The sounds of heavy construction equipment rumble across active work zones along roadways. In 2019, more than 26,000 crashes, resulting in 690 serious injuries and 167 deaths, occurred in construction and maintenance work zones statewide in Texas City. Five construction workers, 138 motorists or passengers, and 24 pedestrians or bicyclists were among those killed. The leading causes of these accidents speeding and driver inattention are preventable so in the article below we will outline the following to ensure driving safely in work zones:

- Work Zone Safety is Everyone’s Responsibility

- Accident Prevention for Road Workers

- Accident Prevention for Motorists

Also Read: Safe work site Design for Traffic Management

Work Zone Safety is Everyone’s Responsibility

Many road construction employees are working on over 1,000 miles of projects underway on roadways at any given time. These work zones are hazardous environments for road workers, motorists, passengers, cyclists, and pedestrians alike. The dangerous combination of on-foot workers laboring beside large tractors, bulldozers, rollers, and other moving machinery is made more hazardous by the daily stream of traffic passing close by these work zones.

Work zone safety is everyone’s responsibility. It takes:

- engineers, contractors, and traffic control plan supervisors to properly plan and design the work zones;

- flaggers to guide the public through the work zones;

- drivers, cyclists, and pedestrians to remain alert and pay attention while entering and driving through the work zones; and

- local and state government, area police, and emergency responders to help ensure that everyone goes home safe at the end of the day.

Engineers

Before any roadwork begins, engineers survey and design each work zone in advance. Surveys include the locations and clearances of utility lines and gas pipes. Engineers must call “Authority” sources, to help identify these and other potential buried equipment or hazards

Also Read: Defensive Driving and Traffic safety tips

Contractors or Project Managers

The contractors, or project managers, use the survey to oversee and allocate resources for the road construction project. They are responsible for ensuring all work zones comply with the Federal Highway Administration’s (FHWA) Manual on Uniform Traffic Control Devices for Streets and Highways (MUTCD) and the Occupational Safety and Health Administration’s (OSHA) rules and regulations on excavations and signs, signals, and barricades.

The MUTCD contains specifications for designing and correctly marking traffic control areas, as well as information on worker training, personal protective equipment, and lighting. OSHA offers standards that must be followed to minimize potential infra- structure hazards from outside and inside the work zone.

Traffic Control Plan Supervisors

If a traffic control zone is needed, an experienced traffic control plan (TCP) supervisor begins working with engineers during the planning phase. The TCP supervisor helps ensure a plan is in place so motorists can move safely through the work zone. They are responsible for monitoring the work zone throughout the duration of the project and making any corrections needed. They also determine the placement of control signals, message boards, and barriers to safely direct traffic.

Concrete walls, water-filled barriers, crash cushions (attenuators), and sandbags are devices TCP supervisors may use to implement safety best practices.

Internal Traffic Control Plan Supervisors

Depending on the size of the project, a separate internal traffic control plan (ITCP) supervisor may be needed to help control the movement of workers, vehicles, and equipment within the work area. The ITCP supervisor works closely with the traffic controllers, project managers, and construction supervisors to make an effective plan to help keep workers safe. This plan must be modified as the work progresses and conditions in the work area change.

Flaggers

In some work situations, the TCP supervisor may place flaggers at the beginning or middle of the activity zone. When used, flaggers set up traffic cones and signs around work zones and direct traffic using hand signals and signs. They may also use radios to communicate with other flaggers positioned along the work zone to help coordinate two-way traffic on single-lane roads. Working with the construction crew, flaggers also alert workers to other traffic concerns that might impact workplace safety. During hazardous conditions, such as limited visibility or high-speed traffic, alternative traffic control methods should be used instead of flaggers.

Also Read: Photo of the day: Flagman and Traffic control

Drivers, Cyclists, and Pedestrians

Any vehicle has the potential of becoming a deadly weapon. Add a distracted driver texting or answering the phone while driving and the chances of a fatal accident increase dramatically. When a distracted driver enters a work zone, the likelihood of a fatality is even greater. Drivers who speed, cut through traffic or become distracted cause fatal accidents on both sides of the work zone. Drivers must remain alert and pay attention, especially when driving through work zones. Drivers can also help save lives by obeying traffic laws and signs, wearing seat belts, acting responsibly, and avoiding distractions.

Local and State Government, Area Police, and Emergency Responders

Everyone is responsible for work zone safety. Local and state governments can help promote roadway safety by increasing public awareness about work zone hazards. By enforcing the traffic laws, police also provide work zone safety. Additionally, the presence of patrol officers reduces the likelihood of vehicles speeding through work zones. Emergency responders must also be available to respond to and secure crash locations. Everyone has a job to do to keep work zones safe and maintain the roadway systems that help keep communities connected and goods moving.

Accident Prevention for Road Workers

Traffic Control Plan

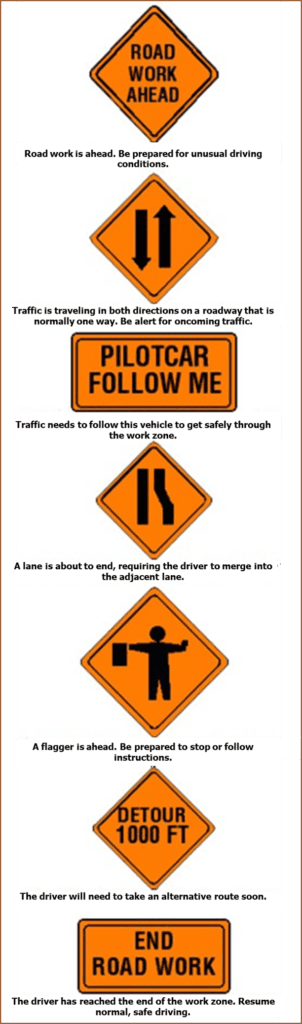

Work zones are marked by cones, barrels, signs, signals, or lane changes. In these areas, signs must be clear, short, and spaced so that the needed information is understood in time for the driver to safely perform the needed maneuvers. Spacing is based on the speed limit where the driver first encounters the signs. These signs should state that the area is a construction or work zone and that fines double when workers are present. They should also indicate where the work zone begins and ends. Other signs may encourage drivers to slow down, use extra caution, or prepare to take a detour route.

If warning lights are in use, ensure light levels are adjusted in a timely manner. Bright daytime lighting can blind drivers in dark hours, and dimmer night levels are difficult to see in daylight hours.

The FHWA concludes that the most effective warning device is an occupied, marked police vehicle with its warning lights flashing. These should be used whenever possible for work zones on roads with high-speed traffic control zones. Marked police vehicles are also recommended in high-traffic urban areas where the work zone is close to traffic control lanes. Despite traffic signs, warning lights, and marked police vehicles, many drivers speed through construction zones. Multiple methods must be used to tackle these dangers.

- Close the road and reroute traffic, when possible. Keep the length of the control zone appropriate to the size of the work zone so drivers do not speed up after passing through a long stretch with no workers.

- Establish a detour route, when possible. If an alternate detour route is available to allow motorists to avoid the work area, place advisory and directional signs before the detours exist. Ensure the signage includes information and instruction on how to safely travel through the rest of the zone.

- Use an advanced warning section. Advanced warning sections may include warning signs, rumble strips, and radar transmitters to advise motorists of an approaching work zone.

- Create a transition section. Following an advanced warning section, the transition section directs traffic into safe lanes using cones and barricades. The transition section must be designed so that motorists do not have to change speed or direction quickly.

- Establish an activity section. The activity section is adjacent to the actual work zone. It should include a buffer zone constructed of strong barriers to separate and protect workers from traffic. These barriers should be placed parallel to the work zone.

- Use flaggers as needed. If flaggers must be used, ensure they are trained in traffic control, as well as procedures to safely allow needed emergency vehicles into the work zone. Training should include techniques to help them gain and maintain eye contact with motorists and how to be courteous, yet firm when communicating with drivers in words and gestures.

Also Read: Photo of the day: How to Avoid the Fatal Four

Always place flaggers in locations that are easily visible to oncoming drivers. Make sure they have an escape route. Never place flaggers in the shadows or close to construction workers. All flaggers must wear bright warning vests, hard hats, and white outer garments (except in snow or fog). Each flagger should be equipped with “Stop” or “Slow” paddles with built-in strobe warning lights. Even when flaggers are in visual contact with each other, ensure they have radios (with extra batteries) to back up their visual communication and to report emergencies.

- Report Problems Immediately. Encourage all employees to quickly report any problems they may witness in the traffic control zone.

- Use pilot cars as needed. In situations where work zones require long, single-lane traffic, a pair of specially- marked pilot cars can lead groups of traffic back and forth through the activity section.

- Finish with a termination section. The final section of the traffic control zone — the termination section – uses channeling devices and signage to return traffic to normal speed and lane configuration.

Test Work Zone Effectiveness

Once the traffic control zone is in use, the TCP supervisor verifies its effectiveness by walking or riding the zone at varying times based on weather conditions and traffic volume. Among other potential hazards, the TCP supervisor is looking for:

- evidence of near misses, such as skid marks or damaged signage and barriers;

- dirty reflective signs that must be cleaned to preserve their reflective intensity; and

- waste materials that may need removal.

Internal Traffic Control Plan

In addition to the traffic control plan which focuses on moving motorists safely through a work zone, an internal traffic control plan (ITCP) protects the people in the work area itself. The ITCP focuses on keeping pedestrian workers from being struck by work vehicles and equipment in the work area and ensures all parties are informed about the locations of others. Objectives of an ITCP may include:

- designating areas where only pedestrians are allowed or only vehicles are allowed;

- scheduling work activities so that pedestrians and vehicles are not present in the same area at the same time;

- posting and enforcing safe speed limits in work activity areas;

- posting other in-zone signs to alert workers to clearances below high voltage lines, blind corners, and hazardous drop-offs for machine operators; and

- establishing an operations communications plan that includes a universally-accepted set of hand signals for all workers.

Training

Mandatory safety training for all workers is required prior to their entry into the work zone. Workers must be trained to:

- always remain aware of their surroundings, in all types of weather, and in both daylight and nighttime hours;

- work with mixed pedestrian and machinery traffic to develop effective communications;

- approach vehicles, if on foot, only after making eye contact with the operator;

- maintain visual contact with spotters and machine operators during operations;

- instruct new spotters on any blind spots around machinery;

- use proximity sensors or cameras at blind spots to warn equipment operators of pedestrians and smaller vehicles, when possible;

- utilize radio communications between spotters and operators for extra safety;ensure that panic stop bars are installed in appropriate locations and pedestrian workers know how to turn off the machine’s motor in threatening situations;

- watch for red flags or tall antennas (designed to increase visibility) on smaller construction vehicles, like pickup trucks;

- ensure large machinery is marked with strobe lights for additional visibility;

- ensure roll-over protection for equipment operators is always in place ;

- ensure fall protection is provided any time workers are working more than six feet above a lower level;

- ensure respiratory protection against silicosis is provided in areas where concrete cutting or mixing is taking place;

- inspect each piece of machinery daily using checklists that should be set up prior to starting operations;

- use proper lockout/Tagout procedures when equipment maintenance must be performed in a work zone; and

- place lighting for night work in a manner that will not blind operators or workers in the work zone.

Accident Prevention for Motorists

Drivers and passengers are more likely than highway workers to be hurt or killed in work zone accidents. Whether traveling for work or pleasure, motorists should consider these tips when driving through a work zone:

- Plan ahead. Plan trips in advance and drives an alternative route when possible.

- Be patient. Show courtesy and slow down for road workers. They may be working in conditions with low visibility, congestion, or inclement weather.

- Avoid distractions. Drivers need full focus on the roadway. Avoid distractions, such as cell phones, music, navigation systems, and other non-driving tasks. A texting driver is 23 times more likely to crash. Sending or reading a text can divert eyes from the road for about 4.6 seconds. At 55 mph that is like driving with closed eyes for the distance of a football field.

- Watch for warning signs. Look for the orange and black signs that give warnings and information.

- Obey the posted speed limit. Road workers or equipment may be only feet away from motorists. Stay alert and drive safe.

- Follow traffic control commands. Respond promptly to flaggers and road workers.

- Do not tailgate. Create a space cushion, or distance, of four seconds or greater between other motorists. Watch for brake lights on vehicles ahead.

- Avoid abrupt driving maneuvers. Use caution on lane elevation changes, degraded road surfaces, and areas where the pavement ends to keep from losing control. Motorcyclists and bicyclists traveling through work zones should pay particular attention to these dangers.

- Avoid lane changes. Change lanes only where pavement markings or signs indicate it is allowed and only when traffic conditions permit.

- Prepare for traffic pattern changes. Be aware that traffic patterns can change daily in work zones.

- Expect the unexpected. Work zones are constantly changing. Heavy construction equipment and large earthmovers are often near the roadway and may enter a driver’s lane with little warning.

- Merge early. Drivers should merge into the proper lane well before reaching a lane closure.

- Use turn signals and headlights. When traveling in a work zone, always use turn signals and the vehicle’s headlights to become more visible to workers and other drivers.

Everyone plays a part in work zone safety. It is each person’s responsibility to help ensure drivers and road workers reach their most important destination. Home!

Also, Read: Construction Site Traffic Management Plan (CSTMP) Guidance

Please visit our Safety Resources SAFETY BAG to have many Safety Resources