As tools, technologies, and processes in the workplace change, so must the methods and practices used to prevent workplace injuries. This article focuses on the three main components of a successful ergonomics program: developing knowledge of musculoskeletal disorders, reporting their signs/symptoms, and controlling ergonomic hazards.

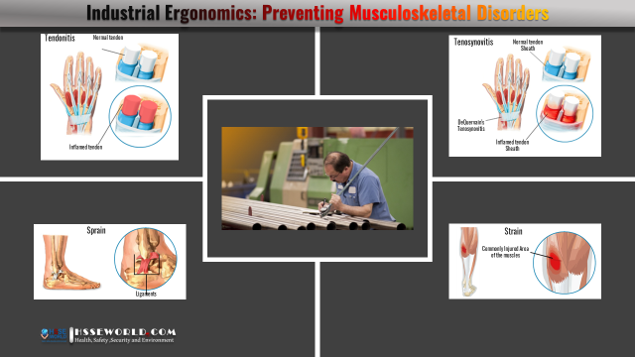

- Tendonitis – Trigger Finger, DeQuervains Syndrome, and Epicondylitis.

- Nerve Compression – Sciatica and Carpal Tunnel Syndrome.

- Other types of musculoskeletal disorders – Tension Neck Syndrome and Raynaud’s Phenomenon.

- Signs and symptoms of MSDs.

- Importance of reporting MSD symptoms.

- Determination of MSD incidents and risk factors.

- Job Hazard Analysis.

- Ergonomic and work practice controls.

Photo of the day: musculoskeletal disorders

BACKGROUND

Preventing injuries is the purpose of the company’s ergonomic program. This program, like other safety programs, requires employee participation to be successful.

The program consists of three main components:

- Developing knowledge of musculoskeletal disorders, including their signs and symptoms;

- Reporting these signs and symptoms so proper action can be taken;

- Controlling ergonomic hazards that are found to exist.

MUSCULOSKELETAL DISORDERS

A musculoskeletal disorder is a disorder that affects a part of the body’s musculoskeletal system, which includes bones, nerves, tendons, ligaments, joints, cartilage, blood vessels, and spinal discs.

Factors that can contribute to musculoskeletal disorders include heredity, physical condition, previous injury, pregnancy, poor diet, and lifestyle.

TENDONITIS

A common musculoskeletal disorder is tendonitis. This occurs when a tendon and its lining become inflamed. Tendons help attach muscle to bone to allow movement of a joint.

When tendons are inflamed, pain, swelling, and tenderness occur in the joint area. Also, stiffness and a decreased range of motion can occur.

Some specific types of tendonitis include Trigger Finger, which affects the ring and middle finger, and DeQuervains Syndrome, which affects the base of the thumb.

Epicondylitis affects the elbow and is also known as tennis elbow or golfer’s elbow depending on which tendons are involved.

Know 9 Tips to Prevent Carpal Tunnel Syndrome

NERVE COMPRESSION

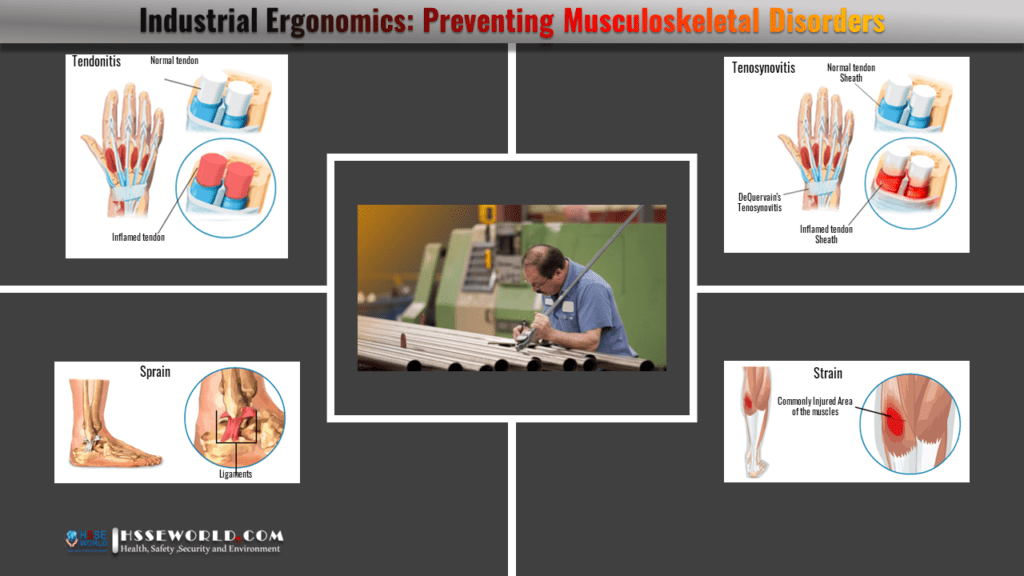

- Nerve compression is another common type of musculoskeletal disorder.

- Nerves that transmit signals from body parts to the brain are located throughout the body. They often run through small tunnels and between vertebrae in the spine.

- Various conditions can cause nerves to become squeezed, pinched or compressed. This can result in shooting pain, numbness, weakness, and loss of coordination.

- Sciatica occurs when the sciatic nerve in the spine becomes compressed. Symptoms appear in the back of the leg and side of the foot.

- Carpal Tunnel Syndrome occurs when swelling causes the median nerve in the wrist to become compressed.

OTHER TYPES OF MUSCULOSKELETAL DISORDERS

- Symptoms of Tension Neck Syndrome are neck stiffness and pain. This disorder is mainly caused by

poor posture.

- Raynaud’s Phenomenon is a loss of blood circulation which results in whitening and numbness of the fingers.

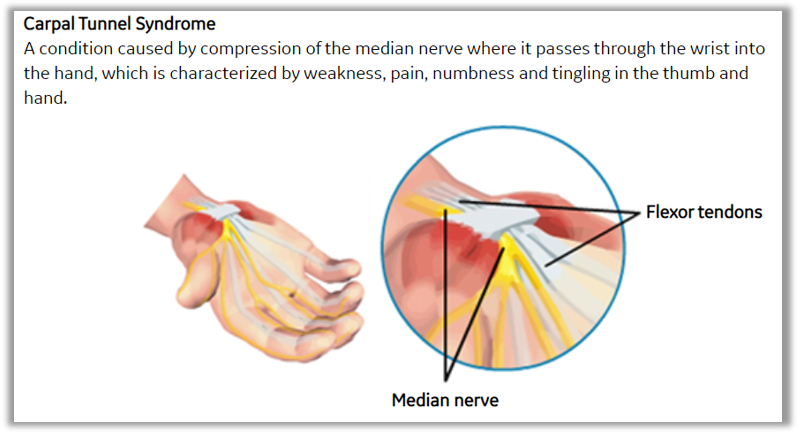

- Torn muscles and sprained ligaments are also considered musculoskeletal disorders.

SIGNS AND SYMPTOMS OF MSD’s

Being familiar with the signs and symptoms of MSD’s allows us to recognize and report potential problems.

The following are some of the signs and symptoms of MSD”s:

- a decreased range of motion, such as restricted or limited movement in the joints (knee, elbow, wrist, neck, or shoulder);

- abnormal formation of extremities, such as curled fingers or toes;

- a noticeable decrease in grip strength, making it difficult to hold and lift objects;

- a loss of muscle function or control, which can cause feelings of heaviness or clumsiness in the affected area;

- fingers or toes turning white;

- sensations such as pain, numbness, tingling, burning, cramping, or stiffness.

If you experience these types of warning signs, you should report them right away.

IMPORTANCE OF REPORTING MSD SYMPTOMS

Failing to report symptoms of musculoskeletal disorders can lead to increased inflammation and increase the severity of the disorder.

As the condition worsens, pain tends to radiate to different parts of the body. This makes a proper diagnosis more difficult.

Without proper treatment, a condition that could have healed easily can develop into a chronic injury.

When reporting possible musculoskeletal disorders, specific information needs to be given. At a minimum, this will include the physical symptoms, the worker’s job description, and the date the symptoms first appeared.

All employees will be given specific instructions on the company’s reporting procedures. Only through prompt and proper reporting can appropriate medical treatment and preventive action be taken.

DETERMINING MSD INCIDENTS

When beginning the process of controlling possible MSD hazards, two important determinations must be made concerning the reported symptoms and the job tasks in question. First, it must be determined if the reported signs and symptoms are, in fact, due to a work-related musculoskeletal disorder. Because many symptoms of MSD’s are also symptoms of normal aches and pains, OSHA has established guidelines for determining work-related musculoskeletal disorders. If a work-related MSD has occurred, it is referred to as an MSD incident.

An MSD incident has occurred if the reported signs and symptoms meet any of the following conditions:

- the condition is work-related and medical treatment beyond first aid is required to treat the symptoms;

- the condition is work-related and the affected employee requires restricted duty or time away from work to recover;

- the condition is work-related and the reported signs and symptoms last more than seven consecutive days.

DETERMINING MSD RISK FACTORS

The second step toward controlling possible ergonomic hazards is to determine whether the job in question has MSD risk factors. These factors are work conditions that may increase the risk of musculoskeletal disorders.

- Force is an MSD risk factor. Some tasks require pushing, pulling, lifting, squeezing, or other physical activities to do the work.

- Awkward posture occurs when the ideal body position is not maintained while performing work. Examples include reaching behind, twisting, kneeling, or reaching overhead.

- Repetition is performing the same motions over and over gain. The level of risk depends on speed, duration, and the number of muscle groups used.

- Vibration usually occurs when using powered tools or equipment. The action of the tool transmits vibrations through the hand and arm and into the body.

- Contact stress can occur when body parts are forcefully pressed into a hard surface or edge and soft body tissue is pinched or crushed. Examples include the stress placed on the knees when kneeling or on the thighs by repeatedly leaning into the edge of a counter or table.

- The temperature of the work area may also be a risk factor. Extreme cold temperatures reduce blood flow, dexterity, and muscle strength while extreme heat can cause rapid muscle fatigue.

- You must be able to recognize MSD risk factors so you will know when preventive measures should be used.

- You should also understand the difference between a risk factor and a hazard. The presence of risk factors does not necessarily make a job hazardous.

- When work is performed properly while using approved control measures, a job with risk factors can be done safely. Ergonomic control measures are used to control MSD risk factors and prevent them from becoming hazards.

Musculoskeletal Disorders (MSDs) in the Prep Kitchen

JOB HAZARD ANALYSIS

- If an MSD incident occurs while a job with risk factors is being performed, a job hazard analysis will be conducted to determine what control measures are needed.

- This combination of events is referred to as an action trigger because it triggers further action to be taken.

- The job hazard analysis is performed to determine whether the MSD risk factors present a hazard to the employee performing the job.

- This process includes talking with employees who perform the job. Employees give valuable information about job tasks and actions.

- In addition, actual job functions will be observed so data can be gathered on the specific risk factors involved. Part of this data will include the magnitude, frequency, and duration of exposure.

- Magnitude is a measurement that reflects the amount of effort or strength required to do the task.

- Frequency is a measure of speed and indicates how often a task is performed during a unit of time.

- Duration is the length of time the sequence of actions is performed continuously.

- Each of these measurements is taken into account when assessing a job for MSD hazards.

Templates: Ergonomics Program and Ergonomic Assessment Tool

ERGONOMIC CONTROLS

- When the job hazard analysis indicates the presence of an ergonomic hazard, measures will be put in place to control the hazard.

- Engineering controls are physical changes to the job that reduce ergonomic hazards. These may include such things as redesigning the workstation to better fit the employee; changing the type, style, or use of tools; or, adding equipment to the job to assist employees.

- Because engineering controls are not practical in many cases, it is often necessary to use administrative controls to address a hazard.

- Administrative controls are changes in the way work is assigned or scheduled to reduce the frequency or duration of exposure.

- This may include periodically rotating employees from one job to another to reduce time spent performing specific tasks; enlarging the scope of a job so an employee can participate in related job tasks rather than constantly performing the same tasks; and, reducing the pace of work to reduce the frequency of exposure.

- Work practice controls are techniques used by employees to control ergonomic hazards. Each of us must take responsibility for our own safety by performing tasks in the safest possible manner.

A Model for Managing Workplace Ergonomics ISO45001

WORK PRACTICE CONTROLS

- Maintaining a neutral posture while performing job tasks is an example of work practice controls.

- Neutral posture for the wrist is 10-15 degrees of extension with either the thumb to the side when keyboarding or with the thumb up while using tools.

- Never work with the wrist flexed downward or to either side.

- A neutral position for the shoulders and arms is obtained when the upper arm hangs straight down and

forms a 90-degree angle at the elbow. Working with arms raised too high or too low causes added strain.

- Neutral posture for the back is when the spine maintains its natural shape and lumbar curve. This is very important when lifting, but is also critical when standing or sitting as well.

- Neutral posture also includes keeping the head and neck centered over the shoulders rather than twisted or bent. This often means adjusting your work area so the primary work focus is centered in front of you.

- Other examples of work practice controls include team lifting to reduce back strain and taking quick breaks to interrupt repetitive tasks. These breaks, sometimes called micro or recovery breaks, are taken at your workstation to break up periods of repetitive tasks.

- Because every job task is different and every employee is unique, ergonomic control measures must be designed for a specific task and often for a specific employee.

- If you have any questions about your job tasks or the company’s ergonomic program, ask your supervisor.