Liquid Hydrocarbon Storage Tank Fires system

13 min readA major fire is a credible scenario for any site or installation that is involved in the storage of liquid hydrocarbons (oil and fuels). Similarly, a major explosion scenario (albeit less probable than a major fire scenario with respect to hydrocarbons storage) could be considered for bulk hydrocarbon storage sites if the lessons of the Bunce field explosion in 2005 are put in perspective.

This article is therefore set to highlight the scale of the threat posed to people, assets, business continuity, and the environment by hydrocarbon storage tank fires, and discuss the main tank fire hazards and key factors that influence the success or failure in the prevention and suppression of oil storage tank fires

Introduction

Hydrocarbon storage tank fires present peculiar hazards that should require owners and managers of such facilities to exercise adequate diligence with respect to the prevention, protection, and emergency preparedness suitable for managing risks associated with hydrocarbons storage fire and explosion events. Hydrocarbon’s storage tank fires do not occur frequently, nevertheless, such incidents still happen notwithstanding the various engineering and fire protection improvements learned from previous fire incidents and furnished in different codes and standards such as NFPA (National Fire Protection Association) and API (American Petroleum Institute).

Managing fire safety in oil storage sites goes beyond the existence of safety reports, procedures, and the availability of inbuilt safety features (e.g. fixed/mobile firefighting systems and tank overflow protection). Although safe designs, operating procedures, and safety reports complete with risk assessment are very important, nevertheless experience has shown that oil tank fires still occur due to lapses in prevention.

measures and in some cases such fires progressed to catastrophic dimensions due to inadequacies in fire pre-plans and emergency preparedness.

Perhaps, some of the historical oil tank fires would have been prevented or their consequences mitigated if adequate attention had been paid to maintenance and integrity assurance of facilities on one hand and fit-for-purpose emergency preparedness reviews on the other hand. Emergency preparedness reviews shall particularly address the adequacy or otherwise of protection against primary containment aspects including tanks, piping, overfill protection, valves (are shutoff valves fire safe?), venting systems, roof seal, corrosion monitoring, and pumps. Other important aspects of the emergency response review are operational controls (adequate logistics and materials – equipment, water, foam, and manpower) and administrative controls (major accident hazard identification, pre-fire plan, tank fire training, and drills for emergency response crew).

Types of storage tanks

Above ground and atmospheric storage tanks are usually described by the nature of their roof, and the physical properties of the stored hydrocarbon liquid. There are three main types of tanks used for storing combustible or flammable liquids, namely:

- Fixed Roof Tank (Cone Roof)

- External Floating Roof Tank (Open Top)

- Internal Floating Roof Tank (Covered Top)

Flammable liquids are normally stored in floating roof tanks while combustible liquids are normally stored in fixed or cone roof tanks.

Fixed roof tanks have vertical cylindrical sides and are covered with fixed cone-shaped roofs that are welded to the top edge of tank shells. The roof-to-shell seam is required by API standards to be a weak seam such that in the event of an internal explosion, the roof would separate from the tank vertical shell to prevent failure of the tank bottom seam. This design requirement prevents the tank from propelling upwards and permits the tank to retain its contents so that any resulting fire will involve the full surface of the exposed flammable liquid.

External floating roof tanks (open top) have vertical cylindrical sides and the tank contents are covered with floating roofs that move along shells in tandem with tank liquid level. The floating roof consists of pans that float on pontoons or double decks that float directly on the flammable liquid surface. The floating roofs have rim seals attached to their full perimeter, covering the space between the floating roof and the tank shell, thus preventing the escape of vapors from the tank.

The internal floating roof tank (covered top) is a combination of the fixed roof and the external floating roof tanks. The main difference between an internal floating roof and an external floating roof is the incorporation of a fixed roof in the former to protect tank contents from the atmosphere. This type of tank is typically used in the storage of highly flammable products such as gasoline or naphtha and can be identified by the open vents in the tank sidewalls just beneath the roof joint.

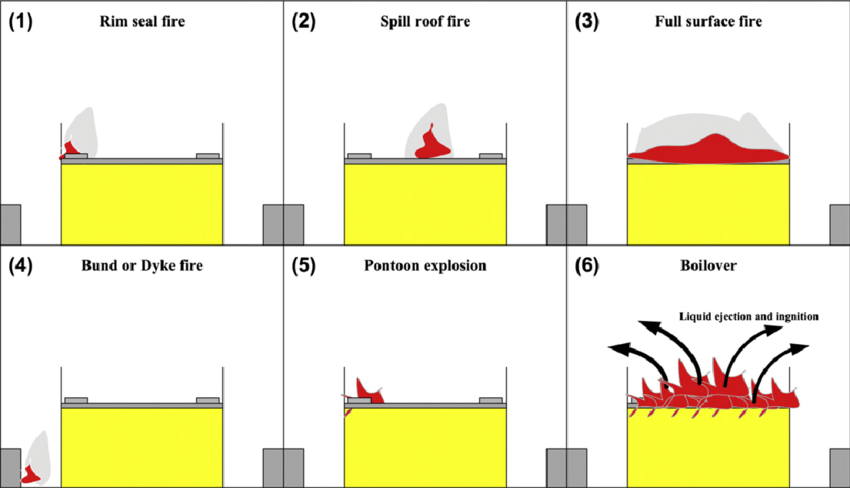

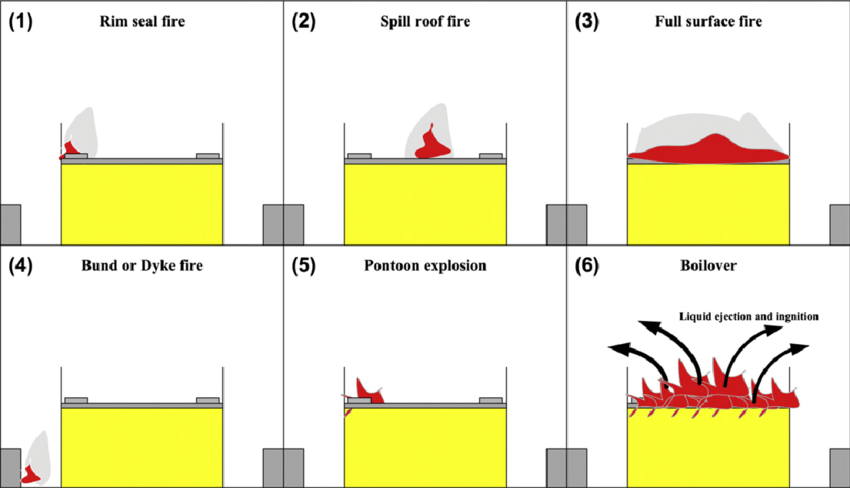

Typical incident scenarios

Different incident scenarios associated with storage tank fires present different hazards with consequences ranging from minor to catastrophic. The following incident scenarios are typical for hydrocarbon storage sites.

- Explosion– often disables fixed firefighting systems leaving no other suppression option other than mobile foam application

- Boilover – a violent and catastrophic event during prolonged crude oil tank fires. See section 6.6.

- Rim Seal fires – rim seal fires are common to open-top tanks but could also occur in covered top tanks. It is usually less challenging to suppress provided the roof is not destroyed by explosion or made to sink by excessive dumping of water on the roof during firefighting.

- Vent fires – vent fires are associated with cone roofs and covered top tanks, and usually happens when hydrocarbon vapors escaping from vents are ignited by lightning strikes.

- Overfill ground fires (pool fires) – overfill ground fires are common to the three main types of storage tanks and can be a result of tank overfill due to overfill protection equipment failure or operator error or both. Provided the dikes are not compromised and the tank overfill detected in a reasonable time, the product will be confined to the dikes and the fire would be treated as a pool fire. However, if the dike walls, penetration, and valves are compromised, the burning product could escape from the dike creating possible escalation of the fire

- Full surface fire (unobstructed) – obtainable when the floating roof sinks or when the fixed-top is blown away.

- Full surface fire (obstructed) – obtainable when the roof fails and impedes 360 ° access to the burning surface

Pre-incident planning

Tank fires present a formidable challenge and could escalate to complex events with catastrophic consequences if approached without an effective strategy. Having an incident plan in itself does not guarantee success in tank fire fighting unless such a plan is tested regularly and also sufficient in terms of preventive and mitigation measures as reasonably practicable. Pre-incident planning should focus on aspects such as facility layout, access to and within the facility, tanks (number of, diameter, height), stored product/fuel type and inventory, environmental conditions (weather – ambient temperature, rain; flooding, wind), terrain – equipment staging and water runoff, fire scenarios including the worst-case scenario, firefighting equipment (fixed, mobile systems), facility location – remoteness or proximity to mutual/municipal assistance, facility fire brigade, availability of foam concentrate and other foam making and discharge materials, water supply and logistics (which is a critical success factor for oil tank fire suppression).

Site-specific pre-incident desktop planning essentials including but not limited to the following:

- Consideration of the results of emergency preparedness review, hazard identification, and risk assessment based on foreseen incident scenarios – tank fire, bund fire, tank collapse, etc.

- Review of existing calculations for water/foam requirements, review of installed systems (fixed/mobile), and compare resultant requirements with available resources (materials, systems, manpower)

- Determine the sort of firefighting policy that fits your site? – attack fire with fixed equipment or mobile equipment, pump tank inventory out, let tank burn, protect adjacent tanks, etc.

Limitations of applicable standards

The design and installation of most fixed or semi-fixed foam fire protection on storage tanks are based on NFPA 11. Provided a fixed fire installation is not damaged, it should on proper application suppress rim seal fires. However, when an explosion precedes fire in storage tanks incidents, the fixed systems are most likely to be damaged thus making it impossible to suppress associated fires unless an alternative fire fighting system (mobile system) is employed.

For brevity, the limitations of the NFPA 11 standard are as follows:

- Monitor nozzles shall not be considered as the primary means of protection for fixed roof tanks over 18 m (60 ft) diameter (design criteria for foam monitors and hand lines)

- Fixed fire protection is likely to work for small tanks particularly for seal fire conditions.

- Fixed fire protection design is solely for seal fires, NOT for full-surface fires.

- For full surface fires, monitors are the only option for suppression.

- In most cases, storage tanks firefighting sized on prevailing NFPA guide involved in surface fires have been allowed to burn out

Therefore, when storage tank protection is limited to fixed systems, there would be no chance to confront the fire once the system has been disabled by the explosion. In this circumstance, dependence on fire truck monitors may not be effective particularly for full-surface fires considering the sustained and higher rates of foam application required to produce reasonable foam bite and fire knockdown.

In the absence of mobile equipment (high volume nozzles and foam lines), storage tank fires may rage beyond the capability of the emergency response team forcing them to surrender to the fire allowing tank burnout with grave consequences of boilover for products with boilover tendencies (e.g. crude oil, hydrocarbon mixtures of different boiling points).

Specific storage tank fire hazards

Compromised bunds

The focus in oil storage tank hazard management is the prevention of fire and control of fire escalation. Therefore, it is fundamental that tank inventory must be kept in containment at all times and should not be let out. Failure to keep inventory within primary or secondary containments during emergencies could lead to exposure of people at the site, third party people in the vicinity of the installation and the facilities to the risks of explosion and fire from spreading oil that could not be constrained by secondary containment due to integrity lapses or operational errors. Besides the basic provision of dikes that meet the requirements of tank inventory holding, attention should be paid to bund integrity (ensuring that bunds and rains are properly examined and maintained, and that dike penetration is not compromised) and operational issues like letting the bund drain valve in an open position.

Thermal fluxes and radiation

Thermal fluxes and radiation associated with storage tank fires pose significant hazards to people and facilities. People (emergency response personnel and operators) and adjacent facilities might be affected by radiation and incident thermal fluxes during tank fire incidents depending on the amount of heat released by the burning product (surface area of the fire and the product involved), a distance of the fire to the receptor

(person or facility) and wind speed. Thermal radiation consequences on people could range from first-degree burn injury to fatality, while consequences on facilities could involve the weakening of materials’ stress-bearing capacity leading to structural failure and possible loss of containment of hazardous materials.

Radiation level of 5 kW/m2 and above is capable of causing second-degree burns to people within 60 seconds of exposure (FEMA Publication, 1988) and impairs escape ability, while radiation level of 10 kW/m2 and above would be potentially fatal with 60 seconds. For information on thermal radiation level of concern and associated thermal doses refer to Table 1.

Table 1: Thermal radiation Level of Concern (bare skin basis)

Appropriate and sufficient control measures may include the provision of water curtains and fixed cooling water for incident heat susceptible installations (e.g. vessels/pipes and their supports). Such control measures shall be foreseen in site-specific emergency response procedure and should go beyond the control of hazards of structural collapse and loss of containment, to managing the incident heat hazard posed to people by establishing safe response threshold values for likely heat radiation levels focusing on access for fire-fighters, escape path (emergency exit) and activation of protective cooling for people. The fatality probability relating to thermal dose levels is furnished in Table 2 to underscore the need for adequate assessment and management of people’s exposure to thermal flux levels with respect to acceptable separation distances.

Table 2: Best conservative estimates for thermal dose fatality probability

Heat stress

Heat stress is a common hazard in fire fighting or other hot and humid environments where the body’s natural cooling efficiency could be impeded, thus triggering heat illness. Besides the heat from fire or environment, the body also generates heat during physical work, exertion, or exercise. The effect of heat stress on people particularly emergency responders can be worsened by the properties of the protective clothing and continuous physical exertion. Recognizing heat stress symptoms and taking appropriate action to stop progression to heat stroke (which is a medical emergency) is essential in minimizing the health effects of heat stress and heatstroke. Excerpts from (OHSCO, 2009) on heat stress symptoms are furnished in Table 3. As a rule of the thumb, frequent rehydration and rest rotation are pivotal to forestalling heat illness at work.

Table 3: Heat stress symptoms

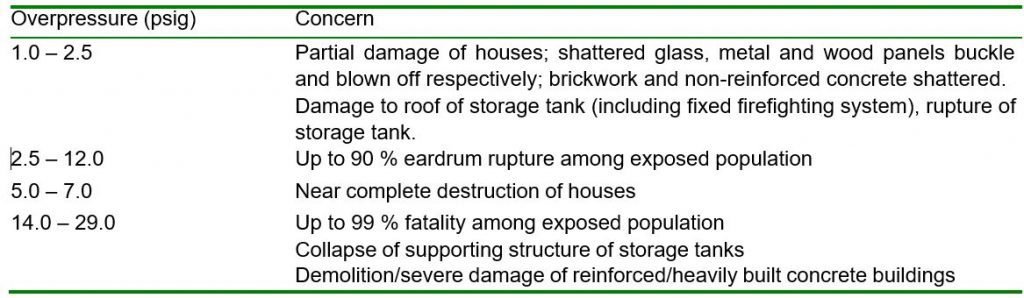

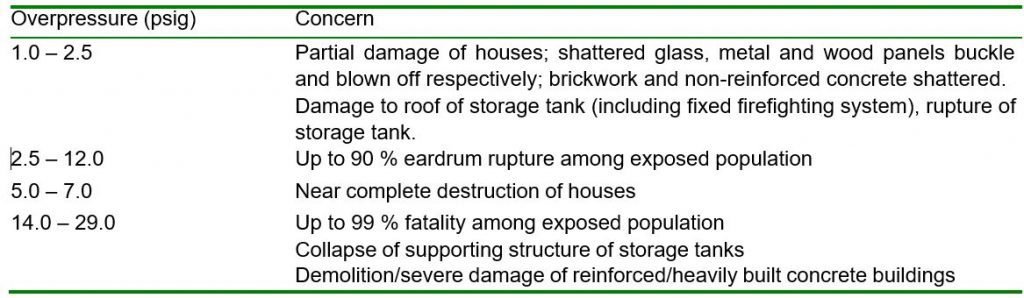

Blast overpressure.

Blast overpressure is a shock wave from an explosion due to the energy released by the explosion. It is instantaneous and travels at the speed of sound. It radiates outwards from the center of the explosion and generates hazardous missiles that may increase the scale of injuries. Excerpts from (NOAA, no date) on overpressure levels of concern are furnished in Table 5.

Table 4: Blast overpressure Level of Concern

Toxic substances

Toxic substances are produced during fire incidents and constitute formidable hazards to firemen, emergency response resources, and operating personnel. The toxicity of smoke and fumes will depend on the type of fuel and materials involved in the fire and to some extent the amount of oxygen available for combustion. Specifically for crude oil fires, the associated smoke contains a mixture of gaseous and particulate compounds including carbon dioxide, carbon monoxide, nitrogen oxides, sulfur dioxide, volatile organic compounds, polycyclic aromatic hydrocarbons, hydrogen sulfide, aerosols, and soot. Health impact could range from respiratory irritation, loss of physical performance, confusion, inability to escape, and chronic life-threatening poisoning to immediately dangerous to life.

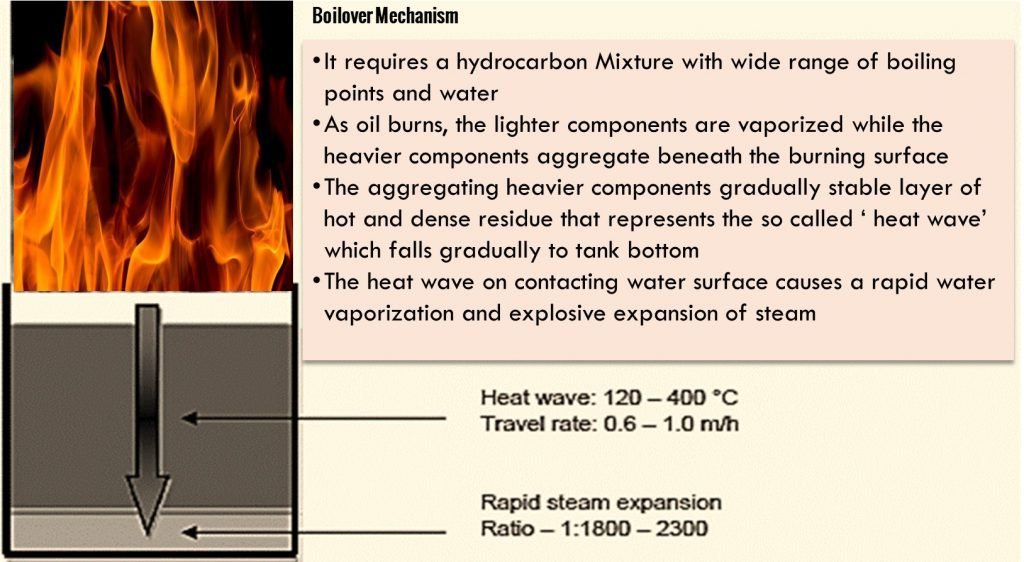

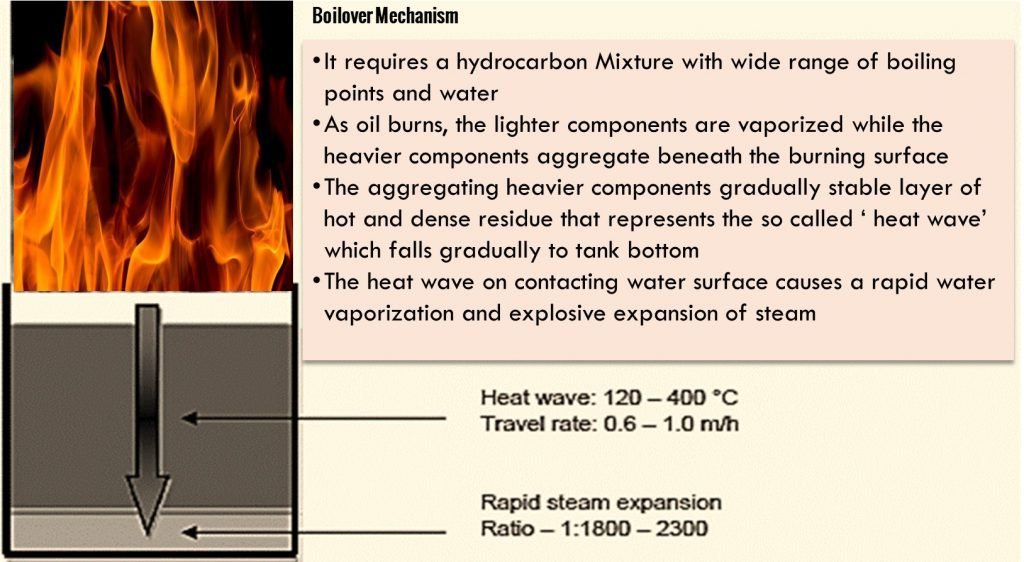

Boilover

Boilover is a phenomenon associated with storage tank fires where the burning product (crude oil or a blend of hydrocarbon liquids) is explosively released from the tank when the burning oil makes contact with water at the bottom of the tank. A boilover represents the worst-case scenario in the event of a crude oil tank on fire. Mid-range gravity crude oils or blended fuels oils with a wide range of hydrocarbons have the potential for boilover during fires that last for extended periods. When faced with a potential boilover, the incident commander must consider the evacuation of people from the tank vicinity when a heatwave approaches the water interface at the tank bottom. Since tank wall temperature or noise are not definitive guides (LAST FIRE update, 2009) in tracking the heatwave, an infrared thermal imaging camera may be employed to locate the position of the heatwave; if available. Alternatively, with respect to pre-fire tank conditions; precautionary estimates of the hot zone position could be made using a generous hot zone advance rate of 1.5 m/h.

The following are typical of crude oil boilover:

- A boilover covers approximately 10D (D is tank diameter) or more (LAST FIRE update, 2009)

- The heatwave advances from the top towards the bottom of the tank at approximately 0.6 –1.0 m/h

Figure 1: Boilover mechanism

Learned lessons

In the aftermath of the Buncefield fire incident, many tank operators and owners of liquid hydrocarbon storage sites are yet to learn the lessons of that incident. Devastating tank fires have continued to occur, catching operators off-guard and exposing the lack of forethought, expertise, and preparedness of victim organizations. Some notable post-Buncefield tank fire incident includes but not limited to Amuay (Venezuala) refinery explosion and tank fires – 2012, Jaipur (India) tank farm fire disaster – 2009, Porto Rico tank farm disaster – 2009, and most recently Kiev (Ukraine) oil depot fire disaster – June 2015.

For brevity, lessons that ought to be learned from numerous hydrocarbon storage tank fires include but not limited to the following:

- NFPA limitations – recognizing NFPA limitations with respect to fire fighting sizing for tanks (i.e. fixed system which is often rendered dysfunctional by fire/explosion, not sized for surface fires) and making appropriate provisions for combating full surface fires which can only be suppressed with

- Logistics – represents the greatest challenge. Portable high-volume water and foam long-range monitors, high-volume fire water relay pumps and hoses, adequate stock or availability of foam concentrate (best packed in totes) based on fire pre-plan assessment, and continuous water supply are imperative for meaningful fire suppression effort.

- Foam quality – foam is the sole extinguishing agent whose quality must consistent and proven to be effective. It is prudent to carry out foam performance tests to check foam quality and verify manufacturers’ claims as poor foam quality is easily broken down or disrupted by light winds leading to prolonged extinguishing times and can present dangerous exposure for firemen.

- Emergency preparedness review – comprehensive and periodic reviews of preparedness in vital aspects such as containment (primary and secondary), equipment, logistics, fire pre-plans and crew training for oil tank fires

Conclusions

Tank fire incidents may not be frequent, but they still happen even in the post-Buncefield era, some with devastating consequences. Recent tank fires continue to expose organizational lapses in preventive measures particularly inadequacy in maintenance and integrity assurance of primary/secondary containment and other engineered safety systems. Further organizational lapses relating to inadequate operational controls, inadequate logistics, absence of suitable and tested pre-fire plan, and poor tactical approach occasioned by inadequate training and experience of the crew all combine to permit tank fire escalation with serious consequences for personal safety, assets, environment, and business continuity.

Oil tank fire emergency is completely different from structural fire emergency, therefore effective control of tank fires would require the intervention of competent crew with the requite knowledge and experience in combating tank fire. In extinguishing the Orion refinery tank fire, Williams Fire demonstrated the importance of knowledge and experience in tank fire emergencies (utilizing high-volume pump and foam monitors with modified NFPA foam requirements). Therefore, for any operator or organization to successfully respond to tank fire emergencies, adequate attention must be paid to fire pre-planning, crew training, emergency preparedness reviews, and regular testing of response plans.