What are pyrophoric materials and what are their hazards?

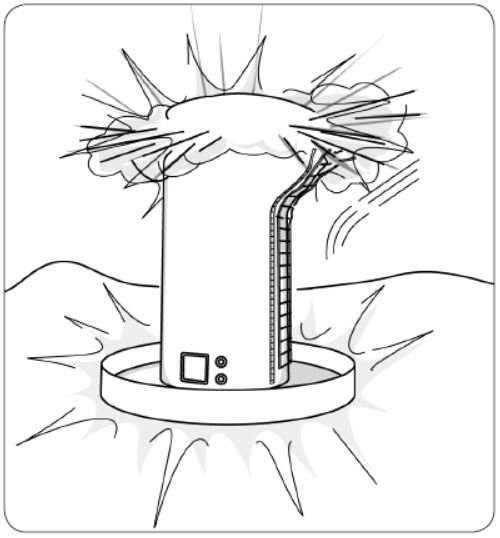

3 min readThree recent explosions involved pyrophoric materials in storage tanks. The following incidents occurred when pyrophoric materials on the insides of the tank walls ignited when exposed to oxygen in the air:

- During a rig-out operation, grounded vacuum trucks were pumping out a vented storage tank. The crew was on a break when the tank exploded, damaging nearby equipment.

- A crew of workers on a sour-lease site isolated the blanket gas (sweet gas) to a 400-barrel condensate tank so they could remove several valves for maintenance. Hours later, the tank exploded. The blast threw the tank beyond its enclosure and propelled burning fluids into the surrounding grassy areas.

- Two connected 750-barrel storage tanks exploded, launching both tank lids more than 50 m (160 ft.). Nearby workers had left the area only a few hours before the explosion and ensuing fire.

What are pyrophoric materials?

Pyrophoric materials are chemicals that can spontaneously ignite when exposed to air. They are often found in refinery piping, tanks, and vessels. A common pyrophoric material is pyrophoric iron sulfide.

Pyrophoric iron sulfide is created when iron oxide (rust) is converted into iron sulfide in the presence of hydrogen sulfide. This chemical reaction only takes place in low oxygen conditions.

When the pyrophoric iron sulfide particles are exposed to air, they are oxidized back to iron oxide, generating a considerable amount of heat. So much heat is produced that the particles can burn, igniting nearby flammable hydrocarbon gases.

Fires and explosions caused by pyrophoric materials can occur during shutdowns when tanks or vessels are emptied or equipment and piping are opened for inspections and maintenance.

How did the tanks explode?

Incident reports for these three separate explosions reveal a number of similarities. All the tanks held hydrocarbon condensate with hydrogen sulfide. The tanks also had oxygen-deficient atmospheres. The conditions in all three incidents led to the formation of iron sulfides.

When the liquid levels in the tanks dropped, iron sulfide deposits on the tank walls were exposed to the gases inside the tanks. As oxygen entered the tanks (which can occur minutes or even months after the iron sulfides are formed), two things happened:

- The oxygen mixed with the vapors and gases in the tanks to create an explosive atmosphere.

- The oxygen reacted with the pyrophoric iron sulfide to provide a source of ignition. The pyrophoric iron sulfide then ignited the explosive atmosphere, leading to severe damage but, fortunately, no injuries.

Tanks that have sat empty for an extended time can still be hazardous. Pyrophoric iron sulfide can remain on tank walls for long periods of time before finally igniting when exposed to oxygen.

How can you prevent these types of explosions?

- Implement and follow a fire and explosion management plan and safe work procedures when emptying tanks and vessels. The plan and procedures should address ignition sources, oxygen, and fuel sources.

- Consider possible ignition sources, including the following:

- Pyrophoric materials that can form in both sour and sweet sites

- Automatic flare stack igniters

- Electrical discharge from improper bonding/grounding

- Lightning

- Hot work

- Consider how oxygen could enter the tank. Possible entry points include the following:

- The thief hatch

- An extinguished flare stack

- The level indicator

- Open valves, piping, and hatches

- The heater, thermostat, and anode ports

- Inert the tank with a gas that does not burn, such as carbon dioxide or nitrogen. Once a flammable blanket gas is shut off, the amount of oxygen in the tank may increase until an explosive gas mixture is created. Inerting the tank may help prevent an explosive atmosphere from developing.

- Maintain and inspect the inner linings of storage tanks regularly.

- Consider a chemical treatment to remove pyrophoric materials when you empty a tank:

- Use acid cleaning.

- Add a hydrogen sulfide suppressant to scrub or convert hydrogen sulfide gas.

- Dissolve sulfide deposits using a high pH chelating solution.

- Add an oxidizing chemical to oxidize the iron sulfide. Oxidizing chemicals include sodium hypochlorite, hydrogen peroxide, and potassium permanganate.