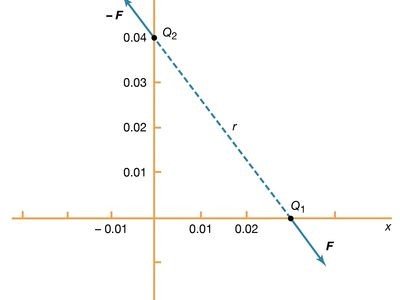

Sparks are responsible for most industrial fires and explosions as a result of static electricity. A spark is a discharge of static electricity between two conductors. You may have felt or seen a spark jumping from a key or finger to a metallic grounded object after walking across the carpet. Spark discharges occur when the charges accumulated on conductive objects create an electric field that exceeds the ambient atmosphere’s electric strength. Figure 2 shows a spark discharge between two conductors. this article is a guide for electrical workers who would like to know more about static electricity and how it builds up and control methods to avoid its risks at the workplace

Also Read: 5 Leading Electrical Hazards and How to Avoid Them

General Static Electricity

The material universe is composed of atoms, and the outermost parts of atoms are composed of electrons. There are many ways in which an outer electron may be detached from an atom. Detached electrons appear in electrical occurrences of static electricity. Static electricity is extremely commonplace, as electrons can be detached and transferred from surface atoms through mere contact and separation of material bodies. Fortunately, however, in the majority of cases, contact is made only at a few points, and as there is often little resistance to the return of electrons at the moment the contacting bodies are separated, the external effects are feeble and pass unnoticed.

In certain materials, notably metals, electrons can move from atom to atom with considerable natural freedom. This makes these materials good conductors of electricity. Other materials, such as glass, stone, rubber, plastics, and textiles, have molecular structures that offer great resistance to the flow of electricity, and, consequently, these are called nonconductors or insulators. Materials that are neither good conductors nor good insulators are sometimes called semiconductors. Moderate opposition to the flow of electricity is expressed in units called ohms. A larger unit, the megohm (1,000,000 ohms), is generally employed in high-resistance measurements.

Also Read: High-Voltage Electrical Safety

When dissimilar materials are pressed together, free electrons from the surface structure of one material may shift across the contact, or interface, to the other. If the materials are separated, the new distribution of electrical entities probably will persist if one or both of the materials are conductors. The extent and direction of the electrical shift between contacting surfaces depend largely upon the nature of the materials and are usually in accord with their position in tabulations known as triboelectric series. The object that acquires extra electrons is said to have a negative (–) charge and the one that loses electrons has a positive (+) charge. Considered minutely, a normal atom or molecule that gains an electron is a negative ion, and one that loses an electron is a positive ion. The transfer of electrons or ions by contact and separation is often facilitated by rubbing and friction, whence the name “friction electricity.” Positive and negative charges (quantities) of electricity produced and kept apart by nonconductors are virtually at rest: that is, they are static. Owing to their difference in potential, they are acted upon by a force that tends to unite them. This reunion will take place instantly if a low-resistance circuit is provided. It will occur in any event because there are no perfect insulators.

Charges acquire voltage or potential in proportion to the amount of work or energy required to separate them. Stress in the electrical field or region around charged bodies is seen not only in the attraction of opposite charges but also in the repulsion of charges of like kind. As this effect is elemental, static charges in the aggregate are self-repellent and, thus, normally reside only on the external surfaces of electrified objects.

The quantities of electricity dealt with in electrostatics are generally so small that it is convenient to employ the terms picofarad (10–12 farad), picocoulomb (10–12 coulomb), and millijoule (10–3 joule). Static electric potentials are conveniently expressed either in volts or kilovolts (103 volts).

Some Examples and Areas of Static Buildup

Static buildup can be found just about anywhere friction occurs. Here are some examples.

- Gears and belts: V belts, mostly flat power transmission lines, are particularly susceptible to static charge buildup due to the friction between the belt and the pulley. Rubber conveyor belts employed in material-handling systems do not cause appreciable charge buildup due to their low linear speed.

- Pouring powders: Pouring pulverized non-conducting solid particles down chutes or troughs.

- Dust transport: Pneumatic transport of powders and solids.

- Jet nozzles: Air, gases, and liquids expelled from jets, or processes such as sandblasting and shotcrete (sprayed concrete).

- Metal tanks: When resting on a non-conductive base, such as a tank truck on rubber tires, mostly when filled through the dome.

- Metal tanks with a non-conductive liner.

- Tanks or vessels made of non-conductive material.

- Liquid falling into a tank during filling operations.

- Non-conductive piping, such as fiberglass or PVC, can build up static charges outside due to liquid flow.

- Isolated sections of metallic piping, such as sections separated by gasketed flanged joints or swing joints.

- Rubber wheels on furniture in motion over non-conducting flooring, and automobile tires on the road.

- People’s bodies due to the friction of rubber shoes.

- Charges generated on fabrics.

Risks of Static Electricity

Some dangers posed by static electricity are:

- Electric shock is due to the flow of current through the body, causing a person everything from an uncomfortable zap to falls, burns, or stopping the heart.

- Fires or explosions due to the ignition of flammable or explosive mixtures.

- Production disturbances in the processing of paper, plastics, composites, powder, granules, and liquids.

- Damage to electronic equipment and components from electrostatic discharge (ESD).

- Damage to mechanical components such as bearings due to sparking through the oil films on bearing surfaces.

It is vital to analyze the static buildup potential of facilities and establish protective procedures.

Spark Discharge and Ignition Energy

Sparks are responsible for most industrial fires and explosions as a result of static electricity.

A spark is a discharge of static electricity between two conductors. You may have felt or seen a spark jumping from a key or finger to a metallic grounded object after walking across the carpet.

Spark discharges occur when the charges accumulated on conductive objects create an electric field that exceeds the ambient atmosphere’s electric strength. Figure 2 shows a spark discharge between two conductors.

Also Read: Navigate Flammable and Combustible Liquid Safety

General Control Methods

Humidification

The addition of water vapor does not make air electrically conductive; however, the leakage resistance of most substances (with the exception of a few waxes and resins) decreases greatly as the atmospheric humidity increases, owing to the absorption of moisture from the air.

Humidification has long been employed in industrial processes for controlling static. This is particularly true of the textile industry, where the attraction and repulsion of charged fibers and strands can affect the quality of the manufactured products. Control of humidity has frequently been proposed as a means of eliminating static electricity in hospital operating suites.

To be effective in reducing static to a nonhazardous level, the relative humidity must be at least 60 percent and probably considerably higher owing to the present extensive use of nonconductive rubber. In the 10 textile industry reference is made to a standard atmosphere of 65 percent relative humidity and 70 degrees Fahrenheit, at which practically no static will develop.

Since several hours may be necessary for materials to come to moisture equilibrium in a changed atmosphere, safety from static cannot be ensured unless proper humidity has been maintained for a long period before activities begin.

Probably the system should be run continuously. No enduring protection is afforded when the system is shut down for repairs or servicing or when its operating schedule is irregular.

Bonding and Grounding

Static sparking does not occur between objects at the same potential. Bonding is the term used to indicate the equalization of potential between two conductive bodies by connecting them together by means of a conductive wire. Objects bonded together have a zero potential difference from each other but may still retain a charge and have a potential difference with respect to adjacent unbonded objects.

Grounding is the connecting of a conductive body to the earth by a conductive wire. It is assumed that the potential of the ground is invariant. Therefore, objects connected to the ground by conductive wires will have zero potential differences with respect to each other. When a charged object is grounded, it is said to have a positive potential if electrons flow from the object to the ground and a negative potential if electrons flow from the ground to the object.

Bonding and grounding are usually effective if the objects so treated are good conductors. They are effective as a control measure for semiconductors if the rate of charge accumulation is less than the rate of charge dissipation. A rapid neutralization of a poor conductor will probably not occur or may occur only at the area of contact between the ground wire and the object.

A bond or ground wire should have adequate mechanical strength, be corrosion resistant and have the necessary flexibility for the service intended. Size No. 8 or No. 10 AWG copper wire is about the minimum suitable size. Permanent connections should be welded or brazed. Temporary connections may be made using tight battery clamps or screw clamps. Any ground wire suitable for power circuits is more than adequate for static grounding; however, it is not wise to use the same ground for the two purposes simultaneously. Insulated or non-insulated wires may be used for bonding or grounding. If an insulated wire is used, more frequent tests for electrical continuity should be made.

Also Read: E-Books: Practical Guide To Electrical Grounding(

Ionization

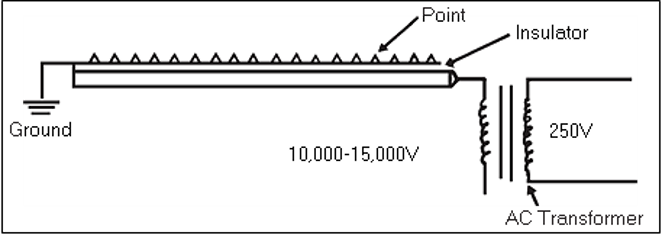

Ionization of the air in immediate contact with a charged body provides a conducting path through which the charge may dissipate. Methods by which such ionization can be accomplished form the basis for a variety of control measures.

Static charges on a conducting surface are free to flow and, due to repulsion between like charges, tend to distribute themselves as uniformly as possible. On a spherical body, this distribution is uniform. If the object is not spherical, the charge will concentrate on the surface with the least radius of curvature. If the surface has an almost zero radius of curvature such as the needlepoint, the charge concentration on this surface can become great enough to cause ionization of the surrounding air.

A static comb is a metal bar equipped with rows of needle points or a metal wire wrapped with metallic tinsel. When a grounded static comb is brought close to an insulated charged object, ionization of the air surrounding the points of the comb will provide a conductive path over which the charge on the object dissipates to the ground.

Also Read: Ionizing Radiation’s Quantities and Units(

The ionizing charge on a simple static comb is induced by the close proximity of a charged object. Such an induced charge is not constant in intensity nor uniform along the length of the bar. In order to improve the efficiency of such static control bars, a constant high voltage may be impressed upon the bar by some outside source such as an AC transformer. The points on these high-voltage electrostatic eliminators are arranged to act as capacitors. The bar itself is grounded.

Figure 3 illustrates a high-voltage static eliminator.

Also Read: Working with Electricity Electrical Accidents Guide for Electrical Workers

For more safety Resources Please Visit Safetybagresources