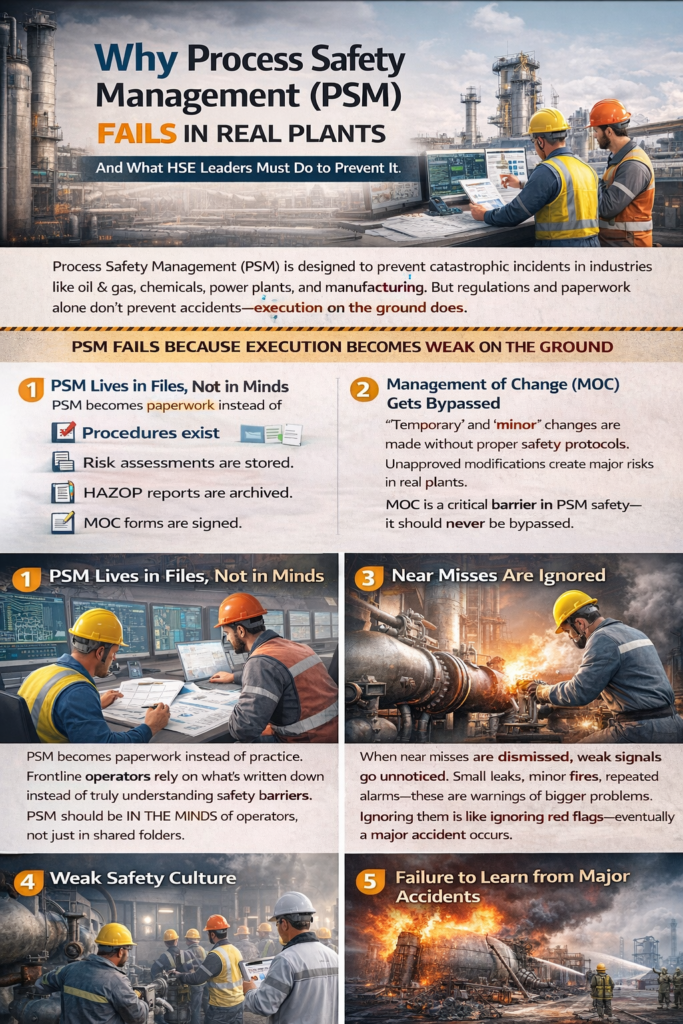

Process Safety Management (PSM) is designed to prevent catastrophic incidents in industries such as oil & gas, petrochemicals, chemicals, power plants, and manufacturing facilities. On paper, PSM systems are strong. Regulations exist. Procedures are written. Audits are conducted.

Yet, serious incidents continue to occur.

So the real question is:

Why does Process Safety Management (PSM) fail in real plants?

The answer is simple but uncomfortable:

PSM rarely fails because the system is weak. It fails because execution becomes weak on the ground.

In this comprehensive guide, we’ll explore the real reasons PSM fails in operational environments, how organisations unknowingly weaken their safety barriers, and what practical steps HSE professionals can take to strengthen execution.

Understanding Process Safety Management (PSM)

Process Safety Management is a systematic approach to managing hazards associated with highly hazardous chemicals and industrial processes. It focuses on preventing:

- Explosions

- Toxic releases

- Fires

- Major environmental damage

- Fatalities and serious injuries

Unlike occupational safety (slips, trips, falls), process safety deals with low-frequency but high-consequence events.

PSM typically includes:

- Process Hazard Analysis (PHA / HAZOP)

- Management of Change (MOC)

- Mechanical Integrity

- Operating Procedures

- Training & Competency

- Incident Investigation

- Emergency Planning

- Compliance Audits

On paper, these elements look comprehensive.

But real-world plants operate under pressure production targets, cost constraints, ageing equipment, contractor turnover, and human behaviour.

That’s where cracks begin.

Read: Guideline for Process Safety Management Program with Free Training

1. PSM Lives in Files, Not in Minds

The Paperwork Problem

One of the biggest reasons PSM fails is that it becomes a documentation exercise instead of a living system.

Procedures exist.

Risk assessments are stored.

HAZOP reports are archived.

MOC forms are signed.

But the workforce does not internalise them.

When PSM becomes “something the safety department handles,” it loses operational ownership.

Signs This Is Happening:

- Operators can’t explain critical safety interlocks.

- Supervisors rely on “how we’ve always done it.”

- Procedures are outdated but still used.

- Safety meetings focus only on minor injuries.

PSM should live in the minds of operators, engineers, and managers, not just in shared folders.

2. Production Over Safety: The Silent Killer of PSM

When production pressure increases, safety barriers weaken.

This doesn’t happen through malicious intent; it happens gradually.

Examples:

- Delaying shutdowns for maintenance.

- Overriding alarms to avoid trips.

- Extending inspection intervals.

- Running equipment beyond design limits.

These decisions may seem minor individually. But collectively, they erode process safety integrity.

The Real Risk

Process safety failures rarely happen suddenly. They result from:

- Barrier degradation

- Normalisation of deviation

- Risk tolerance increases over time

When production KPIs dominate leadership discussions more than safety KPIs, PSM slowly collapses.

Leadership Question:

Does your plant celebrate production milestones more than safe operations milestones?

If yes, your PSM system may already be under stress.

3. Management of Change (MOC) Gets Bypassed

Management of Change (MOC) is one of the most critical elements of PSM.

Yet it is also one of the most bypassed.

Why?

Because changes are often labelled as:

- “Temporary”

- “Minor”

- “Emergency fix”

- “Just for this shutdown”

Temporary changes that stay for years are common contributors to major accidents.

Common MOC Failures:

- No risk assessment before modifications.

- Contractors are installing equipment without a full review.

- Control system changes are undocumented.

- Emergency bypasses left active.

When MOC is treated as a bureaucratic delay instead of a safety control, plants become vulnerable.

4. HAZOP Becomes Routine Instead of Meaningful

Hazard and Operability Studies (HAZOP) are designed to deeply analyze process risks.

But in many plants, HAZOP becomes:

- A checkbox exercise.

- A repeated template.

- A rushed workshop.

Why Is HAZOP Important for Safety Professionals?

Warning Signs:

- Same comments copied from previous reports.

- No follow-up on recommendations.

- Operators excluded from sessions.

- Actions remain open for years.

A HAZOP study without implementation is worse than no HAZOP because it creates a false sense of security.

Effective HAZOP Requires:

- Skilled facilitators.

- Experienced operators.

- Updated P&IDs.

- Management accountability for action closure.

Read: E-Books: HAZOP-Guide to Best Practice Third Edition(Opens in a new browser tab)

5. Near Misses Are Ignored

Near misses are free lessons.

But many organisations:

- Underreport them.

- Downgrade them.

- Close them without root cause analysis.

When near misses are ignored, weak signals go unnoticed.

Major accidents are often preceded by multiple warning signs:

- Small leaks

- Minor fires

- Equipment vibration issues

- Repeated alarm activations

If these signals are dismissed in reports, the plant loses its early warning system

6. Poor Maintenance and Mechanical Integrity

Mechanical Integrity is the backbone of PSM.

Ageing equipment, corrosion, fatigue, and vibration gradually reduce reliability.

Common Mechanical Integrity Failures:

- Skipping inspections due to budget cuts.

- Ignoring corrosion under insulation.

- Using temporary clamps instead of permanent repairs.

- Delaying pressure relief valve testing.

When safety-critical equipment is not maintained properly, protective layers disappear.

Ask Yourself:

- Are pressure relief valves tested as scheduled?

- Are safety instrumented systems verified?

- Are inspection findings acted upon promptly?

If maintenance becomes reactive instead of preventive, PSM integrity collapses.

7. Weak Safety Culture

Culture is the invisible force behind every safety system.

You can have:

- Perfect procedures

- Certified engineers

- Compliance audits

But if the culture is weak, PSM will fail.

Characteristics of Weak Safety Culture:

- Blame instead of learning.

- Fear of reporting issues.

- Management rarely visiting plant floor.

- Compliance mindset instead of risk mindset.

A strong PSM culture is action-driven, not compliance-driven.

It encourages:

- Reporting

- Questioning

- Stopping unsafe work

- Learning from mistakes

8. Training Without Competency

Training programs exist in most organisations.

But training does not equal competency.

Real competency means:

- Understanding process hazards.

- Knowing emergency response actions.

- Recognizing abnormal situations.

Operators must understand:

- What happens if pressure increases?

- What causes runaway reactions?

- What alarms indicate catastrophic potential?

If training is limited to slides and attendance sheets, PSM effectiveness declines.

9. Failure to Learn from Major Accidents

History has shown us devastating incidents:

- Bhopal

- Texas City Refinery

- Piper Alpha

- Beirut Explosion

Common patterns appear in investigations:

- Cost cutting

- Ignored warnings

- Deferred maintenance

- Weak leadership oversight

Plants that fail to study and internalize these lessons repeat the same mistakes.

Process safety failures are rarely new problems they are repeated problems.

10. Audits Focus on Compliance, Not Risk

Internal and external audits are required in PSM.

However, many audits focus on:

- Documentation completeness

- Signature verification

- Procedure formatting

Instead of:

- Barrier effectiveness

- Risk exposure

- Operational reality

An audit that confirms paperwork but ignores plant conditions provides false confidence.

Effective audits must ask:

- Are safety barriers working?

- Are operators confident?

- Are actions closed on time?

How to Prevent PSM Failure in Real Plants

Now that we understand why PSM fails, let’s focus on solutions.

1. Strengthen Leadership Involvement

Leadership must:

- Visit plant floors.

- Ask about safety barriers.

- Review near misses.

- Hold managers accountable.

Visible leadership commitment drives cultural change.

2. Make MOC Non-Negotiable

No change should happen without:

- Risk assessment

- Approval

- Documentation

- Communication

Temporary changes must have expiration dates.

3. Track Safety Performance Indicators

Use both:

Lagging Indicators:

- Process safety incidents

- Loss of containment

- Fires and explosions

Leading Indicators:

- MOC backlog

- Inspection compliance rate

- Safety critical maintenance completion

- Near miss reporting rate

Leading indicators prevent disasters before they happen.

4. Improve Mechanical Integrity Programs

- Implement risk-based inspection (RBI).

- Digitize inspection tracking.

- Prioritize safety-critical assets.

- Allocate sufficient budget.

Mechanical integrity is not optional; it is protective armour.

5. Encourage Reporting Culture

Workers must feel safe to report:

- Unsafe conditions

- Equipment issues

- Process deviations

Anonymous reporting systems can help build trust.

6. Invest in Competency, Not Just Training

Conduct:

- Scenario-based drills

- Emergency simulations

- Abnormal operation workshops

Competency reduces human error.

The Core Truth About PSM Failure

PSM does not fail because standards are weak.

It fails because:

- Execution becomes weak.

- Barriers degrade silently.

- Culture shifts toward production.

- Risk becomes normalized.

Rules alone do not save lives.

Action does.

Final Thoughts for HSE Professionals

If you work in HSE, operations, maintenance, or plant leadership, ask yourself:

- Is our PSM system alive?

- Or is it archived?

- Do operators understand risks?

- Or do they follow habits?

Process safety must be:

- Visible

- Measurable

- Owned by operations

- Supported by leadership

When PSM becomes part of daily decision-making, catastrophic incidents decrease significantly.

Conclusion

Process Safety Management (PSM) fails in real plants not because regulations are weak, but because execution weakens under operational pressure.

From bypassed MOC processes to superficial HAZOP studies, from ignored near misses to poor maintenance practices — the failure is rarely sudden. It is gradual.

For organisations serious about preventing catastrophic accidents, the solution lies in:

- Strengthening leadership commitment

- Reinforcing safety culture

- Maintaining mechanical integrity

- Tracking leading indicators

- Ensuring competency at all levels

Process safety is not paperwork.

It is disciplined execution.

And disciplined execution saves lives.