A workplace explosion caused by a worker incorrectly using acetone in a chemical experiment might have been prevented if the company had undertaken more stringent risk control measures and had trained their staff in emergency procedures.

It happened at a pharmaceutical company in Ireland and the man who made the error died from horrific chemical burns, while his co-worker was terribly injured. So terrible were the injuries in fact, that the ambulance attending the scene was actually de-commissioned later; it was so badly damaged from the chemicals.

But the real tragedy is that when the men realized their error they rushed to the main floor to shut down the experiment, and actually ran into the explosion. Had they stayed in the control room they would have been safe.

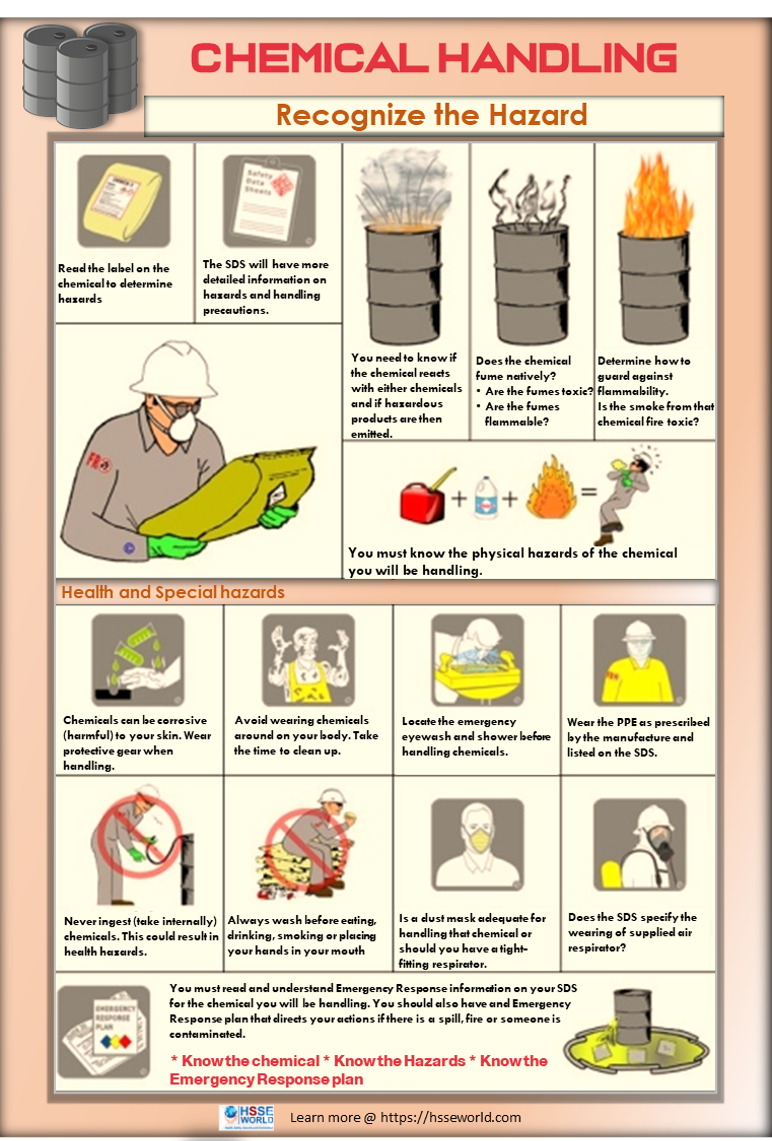

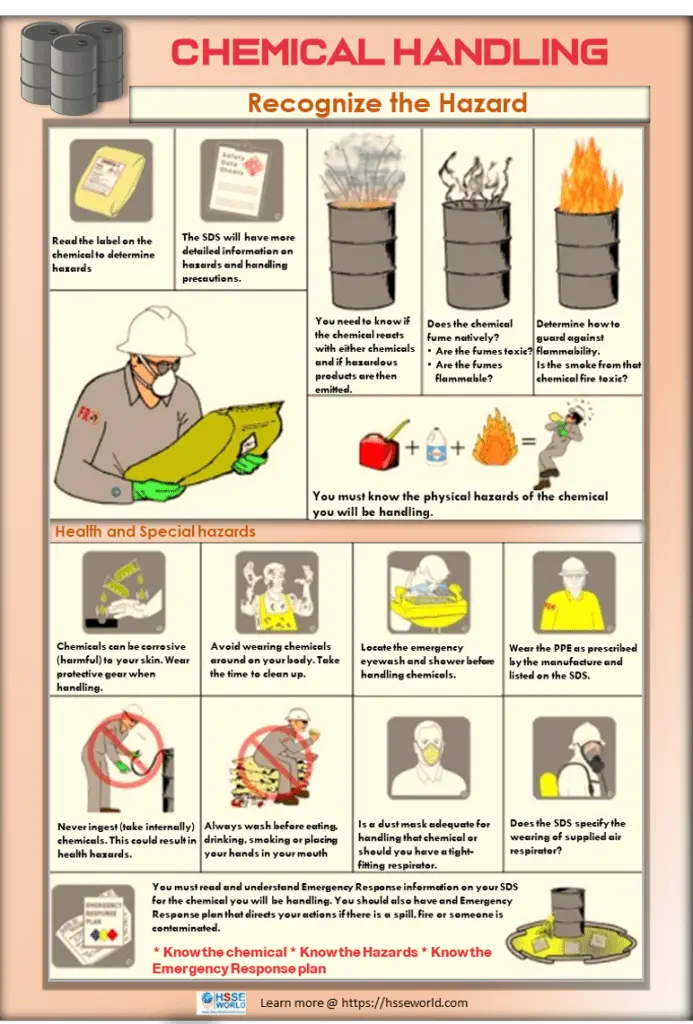

The photo of today is about some of the control measures you can implement at your workplace to keep people safe when handling hazardous chemicals. And while the men in the example above were undertaking a complex chemical experiment. in addition, we provide a free booklet for a three-step approach whereby a small business can safely manage its chemicals

Using chemicals at work

Most workplaces contain hazardous chemicals. Whether you’re using hazardous chemicals for manufacturing, metal fabrication, petroleum processing, or simply just for cleaning the floors … there is a risk involved.

Your job is to minimize the likelihood that someone at your workplace could be harmed by those chemicals. Usually, the best place to start when learning to safely use chemicals in any workplace is with the safety data sheets (SDS). An SDS arrives with each chemical from the supplier.

Safety Data Sheets (SDS)

The Safety Data Sheet (SDS) is a mandatory document that describes a hazardous substance and details advice on how to use it safely. Every SDS contains information about…

- The chemical makeup

- Mandatory labeling and signage

- Hazards

- Health effects

- Exposure control and required PPE

- First aid

- Safe handling and storage

- Emergency procedures

- Disposal

By beginning with the SDS you can identify the type of chemicals you are using and the risks and hazards associated with each of them.

Hazard types associated with chemicals

Let’s look at six different types of hazardous chemical and the hazards associated with each of them.:-

Explosives:

Explosives are volatile and a serious threat to the health and safety of staff, emergency responders, building occupants, chemical waste handlers, and disposal companies. Check the SDS closely to see how they become explosive (subjected to heat, light, friction, or mechanical shock) and make sure they are handled carefully (train your staff incorrect manual handling procedures) and are stored and dispensed away from ignition sources. Explosives must also be kept away from incompatible substances to avoid violent chemical reactions

Because there is still a lot of uncertainty regarding the hazards and safe handling of explosive chemicals it is essential to train your staff in emergency procedures. What’s the worst-case scenario if an explosion did occur? How would staff respond? Remember the two workers killed in Ireland because they had no idea what to do in a chemical emergency? Don’t let this happen at your workplace.

Flammables:

Flammable chemicals catch on fire and burn easily at normal working temperatures. You find them in just about every workplace: fuels, solvents, thinners, cleaners, adhesives, paints, waxes, and polishes. Make sure they are stored and dispensed away from heat and ignition sources.

Flammables are often toxic and corrosive so you should also check the SDS to find out the other hazards associated with the chemical.

Oxidizers:

Oxidizers are dangerous for three reasons:-

- They start fires quickly and make them more intense

- They can start a fire without a spark or a flame

- They can cause substances that usually burn slowly to burn faster and hotter

Oxidizers must be stored away from other chemicals as well as heat and ignition sources. Developing safe handling procedures is essential because many oxidizers can react dangerously to shock and friction. Remember also that oxidizers can be toxic and corrosive so check each SDS closely.

Self-reactive chemicals:

Self-reactive chemicals are particularly dangerous because they can detonate, explode or catch fire even without oxygen. Sometimes all it takes is sunlight, slight heat, friction, mechanical shock, or contamination with incompatible materials. Read the SDS carefully and follow the advice we’ve given above for explosives.

Along with explosives, it’s critical that your organization has clear manual handling procedures and staff are trained in emergency procedures in the event of an explosion. If friction is a source of ignition, safe storage of the self-reactive chemical is critical.

Toxic substances:

Toxic chemicals are poisonous to our human bodies and can cause harm by being swallowed, absorbed, and inhaled, or have them contact with our skin. Toxic chemicals nearly always require the use of Personal Protective Equipment (PPE) and you should check the SDS to make sure you have the right equipment.

It’s not enough to have PPE on site. Train staff how to use PPE properly as well as what to do if they are exposed to the toxins. You may need eyewash stations, breathing apparatus, and first aid equipment.

Corrosives:

Corrosives are very dangerous because they attack and destroy body tissue. Like toxins, they can enter the body through breathing, ingestion or direct contact with the skin. Please make sure you have adequate PPE and all your staff actually use it. Safety glasses and masks are useless hanging on the wall.

Again check the SDS for each chemical and address each of the hazards and safety concerns. And for all types of chemicals, you should also have a master register of what is being used and stored onsite.

Hazardous Chemical Register

A hazardous chemical register is a record of all the hazardous substances used at your workplace. This register must contain the SDSs for each substance and be accessible to all your workers. The register will contain critical information about emergency responses, poisons information, first aid, and treatment; so it’s not enough to place the SDSs in a filing cabinet and send a memo. Your staff needs to know exactly where it is and be able to easily grab it in an emergency.

NOTE: the Hazardous Chemical Register should also be easily accessible to emergency personnel responding to a workplace accident or fire. An explosive chemical or flammable substance impacts their safety too.

Next Steps, Download Booklet of “Your steps to chemical safety”

We strongly recommend downloading and reading our free eBook ” your steps to chemical safety , This booklet shows a three-step approach whereby a small business can safely manage its chemicals. It shows you how to carry out a chemical risk assessment, which is required by law but more importantly, it will help you protect your employees safety and health. It will also potentially introduce cost savings to your business through more effective work practices, such as correct storage, handling, use and disposal procedures. Download from here

Download Infographic

Chemical handling

( Read more: Ebooks-NIOSH-pocket-guide-to-chemical-hazards/).