Welding helmets and gloves are the first things that come to mind when most people think of welder’s safety apparel. But welders themselves know how much they rely on other pieces of protective gear to keep them safe when doing their highly hazardous work.

In this article, we’ll set the helmets and gloves aside. Yes, they’re incredibly important and no welding work should take place without them. But this time, we’ll focus on the other PPE welders require.

General Requirements

With the exception of eye and face protection (those are covered under various pieces of legislation), welding PPE does not seem to be covered under a specific OSHA standard. Employees engaged in welding operations, however, should be provided with appropriate PPE as per OSHA’s PPE standard (CFR 1910.132).

More details regarding protective clothing to be used during welding and cutting applications can be found in ANSI Z49.1 – 2012, Safety in Welding, Cutting, and Allied Processes. It states the following: ”Clothing shall provide sufficient coverage, and be made of suitable materials, to minimize skin burns caused by sparks, spatter, or radiation”.

Additional information is scattered among several other standards.

ISO 11611 specifies “minimum basic safety requirements and test methods for protective clothing including hoods, aprons, sleeves, and gaiters that are designed to protect the wearer’s body including head (hoods) and feet (gaiters) and that are to be worn during welding and allied processes with comparable risks. “

ASTM 6413 covers the minimum manufacturing standards concerning the flame resistance of PPE.

Welding Hazards

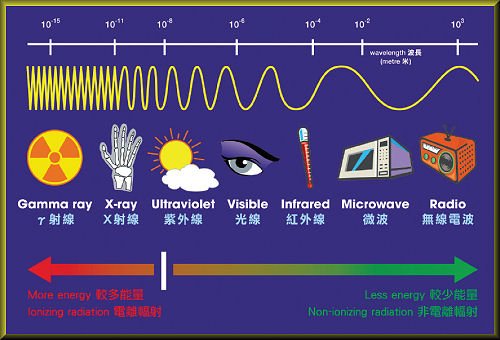

It will come to no one’s surprise that the most common welding injuries by far are burning (either from hot materials or from weld spatter falling into folds, pockets, and so on). This is followed by exposure to arc rays and electric shock. Welding PPE, then, must at the very least provide protection against these hazards.

To minimize these hazards, CCOHS recommends taking the following precautions, among others:

- PPE should be made of heavyweight, tightly woven, fire retardant treated wool or cotton or leather that can offer protection from UV radiation, weld spatter, sparks, and open flame.

- Wear dark color clothes and PPE to prevent reflection (and burns) and cover all skin. Some options are listed below:

- Long sleeve shirts/jackets,

- Long pants,

- Welding caps with neck cover

- Helmet bib

- Welding sleeves

- Welding apron

- Welding cape

- Avoid pockets, or ensure they have a flap to cover them. Alternatively, tape them shut, to avoid collecting sparks and spatter. Many new welding clothes have internal pockets to mitigate this hazard.

- Wear high boots, fully laced; ensure the pant covers the boot and that it has no cuffs, as those collect sparks. Don’t tuck pants into the boot!

- To avoid collecting sparks and spat use a leather apron.

Leather vs. FR Cotton

Flame-resistant cotton is a very common fabric for many of these garments because it is lightweight, relatively inexpensive, and the chemicals in its structure deprive the area of oxygen and inhibit combustion when they come in contact with flames or hot materials. It is also more breathable than leather and more comfortable.

Cotton, however, does not provide enough protection for all welding tasks and its lifespan is shorter than leathers.

Because of its density and thickness, leather prevents heat from penetrating through the garments and is considered to be the best material for welding PPE. It is very durable, has a substantially longer lifespan, and can be used in a most welding applications.

But all these qualities come with a cost. Leather garments are heavier and can result in fatigue. The insulating properties of leather that make it so desirable when dealing with sparks and spatter also impede body heat from escaping, leaving users sweaty and hot. And over time, due to exposure to heat and repeated washes, the leather becomes stiffer and more uncomfortable.

Ultimately, when deciding between cotton and leather the best material is the one that protects you from the hazard, so do a proper hazard assessment: know your tasks and the limitations of your PPE. If both materials would do for the job, then consider comfort and durability.

(Find out How to Conduct a Risk Assessment.)

Common Welding PPE

Head Protection

While your welding mask protects your face and eyes from harmful radiation, it is not enough. To protect your head and hair from sparks, spatter, burns, and radiation, consider wearing an FR cap, beanie, do-rag, or other head covering under your helmet. If this does not cover the back your neck, consider wearing a hoodie.

When sparks or hot material can enter your shirt, a helmet bib is a good option to cover that area and deflect sparks.

Shirts, Jackets, and Capes

Shirts and jackets could be made from either FR cotton or leather, while capes are generally made of leather.

Jackets and shirts extend from the waistline to the neck and cover the torso and the arms. They are designed to cover your body and protect against burns and radiation. Some shirts have leather sleeves and a cotton body in order to save weight, make them more comfortable, or just saving you the pain of donning and doffing leather sleeves.

Welding jackets are considered a must for overhead welding. The coverage it provides will prevent debris and spatter from causing injury.

Shirts and jackets should be kept dry, since getting them wet increases the possibility of an electric shock. If the shirt becomes wet, change it before doing additional work.

Capes do not cover or protect the torso, only the shoulders, and the arms.

Welding Sleeves

Sleeves are intended to provide protection in low-volume welding processes. They protect exclusively the welder’s arms by preventing sparks, hot debris, and spatter from coming in contact with your skin.

As with shirts and jackets, they can be made of leather or fabric and present the same pros and cons. They come in various sizes are usually secured on the arms with elastic.

Both sleeves and jackets provide a fairly natural feel and allow good, fluid movement, which is not necessarily the case with aprons.

Welding Aprons

In general, aprons are not sized, but come in standardized lengths, with some featuring adjustable neck-straps.

Aprons cover the area from the chest to knee but don’t provide any coverage on shoulders and arms.

Aprons are most commonly made of leather and are worn in combination with other FR clothing (usually cotton) to supplement the protection without resorting to a full leather suit.

Foot Protection

Typical leather safety boots that meet ASTM F2412 and ASTM F2413 requirements are considered acceptable for most occasional welding work. To gain extra protection, there are slip-on or slip-over leather shields that will prevent sparks and spatter from diminishing the integrity of the safety boot.

For welding professionals, there are temperature-resistant safety boots that have lace covers to protect laces from material burns.

Leg Protection

These come in different shapes and sizes, from leggings to chaps and pants. Leggings are generally geared to low-volume work, while professionals would likely go for the chaps or pants instead, since they offer the highest degree of protection, especially when worn in combination with a jacket.

Leggings are usually made of denim, which makes them light, comfortable, and easy to fasten (generally with a Velcro or spring-loaded strap). They’re also not very durable and offer less protection than pants or chaps, especially if those pants or chaps are made of leather.

Chaps are leg coverings that do not have a seat, are not joined at the crotch, and fasten around the waist with a strap or a belt. This makes them versatile and able to accommodate many waistlines. Chaps come in standardized lengths and are generally made of leather.

Pants are made of either cotton or leather. While cotton pants (FR denim and other FR blends) are comfortable, they have limited durability when compared to leather. To overcome this limitation, welders can wear leather chaps in combination with FR jeans.

Take the Time to Make the Right Choice

There are many types of PPE for welding and they can be combined in many ways. What you will decide to wear when welding depends much on the hazard, where you work (on a welding table vs. overhead), how often you do the task (full time vs. occasionally), work or client requirements, your budget, and ultimately what you are comfortable with.