If you have workers at heights, you probably already know that you need to provide adequate fall protection and fall arrest systems to keep them safe. And while we all know what guardrails are for and how much protection a fall harness offers, there are some things we often overlook.

Your fall protection gear is inspected, donned properly, connected to appropriate anchorage with clearances figured out, and you confidently set to work. In a moment of inattention, you step close to an edge and the uneven footing causes you to stumble and fall. Next thing you know, you’re dangling a few feet above the ground, shocked but unharmed because your fall protection gear worked as designed.

This is the best-case scenario when a fall happens. That’s how we hope the story goes, but in reality fall protection planning has to consider additional and sometimes less talked-about hazards. Here are five that should not be overlooked.

Employees working from an unprotected elevation starting at 6 feet or more must use fall protection equipment, whether they are traveling or stationary. The 6 foot fall distance is measured from the employee’s feet to the walking and working surface below. This applies to unprotected sides and edges, leading edges, hoist areas, holes and floor openings, formwork and reinforcing steel, excavations, roofing work, precast concrete erection, and other walking/working surfaces.

There are different control methods that can be employed to deal with fall hazards. These come in the form of fall prevention systems and they include guardrail systems, scaffolds, aerial lifts, barricades, and hole covers. Other fall protection measures include the use of personal fall arrest systems and safety net. You will also need to provide protection from falling objects and slips and trips from the same level. The use of “controlled access zones” is not permitted.

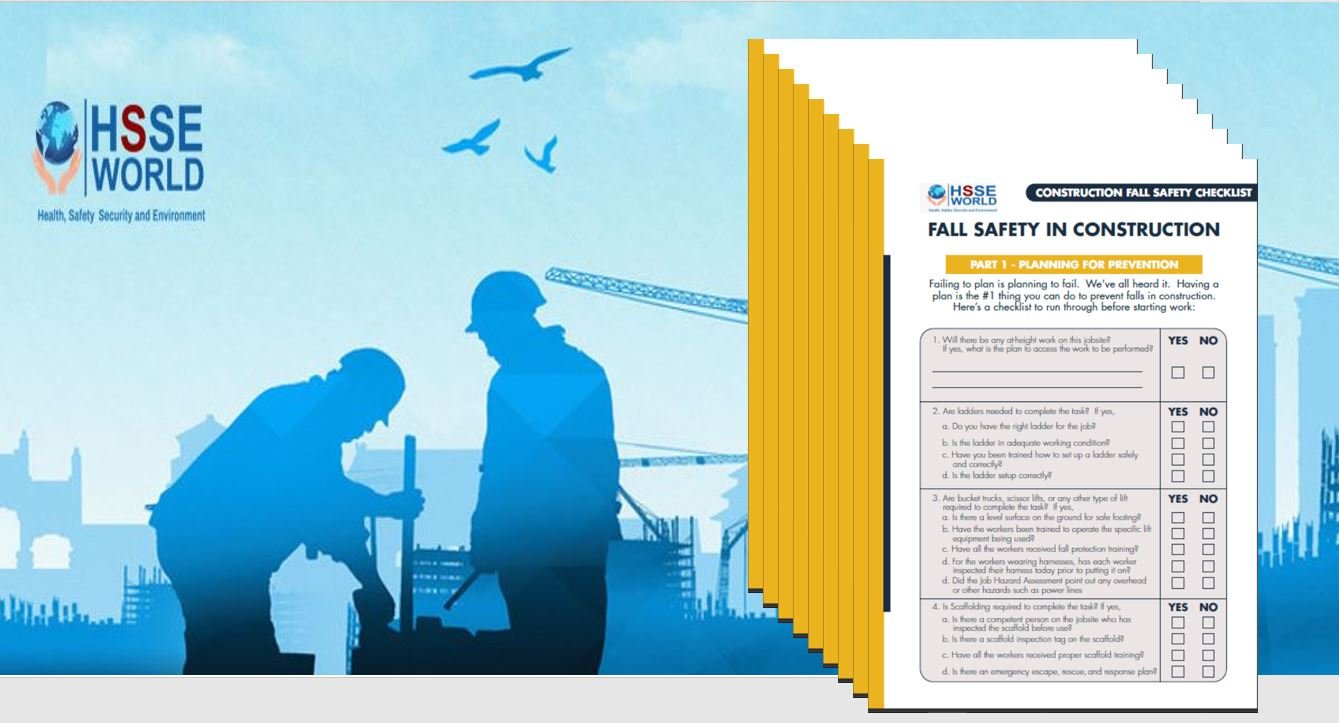

HSSE World offer you a go by of Construction fall safety checklist to ensure Safe implantation of fall protection system the checklist include :

- Part 1 – Planning for Prevention

- Part 2 – Equipment Inspection

- Part 3 – Equipment Inspection Log