Fire and Gas detection system and types of Fire and Gas Detectors

6 min readA fire and gas safety system continuously monitors for abnormal situations such as a fire, or combustible or toxic gas release within the plant; and provides early warning and mitigation actions to prevent escalation of the incident and protect the process or environment.

A typical F&G safety system comprises detection, logic control, and alarm and mitigation functions. Logic solver is the central control unit of the overall F&G detection and control system. The controller receives alarm and status or analog signals from field monitoring devices required for fire and gas detection. The controller handles the required actions to initiate alarms and mitigate the hazard

Components of a Good Fire and Gas System

A good F&G system combines innovative fire and gas detectors, conventional and analog addressable fire panels, clean agent and inert gas fire suppression systems, and a SIL 3-certified fire and gas logic solver into a consistently designed and executed solution. An integrated system provides common tools, operating interface,, and networking, resulting in a common platform with independent systems

Type of Detectors in Fire and Gas Systems

Gas Detectors

Gas Detectors are broadly divided into 2 types:

Flammable Gas Detectors:

Detects the percentage by volume of flammable gas in air in terms of LFL (Lower Flammable Limit) and UFL (Upper Flammable Limit)

Toxic Gas Detectors:

Detects the concentration in ppm of Toxic gas in terms of TLV (Threshold Limit Value)

1. Flammable Gas Detectors:

The three types of Flammable gas detectors are:

- Catalytic Gas Detectors

- Infrared Gas Detectors

- Open Path (Line of Sight) Gas Detectors

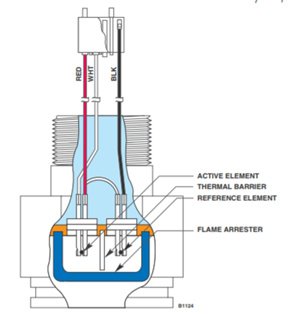

A. Catalytic (Pellistor) Gas Detectors :

Working Principle: Catalytic gas detectors determine gas concentration through oxidization which results in heat, and this is sensed by a bridge circuit. It follows that catalytic gas detectors under-read in the low oxygen atmospheres which exist with gas-rich releases.

SetPoint: Catalytic detectors have a typically recommended minimum alarm setting of 20 % LFL and 60 % LFL to indicate a low and high level of gas

B. Infrared Gas Detectors:

Working Principle: Infrared Gas Detectors make use of the property of Hydrocarbons and other gases to absorb infrared energy at certain wavelengths but not others. For HCs the absorption peak occurs around 3.4 µm. A reference measurement is normally made close to the measurement wavelength that is not absorbed by expected gases. The ratio from the two measurements gives the gas concentration free from variations in signal intensity and detection sensitivity.

SetPoint: Infra-red detectors have a typically recommended minimum alarm setting of 20 % LFL and 60 % LFL to indicate a low and high level of gas

C. Open Path (Line of Sight) Gas Detectors :

Working Principle: Open path gas detectors make use of properties of gases to absorb infrared energy at certain wavelengths but not others. This property coupled with high energy sources enables open path detectors to sense gas over relatively long distances.

SetPoint: Open path detectors have a typically recommended minimum alarm setting of 0.5 LFL m (50 % LFL extended for one meter)

2. Toxic Gas Detectors

Major 2 categories are available:

- Detectors for gases which create an immediate health hazard (eg. H2S, CO, HF, HCl, Cl2)

- Detectors for gases that create a health hazard on long term exposure (eg. Vinyl Chloride, Benzene, Toluene etc.)

H2S detectors:

The two types of H2S detectors available are:

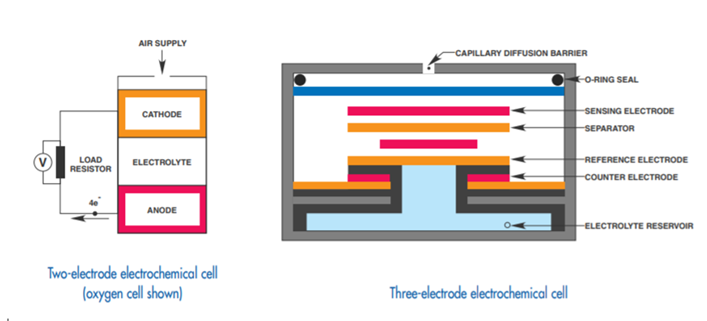

A. Electro-chemical cell type:

This type is based on an electrochemical cell, developed to react exclusively to H2S. As a result of the chemical reaction of the cell organic electrolyte with H2S, an electric current is generated, which is proportional to the H2S concentration in the sample gas.

B. Semi-conductor (MOS) type:

Working principle: The semi-conductor type is based on the adsorption of H2S molecules on the surface of a solid-state semiconductor crystal which causes a change in electrical resistance of the electrical circuit of which the semi-conductor forms the part.

SetPoint: H2S detectors have a typically recommended minimum alarm setting of 5 ppm. If a second stage alarm is used, 10 ppm shall be used.

Fire Detectors

Fire Detectors are broadly divided into 3 types:

- Smoke Detectors

- Ionisation

- Photo-Electric

- Heat Detectors

- Flame Detectors

1. Smoke Detectors:

There are two types of smoke as mentioned above

A. Ionisation Smoke Detector

Detection Principle:

These Detectors have an ionization chamber with an 8 particle radiator consisting of an Americium-241 foil at its center and it ionizes the air inside the chamber.

An electric voltage is applied to the needle electrode and as a result, a known current flows through the detection chamber when the detector is in its normal state. In the event of a fire, minute aerosol particles (soot particles, combustion gases, etc.) attach themselves to the ionized particles. This increases the resistance in the chamber and consequently reduces the current flow within the detection chamber. This change is registered by Detector’s electronics and a fire signal is sent to the Control Panel.

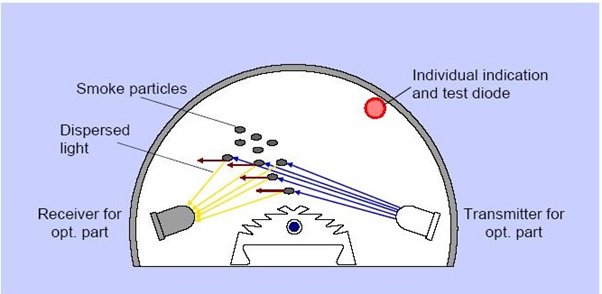

B. Photoelectric (Optical) Smoke Detector

Detection Principle:

The sensor consists of a transmitter LED and a receiver photo-diode. These two devices are installed at a specific angle to one another and separator by a screen, so that light from the LED cannot impinge directly on the receiver diode.

The transmitter LED emits infrared light into the detection chamber. In the event of a fire, visible combustion products enter into the chamber and some of the light emitted by the LED is scattered by the particles so that it impinges on the receiver diode. This naturally increases the signal level generated by the receiver, which is registered by the detector electronics, which in turn triggers the alarm signal.

2. Heat Detectors:

Heat or Thermal Detectors register the increase in temperature caused by a Fire.

Fixed Temperature

It triggers automatically when a preset ambient temperature is reached.

Rate of Rise

In addition to the present trigger temperature, the rate-of-rise detectors also evaluate the speed of temperature increase. If the temperature rises faster than the pre-set amount within a specific period, a rate-of-rise detector will trigger an alarm even if the setpoint trigger temperature has not actually been reached.

Rate Compensated

It responds when the temperature of the air surrounding the device reaches a predetermined level, regardless of the rate of temperature rise.

3. Flame Detectors

- Flame detectors are typically used in open areas outdoors, but can also be used indoors

- Used to protect high risk areas such as oil rigs, fuel stores, petro-chemical plants, hangers etc

- They work by analysing the energy emissions from a fire (UV or IR) not the combustion products such as smoke and heat

- Hot objects (engines / exhausts / heaters) are potential false alarm sources, including the Sun

- Need to distinguish between emissions from a real fire and a false alarm source

- High value detectors covering large areas

The different types of Flame detectors are:

- Ultra Violet detectors

- Single Channel IR detectors

- Combined UV and Single channel IR

- Dual Channel IR flame detectors

- Triple Channel IR flame detectors

- CCTV flame detection

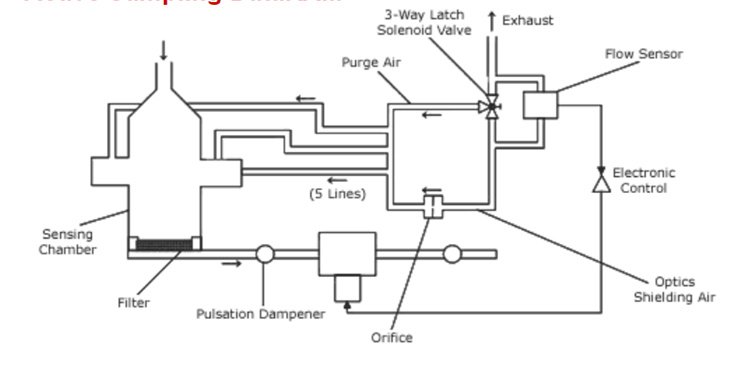

Dust Monitors

Used to measure mass concentrations of dust, smoke, mists, and fumes in real-time, Thermo Electron dust monitors are widely recognized for their reliability, sensitivity, and long-term stability.

Working principle

They are light scattering photometers (i.e, nephelometers) incorporating a pulse, high output, near-infrared light-emitting diode source, a silicon detector/hybrid preamplifier, and collimating optics, and a source reference feedback PIN silicon detector. The intensity of the light scattered over the forward angle of 50° to 90° by airborne particles passing through the sensing chamber is linearly proportional to their concentration. This optical configuration produces an optimal response to particles in the size range of 0.1 to 10.0 µm, achieving a high correlation with standard gravimetric measurements of the respirable and thoracic fractions.

3 thoughts on “Fire and Gas detection system and types of Fire and Gas Detectors”