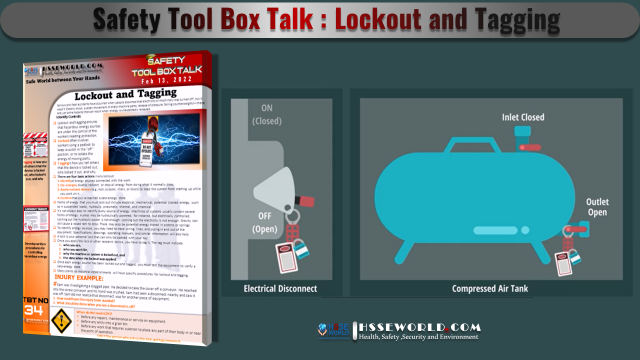

Worker safety is of utmost importance in any industry. To ensure the well-being of employees, it is crucial to implement proper safety measures, especially when dealing with hazardous energy sources. One such safety procedure is LOTO, which stands for Lockout and Tagout. In this blog post, we will explore the concept of LOTO, its importance, and the steps involved in its implementation. We will also discuss the significance of Energy Isolation and the role of Isolation Confirmation Certificates (ICC) in ensuring a safe work environment.

Read: procedures-of-lockout tagout-at-chemical-plants

Introduction to Energy Isolation and Its Importance

Energy isolation, often encompassing practices such as Lockout/Tagout (LOTO), refers to the procedural safeguarding of machinery and equipment. This safety protocol ensures that machines are properly shut off and isolated from any source that can release hazardous energy during service or maintenance activities. Its critical purpose is two-fold: preventing the inadvertent release of stored energy and protecting workers from the dangers posed by operational equipment.

Energy isolation is a vital component in industrial safety protocols because hazardous energy release can lead to catastrophic events, including electrocutions, burns, crushing injuries, or even fatalities. Establishing a rigorous energy isolation protocol is not just a compliance measure with Occupational Safety and Health Administration (OSHA) regulations; it is integral to fostering a culture of safety in any operation involving heavy machinery or equipment with the potential for unexpected startup or release of stored energy.

To ensure a robust energy isolation approach, the following procedures are typically included:

- Personal lockout devices: These are individual locks that personnel affix to energy isolation points to ensure that only they have the key to reinstate power or motion to the equipment.

- Tagout signs: Accompanying the physical locks, tagout signs serve as clear warnings that machinery is out of service and should not be operated.

- Group lockout systems: In situations involving multiple maintenance personnel, a group lockout system ensures coordinated control over energy isolation.

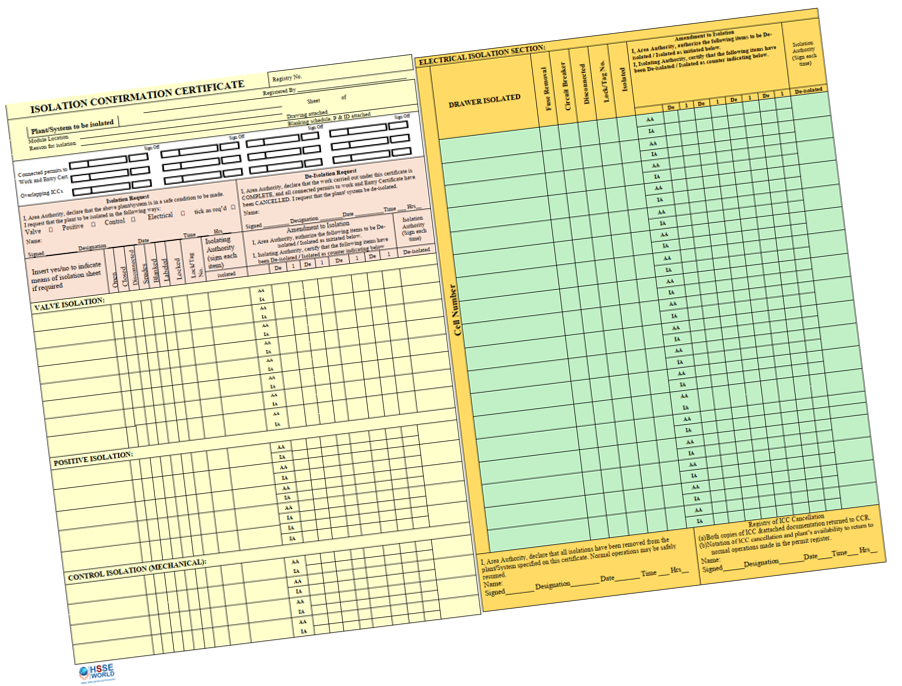

- Isolation confirmation certificates: These documents act as official records confirming that machinery has been successfully isolated and is safe for maintenance work.

Energy isolation is crucial not only for worker safety but also for preserving the integrity of equipment. Properly isolated machines are protected from damage that may occur if they are accidentally energized during maintenance. This comprehensive approach to energy control is indispensable for creating a fail-safe environment thereby minimizing risks and promoting operational efficiency.

Understanding the Legal Requirements for Lockout/Tagout

Lockout/Tagout (LOTO) procedures are mandated by the Occupational Safety and Health Administration (OSHA) under standard 29 CFR 1910.147, which stipulates the guidelines for controlling hazardous energy during the service and maintenance of machines and equipment. These regulations have been designed to prevent accidental startup or release of stored energy, which could lead to injuries or fatalities.

Adhering to the legal requirements for LOTO involves several critical steps:

- Developing a LOTO Program: Employers are required to establish a LOTO program that includes energy control procedures, employee training, and periodic inspections.

- Energy Control Procedures: These written procedures must delineate the steps for shutting down, isolating, blocking, and securing machines to control hazardous energy.

- LOTO Training: Employees must receive training to ensure they understand the purpose and function of the energy control program, with specialized instruction for authorized employees who are responsible for implementing the energy control procedures.

- Periodic Inspections: Employers must conduct annual inspections of the energy control procedures to ensure their efficacy and the competence of authorized employees.

- LOTO Devices: These include locks and tags that must be standardized within the facility in color, shape, or size and must be durable and substantial enough to prevent removal without excessive force.

Compliance with these requirements ensures not only the physical safety of employees but also shields the employer from liability and potential penalties for non-compliance. Furthermore, employers need to keep abreast of any changes in the laws or regulations pertaining to LOTO to maintain a compliant and up-to-date energy control program. Understanding and implementing these legal requirements is crucial for the prevention of workplace injuries and the promotion of a safe working environment.

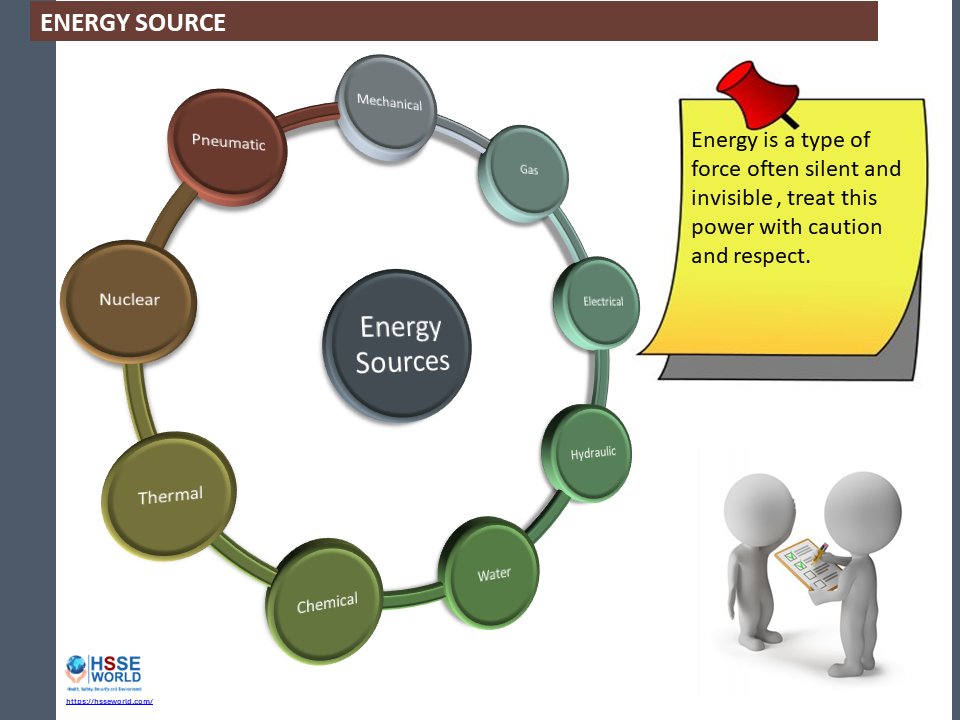

Identifying the Different Types of Energy Sources

In the context of Lockout/Tagout (LOTO) procedures, understanding the various types of energy sources present is essential for the safety of workers. The primary sources of energy that may require isolation in industrial settings include but are not limited to the following:

- Electrical Energy: Utilized in nearly every workplace, electrical energy is often the most recognized hazard. It includes sources from wall outlets to high-voltage lines and encompassing equipment like generators and batteries.

- Mechanical Energy: This involves energy stored in objects under tension or compression. Examples include springs under compression, rotating flywheels, or raised loads.

- Pneumatic Energy: Pneumatic systems use compressed air to perform work. Isolating this energy might involve depressurizing tanks, lines, and cylinders.

- Hydraulic Energy: Similar to pneumatic, hydraulic systems utilize liquid under pressure. Ensuring machinery is relieved of pressure and cannot actuate is key to isolation.

- Chemical Energy: Present in fuels, solvents, and other substances that might react or release energy under certain conditions. Proper containment and neutralization are methods of isolation.

- Thermal Energy: Extreme heat or cold can pose risks, particularly in processes involving welding, cryogenics, or steam systems. Isolation may require allowing equipment to cool or stabilize to ambient temperature.

- Potential Energy: Often linked with mechanical, potential energy can exist in an elevated object or piece of equipment that could release energy if moved.

- Gravitational Energy: An object’s energy due to its position can lead to movement if the object falls, requiring certain measures to prevent a release of this energy.

Each energy source demands specific methods of isolation. LOTO protocols ensure the effective control of these sources by defining the procedures to render equipment or energy systems safe for maintenance or inspection. Compliance with isolation confirmation certificates further verifies that isolation is proper and complete before work begins, minimizing the risk of accidental energy release.

The Step-by-Step Breakdown of the Lockout/Tagout Procedure

Lockout/Tagout (LOTO) is a critical safety procedure used in industrial settings to ensure that dangerous machines are properly shut off and not started up again before maintenance or repair work is completed. It involves several steps to isolate energy sources and verify that isolation is successful. Following is a step-by-step guide to the LOTO procedure:

Preparation

- Identify all energy sources that need to be controlled, including electrical, mechanical, hydraulic, pneumatic, chemical, and thermal sources.

- Notify all affected employees that a lockout/tagout procedure is going to be implemented.

Shutdown

- Shut down the equipment following the manufacturer’s instructions or standard operating procedures (SOPs).

Isolation

- Isolate the equipment from its energy source(s) by applying appropriate lockout devices.

Lockout/Tagout

- Apply lockout devices to the energy-isolating devices. These can be locks or multi-lock hasps alongside the appropriate tags.

- Ensure that all stored or residual energy (such as that in capacitors, springs, elevated machine parts, rotating flywheels, hydraulic systems, and air, gas, steam, or water pressure) is relieved, disconnected, restrained, or otherwise rendered safe.

Control of Stored Energy

- Verify that the equipment isolation is effective by attempting to operate the equipment using normal operating controls (ensure no one is exposed to potential harm during this test).

Isolation Verification

- Perform a try-out to ensure that the equipment will not operate.

- Confirm that the equipment is isolated from the energy source by using appropriate testing or measuring methods to verify that energy has not been reconnected.

Also Read: E-books the-safe-isolation-of-plant-and-equipment

Ongoing Controls

- Ensure that lockout and tagout devices remain in place until work is completed and confirm that the equipment is isolated from the energy source during the entire duration of the maintenance or repair work.

These steps, applied with rigor and attention to detail, create a secure environment for maintenance personnel to operate. Proper execution of the LOTO procedure prevents unintentional start-up of machinery, averting potential injuries, and saving lives. It is also essential that workers involved in the process have energy isolation and isolation confirmation certificates, indicating they are trained and competent to carry out these safety measures.

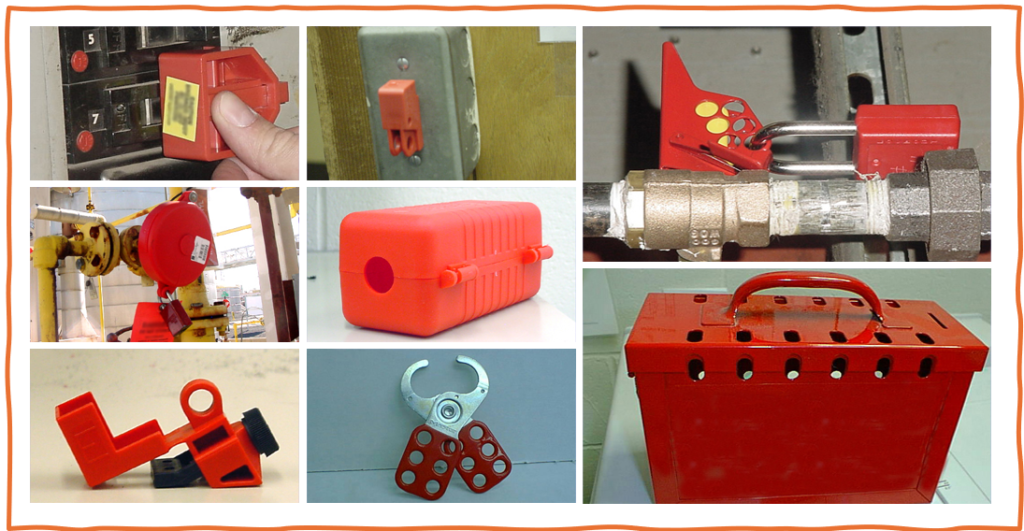

Preparing for Energy Isolation: Tools and Equipment

When establishing a Lockout/Tagout (LOTO) program, it is critical to prepare by securing the appropriate tools and equipment. This preparation is vital to ensure the safety of workers who will perform maintenance or servicing tasks on machines or equipment that could unexpectedly energize or start up. Below is an essential list of tools and equipment needed for energy isolation:

- Lockout Devices: These devices physically prevent the operation of energy-isolating equipment. Examples include padlocks, hasps, valve lockouts, and circuit breaker lockouts. Each device should be durable, standardized, and identifiable.

- Tagout Devices: Tags must accompany lockout devices when possible. They provide warning messages and identification about the maintenance currently taking place and the worker who placed the tag.

- Lockout Kits/ Stations: Portable or fixed stations should contain all the necessary devices and accessories for locking out different types of energy sources. Kits should be easily accessible to authorized employees.

- Isolation Confirmation Certificates: Certificates or tags that confirm the isolation and de-energization of equipment are necessary to ensure double-checking and verification processes.

- Group Lockout Boxes: When a team of workers is involved, group lockout boxes can be used to consolidate and control keys for the individual lockout devices.

- Personal Protective Equipment (PPE): Safety goggles, insulated gloves, and other forms of PPE are essential to protect workers from hazards during the lockout process.

- Energy Isolation Devices: Specialized devices, such as blank flanges and bolted slip blinds, are used to block or isolate the flow of hazardous energy.

- Documentation Materials: These include procedure manuals, energy isolation checklists, and maintenance schedules to ensure standardized practices.

Having the appropriate tools and equipment on hand is crucial for the successful implementation of a LOTO program. Employees must be trained on how to use these tools properly and to understand the importance of not bypassing energy isolation procedures. Proper preparation ensures a safe environment for workers servicing or maintaining equipment.

Download: photo-of-the-day-lockout-and-tagout-safety/

Common Isolation Methods

Contents of pipes, tanks, and supply lines need to be properly isolated when LOTO is performed. Here are some common isolation methods, which may be combined as needed to ensure the proper level and assurance of isolation:

A pair of valves (#1 and #2) with a bleeding valve (#3) in between are locked closed and the contents of the pipe are drained through the bleed valve, which may be locked open.

An upstream valve is locked closed and disconnected from a downstream pipe or Ǝange. A container is placed where pipes are misaligned to catch spills.

An upstream valve is locked closed and disconnected from a downstream Flange and a blank is inserted into the Flange and put back together.

A pair of valves are locked closed, the spool piece is physically removed from the pipe or line, and a blank is inserted at each end of the Flange or pipe.

Executing the Lockout: Best Practices for Safety and Compliance

When implementing lockout/tagout (LOTO) procedures, certain best practices ensure the safety of workers and adherence to regulatory standards. These practices help in avoiding accidents and maintain a safe working environment.

- Preparation is Key: Before initiating LOTO, it is critical to identify all energy sources connected to the equipment. This includes not just electrical, but also pneumatic, hydraulic, mechanical, chemical, and thermal sources.

- Personal Locks and Tags: Each worker should apply their personal lock and tag to the isolation point. This personalizes the lockout and ensures that only the individual who placed it can remove it, preventing accidental or unauthorized re-energizing.

- Verification of Isolation: After the lockout devices are applied, it is imperative to verify that all energy sources have been effectively isolated. This may involve trying to turn on the machine or checking for the absence of energy with test equipment.

- Lockout Devices and Their Maintenance: Use appropriate lockout devices designed to handle the environment and the energy they’re meant to control. Regular inspections of these devices ensure their functionality and reliability.

- Training and Communication: Workers involved in LOTO should receive comprehensive training on procedures and the specific types of energy they may encounter. Moreover, clear communication is required amongst all workers about the lockout status.

- Documentation and Audits: Maintain an up-to-date record of all LOTO activities. Regular audits of the LOTO process help in identifying potential improvements and ensuring continuous compliance.

- Return to Service: Once the work is complete, remove lockout devices in the reverse order they were applied, making sure that all tools and non-essential personnel are clear of the equipment.

Adhering to these best practices helps to safeguard the workforce and ensures a systematic approach to energy control that aligns with safety regulations and industry standards.

Tagout Tactics: How to Effectively Use Tags in Energy Isolation

Utilizing tags in energy isolation, commonly referred to as tagout, is an essential component of the Lockout/Tagout (LOTO) procedure. Tagout devices are warning devices constructed from materials such as cardstock or laminate that can withstand the environmental conditions they will be exposed to. These devices are used to reinforce that the energy-isolating devices are not to be operated until the tagout devices are removed. To ensure tagout effectiveness:

- Clear Communication: Tags must convey a clear and unequivocal message that the equipment is out of service and must not be operated. This message should include the reason for the tagout, the duration, and the name of the authorized person who placed the tag.

- Visibility: Always place tagout devices in such a way that they are immediately noticeable to anyone attempting to operate the device. They should be located as close as possible to the normal point of operation.

- Training: All employees must be trained to understand the significance of tagout devices and the repercussions of ignoring them. They should also know the limits of tags, as tags do not provide the physical restraint that a lock might.

- Durability: Choose tagout materials suitable for the working environment to withstand wear, extreme temperatures, or chemical exposure. Tags should remain legible for the duration of the isolation.

- Attachment: Tags should be attached securely to energy-isolating devices so that they cannot be inadvertently or accidentally removed. Cable ties, self-locking nylon fasteners, or other substantial means of attachment are typically used.

- Audit: A regular audit of tagout procedures and tag conditions is essential. This ensures ongoing compliance with safety regulations and the efficacy of the tagout system.

- Standardization: Organizations should standardize tags to prevent confusion. Colors, shapes, or additional warning graphics can quickly convey the tag’s purpose and status.

Remember, tagout devices are not to be used as a substitute for lockout devices unless lockout is not feasible. Tagout should only complement an effective LOTO program, where the primary goal is always the elimination of hazardous energy release during service or maintenance activities.

Training and Communication: Keys to a Safe Lockout/Tagout Process

Effective lockout/tagout (LOTO) practices are essential for safeguarding workers from hazardous energy releases during maintenance and servicing of equipment. The success of a LOTO program hinges on two critical components: comprehensive training and clear communication.

- Comprehensive Training: All personnel must be thoroughly trained in recognizing the sources of hazardous energy they might encounter. Training should include:

- Identification of applicable energy sources.

- Understanding the type and magnitude of the energy available in the workplace.

- Familiarization with LOTO devices and procedures.

- Demonstrations on the proper placement and removal of lockout devices.

- Education on the potential consequences of failing to correctly apply LOTO procedures.

- Clear Communication: Communication ensures that all employees know when and why LOTO procedures are being implemented. This can be achieved through:

- Consistently used signage and labelling that clearly marks energy control points.

- Routine announcements before the application of a LOTO procedure.

- The use of isolation confirmation certificates that provides a detailed account of the devices used and the steps taken to isolate energy sources.

- Isolation Confirmation Certificates (ICC)

- Isolation Confirmation Certificates (ICC) are essential documents that provide evidence of successful isolation and de-energization of equipment. These certificates are issued after the completion of LOTO procedures and serve as a record of compliance with safety regulations. ICCs are crucial for maintaining a safe work environment and can be used for auditing and regulatory purposes.

Energy Isolation

Powerpoint training Material

Regular audits and refresher training sessions are vital to keep the LOTO process robust and front of mind. Moreover, workers must understand that they have the authority to initiate and participate in LOTO procedures without fear of repercussion to reinforce a safety-first culture.

A proactive approach to training and communication not only enhances safety but also boosts workers’ confidence when performing potentially hazardous tasks. A well-implemented LOTO program, underscored by these two pillars, dramatically reduces the risk of workplace injuries and fatalities associated with uncontrolled energy release.

Isolation Confirmation Certificates (ICC)

Isolation Confirmation Certificates (ICC) are essential documents that provide evidence of successful isolation and de-energization of equipment. These certificates are issued after the completion of LOTO procedures and serve as a record of compliance with safety regulations. ICCs are crucial for maintaining a safe work environment and can be used for auditing and regulatory purposes.

Periodic Inspections and Maintaining Lockout/Tagout Equipment

To ensure the effectiveness and integrity of a lockout/tagout (LOTO) program, it is imperative that inspections and maintenance of LOTO equipment are routinely conducted. This is crucial not only for compliance with safety regulations but also for safeguarding workers from potential hazards associated with unexpected energization or startup of machines and equipment.

- Regular Audits: Conduct periodic inspections of the LOTO program to verify that procedures are up to date and that they are being followed correctly. These audits should be performed at least annually and must be conducted by an authorized employee who is not using the energy control procedure being inspected.

- Equipment Inspection: Check all lockout and tagout devices for signs of wear, damage, or deterioration. Equipment must be immediately replaced if it is found to be ineffective or deficient in any way.

- Recordkeeping: Maintain records of inspections, including the identity of the equipment, the date of the inspection, the employees included in the inspection, and the person who performed the inspection. These records serve as documentation of compliance and as a reference for continuous improvement.

- Training Reassessment: Use inspection findings to identify any gaps in knowledge among employees and provide refresher training as needed. Ensure all workers understand the purpose, function, and correct usage of LOTO devices.

- Device Functionality: Test lockout devices and tagout signs to guarantee they function correctly. Devices must be capable of withstanding the environment in which they are used and must be standardized in color, shape, or size.

- Removal Authority: Enforce strict rules on who is authorized to remove a lockout or tagout device. Only the individual who applied the device should remove it, unless specific procedures are in place for removal by someone else in their absence.

Continuous attention to periodic inspections and maintenance of LOTO equipment is key in maintaining a robust workplace safety system. By adhering to these guidelines, organizations can protect their workers and comply with the Occupational Safety and Health Administration (OSHA) standards.

Handling Special Situations: Group Lockout and Shift Changes

Effective Lockout/Tagout (LOTO) procedures must address complex situations such as group lockouts and shift changes to maintain safety and continuity.

Group Lockout

When multiple workers service equipment, a group lockout ensures everyone’s safety. The procedure typically involves:

- Assigning a lead authorized employee to oversee the lockout process.

- Ensuring each worker applies a personal lock to a group lockout device, like a hasp, which is then secured to the energy isolation device.

- Utilizing lock boxes, where keys to individual locks securing the isolation device are placed. Each worker has a personal lock to the box, preventing access until all are removed.

- Verifying that all energy sources are isolated, and each worker confirms the equipment is de-energized by performing a try-out.

Shift Changes

Handover during shift changes can introduce risks if not managed properly. Key steps include:

- Informing incoming workers of the current LOTO status and any existing hazards.

- Conducting a briefing between outgoing and incoming personnel to ensure clear understanding of the work status.

- Transferring locks and tags from outgoing to incoming personnel or using a procedure like a lockbox system to ensure no gap in protection occurs during the transfer.

- Documenting each step of the handover process to maintain clear records of responsibility.

Effective management of special LOTO situations requires careful coordination and adherence to established procedures to protect workers from the unexpected release of hazardous energy.

Restoring Equipment to Service: Steps to Ensure Safety Post-Lockout/Tagout

After the completion of maintenance or repair work, restoring equipment to service following a lockout/tagout (LOTO) procedure must involve meticulous steps to ensure the safety of all personnel. The process needs to be managed carefully to avoid any accidental release of stored energy or premature equipment startup. For a safe transition from a locked out state to operational use, specific measures need to be observed:

- Inspection

Before reenergizing the equipment, inspect it to ensure that all tools and items used during maintenance are removed. Confirm that the equipment components are intact and appropriately assembled. - Notification

All affected employees must be notified that the lockout/tagout devices are about to be removed and that the equipment is to be reactivated. - Vital Signoffs

Ensure that all involved maintenance personnel confirm the work is complete and it’s safe to remove LOTO devices. These confirmations typically culminate with an isolation confirmation certificate. - LOTO Device Removal

Only the authorized personnel who applied the lockout/tagout devices should remove them. In situations where the original employee is unavailable, strict procedures must be followed to remove the device safely. - Energy Gradation

Restore energy in stages if possible, especially for complex systems. This can help to safely manage any unforeseen issues. - Functional Test

Once energy has been restored, conduct a functional test to ensure that the equipment is operating correctly. - Clear Communication

Clearly communicate to all affected personnel that the equipment has been returned to service and that normal operations can resume.

Adherence to these steps helps to safeguard every individual involved in or around the process, ensuring a return to normal operations without incident. Each action aids in minimizing risk and reinforces the importance of a comprehensive safety culture within the workplace.

Conclusion: Integrating Effective Energy Isolation into Workplace Safety Culture

Creating a comprehensive workplace safety culture requires integrating effective energy isolation practices, such as Lockout/Tagout (LOTO) protocols, at the heart of its safety standards. Embedding these practices involves the collective efforts of management and workers, a shared commitment to safety, and consistent execution of best practices across an organization.

- Establish thorough training programs to ensure that all employees are aware of and fully understand their roles in energy isolation and the risks of non-compliance.

- Develop a cross-functional safety team that includes employees from various departments to promote a broad-based approach to safety and foster company-wide buy-in.

- Regularly review and update energy isolation procedures to ensure they are current with technological advancements and changes in protocols or standards.

- Encourage active communication and feedback loops so that employees can report potential hazards or suggest improvements without fear of reprisal.

- Invest in high-quality isolation and lockout equipment, ensuring it is accessible and in proper working order to facilitate effective energy isolation.

- Create an atmosphere of accountability where compliance with energy isolation procedures is non-negotiable and both management and staff are held accountable.

- Incorporate routine audits and certification renewals, such as the Isolation Confirmation Certificates, to maintain a high standard of safety and compliance.

Adapting these strategies can result in a robust safety culture that prioritizes the well-being of employees and mitigates the likelihood of energy-related incidents. Ultimately, mastering energy isolation processes ensures a safer workplace where the risk of injury or death from uncontrolled energy releases is significantly reduced.