One of the most important safety measures to prevent any accident in the working of mechanical appliances is what is known as the fusible plug. The working of machines always comes with the risk of incident. So what the manufacturers do is, include certain devices in these machines which could ensure their safety and lessen the risk of any kind of disaster. One such machine is the steam engine, whose working involves tremendously high temperatures in a closed vessel.

In 1803, Richard Trevithick invented the threaded fusible plug. After one of his own boilers exploded during a water leak, he was determined to make a detection device that could offer a means of prevention. so in this article, you will be familiar with

- The fusible plug and how it’s work

- Application of fusible plug

- Advantages and Disadvantages of Fusible Plug

First: What is a Fusible Plug?

A Fusible plug is a type of warning device which operates as a safety valve when dangerous temperatures, rather than dangerous pressures, are reached in a closed vessel (Air compressor, Boiler ).

They are employed on compressed air systems and steams systems, wellheads, etc.

They are considered as a last line of defense and often are used to avert a catastrophic failure occurring, for example, an explosion.

It is also called the Last line of defense.

Note:- While safety valve did the work of protecting machinery and system from overpressure, while fusible plug protect machinery items and system from over temperature.

They consist of a hole that is plugged with an alloy melting to a pre-set temperature. It may be any temperature value higher than the maximum ambient temperature (30° C, or 70 ° C, or 100 ° C).

They are used as safety equipment with the directive to take fire and automatically activate all the sequences to protect the plant and to safeguard the people.

Because of their important safety service, it is necessary that fuse plugs, as well as all the other components included in the system, are designed, manufactured, and installed in the correct way.

A few manufacturers consider the fuse plug a poor component.

There are a wide variety of safety devices put in place to ensure the safety of electrical, as well as mechanical machines.

Application of fusible plug

The fusible plug has found widespread application in many industries because they have a very simple design, they are very effective and improvements to safety and they are also cheap. They are normally installed

- Within compressed air system

2. Coal-fired boiler; Boiler burning light fuel oil (LFO ) or gas are not always equipped with fusible plugs.

( read more Fire and Gas detection systems and types of Fire and Gas Detectors )

Construction of fusible plugs

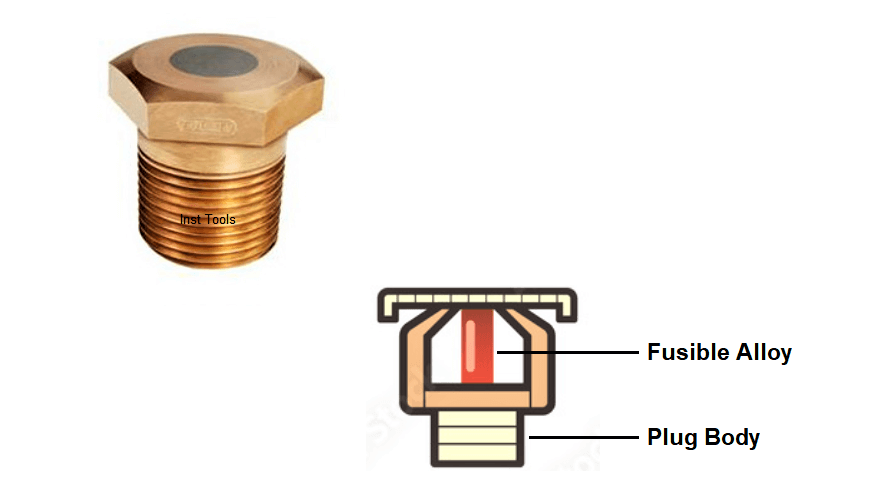

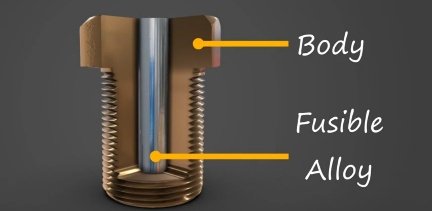

A fusible plug is a threaded metallic cylindrical object usually made up of bronze, brass, or gunmetal, with a tapered hole drilled completely through its length.

This hole is sealed with a low melting point metal that flows away if a predetermined high temperature is reached.

Fusible plug parts

A fusible plug essentially consists of two parts

A) A body and B )fusible alloy channel running through the middle of the body.

It’s from the fusible alloy channel that the fusible plug gets its name.

Material of construction

Fusible plugs are formed with a tapered hole, this hole runs the entire length of the fastener. Materials of construction are brass, bronze, or gunmetal.

The hole is then fixed with a metal sealant, such as tin or lead.

How fusible plug work

Now we know that a fusible plug consists of two parts, the plug body, and the fusible alloy channel, let’s have a look at how it works;

The fusible allow within a fusible plug is designed to melt at a lower temperature than the surrounding plug body.

Fusible alloy melts before plug body.

If the plug is exposed to elevated temperatures, the fusible alloy will melt and a straight or tapered channel will be formed lengthwise through the plug body.

The now open channel allows the system pressure to vent directly to a predetermined location.

Types of fusible plug a/c to actuation

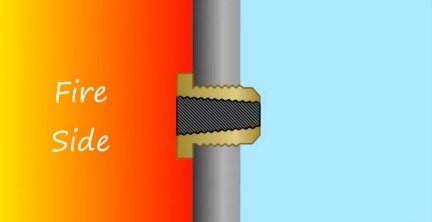

Boiler fusible plugs are classifieds as a) steam-actuated or b)fire actuated and can be installed both on fire tube boilers and water tube boilers.

It is also possible to classify boiler fusible plugs as being either a) fire side or b) water side plugs.

a)Fire side plugs are screwd from the fire side to the water side.

b)Water side plugs are screwd from the water side to the fire side.

The boiler fusible plug usually did the work of venting steam to the firebox which extinguishes the flame of the boiler and thus reduces the temperature and pressure of the steam system.

What is a Fusible Loop System?

The fusible loop system consists of a fusible plug, tubing network, network loop pressure transmitter/switch.

One pressure transmitter or pressure switch is connected across a tubing network consisting of fusible plugs.

Where do we use them?

We mentioned some of the example applications of fusible plug in the below sections.

Electrical equipment

Fusible plug loop systems are installed near the electrical motors of critical applications, or transformers in an oil and gas plant.

In case of the eventuality of fire, fusible plugs get melted due to the surrounding fire. Pressurized air is released from the same fusible plug holes.

A pressure transmitter or pressure switch connected in the loop gets depressurized, an ESD alarm will alert the operator in the control room.

The next step is to extinguish the fire, which will be initiated.

Steam Engines

A fusible plug, also known as a safety plug, or threaded fusible plug. It is one such safety device that is commonly used in steam engines. It ensures that in case of water levels recede to dangerous levels, operators will be alerted by a strong stream of steam, allowing them to take action.

Once in place, the fusible plug carries a good one-inch effect on the water space above it. It works by heating up when the tip is no longer submerged in water, indicating that the levels are too low. As it overheats, its sealant melts, allowing it to become a simple whistle, just like a cup of tea.

This is considered a last resort, as the water level so low at this point would already prove dangerous.

The danger is in the heat of the steam engine’s combustion chamber, particularly that of the combustion gases. They can reach up to 550 ° C, which is dangerous to both the engine and humans.

Aircraft Wheel tire

As a safety measure, to avoid the explosion of tires because of over pressurization due to breaking heat, fusible plugs are provided in all tires’ of aircraft wheels.

Apart from the above, fusible plugs are used in air compressors, refrigeration systems for equipment protection that arise due to high temperature.

Advantages of Fusible Plug

- Fusible plugs are simpler and don’t require any maintenance.

- Fire protection can be provided in a surrounding fusible plug radial field.

- The system is very cost-effective.

Disadvantages of Fusible Plug

- Although useful, threaded fusible plugs can fail. If the sealant rusts or fouls as it ages, it can damage the reliability of the plug.

- Formation of rust conditions can increase the melting point of the metal, which does not react when heated. Some fuse plugs fail to activate even after being exposed to higher temperatures.

- Fusible plug system is slower than heat detectors.

- In some areas, fuse plugs must be replaced after thirty to sixty days of use. This is as per local regulations.

Learn more : Overview of Wellhead Control Panel(WHCP)