Industrial ergonomics is concerned with adapting the requirements of a job to the physical needs of the employees who perform it. When assessing a workplace, ergonomics looks at all the individual tasks involved in performing a job and analyzes how those tasks will affect the health and safety of the worker. Ergonomic assessments look at how many times a task must be performed in a row, how long it must be performed, what equipment is used to perform it, and the environment where the task is performed. The goal of these assessments is to reduce risk factors that increase stress-related injuries to muscles, nerves, tendons, joints, cartilage, or the spine. These types of injuries – known as musculoskeletal disorders (MSDs) – can occur instantly or slowly over time due to overuse and repetitive movements.

This Article is divided into four parts. Part 1 provides general ergonomic information to help employees work more comfortably and effectively. Part 2 provides a checklist to help identify workplace ergonomic risk factors. Part 3 provides a quick reference to ensure workstations are adjusted appropriately. Finally, Part 4, provides employees with an individual workstation assessment to evaluate the ergonomic design of their work area.

All workstation adjustments must be based on an understanding that working intensely or for a long time in uncomfortable or unnatural positions can pose risks. Many factors in the work environment determine whether employees work efficiently and in a manner that promotes good health and safety. By considering, acting on, and periodically reevaluating the recommendations described in this Article, it is possible to create a more comfortable, efficient, and safer work environment.

Also Read: Five Steps to Improve Ergonomics in the Office

PART 1:

General Ergonomic Information

Ergonomics in the general industry ensures employees have access to the best tools and working techniques for their work environment. Every industry can benefit from employing ergonomic equipment such as well-designed:

- lifting tools and column lifts to help during precision repairs or assembly;

- loading and offloading equipment between storage areas and workspaces; and

- positioning and response touch controls, keyboards, and screens in scanning and data input equipment.

Ergonomically-designed electric lifting columns, electric hydraulic positioners, tool lifts, and positioning equipment can keep employees from having to lift or readjust large or heavy items manually. Designs that allow for smooth control and a variety of different movements can minimize the amount of motion-related strain experienced by operators through their shifts.

All of the ergonomic ideas can be applied and customized to each industry – from aerospace, medicine, warehouses, and factory floors. The goal is to reduce injuries caused by:

- heavy repetitive tasks;

- heavy load carrying and handling tasks; and

tasks requiring repetitive or sustained awkward poses. By committing to the ergonomic principles below, employers can reduce the risk of workers developing short-term and long- term injuries that can impact performance, productivity, and the bottom line.

Read More: E-Books: Occupational Ergonomics A Practical Approach

Posture

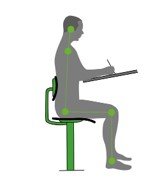

Most people think of sitting as a resting position. However, in most situations the opposite is true. Many seated postures place more strain on the body than standing. Backaches, headaches, stiff and sore muscles, and fatigue are common signs of an unhealthy posture. The ideal posture lessens the strain of sitting and increases freedom of movement in the waist. Whereas poor posture and awkward positions can create workplace injuries

Ideal Posture

- places the body at an open angle of 90° or more with the head erect and arms relaxed at the side;

- requires that equipment and materials are positioned at the height, angle, and distance to allow the operator to maintain an ideal posture;

- permits free movement;

- reduces compression of organs and back strain; and

- reduces neck and shoulder strain.

Three Main Factors Affecting the Way We Sit

Distance:

the distance required to effectively see tasks .

Angle:

the maximum angle to effectively see tasks without bending the neck.

Reach

the minimum distance required to effectively reach tasks without altering the position of the upper body.

Awkward Postures

Prolonged Overbending

- strains ligaments and muscles in the back;

- creates lower back pain and fatigue; and

- creates lower back pain and fatigue; and

Prolonged Arm Extension:

- strains muscles in the neck and shoulders;

- creates headaches; and

- causes neck and shoulder pain.

Prolonged Head Stooping:

- strains muscles in the neck and shoulders; and

- causes stiffness and pain in the neck and shoulders.

Equipment

Computer monitors and equipment display screens

When selecting a monitor or display screen, choose one with :

- a design that fits the user’s tasks;

- a large enough screen to display a sizable amount of information;

- clear and stable images that do not flicker or waver;

- brightness and contrast controls easily accessible to the user;

- adjustable screens that swivel, tilt, and elevate to provide the operator with the best viewing angle; and

- a mounting arm that allows movement in all directions, giving the added benefit of freeing up the workspace.

When adjusting the height of the monitor or display screen:

- align the top of the display no higher than the user’s eye level;

- adjust the viewing distance, usually 20 to 26 inches or arm’s length from the eyes to the screen;

- position the screen to reduce glare; and

- tilt the screen back 10° to 20° to allow eyes to look slightly downward when viewing the middle of the screen.

Keyboards

Choose a detachable keyboard when possible that:

- allows for independent positioning and angle adjustments;

- provides a fitted palm rest to support the heel of the operator’s hand and minimizes contact with sharp table or equipment edges;

- tilts 10° to help keep wrists flat;

- keeps the user’s upper arms and forearms at a 75° to 125° angle with the hands and forearms in a straight line;

- has a matte-finish surface to reduce reflection and eye strain; and

- adjusts to allow the keyboard or keyboard tray to extend below the worksurface (ranging from 26 to 28 inches).

Document Holders

A document holder should:

- be stable and adjustable in height, distance, and angle;

- provide full support for the document;

- have the flexibility to be used on

- either side of the monitor; and

- set adjacent to and at the same height as the monitor so the operator can look from one to the other without having to refocus or move the neck or back.

Work Surfaces

- Work surfaces need to:

- adjust to accommodate multiple operators and a variety of tasks (usually 23 to 30 inches);

- be large enough to accommodate all the required equipment;

- minimize glare and reflections (matte finishes are recommended);

- have adequate clearance under the work surface to prevent injury to knees, legs, shins, or thighs;

- have a depth for knee space of at least 23.5 inches at knee level and

- 31.5 inches at toe level; and

- provide room for at least a 27-inch knee width.

Chairs

The first considerations in selecting a chair are the:

- individual’s preference;

- task requirements; and

- workplace surroundings.

With these considerations in mind, select a chair that has a:

- the five-point base for maximum stability;

- a contoured seat pan that:

- allows the lower back to contact the backrest;

- supports the full width of the thighs (16 inches fits most people);

- provides a 3 to 3.5-inch allowance between the front edge of the seat pan to the bend of the worker’s knees; and

- offers soft, rounded padding at the front edge of the seat pan to prevent thigh tissue compression, blood flow restriction, and leg pain; seat pans that are too deeply padded can cause tension in hip muscles due to the user sinking too low.

- seat covering material that is porous and breathable;

- a backrest that:

- provides an easily adjustable angle and height with a support surface of at least 20 inches high and 13 inches wide;

- a lumbar adjustment of 2 inches; and

- support to the entire back without interfering with the use of arms during assigned tasks.

- adjustable armrests that:

- fit under the work surface to allow the user to remain close to the work while maintaining contact with the backrest; and

- provide support for the entire forearm to prevent shrugged shoulders and slumping, which can cause lower back and neck stiffness and pain.

- footrests for workers whose feet do not rest on the floor once the chair height has been properly adjusted are:

- large enough to support the soles of both feet;

- adjustable in height and incline (but no more than 30°);

- easy to move; and

- covered with a nonskid material to reduce foot slippage.

When adjusting the chair height ensure the:

- soles of the worker’s feet rest completely on the floor or footrest; and

- the back of the knees is slightly higher than the seat to allow free blood flow to the legs and feet

- soles of the worker’s feet rest completely on the floor or footrest; and

- the back of the knees is slightly higher than the seat to allow free blood flow to the legs and feet.

Tools

When evaluating the ergonomic design of hand tools, start by asking these questions:

- Who will use the tool? (Consider body measurements and proportions.)

- What is the work surface (where will it be used)?

- What are the specific task requirements?

- What is the tool’s function?’

Look for these ergonomic features when purchasing tools:

- The grip surface is non-slippery.

- The grip surface does not have sharp edges, undercuts, deep ribs, or finger grooves.

- The grip surface is thermally insulated so as not to get hot or cold quickly when working in a hot or cold environment.

- The grip length is 4 to 6 inches.

- The handle is made of wood and the grip surface is coated with semi-pliable material similar to the rubber used in the soles of sports shoes.

- The handle does not end inside the palm of the hand.

- The angle of the handles is formed so that the work can be done keeping a straight wrist.

- The tool’s weight is less than 5 pounds.

- The tool can be used with either hand.

- The tool and accessories are marked or color-coded for easy identification.

- The size of a one-handed tool’s handle allows the index finger and thumb to overlap by 3/8 inches when gripping. (For hammers and hammer-like tools, an overlap of 1 inch is acceptable.)

- The grip span on two-handed tools (plier-like tools) should be greater or equal to 2 inches when fully closed and less than or equal to 3.5 inches when fully open.

Environment

The physical aspects of a workplace environment can have a direct impact on the productivity, health, safety, comfort, concentration, job satisfaction, and morale of employees. Some important ergonomic factors in the work environment that deserve consideration include reach, lighting, noise, and radiation.

Reach

The maximum work area is determined by the reach of the operator without leaning forward. Most adults can reach from 22 to 26 inches. The most effective work area is the space under the operator’s forearm without extending the arm or leaning forward.

Organize a work environment so:

- routine operations are within easy reach;

- the work is directly in front of the employee; and

- it is as close and comfortable to the body as possible.

The work environment should also:

- accommodate the operator;

- allow the operator’s full range of motion to perform various tasks; and

- provide adequate room for all required equipment and materials.

Lighting

Correct lighting adds to work effectiveness and comfort. Arrange lighting to support the type of work an employee does most often. For example, if most of the work is done sitting in front of the computer or display screen, consider these factors when arranging the lighting:

- Position the equipment or sources of light so that glare or bright reflections on the display are minimized.

- Use blinds, shades, or drapes on windows to control the amount of daylight in the room.

- Locate display screens away from windows or position them at right angles to windows to minimize glare.

- Position the display between the rows of overhead lights to avoid glare.

- Avoid bright light sources in the

- worker’s field of vision.

- Use recessed or indirect lighting to avoid bright spots on the display.

- Minimize glare and avoid eye fatigue by painting surrounding walls and work surfaces with a medium color in a non-reflective finish.

- Screen glare filters reduce glare

- but are not a substitute for proper lighting since they can contribute to blurring and poor contrast of screen characters.

- Equip overhead lighting with diffusers, cube louvers, or parabolic louvers to reduce glare.

Noise

Noise, within the context of industrial ergonomics, refers to the sound levels in and around the worksite. Equipment noise can be disruptive, annoying, and harmful. Specifically, unwanted sounds can have a negative effect on workplace safety, productivity, and employee hearing. Employers should control or mitigate hazardous noise in the workplace to prevent injury and improve job quality.

Noise in the workplace can include a range of unwanted sounds from distracting annoyances to continuous high decibel levels that can lead to hearing loss. This noise pollution can impair an employee’s ability to concentrate and create a hazardous environment where safety is compromised due to employees’ inability to focus and communicate clearly.

An employer should consult with employees to evaluate their needs to reduce the risks caused by workplace noise. A noise audit, or assessment, can alert an employer to specific noise hazards. Sound buffering, insulation, and noise mitigation through the use of personal protective equipment (PPE) can help provide a safe, productive, and comfortable workplace.

Radiation

Industrial ergonomics also examines excessive levels of radiation, specifically, ionizing radiation, nonionizing radiation, and radiant heat exposure.

In occupations where there is exposure to ionizing radiation, as in x-raying pipe, time, distance, and shielding are important tools in ensuring worker safety. Danger from radiation increases with the amount of time an employee is exposed to it. Distance, too, is a tool in controlling radiation exposure. Radiation declines the further away a person is from the source. Shielding also is a way to protect against radiation. The greater the protective mass between a radiation source and the worker, the lower the radiation exposure.

Nonionizing radiation, like heat and light, is also dealt with by shielding workers from the source. Sometimes with nonionizing radiation, limiting exposure times or increasing the distance is not effective. For example, laser radiation cannot be controlled by imposing time limits. An exposure (and the resulting injury) can be faster than the blink of an eye. Increasing the distance from a laser source may require miles before the energy level reaches a point where the exposure would not be harmful. Therefore, shielding is the most effective precaution.

Another physical hazard, radiant heat exposure from the sun or in factories such as steel mills, can be controlled by installing reflective shields and by providing protective clothing. Radiation from display monitors is negligible and is not considered hazardous. However, it is recommended that operators work at arm’s length from the screen and position all workstations at least 4 feet from the sides or backs of other monitors.

Personal Health

These simple steps can reduce operator fatigue:

- Encourage employees to get up and move regularly.

- Design the operator’s workload to accommodate reasonable rest pauses.

- Practice good posture.

- Body stretches help prevent operator discomfort and fatigue.

- Use the 20-20-20 rule to reduce eye fatigue: every 20 minutes look 20 feet away from the task or monitor for 20 seconds.

- Job rotation or substitution of a less demanding activity can allow the operator to recover from fatigue.

Also Read: Photo of the day: musculoskeletal disorders(Opens in a new browser tab)

Vision Care

Anyone may experience eye problems for many reasons, including ageing, sleepiness, general fatigue, improper lighting, or untreated vision conditions. Conduct eye examinations for early detection and correction of poor vision.

Employees should discuss the type of work they do with their eye care specialists to ensure the best corrective lenses are prescribed. Knowing the viewing distance from the employee’s eyes to a display screen helps determine the focal distance. Holding a piece of string from the bridge of the employee’s nose to the screen can easily measure the distance.

As employees age, the eye lens hardens, and focusing up close becomes more difficult. This becomes noticeable from about age 35 to 40. Using a display monitor does not bring on this change, but it may bring it to the employee’s attention. Display monitor users over 40 should pay particular attention to viewing distance, glare reduction, and adequate lighting. The use of bifocals or trifocals depends on personal preference as well as the kind of on-the-job tasks.

The Center for Disease Control and Prevention reports that 8 million Americans have an uncorrected vision problem. So encourage employees to check their vision as part of a regular health care program.

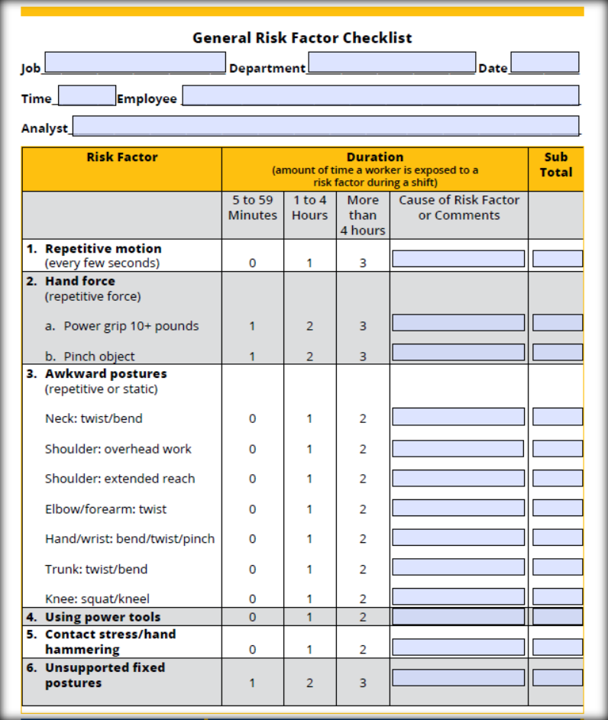

PART 2:

Ergonomic Risk Factor Checklist

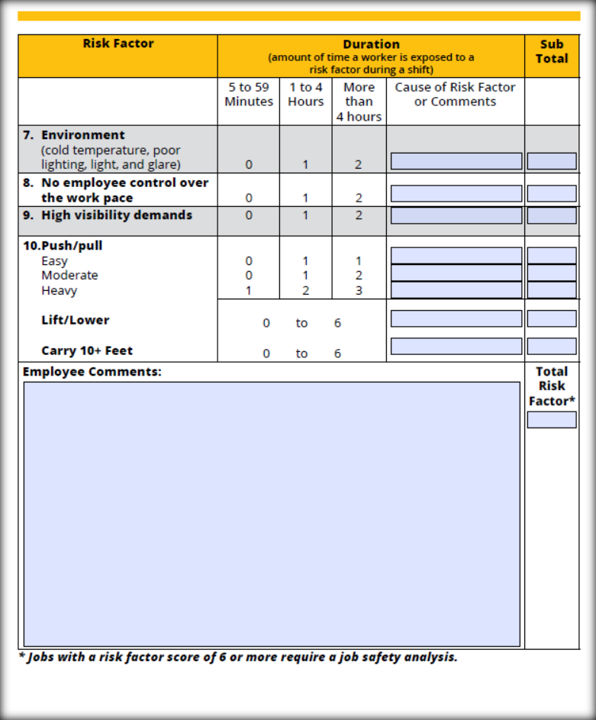

The checklist in this section is a quick way to identify on-the-job risk factors for MSDs. One checklist should be used for each employee. Each task an employee performs is scored separately. If more than one task is performed, the scores are added together.

Each risk factor is scored by the length of time (the duration) the employee does the task. In the case of “repetitive motion” (see page 16), the task is scored a 0 for 5 to 59 minutes, 1 for 1 to

4 hours, or 3 for more than 4 hours. However, if the employee performs a repetitive task multi- ple times during a shift, such as bending and twisting the hand for the first 50 minutes of the shift and again in the last 50 minutes of the shift, the total duration the employee performs the task is 1 hour and 40 minutes, or a score of 1 (not 0 + 0). For any score of six or more, employers should conduct a job safety analysis to make corrections or modifications for the safety of the employee.

before beginning the ergonomics checklist to better understand and identify the risk factors that can cause injury.

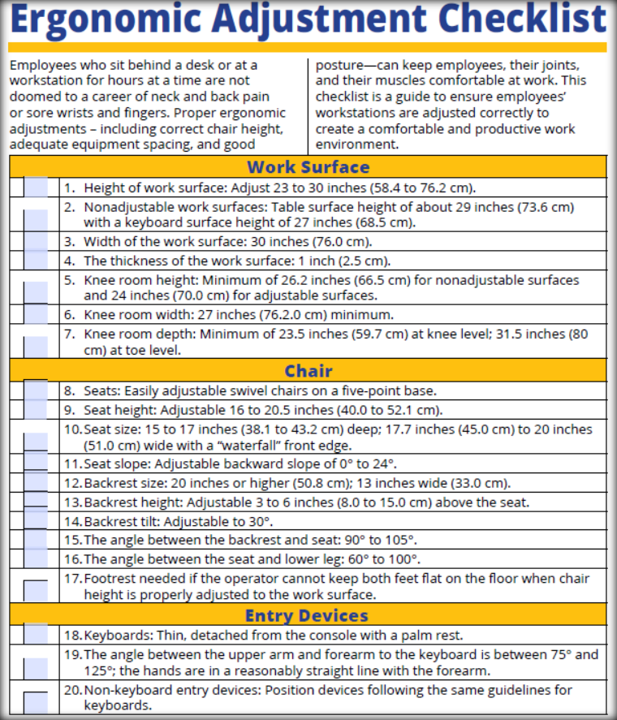

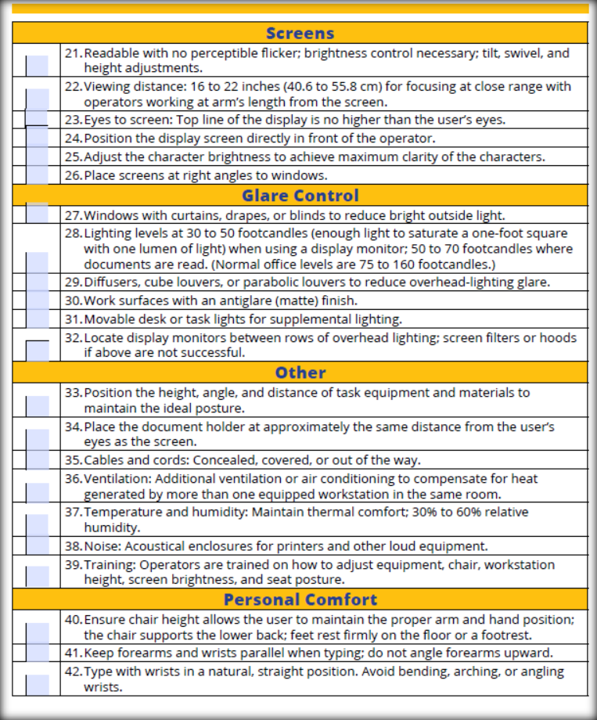

PART 3:

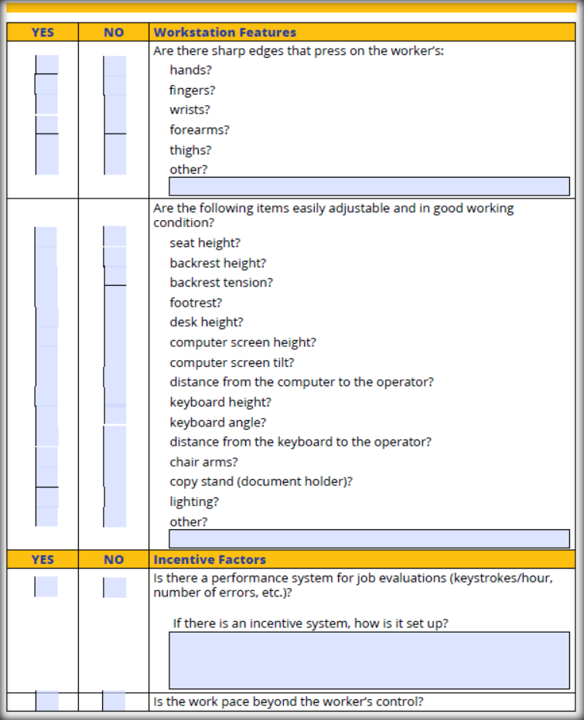

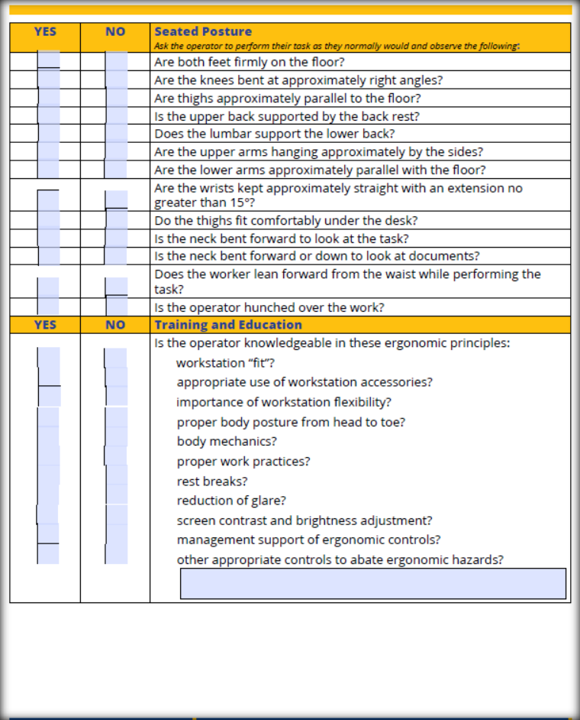

Ergonomic Adjustment Checklist

Employees who sit behind a desk or at a workstation for hours at a time are not doomed to a career of neck and back pain or sore wrists and fingers. Proper ergonomic adjustments – including correct chair height, adequate equipment spacing, and good posture can keep employees, their joints, and their muscles comfortable at work. This checklist is a guide to ensure employees’ workstations are adjusted correctly to create a comfortable and productive work environment

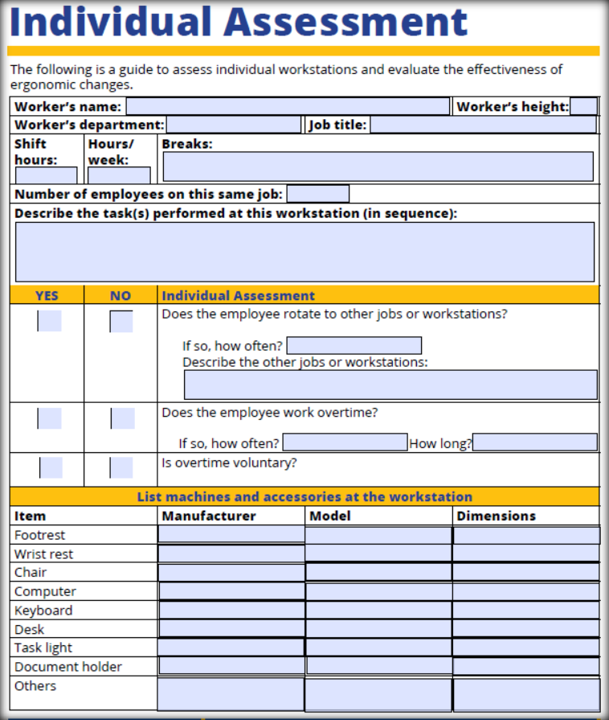

PART 3:

Individual Assessment

Also Download: Templates: Ergonomics Program and Ergonomic Assessment Tool