition of a motor blower that pulls air through the filter and into the user’s breathing zone.

Some of the advantages of wearing a PAPR include the virtual elimination of breathing resistance, which can help provide comfort and reduce stress when working in hot or strenuous work environments.

Also, PSPRs can be equipped with loose-fitting hoods that allow facial hair as long as it doesn’t interfere with the seal of the headgear.

In addition, because PAPRs reduce breathing resistance, they may be an option for a worker who has been disqualified from wearing a respirator for medical reasons.

A potential PAPR user must still undergo a medical evaluation to determine if he or she can wear the device safely.

IDLH atmospheres

Be aware that all of the types of respirators we have discussed to this point only filter breathable air. They do not supply oxygen that is needed by workers in many hazardous work environments.

There are also environments that have dangerously high concentrations of gases or fumes. These areas, as well as those that are oxygen-deficient, can be so hazardous that they are known as IDLh atmospheres because they are immediately dangerous to life and health.

Many workers die each year when they mistakenly wear filter respirators inside IDLH atmospheres.

For adequate protection in an IDLH atmosphere, a self-contained breathing apparatus, SCBA, or a supplied-air respirator, SAR, is required.

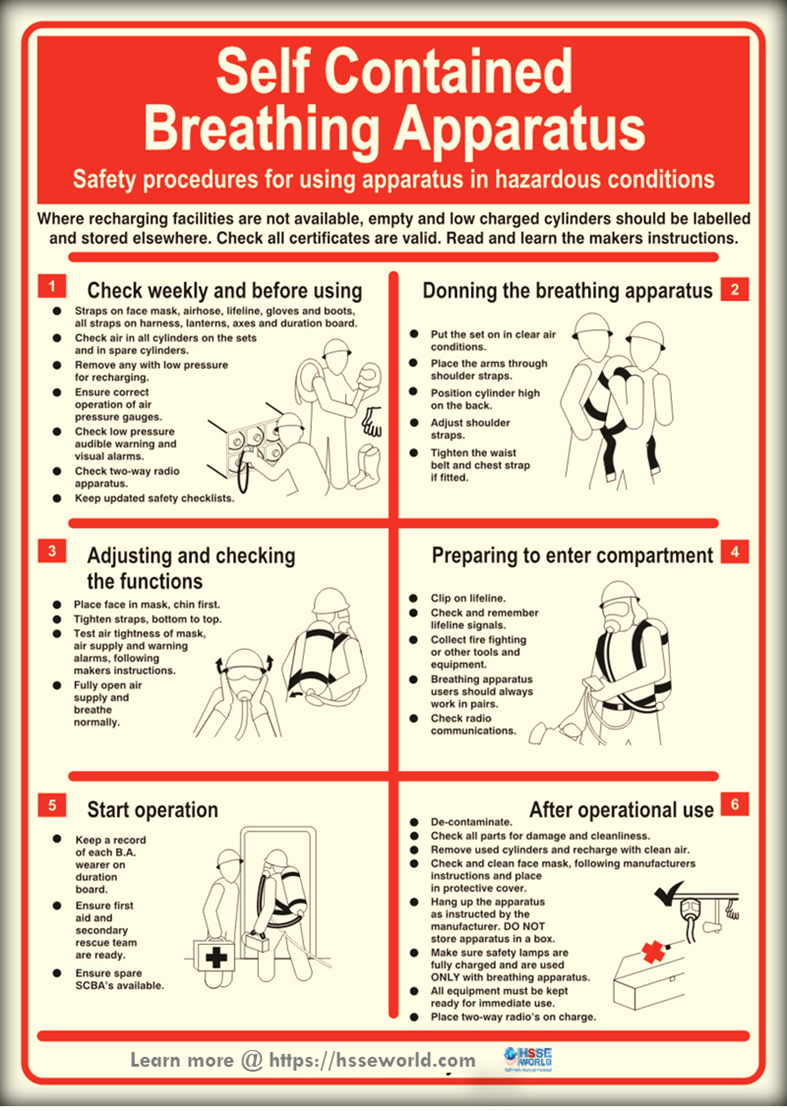

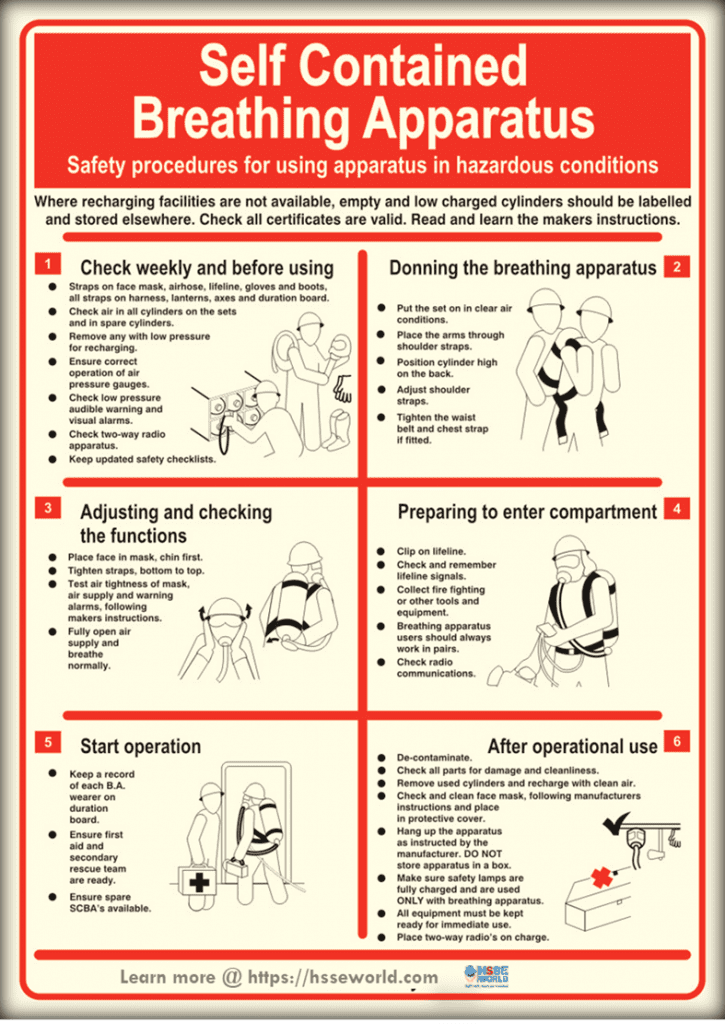

SCBAS & SARS

The basic supplied air respirator is comprised of a respirator face piece, which could be a tight-fitting half mask or full face mask, or a loose-fitting hood or helmet assembly, connected by an air supply hose to a compressor. The compressor supplies air that has been purified of all contaminants.

An SCBA typically has three main components: a high-pressure tank, a pressure regulator and a mouthpiece or face mask connected together and mounted to a frame that is carried on the user’s back.

Most tanks contain enough breathable air to last for 30 to 60 minutes. This duration can be affected by your weight and the physical stress of the task being performed.

User seal checks

The user seal check must be performed to ensure you have put on the respirator properly and an appropriate seal has been established. There are two types of seal checks, a positive pressure test or a negative pressure test.

To perform a positive pressure test, place the palm of your hand over the exhalation valve of the respirator and lightly breathe out into the face mask. If you can detect a build-up of pressure beneath the mask and see the side of the face piece bulge out, you have a proper fit.

A negative pressure test entails putting both hands over the inhalation valves and gently breathing in. The face piece should collapse slightly against your nose. Then hold your breath for 10 seconds. If the mask remains collapsed, you have a good fit.

If you have any difficulty achieving a proper seal, notify your supervisor.

Proper respirator use

Be aware that a respirator is your last line of defense against various airborne contaminants. They cannot provide the appropriate protection if they are used improperly. Always follow your organization’s and manufacturer’s recommendations for respirator use.

Never remove your respirator in a hazardous area. Certain gases and vapors can overwhelm your lungs and other organs in a matter of seconds. Make sure to travel to a safe area before removing your equipment.

If you have any difficulty breathing or can taste or smell the odor of a hazardous chemical when wearing a filter respirator, exit the area immediately and replace the cartridges. Remember to perform a user seal check before returning to the hazardous area.

Never attempt to rescue a co-worker who has been overcome by hazardous fumes or vapors without wearing the proper protection. If a rescue respirator isn’t readily available, activate your company’s emergency action plan so a prompt rescue by emergency responders can begin as soon as possible.

Cleaning, disinfecting & storing respirators

After you have completed your work requiring a respirator, it is important that it is cleaned, disinfected, and stored properly.

If you have a personal respirator that only you wear, it should be cleaned and disinfected after each shift or as often as necessary to keep it sanitary.

Respirators shared among co-workers should be cleaned and disinfected after each individual’s use.

Begin cleaning the device by removing filters or cartridges.

Inspect the condition of the straps, tubes, and cartridges. Defective parts should be repaired or replaced by a person qualified by your organization to do so.

Thoroughly wash all parts of the respirator with warm water and a detergent recommended by the manufacturer.

The parts should then be carefully rinsed and drained before being disinfected by submerging in a sanitizing solution approved by the respirator manufacturer for two minutes.

Remove the parts, rinse and drain completely, then allow the parts to air dry or wipe them dry with a lint-free cloth.

When the parts are dry, reassemble the respirator and put it in its case or a plastic bag. Store it in a clean, dry location approved by your organization.

Download Infographic