Companies all over the world put electrical safety programs into place to protect their teams from electrical injuries and casualties, and to prevent fire damage on their property. These companies are lead by business leaders who are responsible for reducing and eliminating the risk of arc flash/electric shock hazards, but they are falling short of protecting their employees

Arc flashes are deadly electrical blasts that pump out serious amounts of energy. According to statistics provided by Capshell, Inc., five to 10 American workers are killed or injured from arc flash hazards every day. That’s a staggering amount when you put it into perspective.

Companies face constant dilemmas in how to protect their workers from arc flashes, like purchasing expensive personal protective equipment (PPE) while maintaining a tight budget or making sure employees wear PPE without understanding if it’s adequate. Some employees don’t want to wear their protective gear if it isn’t comfortable or during hot temperatures.

Another dilemma they face is that their electrical utility performs system upgrades that are necessary to keep up with higher electric demands for contract capacities while maintaining power quality and reliability. It’s a bit of a catch-22 because upgrading their electric system, can put workers at greater risk to electric hazards and higher incident energy due to the increasing fault current.

(Learn more in 5 Leading Electrical Hazards and How to Avoid Them)

The severity of an electrical injury depends on a few factors, such as:

Shock

- Amount of current AC or DC – (60 mA for heart fibrillation) both are lethal

- The electrical pathway the current took through the body (across the chest left hand to right hand would be very lethal)

- Duration of the shock (before disconnected from the circuit): The heat energy to our tissue is proportional to the square of the voltage (increasing the voltage by a factor of 1 increases the heat energy by a factor of 10)

A 2016 Industrial Safety & Hygiene News report showed that after surveying 500 workers who were active in fields exposed to arc flash and flash fire hazards, 38% of those said they didn’t wear PPE. They claimed their employer failed to provide the proper PPE and/or the PPE cost too much. Those who did choose to wear PPE claimed it was because of their belief that workplace safety is a top priority and they wanted to be compliant with industry regulation and company policy. 56% of those surveyed also admitted to narrowly escaping an arc flash injury at some point in their career. And half of those who were injured didn’t return to work immediately because of the severity of their injuries.

Documented injury examples in this report included:

Arc Flash

- Tissue burns at points of contact or points of exposure

- Internal organ damage (60ma (milli-amps) will stop the heart)

- Death — blunt force trauma, immediate electrocution.

- (50cal/cm2 will crush the lungs)

- Secondary injuries, such as falling, choking/suffocating, etc.

So, What Are the Causes?

- Human error & mistakes

- Commonly during maintenance

- Mishandling a tool, wire, metal cover, etc.

- Negligent preventive maintenance

- Faulty electrical system design or legacy equipment

Sometimes energized work can be justified for reasons of infeasibility or life-safety. In these types of justified energized work, special safety-related work practices are implemented to lower all risks to an acceptable level.

But even if a worker does wear the recommended PPE while working energized and the company follows all of the proper industry compliance standards and rules, there’s still a potential risk and it’s on the team leader and all employees to protect themselves from injury, otherwise, the job simply stops.

All processes to mitigate shock hazards are standardized and definitely available but the solutions are not so simple. The solutions to mitigate are completely relative to the risk for that specific task during any given day. This puts heavy pressure on the leadership team and the employees performing the task and put even more pressure on the process to make sure human error and lack of knowledge increase the risk resulting in an accident.

Obviously, there’s a need for increased training, decision making and specialized skills for working on or about electrical hazards. This is what leaders in organizations are accountable to keep in check.

4 Ways to Improve Arc Flash Safety

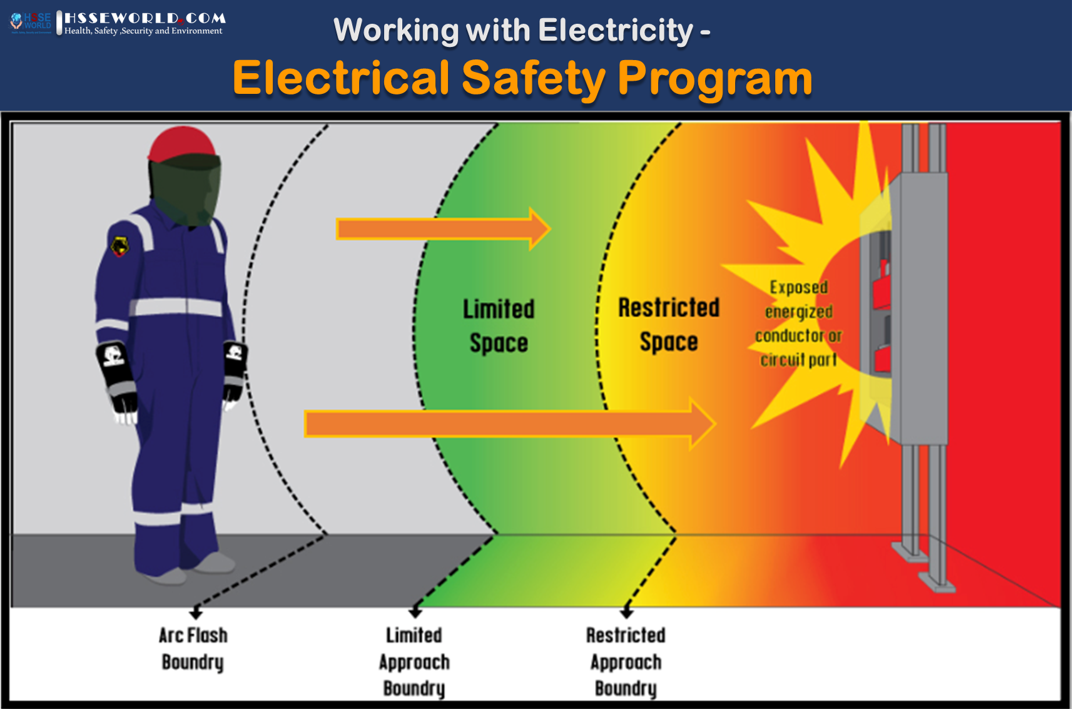

Every company dealing with energized work must make their primary objective to establish an electrically safe work condition (ESWC) when their employees are working on or near electric shock hazards and energized equipment. But until an ESWC is set in place, there’s a serious risk of injury to the workers and special procedures should be implemented to prevent injuries and mitigate risk while they’re working on or near these hazards.

1. Systems Engineering: Conduct an Arc Flash and Electric Shock Study – (Incident Energy Study)

An Arc Flash and Electric Shock study is performed at the job site to eliminate any arc flash and electric shock incidents. While completely eliminating the incidents may not always be possible, reducing the likelihood and severity of the incident is absolutely 100% possible with the right person, the right tools, and the right processes.

Part of this system engineering approach includes Coordination and a Short Circuit Study. This calculates the fault current at each bus (panel, feeder, switchgear, disconnect). The results are compared to the ratings of the equipment measured in Kaic (Kilo-Amps-Interrupting-Current). This is a specification that all electrical equipment connected to the system must verify it will withstand the brute impact of a fault without mechanically coming apart and will self-contain the explosion.

Incident energy is the amount of incident heat impressed on a surface and is measured in cal/cm2. This energy level is to be calculated at every circuit. Think of this as each maintainable electrical asset requires a visual inspection and/or maintenance. Or in other words, if by opening the asset your face and chest are exposed to an energized bus, then it must be evaluated.

The shock energy is the amount of voltage that one would experience if contacted. This energy level is dictated by the existing design, the utility connection, and the transformation of energy throughout the electrical distribution of a facility.

2. Define Hazard Levels

The 2018 NFPA 70E 130.5(H) standard requires all electrical assets to be marked with an incident energy label. Also, OSHA 1910.335(b) requires employers to use alerting techniques, such as safety signs and tags (like labeling), barricades, and attendants to warn and protect employees from all hazards which could cause serious injury due to electric shock, burns or failure of electric equipment parts.

OSHA is the regulation to provide safe working conditions, now codified in the Law (the Code of Federal Regulations or CFR), that can require companies to pay fines when found to be negligent. The civil liabilities for this type of negligence will be significant as well and, if deemed egregious, criminal negligence can be applied.

- OSHA is the “What”: the safety regulation

- NFPA is the “How”: what to do to comply with the regulation

Defining all electrical hazards with specific laws just isn’t possible. That’s why the emphasis is put on building owners to satisfy OSHA by following NFPA 70E’s electrical safety standards. There are just too many different electrical systems, ages of facilities, configurations, etc., for the NFPA 70E to prescribe specifics for every possible situation, but the intent of the regulation is made very clear: To protect employees, property, and employers with risk assessment.

Once the hazards and their energy levels are known, an arc flash risk assessment can now be implemented within the hierarchy of risk controls. And based on its results, it will steer the appropriate person, process, and tools for working safely. ISO 45000 recently adopted in the United States outlines methods for the risk assessment which complement OSHA and NFPA documents for providing a safe work environment.

3. Implement Electrical Maintenance

Preventive Maintenance is a crucial part of the overall health of the electrical distribution and the safety of personnel working on or near these electrical assets.

Electrical Preventive Maintenance as prescribed by NFPA 70B and NETA MTS, has historically been implemented in the pursuit of increasing systems reliability, and reduce the risk with regards to the potential of property damage and/or fire.

The maintenance and testing companies along with their skilled labor in this industry segment have been doing these tasks for building owners for many years. At times, technicians can be blind to the magnitude of the incident energy inherent risk they face on a daily basis. Sometimes, reports find on occasion that the maintenance companies and their “qualified” technicians are simply guessing to what the appropriate PPE shall be worn when exposing their face and chest to hazards with the energized bus.

(learn: What can we do about rain protection for Arc flash work).

This is a trap/gap to solve in the electrical industry. Building owners must take ownership of their liabilities with regards to their electrical assets and implement incident energy studies to be performed on their electrical equipment and NFPA 70E followed before any worker is asked to perform hazardous electrical preventive maintenance work. But when building CFOs create operating budgets for maintenance, their argument sometimes is that there’s no money to perform incident energy studies. The gap here is the incident energy study can be an operating expense and even a capital expense.

Let this be a fair warning to those CFOs. They should brush up on their accounting strategy and work with their risk departments and never use budgets as an excuse because if they get caught by OSHA it would be deemed negligent. The incident energy unique labels are installed on the electrical asset which is part of the electrical system which can be depreciated out 5 years when it is due for renewal.

The most important aspect of electrical maintenance and testing however is not the reliability of the equipment, it’s the accuracy with which the equipment clears faults. If the electrical equipment does not operate per its intended design, qualified workers could be killed.

The incident energy calculations should be based on the equipment manufacturer’s time-current curves and their ability to open under a fault condition within a specified period of time. This time ranges from three cycles to 120 cycles of the 60Hz sine wave ( .05-2 seconds.) If the engineers calculate incident energy and the qualified worker performs an arc flash risk assessment and uses this data to support adequate PPE, the qualified worker could still be injured or killed based on a breaker opening slower than it was calculated to.

The unknown is: Will the breaker open as specified? The only way to reduce this risk or prove the breaker will open is with prescribed electrical maintenance and breaker testing. This can be tied to the age-old debate, which comes first: the chicken or the egg? The reality is no facility should be allowed to receive a Certificate of Occupancy (C of O) from AHJ without an incident energy study and prescribed preventive Maintenance on a 3-5-year recurring contract.

Let’s put this into perspective. Imagine a building owner driving with you on the highway in their car. They have no driver’s license (safety program) and he blows a tire (lack of maintenance). As a result, he hits a tree head-on at 90 mph and the airbag fails to open, plus the seat belt latch breaks (no operating of equipment nor testing on airbag). Picture what horrific injuries would ensue.

Electrical equipment must be cleaned, maintained, and tested or severe injuries and/or death is a guaranteed certainty.

4. Institute Arc Flash Safety Training

Training in the workplace is all relative to the risk to the employee. Though important, training a building owner on electrical hazards is usually ignored and is considered by some as a trap/gap. These owners (typically without electrical skills) must understand the risk they have with owning this equipment otherwise injuries are bound to happen. There’s rarely an owner’s manual for a building, and if there is, it’s even more unlikely to see an investment banker/owner or CEO to read it.

If these owners don’t know the risks, how can we expect them to steer training that their employees need? Much like the blind leading the blind. What needs to happen is all industry experts, environmental health and safety (EHS) staff, and risk managers must continually demonstrate best safety practices and wrap a theoretical safety sweater around the risks with proper training and processes. Pull CEOs and building owners into all training environments. Even though they may think that they know everything, they’ll still learn. The most credible source for building culture in the workplace is from the top down.

Think about how the workers would see their CEO sitting in the same class as them. It would certainly paint a real picture of how valuable the training is to the company and for its future.

The solution rests on the job training, manufacturer training, and classroom training, plus everything mentioned above to fully mitigate arc flash and electric shock hazards in the workplace. Challenging? Yes. Possible? Always.

( Read More: E-books the workplace guide to Arc Flash Safety).