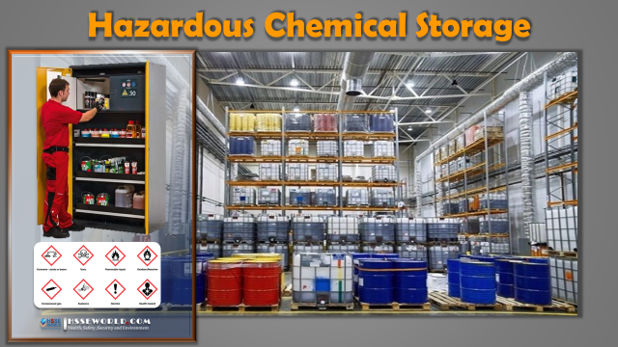

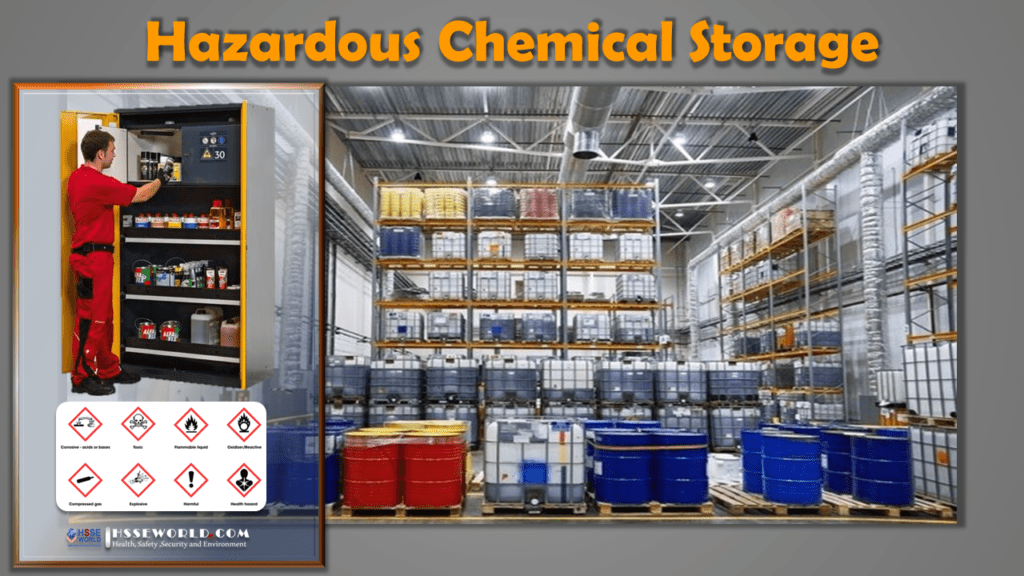

The safe storage of hazardous chemicals is an essential part of Workplace safety. Chemical storage is complex there is no one-size-fits-all plan to store chemicals but there are regulations, workplace requirements, and best practices that can guide the process. The general concept is to prevent chemicals from causing harm to people, property, other chemicals, or the environment.

Even when not in use, hazardous chemicals can still pose a risk. Some can cause or contribute to a fire or explosion, injure or poison people, and damage property if they are stored unsafely.

Some hazardous chemicals are also not compatible with one another. When incompatible hazardous chemicals mix, they may cause an explosion, release toxic, flammable, or corrosive gases, or corrode chemical containers.

It is important to identify incompatible hazardous chemicals and ensure that these chemicals are stored well away from each other so that it:

- minimizes the chance of any incidents and reactions, and

- reduces the chance that stored chemicals will contribute to or worsen an incident.

Storing hazardous chemicals safely

In order to fully understand the hazards associated with stored chemicals you first need to know what chemicals are being stored. Safe storage begins with an up-to-date inventory of chemicals and knowledge of the hazards posed by each chemical

Storing chemicals safely in your workplace includes using the appropriate:

- container

- storage and handling systems

- signs.

You must also keep a manifest and use placards if you store hazardous chemicals above a certain amount.

There are different requirements for storing hazardous chemicals in bulk.

General Chemical Storage Requirements

- All chemicals must be stored in a safe, secure location.

- Shelves should be level, stable, and secured to the wall or another stable

- Store chemicals away from direct sunlight, sources of heat, and egress pathways

- Hazardous chemicals must be stored below eye level.

- Do not store chemicals on the floor, window ledges, or balconies.

- Keep containers closed unless you are dispensing a chemical or adding to the container.

- Provide secondary containment for liquids whenever possible. Dishpans or polyethylene trays work

- Don’t store chemicals in a sink or fume hood, except for certain toxic gases that are so dangerous they can only be stored in a gas cabinet or fume

- Label containers, and be sure the container is compatible with the chemical

- Use rated storage cabinets or safety cans whenever possible—required for >10 gal. of flammables.

- Cold rooms, refrigerators, and freezers have additional requirements, particularly for flammables.

Chemical Segregation

Chemicals should always be segregated according to their specific hazard(s) to prevent unintended reactions. Begin by categorizing and separating chemicals into the following categories. Note that the order is intentional, as discussed below.

- Pyrophoric

- Water-reactive

- Flammables

- Corrosives

- Oxidizers

- Toxics

Other types of materials require more specific storage requirements such as

- Explosives

- Compressed gases

- Cryogens

As a general rule, chemicals need to be physically segregated from incompatible chemicals; some key requirements are listed below.

- Store flammable liquids in approved safety containers in . Do not store anything but flammable or combustible liquids in these

- Segregate acids from

- Keep oxidizers away from flammables and combustibles.

- Keep corrosives away from substances that they may react with and release corrosive, toxic, or flammable vapors

- Do not store chemicals alphabetically unless they are compatible.

Store the chemical in a safe container

When you store chemicals, the container must:

- be in a sound condition

- safely contain the chemical

- be compatible with the chemical.

Someone must not be able to mistake the container and packaging for food or drink.

For flammable gases or gases under pressure, your container size must:

- be less than 500 kg or 500 L

- comply with your country’s Dangerous Goods (Code.

For all other hazardous chemicals:

- your container must be less than 500 kg or 500 L or in an intermediate bulk container (IBC).

Using underground storage

If you’re not using underground storage anymore, you must empty and remove it.

If you used it for flammable gases or flammable liquids, and it has been empty for 2 years, it’s considered abandoned. You must notify the WHS regulator in your jurisdiction of the abandonment of the tank.

Storage and handling systems

You must:

- only use storage and handling systems for their intended purpose

- consider whether your storage and handling system is safe to work with before you use it

- provide training to ensure these activities are safe.

Empty handling systems before disposal. If you can’t empty the system, label it as if it contains hazardous chemicals.

Storing chemicals in bulk

You are storing a hazardous chemical in bulk if it’s in:

- a container with a capacity over 500 L or 500 kg or

- an undivided quantity over 500 kg, if the chemical is solid.

You must put a placard on these containers in line with WHS Regulations.

Secure bulk containers and any pipework or attachments to foundations and supports so they’re stable and don’t move.

Flammable substances, asphyxiants and combustible dusts

You have specific WHS duties for flammable substances, asphyxiants and combustible dusts that can create hazardous atmospheres.

Your duties apply to the:

- correct storage for flammable substances, asphyxiants, and combustible dust in confined spaces

- compatibility of the storage area to contain spills

- restriction on supplying and access to minors under the age of 16 years.

Storage Cabinets and Safety Cans

Flammable storage cabinets

Flammable storage cabinets are designed to meet specific requirements outlined by various standards such as OSHA, NFPA, IFC, and UL. They are specifically constructed to contain flammable materials and slow the spread of fire toward the materials in the cabinet.

When purchasing a cabinet for your lab, look for a cabinet that is OSHA and NFPA approved (which will fulfill UL 1275) and has self-closing doors to comply with IFC. If you have an existing cabinet, it should be labeled if it meets any of these standards.

Flammable storage cabinets are not required to be vented, and it is not recommended to do so in most cases. Improper venting can negate the fire protection provided by a cabinet.

Safety Cans

A safety can is a rated container of not more than 5 gallons (20 liters) capacity having a screen or strainer in each fill-and-pour opening and having a spring-closing lid and spout cover designed to safely relieve internal pressure when exposed to fire. They should be UL or FM approved as well as OSHA approved. They make appear similar, but typical home gasoline storage cans are not the same and should not be used in laboratories.

Corrosive Storage Cabinets

Corrosive storage cabinets do not have specific regulatory requirements. They should be designed by the manufacturer to resist corrosion. Polyethylene cabinets are generally the most resistant, while steel cabinets will have a corrosion-resistant coating and oftentimes contain polyethylene liners. As an added benefit, some steel cabinets also meet the requirements of flammable storage cabinets, which may be necessary if you are storing flammable corrosives such as pyridine, triethylamine, or glacial acetic acid—always confirm this rating with the manufacturer. Wooden cabinets will generally resist corrosion (except for the metal hardware), but they should never be used for storing any oxidizing acids, such as nitric or perchloric acid.

Venting of corrosive cabinets may be beneficial if storing volatile corrosives such as hydrochloric acid, but it is not a requirement. Many cabinets below fume hoods have ventilation connections for this purpose. If you have questions about your existing cabinets

( Navigate Flammable and Combustible Liquid Safety )

Storage Limitations

It is best practice to minimize the quantities of hazardous chemicals on hand whenever possible. Minimization of stored chemicals is a key way to reduce the likelihood and severity of an incident involving said chemicals. It is important to note that storage limitations, particularly based on fire code, often extend to large groupings of labs or even entire floors of buildings. Each space is different, so contact the Chemical Safety staff for an evaluation. Chemical Risk Assessment form )

Where to find information

The first source for chemical-specific information should be the labels and safety data sheets (SDSs) from the manufacturer. You may also contact Chemical Safety for advice.

(E-Books: Preparation safety data sheets for hazardous chemicals )