This fire prevention plan is provided only as a guide to help employers and employees comply with the requirements of the Occupational Safety and Health Administration’s (OSHA) Fire Prevention Plan Standard, 29 Code of Federal Regulations (CFR) 1910.39. It is not intended to supersede the requirements of the standard. This sample plan contains the basic elements of a fire prevention plan. However, an employer should review the OSHA standards that apply to its situation, company, and facility, and customize this plan to its specific processes and procedures. Modifications other than those indicated in parentheses may be necessary to establish an effective, comprehensive program.

Also Read: Fire Prevention & Response

I. OBJECTIVE

The purpose of this Fire Prevention Plan is to eliminate the causes of fire, prevent loss of life and property by fire, and comply with the Occupational Safety and Health Administration’s (OSHA) standard on fire prevention, 29 CFR 1910.39. The plan helps employees recognize, report, and control fire hazards.

II. BACKGROUND

(Company Name) is committed to minimizing the threat of fire to employees, visitors, and property. (Company Name) complies with all applicable laws, regulations, codes, and good practices pertaining to fire prevention. (Company Name’s) separate Emergency Action Plan outlines procedures for responding to fires. This Fire Prevention Plan reduces the risk of fires at (Company Name/Location) in the following ways:

- identifies materials that are potential fire hazards and their proper handling and storage procedures;

- distinguishes potential ignition sources and the proper procedures for control of those materials;

- describes fire protection equipment or systems;

- identifies people responsible for maintaining the equipment and systems installed to prevent or control ignition of fires;

- identifies people responsible for the control and accumulation of flammable or combustible material;

- describes good housekeeping procedures for ensuring control of accumulated flammable and combustible waste material and residues; and

- provides employee training about fire hazards they may encounter.

Also Read: Fire Extinguisher Classification Meaning

I. ASSIGNMENT OF RESPONSIBILITY

Fire safety is everyone’s responsibility. All employees should know how to prevent and respond to fires, and should understand that they are responsible for adhering to company policy regarding fire emergencies.

A. Management

Management determines the (Company Name) fire prevention and protection policies. Management will provide adequate controls to provide a safe workplace and will provide adequate resources and training to its employees to encourage fire prevention and the safest possible response in a fire emergency.

B. Plan Administrator

(Responsible Person(s)) will manage the Fire Prevention Plan for (Company Name)and will maintain all records pertaining to the plan. The Plan Administrator will also:

- develop and administer the (Company Name) fire prevention training program;

- ensure that fire control equipment and systems are properly maintained;

- control fuel source hazards; and

- conduct fire risk surveys (see Appendix A) with the local fire department and other emergency responders, and make recommendations.

C. Supervisors

Supervisors are responsible for ensuring that employees receive appropriate fire safety training and for notifying (Responsible Person) when changes in operation increase the risk of fire. Supervisors are also responsible for enforcing (Company Name) fire prevention and protection policies.

D. Employees

All employees will:

- complete all required training before working without supervision;

- conduct operations safely to limit fire risk;

- report potential fire hazards to supervisors; and

- follow fire emergency procedures.

Also, Read E-Books: Safety identification: Escape and evacuation plan signs- ISO 23601

II. PLAN IMPLEMENTATION

A. Good Housekeeping

To limit the risk of fires, employees will take the following precautions:

- Minimize storage of combustible materials.

- Make sure doors, hallways, stairs, and other exit routes are free of obstructions.

- Dispose of combustible waste in covered, airtight, metal containers.

- Use and store flammable materials in well-ventilated areas away from ignition sources.

- Use only nonflammable cleaning products.

- Keep incompatible (chemically reactive) substances away from each other.

- Perform “hot work” (welding or working with an open flame or other ignition sources) in controlled and well-ventilated areas.

- Keep equipment in good working order; inspect electrical wiring and appliances regularly and keep motors and machine tools free of dust and grease.

- Ensure that heating units are safeguarded.

- Report all gas leaks immediately to (Responsible Person), who will ensure they are repaired immediately.

- Repair and clean up flammable liquid leaks immediately.

- Keep work areas free of dust, lint, sawdust, scraps, and similar material.

- Do not rely on extension cords if wiring improvements are needed, and take care not to overload circuits with multiple pieces of equipment.

- Ensure that required hot-work permits are obtained.

- Turn off electrical equipment when not in use.

((Responsible Person(s)) will ensure that equipment is maintained according to manufacturers’ specifications. (Company Name) must also comply with requirements of National Fire Protection Association (NFPA) codes for specific equipment. Only properly trained people may perform maintenance work.

The following equipment is subject to maintenance, inspection, and testing procedures:

- equipment installed to detect fuel leaks, control heating, and control pressurized systems;

- portable fire extinguishers, automatic sprinkler systems, and fixed extinguishing systems;

- detection systems for smoke, heat, or flame;

- fire alarm systems; and

- emergency backup systems and the equipment they support.

I. TYPES OF HAZARDS

The following sections address the major workplace fire hazards at (Company Name’s) facilities and the procedures for controlling the hazards.

A. Electrical Fire Hazards

Electrical system failures and the misuse of electrical equipment are leading causes of workplace fires. Fires can result from loose ground connections; wiring with frayed insulation; or overloaded fuses, circuits, motors, or outlets.

To prevent electrical fires, employees will:

- make sure worn wires are replaced;

- use only appropriately rated fuses;

- never use extension cords as substitutes for permanent wiring;

- use only approved extension cords [those with the Underwriters Laboratory (UL) or Factory Mutual (FM) label];

- check the wiring in hazardous locations where the risk of fire is especially high;

- check electrical equipment to ensure it is properly grounded or double insulated; and

- ensure adequate spacing during maintenance.

Also Read: Photo of the day: First Aid for Electrical Burns-Infographic free

B. Portable Heaters

All portable heaters must be approved by (Responsible Person). Portable electric heaters must have tip-over protection that automatically shuts off the unit when it is tipped over. A portable heater may only be plugged into a wall outlet and never into an extension cord or cubicle outlet. Allow adequate clearance between the heater and combustible furnishings or other materials at all times.

C. Office Fire Hazards

Fire risks are not limited to (Company Name’s) industrial facilities. Office fires have become more likely due to the increased use of electrical equipment, such as computers and copiers. To prevent office fires, employees must:

- avoid overloading circuits with office equipment;

- turn off and unplug nonessential electrical equipment, such as coffee pots, at the end of each workday;

- keep storage areas clear of rubbish;

- ensure that extension cords are not placed under carpets; and

- ensure that trash and paper set aside for recycling is not allowed to accumulate.

Also, Read Fire safety for office workers.

D. Cutting, Welding, and Open-Flame Work

(Responsible Person(s)) will ensure the following:

- All necessary hot work permits have been obtained before work begins.

- Cutting and welding are done by authorized personnel in designated areas whenever possible.

- Adequate ventilation is provided.

- Torches, regulators, pressure-reducing valves, and manifolds are UL-listed or FM-approved.

- Oxygen-fuel gas systems are equipped with listed or approved backflow valves and pressure-relief devices.

- Cutters, welders, and helpers are wearing eye protection and protective clothing, as appropriate.

- Cutting or welding is prohibited in sprinklered buildings while sprinkler protection is out of service.

- Cutting or welding is prohibited in areas where explosive atmospheres of gases, vapors, or dust could develop from residues or accumulations in confined spaces.

- Cutting or welding is prohibited on metal walls, ceilings, or roofs built of combustible sandwich-type panel construction or combustible covering.

- Confined spaces, such as tanks, are tested to ensure that the atmosphere is not more than 10 percent of the lower flammable limit before cutting or welding in or on the tank.

- Small tanks, piping, or containers that cannot be entered are cleaned, purged, and tested before cutting or welding on them begins.

- A fire watch has been established.

E. Flammable and Combustible Materials

(Responsible Person) will regularly evaluate the presence of combustible materials at (Company Name) (see Appendix D).

Certain types of substances can ignite at relatively low temperatures or pose a risk of catastrophic explosion if ignited. Such substances obviously require special care and handling.

1. Class A combustibles.

These include common combustible materials (wood, paper, cloth, rubber, and plastics) that can act as fuel and are found in non-specialized areas, such as offices.

To handle Class A combustibles safely:

- Dispose of waste daily.

- Keep trash in metal-lined receptacles with tight-fitting covers. Metal wastebaskets that are emptied every day do not need to be covered.

- Keep work areas clean and free of fuel paths that could allow a fire to spread.

- Keep combustibles away from accidental ignition sources, such as hot plates, soldering irons, or other heat- or spark-producing devices.

- Store paper stock in metal cabinets.

- Store rags in metal bins with self-closing lids.

- Do not order excessive amounts of combustibles.

- Frequently inspect areas where combustibles are kept.

Water, multi-purpose dry chemical (ABC), and halon 1211 are approved fire-extinguishing agents for Class A combustibles.

2. Class B combustibles.

These include flammable and combustible liquids (oils, greases, tars, oil-based paints, and lacquers), flammable gases, and flammable aerosols.

To handle Class B combustibles safely:

- Use only approved pumps, taking suction from the top, to dispense liquids from tanks, drums, barrels, or similar containers (or use approved self-closing valves or faucets).

- Do not dispense Class B flammable liquids into containers unless the nozzle and container are electrically interconnected by contact or a bonding wire. Either the tank or container must be grounded.

- Store, handle, and use Class B combustibles only in approved locations where vapors are prevented from reaching ignition sources, such as heating or electric equipment, open flames, or mechanical or electric sparks.

- Do not use a flammable liquid as a cleaning agent inside a building. The only exception is in a closed machine approved for cleaning with flammable liquids.

- Do not use, handle, or store Class B combustibles near exits, stairs, or other areas normally used as exits.

- Do not weld, cut, grind, or use unsafe electrical appliances or equipment near Class B combustibles.

- Do not generate heat, allow an open flame, or smoke near Class B combustibles.

- Know the location of and how to use the nearest portable fire extinguisher rated for Class B fire.

Do not use water to extinguish Class B fires caused by flammable liquids. Water can cause burning liquid to spread, making the fire worse. To extinguish a fire caused by flammable liquids, exclude the air around the burning liquid. The following fire-extinguishing agents are approved for Class B combustibles: carbon dioxide, multi-purpose dry chemical (ABC), halon 1301, and halon 1211. (NOTE: Halon is an ozone-depleting substance and is no longer being manufactured. Existing systems using halon can be kept in place, but employers must post signs indicating where halon or other agents that pose a serious health hazard are used.)

F. Smoking

Smoking is prohibited in all (Company Name) buildings. Certain outdoor areas may also be designated as no smoking areas. The areas where smoking is prohibited outdoors are identified by NO SMOKING signs.

II. TRAINING

(Responsible Person) will present basic fire prevention training to all employees upon employment and will maintain documentation of the training, which includes:

- review of 29 CFR 1910.38, including how it can be accessed;

- this Fire Prevention Plan, including how it can be accessed;

- good housekeeping practices;

- proper response and notification in the event of a fire;

- instruction in the use of portable fire extinguishers, as determined by company policy in the Emergency Action Plan; and

- how to recognize potential fire hazards.

Supervisors will train employees about fire hazards associated with the specific materials and processes to which they are exposed, and will maintain documentation of the training. Employees will receive this training:

- at their initial assignment;

- annually; and

- when changes in work processes necessitate additional training.

III. PROGRAM REVIEW

(Responsible Person) will review this Fire Prevention Plan at least annually for necessary changes.

Appendix A

Fire Risk Survey

(Company Name/Location)

(Date)

Perform a walkthrough of the facility with the local fire department and other emergency responders to assess the layout of the structures, types, and volume of hazardous chemical storage, and other hazards they may encounter when responding to an emergency. Provide a copy of this survey to local authorities for their records.

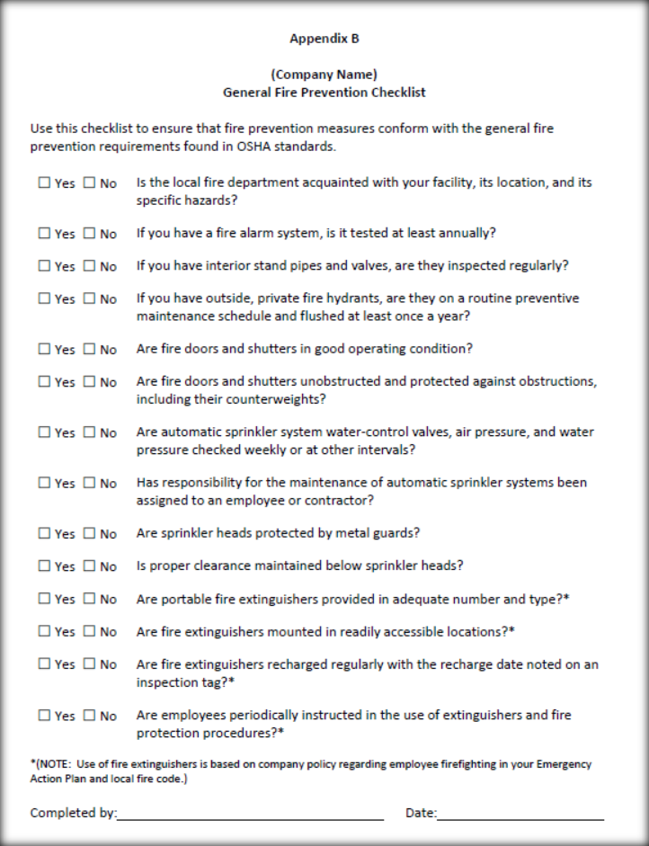

Appendix B

General Fire Prevention Checklist

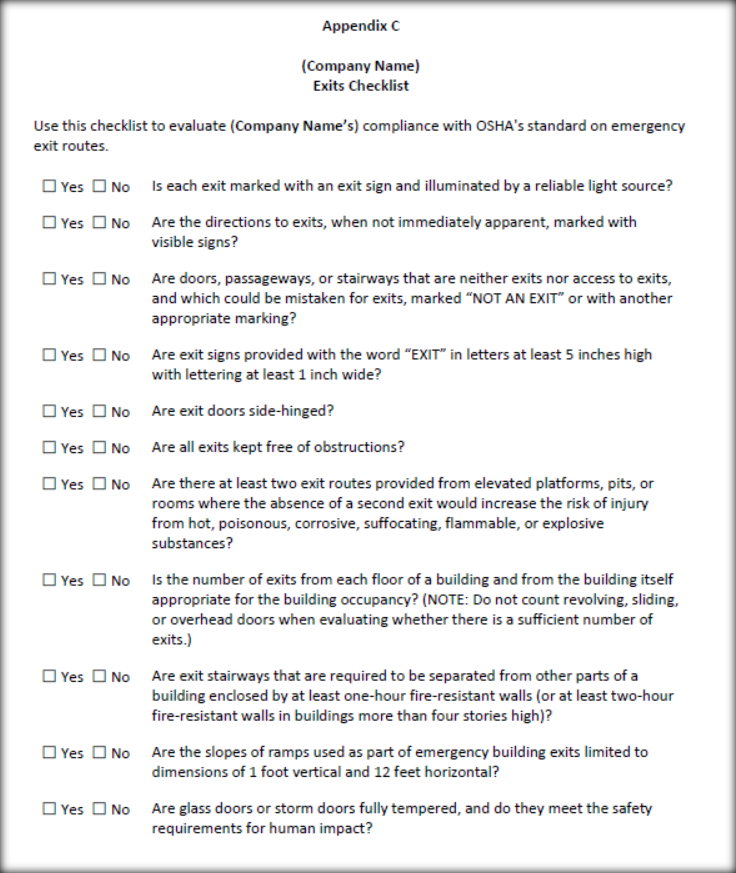

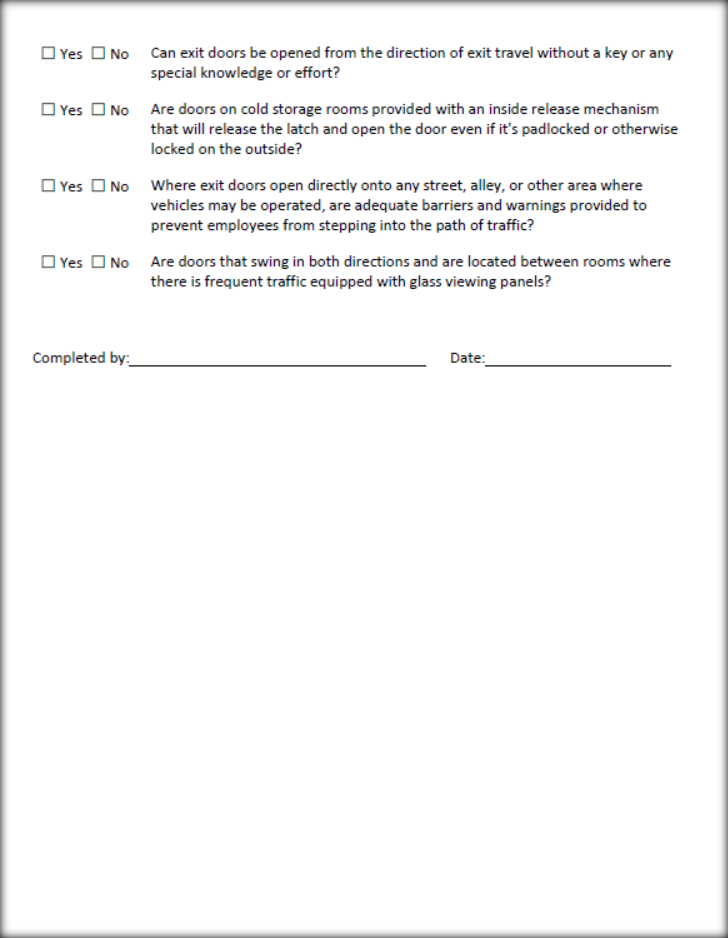

Appendix C

Exits Checklist

Don’t Miss to Download a Free copy of the Sample Written Program For the Fire Prevention Plan

Download the Fire Prevention Plan sample

For many Resources please visit safetybagresources