Many dusts are combustible, which means they can catch fire and burn. When fine dust particles catch fire while they’re suspended in the air, known as deflagration, fire can spread rapidly and sometimes leads to an explosion.

Industry sectors that typically generate combustible dust, such as bakeries, metal foundries, and sawmill operations, need to recognize and control these risks in order to prevent a devastating workplace incident.

How workers are exposed

Workers in almost every industry involved in product manufacturing will be exposed to dust, and often that dust will be combustible. Specifically, workers who transport, handle, process, polish, ground, or shape a variety of workplace materials can be exposed to combustible dust. Workers can also release combustible dust when they take part in abrasive blasting, cutting, crushing, mixing, sifting, or screening dry materials.

Common sources of combustible dust are as follows:

| Industry | Material |

| Agriculture | Fertilizers, grain |

| Food and beverage processing | Grain, sugar, flour |

| Machining and manufacturing | Wood, fabric, metal, plastic, rubber |

| Coal mining and processing | Coal |

| Chemical products manufacturing | Pharmaceuticals |

The risks

When dust is exposed to enough heat or even a spark, it can ignite. When airborne dust is near a fire, it often results in an explosion. Poor work procedures can stir dust into the air, and something as simple as a spark from welding or a hot machine motor or bearing, for instance, is all it takes to trigger an explosion.

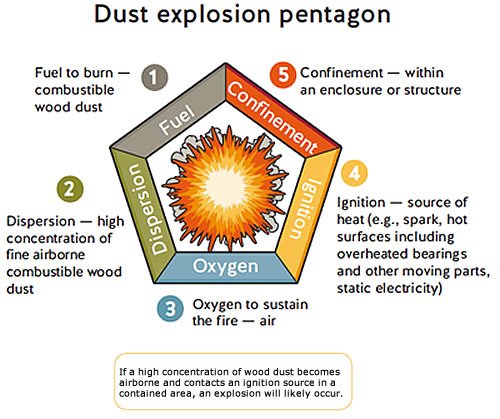

In order for an explosion to occur, the following five factors need to be present: fuel, dispersion (making the dust airborne), oxygen, ignition, and confinement.

When all five factors are present, it can result in an explosion. When a combustible dust explosion occurs, it is often followed by one or more subsequent explosions. The first explosion stirs up dust that has settled on surrounding surfaces and forms a dust cloud. The dust cloud can fuel a second explosion, which typically starts almost immediately after the first.

Warning about combustible dust fires

Unless you have been properly trained, do not attempt to fight a combustible dust fire. If you do so improperly, you could disturb accumulated combustible dust. This could trigger an explosion or a fireball. Instead, sound the alarm, alert designated responders, and follow evacuation procedures.

How to reduce the risks

Dust control is the single most important factor in preventing fires or explosions in any dust-generating workplace. Effective dust control can reduce the risk of a catastrophic fire or explosion in the workplace. However, if a dust control system isn’t designed or working properly, it may create conditions that would support a dangerous fire or explosion.

The most effective way to reduce the risk associated with combustible dust is to eliminate its source. If that’s not possible, you can use other risk controls. When you’re choosing risk controls, start by asking yourself the questions contained in the following steps, which are listed in descending order of effectiveness.

- Elimination or substitution

Eliminate the hazard by substituting a safer process or material where possible, which is the most effective control. Some questions to consider:

- Can you use a different material that does not produce combustible dust?

- Can you use a different process that does not generate any dust?

- Engineering controls

Make physical modifications to facilities, equipment, and processes to reduce exposure. Some questions to consider:

- Has your dust collection system been properly designed by an engineer?

- Is your dust being captured at the source?

- Is your dust collector located outdoors?

- Does your dust collector have appropriate explosion venting?

- Are you able to minimize ignition sources and contain sparks or flames?

- Are dust and product conveyance and handling systems designed to minimize dust from spreading?

- Can you use misting to keep dust from dispersing?

- Administrative controls

Change your work practices and policies and provide awareness tools and training to limit the risk of combustible dust. Some questions to consider:

- Have you developed a dust management program, including a risk assessment of all work areas where combustible dust is produced or may accumulate, all potential ignition sources, and all means of dust dispersion?

- Do you properly inspect, measure, and monitor dust accumulations?

- Do you have effective manual clean-up and housekeeping programs?

- Have workers received suitable training and orientation?

- Do you have an emergency preparedness plan?

- Have you developed and implemented safe work procedures to minimize fire and explosion risks?

- Personal protective equipment

Personal protective equipment is not an effective control measure for combustible dust explosions. However, where dust is produced you may also have other hazards to assess. Some questions to consider:

- Do workers have the proper respirators, eyewear, and protective clothing

One thought on “Combustible dust”