Some of the most common construction and manufacturing jobs create high levels of dust. These jobs often involve the use of power tools like cut-off saws, grinders, polishers, breakers, and sanders.

As an Employer, you have a duty to complete a risk assessment. You also have a duty to eliminate risks. If this is not reasonably practicable, use the hierarchy of controls to minimize the risk of dust exposure to workers.

In this Article, the guidance advises Employers on how to choose, use and maintain an on-tool water suppression system to control dust.

Risks presented by breathing in dust

Regularly breathing in dust can cause diseases like:

- lung cancer

- asthma

- chronic obstructive pulmonary disease (COPD, including emphysema and other breathing difficulties)

- silicosis (including accelerated and acute silicosis) from exposure to crystalline silica.

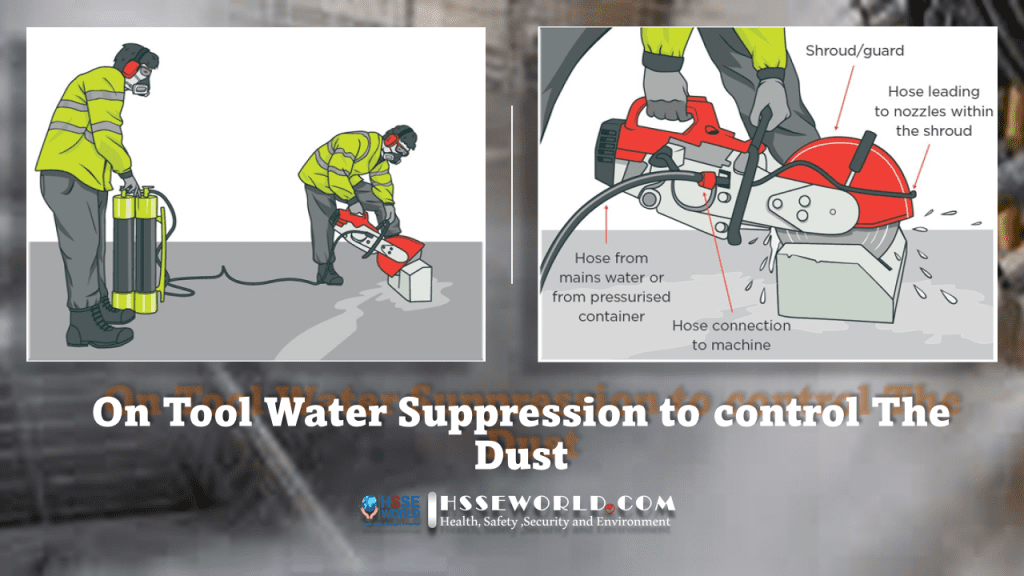

One engineering control measure you can use to minimize worker exposure to dust in the workplace is on-tool water suppression.

Choosing an on-tool water suppression system

On-tool water suppression is a system that fits directly onto a tool and uses water to minimize the amount of dust generated. It also keeps cutting blades and grinding discs cool.

The system has several parts:

- the tool itself

- a shroud with spray nozzles to contain water flow and direct it to the cutting/grinding surface

- water source (mains water or pressurised water bottle. It is not sufficient to pour from a water bottle before you start), and

- a hose.

Each part is critical to the system’s effectiveness and level of dust control. You can buy a complete on-tool water suppression system or, alternatively, parts of the system to use with your existing tools. Make sure to choose parts that are compatible with your tools. Involve workers in selecting a system that is right for the task.

Tools and accessories

Limit the amount of dust created by choosing appropriate tools and accessories.

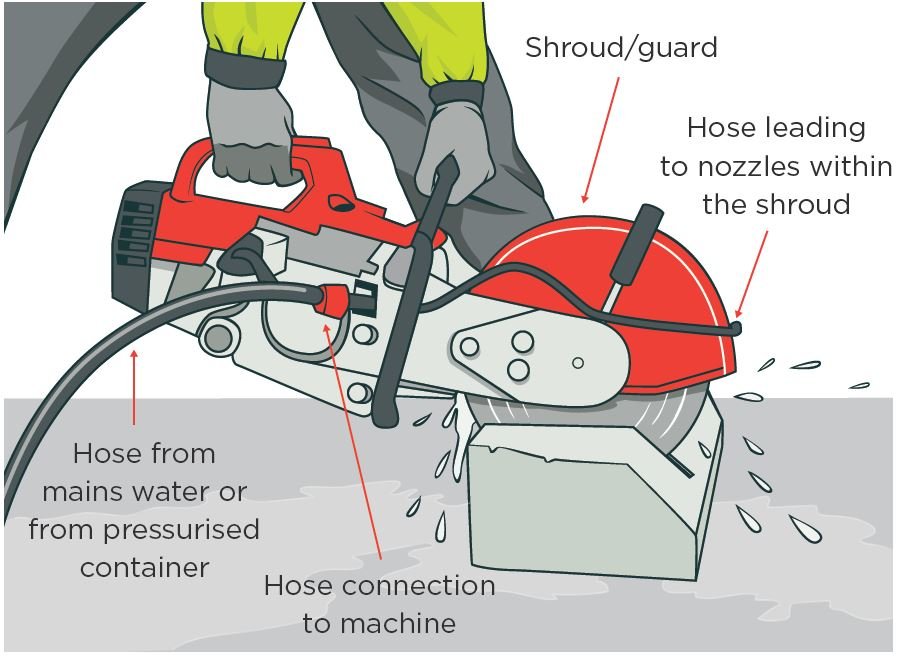

Shroud

The shroud directs water onto the tool and limits the amount of dust generated. It is often part of the tool but can also be retrofitted to existing equipment.

HOW TO CHOOSE THE RIGHT ONE

Poor design or damage to the shroud will significantly affect dust control. Check that the shroud:

- is designed for the tool and the task (ask the manufacturer or supplier if you are not sure)

- sits as close as possible to the work surface when in use, as dust will escape through any gaps. Consider an adjustable shroud that can be used in many situations, particularly with saws

- is easy to clean and does not interfere with work unnecessarily.

Water source

Use fresh water. Do not use water that has previously been used to suppress crystalline silica dust. Where mains water is not available, use a pressurized water bottle. Get an assistant to direct the water stream to the point of dust generation if the pressurized water supply is not already connected to the tool.

If you do not have a water source at your worksite (eg you are working in a remote or isolated area) consider using an on-tool dust extraction system instead of on-tool water suppression. This may be a better option to minimize manual handling that can lead to injuries.

Hose

The hose connects the water supply to the shroud.

HOW TO CHOSE THE RIGHT ONE

Check that the hose:

- is made of durable material

- is the right size (diameter and length) for the work

- fits securely to the shroud and water supply.

Electrical safety

It is important to take extra precautions when using electrical tools and water to control dust.

Always use residual current devices (RCDs) and watertight, sealable electrical connectors when using on-tool water suppression.

Using on-tool water suppression

Providing the right equipment isn’t enough to control dust risks. The equipment must also be operated correctly and be properly maintained. Pay particular attention to each stage below:

Before use

PROVIDE TRAINING FOR WORKERS

Workers must have the right information, training, instruction, or supervision before using on-tool water suppression. This includes information about:

- pre-use checks

- ongoing maintenance

- how to use the system correctly

- other controls that may be needed (eg respiratory protective equipment and how to use/fit it properly)

- common faults, how to spot them, how to fix them

- the importance of having a sharp blade when using a saw. Sharp blades create less dust

- what to do if there is a problem.

During use

FOLLOW OPERATING INSTRUCTIONS

Make sure the on-tool water suppression system is used in the right way and that its use does not introduce new hazards to the work:

- Before work starts, check the shroud and hose connection is undamaged and in good working order.

- Ensure workers follow the agreed methods of work and the manufacturer’s instructions.

- Ensure the shroud is as close as possible to the work surface.

- Ensure that accessories like the blade, grinding/sanding discs or polishing pads are not worn out.

- Do not remove guards from equipment in order to fit parts for controlling dust.

- Ensure that water is supplied to the tool at a sufficient flow rate to minimise release of visible dust – the recommended flow rate is at least 0.5 litres of water per minute.

- Ensure the hose is protected from damage from other activities at the workplace.

- Ensure the hose is securely connected to the shroud and water If necessary, use an adaptor. Do not use tape.

- Wet slurry should be collected in a tray or vacuumed up regularly to prevent it from drying and releasing dust into the To collect slurry:

- use a shovel, and

- For crystalline silica dust, use an H-class vacuum cleaner in accordance with Standard AS/NZS 60335.2.69, fitted with a filter that can achieve an efficiency of 99.995% (eg H14 HEPA filter complying with Standard AS 4260). This includes working in someone’s home (eg to fit a bench). Workers should not use a household vacuum cleaner to remove this dust.

Maintaining an on-tool water suppression system

Regular checks/maintenance

Maintain and operate the on-tool water suppression system according to the manufacturer’s instructions.

Ensure the system works properly every time. It is good practice to carry out regular maintenance checks at least once a week and record the results. You may have to do checks more frequently if there is a high risk of the equipment being damaged. Focus on:

- damage to parts such as the shroud or hose.

- Repair or replace damaged parts straight away

- checking pressurised water bottles for damage

- ensuring water flow is at least 0.5 litre per minute

- train your workers to look for signs of damage.

Inspection and testing

Equipment needs to be properly serviced and tested to ensure it remains effective. For more information, contact the manufacturer or supplier.

Respiratory protective equipment (RPE)

It is important to implement the higher-order control measures – elimination, substitution and engineering controls – and administrative controls before implementing RPE. Whether RPE is required will depend on the amount of dust remaining in the air. This can only be determined by carrying out exposure monitoring (see below). If using RPE, it should be available for all exposed workers, not only those using the tools.

EXPOSURE MONITORING

Exposure monitoring is the measurement and evaluation of exposure to a health hazard experienced by a person at work. It can help determine what control measures are needed or if existing control measures are working.

Monitoring does not control risk and does not replace the need for control measures to eliminate or minimize worker exposure to dust including crystalline silica. See our Introduction to industrial ventilation for more information.

Monitoring should be carried out by a competent person such as an occupational hygienist who has the right knowledge, skills, and experience inappropriate techniques and procedures including interpreting results.