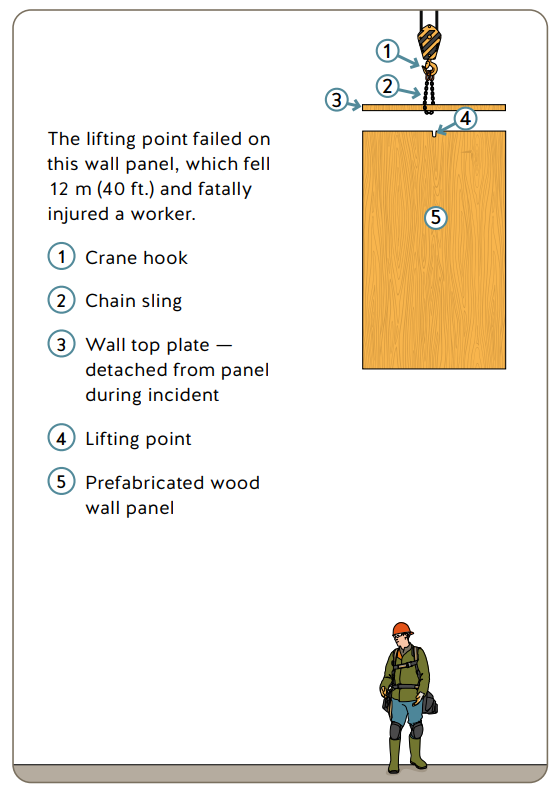

Imagine a crane hoisting a prefabricated wall panel on a multi-story residential site. Without warning, the lifting point fails. The panel plummets 12 meters, striking and fatally injuring a worker below. This tragic, real-life incident underscores a devastating truth: a lifting point failure is not just an equipment malfunction—it’s a potentially fatal event.

In the high-risk environment of construction, understanding and preventing lifting point failures is non-negotiable. This guide breaks down the critical steps every stakeholder must take to ensure that every lift is a safe lift.

Download: E-Books: Hoisting and Rigging Safety Manual

What is a Lifting Point?

A lifting point is the specific location on an item—such as a prefabricated wall, concrete bucket, or mechanical unit—where rigging is attached so it can be lifted by a crane. It is the crucial link between the load and the crane, and its integrity is paramount.

The Hazard: Why Do Lifting Points Fail?

Lifting points fail when the forces applied during the lift (like gravity, dynamic forces, or wind) exceed their strength. This can be due to:

- Inadequate Design or Strength: The point wasn’t designed to handle the load.

- Deterioration: Wear, corrosion, or damage over time compromises its integrity.

- Incorrect Location: Installing the lifting point in the wrong spot, as was a factor in the incident above, drastically reduces its load-bearing capacity.

When failure occurs, the results are often catastrophic, leading to dropped loads, property damage, severe injuries, and fatalities.

How to Prevent Lifting Point Failures: A Role-Based Guide

Prevention requires a coordinated effort from everyone involved in the lifting process.

For Employers:

As the primary responsible party, employers must build a robust safety system.

- Ensure Structural Integrity: Verify that all lifted items and their lifting points can withstand the forces of the lift. Best Practice: Have the manufacturer or a professional engineer determine structural adequacy using standards like ASME B30.20, which recommends a design safety factor of 3.

- Provide and Enforce Instructions: Ensure all equipment comes with clear, reasonable safe-use instructions and that workers follow them.

- Inspect and Maintain: Establish a strict regimen for inspecting, testing, and maintaining all lifting equipment as per the manufacturer’s or engineer’s instructions.

- Respect Rated Capacities: For containers like concrete buckets, ensure the rated capacity is visibly marked and never exceeded.

- Train and Supervise: Provide comprehensive instruction, training, and supervision for crane operators and riggers.

For Suppliers:

Suppliers are the first link in the safety chain.

- Supply Safe Equipment: Provide lifted items that are safe when used according to instructions.

- Provide Clear Instructions: Every item must come with reasonable instructions for safe use. Best Practice: Adhere to ASME B30.20 requirements and engage a professional engineer to help prepare these instructions.

For Crane Operators:

The crane operator is the final authority for initiating a lift.

- Verify Before Lifting: Do not lift an item unless you are satisfied it is safe and has sufficient structural integrity.

- Check for Instructions: Confirm that safe-use instructions exist and are being followed.

- Confirm Inspection & Capacity: Verify the equipment has been properly maintained and that its rated capacity will not be exceeded.

- Assess the Rigger: Confirm the rigger is qualified for the lift’s complexity and has correctly identified and assessed the lifting points. Best Practice: Document this verification process.

For Riggers:

Riggers have a hands-on responsibility for the load’s security.

- Assess Structural Integrity: Be satisfied that the item is safe to lift.

- Follow Instructions: Use and adhere to the provided safe-use instructions.

- Identify and Assess Lifting Points: Correctly identify the lifting points to be used and assess their adequacy.

- Know Your Limits: If you lack the necessary instruction or training for any task, stop and ask for help. Best Practice: Document that all pre-lift checks are complete. (Lifting Plan Audit Checklist )

For Prime Contractors:

Prime contractors must oversee the entire site’s safety ecosystem.

- Verify Systems: Confirm that all employers on site have an effective system to prevent lifting failures.

- Audit Compliance: Ensure that safe-use instructions are available and that crane operators and riggers are following a safe lifting process.

- Enforce Standards: If any party fails to meet their obligations, stop all lifting work until the issues are resolved.

Download: Lift Plan Form

Conclusion: Safety is a Shared Responsibility

Preventing lifting point failures is not the job of a single person; it’s a shared responsibility that spans from the supplier to the rigger. By understanding the hazards, adhering to best practices like the ASME B30.20 standard, and fostering a culture of verification and communication, we can eliminate these preventable tragedies. Always remember: if in doubt, don’t lift.

have more safety resources at Safety Bag