Different industries such as those involved in manufacturing, processing, storing, or transportation of flammable materials, and commercial centers rely on a flame monitoring system for safety. At the core of the system is a crucial component – the flame detector. A flame detector is a fire detector that uses optical sensors to detect it. Here it is emphasized that the flame detector is used to detect the presence of fire, not heat. This device is capable to determine smokeless liquid and smoke that can create open fire. In boiler furnaces flame detectors are widely used, mostly a flame detector can detect heat, smoke, and fire. This device also does fire detection according to the air temperature and air movement. The flame detectors are usually optical devices so they can respond to flame in less than a second. The flame detector would respond to the flame according to the installation, it would sound an alarm and also deactivate the fuel line or it would activate a fire suppression system.

In this article, you will be familiar with

- Flame detectors component and how does it works

- types of Fame Detectors

- Applications of Flame detectors

What are the components of a flame monitoring system? How does a flame detector work?

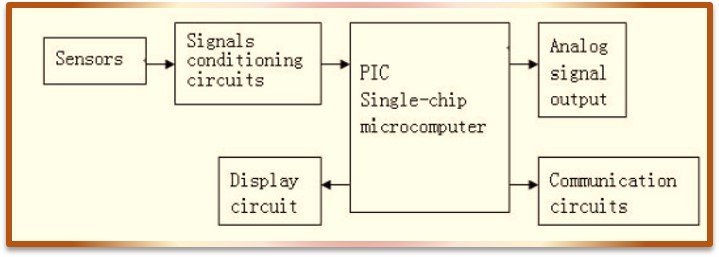

The major component of a flame detector system is a flame detector and it consists of photoelectric detective circuits, signal conditioning circuits, microprocessor systems, I/O circuits, and wind cooling systems.

The sensors in the flame detector will sense the radiation that is sent by the flame, the sensor of the flame detector would be a photoelectric sensor and this sensor would convert the radiant intensity signal of the flame to a relevant voltage signal and this signal would be converted after that it would be processed in a single chip microcomputer and is converted as output.

However, in its implementation, there are other light sources that are apparently not fire and contribute to the emission of light on infrared and ultraviolet waves where these light sources also affect the performance of the flame detector which results in false alarms.

Examples of these light sources are lightning flashes, welding arcs, metal grinding, hot turbines, reactors, and many more.

Types of Flame Detectors

There are many different types of flame detectors available in the market today. Some of the key types are briefly described below:

Infrared (IR) Detector

The infrared flame detector works on the infrared spectral band. The hot gas will emit a specific spectral pattern in the infrared region, where it will be censored by a Thermal Imaging Camera (TIC), a type of thermographic camera.

False alarms can be caused by other hot surfaces and thermal radiation in areas that are obscured by water and solar energy. The frequency in a Single IR Flame Detector has a sensitivity in the range of 4.4 micrometers with a response time of 3-5 seconds.

Ultra Violet (UV) Detector

Ultra Violet Detector works at wavelengths below 300 nm. This detector detects fires and explosions between 3-4 milliseconds through UV radiation emitted during ignition.

False alarms will be triggered by UV sources such as lightning, arc welding, radiation, and sunlight. And in the design of this implementation of UV Flame Detector, a time delay of 2-3 seconds is often used to reduce the intensity of false alarms.

Dual IR (IR / IR) Detector

The Dual IR flame detector compares the initial signal in the two infrared ranges. In this case, one sensor works in the range of 4.4 micrometers and the other sensor is at a reference frequency.

UV / IR Detector

UV / IR flame detector compares the initial signal in the two infrared ranges, namely the “AND” configuration and the ratio are related to each other to ensure the fire signal and minimize false alarms.

UV / IR and Visible Detector

For some detectors, a sensor for visible radiation will be added to the design with the aim of being able to better deal with false alarms or improve the detection range.

Triple IR (IR / IR / IR) Detector

Triple IR flame detectors compare three specific wavelength bands in the infrared spectral region and their ratios in relation to each other for reliable detection of fire in order to reduce false alarms.

In this case, one sensor will work in the range of 4.4 micrometers and the other sensor at the reference frequency. Triple IR detectors are also at risk of blurring caused by water and reduced sensitivity by sunlight.

CCTV (Video) Flame Detector

Closed-circuit television (CCTV) or web cameras can be used for video detection (wavelengths between 0.4 and 0.7 µm). like humans, cameras can also be blinded by smoke and fog.

In the development of the seven types of detectors, the last three types of flame detectors (UV / IR and Visible Detector, Triple IR Detector, and CCTV Flame Detector) are the most mentioned by the manufacturers to replace the other four detectors, especially UV / IR Detector which actually widely used but also many false alarms caused by objects, lightning, or heat caused by metals (among others: pipes) due to the sun’s sting, causing a puff of heat. And that’s why also at this time these three types of flame detectors are widely used in industry as an initial fire detector.

Selection of a flame detector

- It must be selected according to the nature of fire there are many types of flame detectors available so select one of them

- According to the protected area

- Environmental conditions

- It must be selected according to the detector capability

- It must be selected according to the dimensions of the protected area

- It must be selected according to the radiation characteristics of the flame

- It must be selected according to detectors response time

- Rejection of false alarm

( Know the Basic Guidelines for Selection of Fire and Gas Detectors )

Installation of a flame detector

- It must be installed according to the viewing angle of the detector

- Detection range

- We must also consider obstructions such as beams, girders, etc.

- High-risk fire ignition areas

- We must also consider the mounting height too.

What do we connect a flame detector to?

The detector can be connected to a fire alarm panel and it can be a part of the site detection system. The warning device and suppression system can be operated and the power supply to the detector can be monitored too. The detector can be connected to a flame detector control panel and this is only done if the site does not have a fire alarm panel. A flame detector can also be connected to a site monitoring system. (Gas Leak Detection System)

Applications of flame detector

- Industrial warehouses

- Chemical production plants

- Chemical stores

- Petrol storage and pump stations

- Arc welding workshops

- Power plants

- Transformer stations

- Underground tunnels

- Motor testbeds

- Wood stores

( Read more about Fire and Gas detection systems and types of Fire and Gas Detectors )