Near Miss incidents Overview

11 min readNear miss incidents, close calls, or close shaves have often been referred to as “safety in the shadows,” as this is where the heart of the accident problem lies. Near miss incidents offer management an opportunity to rectify a system breakdown before it happens. They are inexpensive learning opportunities. Because there are no losses as a result of an undesired event does not necessarily mean that the event is insignificant. Many of these seemingly unimportant events have high potential for injury and other losses. If recognized, reported, and rectified, near miss incident root causes will be eliminated leading to a radical reduction in injury-causing accidents.

Takeaway: Near miss incidents are warnings and, if an organization eliminates the near miss incidents, the accidents causing damage and injury will look after themselves.

For many organizations, the term near miss is not only misunderstood, but it is underrated with regards to the potential for a near miss incident to become a profitdraining accident and possible injury at a workplace. The term near miss incident also can be defined as a narrowly avoided mishap. What that means in the manufacturing, construction, or mining industry is that a person narrowly avoids an injury due to an unforeseen mishap or when there is an undesired event, which, by a stroke of luck, narrowly avoids damaging a piece of equipment, property, or material. These are missed safety signals.

Reporting and rectifying the causes of near miss incidents has many benefits. Studies of adverse events, such as accidents, indicate that near misses occur more frequently than accidents and are often precursors to accidents. In many cases, the same near miss incident has occurred numerous times prior to the actual accident.

ACCIDENT ROOT CAUSE INDICATORS

Research of thousands of undesired (accidental) events has shown that the outcome of the event cannot be predicted and that, under slightly different circumstances, the consequences could have been better or worse if it were not for some factor of luck or good fortune.

The principle of multiple causes indicates that accidents are usually the result of a multitude of causes and there are usually many immediate causes and numerous root causes behind every event.

These loss-producing events are termed accidents. Some refer to them as incidents, but, for clarity, they will be referred to as accidents in this publication. No-loss events with potential for loss will be termed near miss incidents.

The high risk acts of a worker or a high risk work environment riddled with hazards, or a combination of both, are the immediate causes or the closest causes of an accident, which results in accidental losses, such as death, injury, property damage, fire, or business interruption. High risk acts and/or conditions are the most obvious accident causes, or the causes that lead to the contact with a source of energy that causes the subsequent loss.

Root, or basic, causes are the deep hidden person and job factors that give rise to the immediate causes in the form of high risk acts and/or conditions. If they are not identified and rectified, the accident problem will not be eliminated. Fixing the immediate causes rectifies the symptom, but not the root or basic cause. Risk assessment of all near miss incidents will determine which near miss incidents warrant a full investigation to track and eliminate the source of the problem at the root.

A Proactive Apppproach

S. L. Smith writing in Occupational Hazards (1994) says:

Near miss incidents challenge the tradition of using an accident to initiate a thorough review of safety conditions, practices, and training. Tracking near miss incidents offers organizations a better opportunity to focus their preventative efforts .

If based on near miss incident information, these efforts will be proactive rather than reactive. As another safety professional put it:

Letting a near miss incident go unreported provides an opportunity for a serious accident to occur. Correcting these actions or conditions will enhance the safety within your organization and provide a better working environment for everyone involved. Don’t let yourself or co-workers become statistics report near miss incidents to your supervisor. Prevent an accident that’s about to happen!

H. W. Heinrich

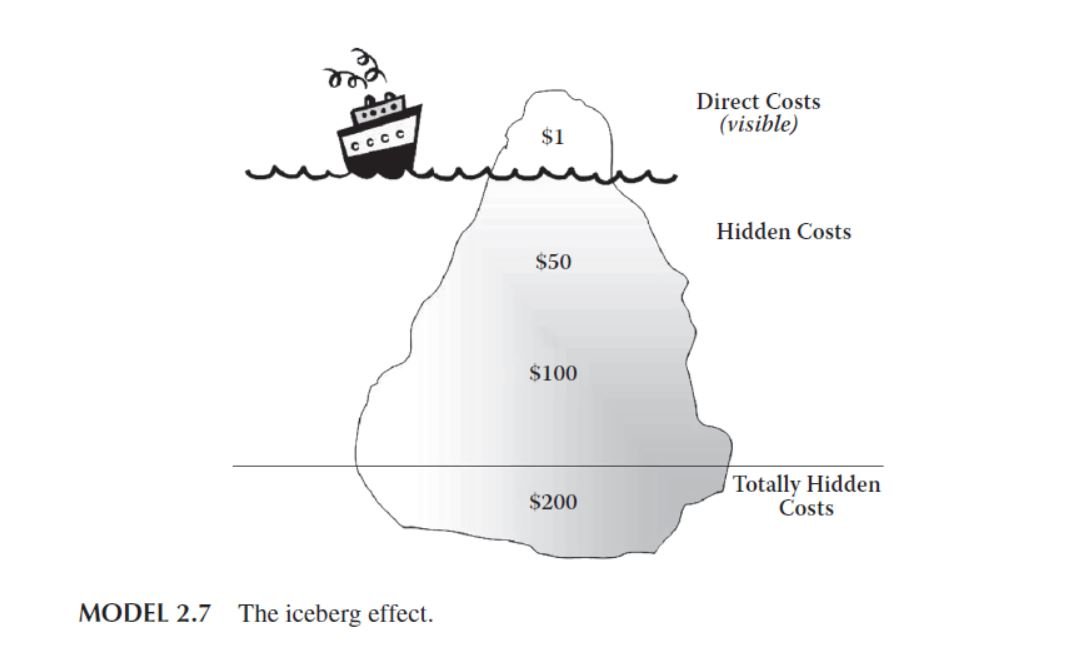

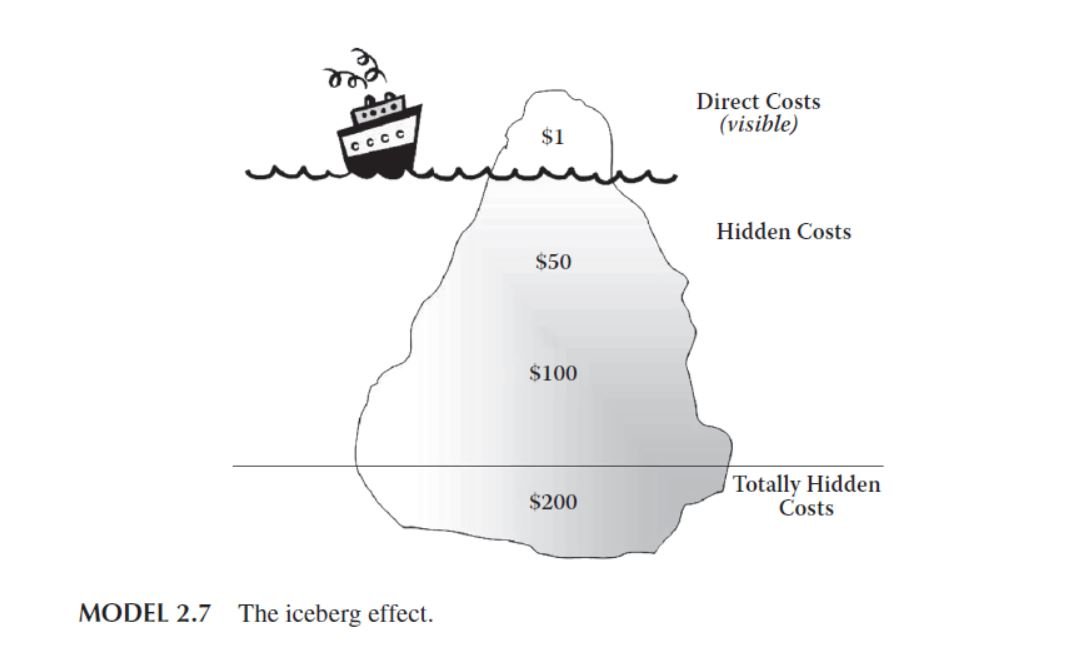

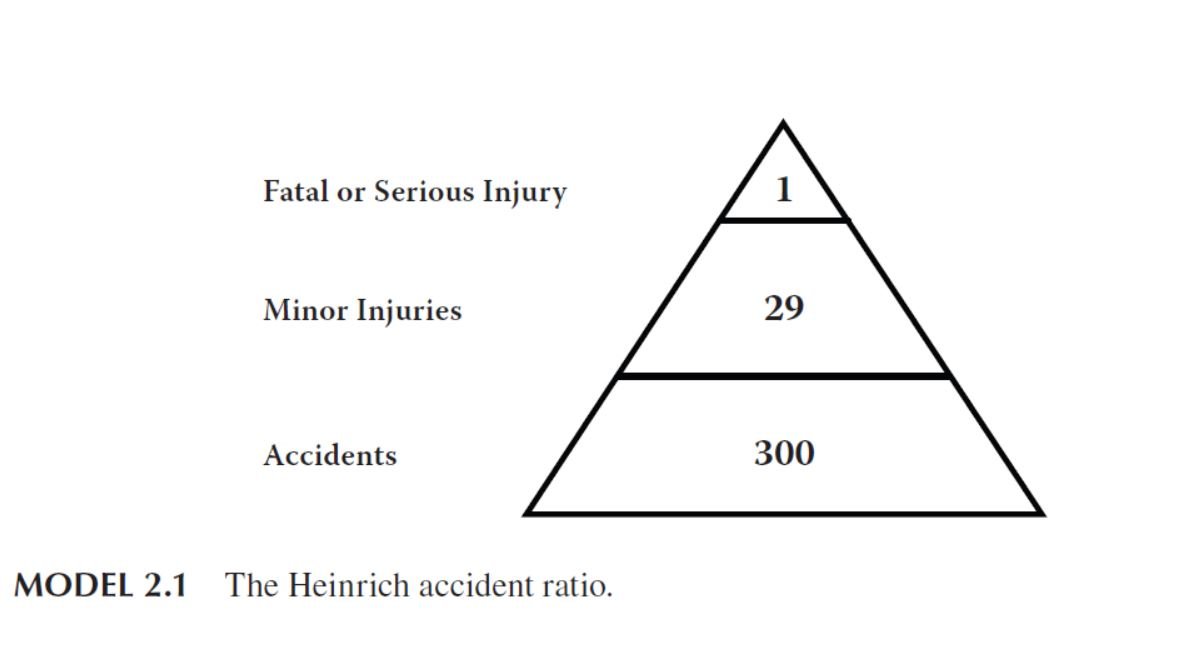

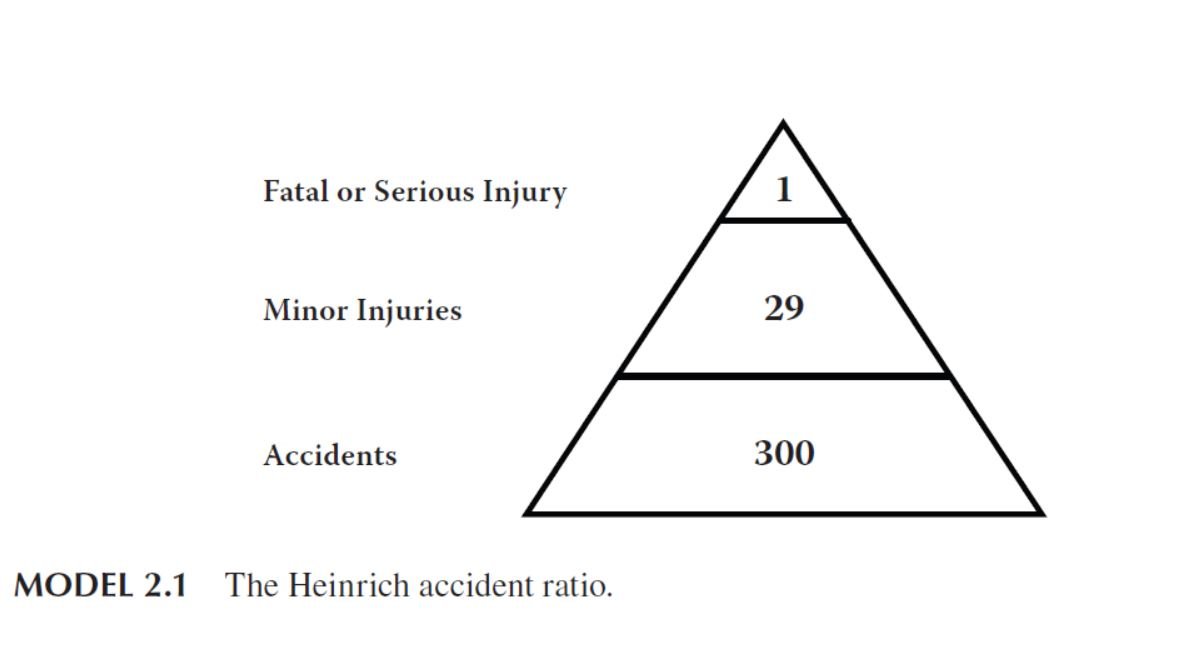

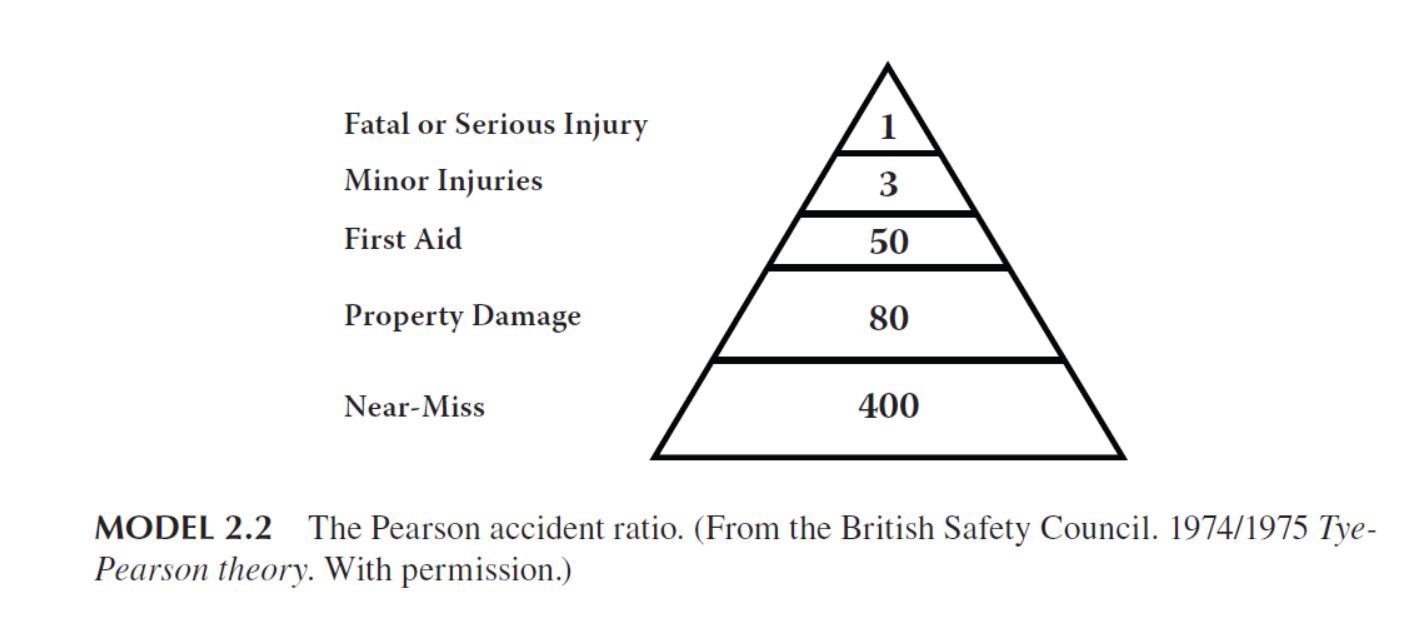

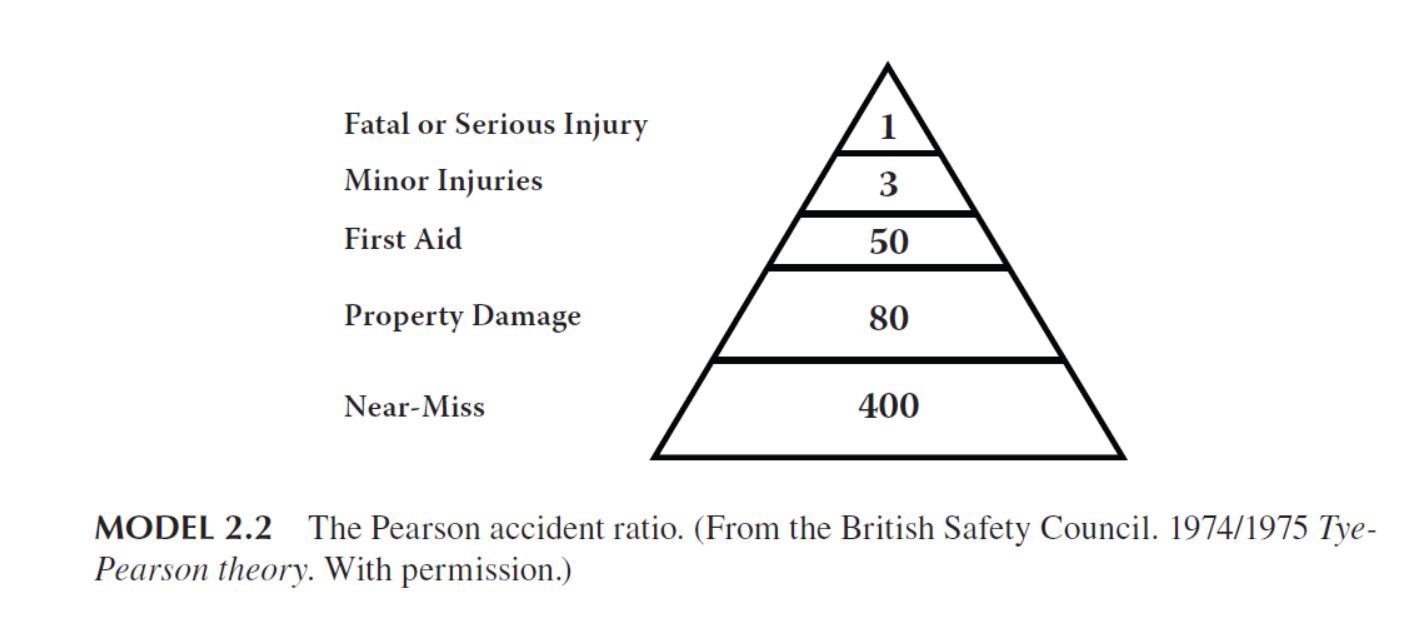

More than 80 years ago, H. W. Heinrich suggested that one should focus on the accident rather than the injury. He was the first to propose a ratio existed between injuries and accidents that produced no injuries.

Accidents and not injuries should be the point of attack. Analysis proves that for every mishap resulting in an injury there are many other similar accidents that cause no injuries whatsoever .

Explaining his ratio, the first ever published, he said:

From data now available concerning the frequency of potential-injury accidents, it is estimated that, in a unit group of 330 accidents of the same kind and involving the same person, 300 result in no injuries, 29 in minor injuries, and 1 in major or lost-time injury

Heinrich’s Third Axiom

In 1931, H. W. Heinrich drew up a list of 10 axioms based on his safety research, which was published in Industrial Accident Prevention, 3rd ed. (McGraw-Hill, 1950). Axiom 3 has great significance for the concept of near miss incidents and he was the first person to derive the following conclusion:

The person who suffers a disabling injury caused by an unsafe act, in the average case has had over 300 narrow escapes from serious injury as a result of committing the very same unsafe act. Likewise, persons are exposed to mechanical hazards hundreds of times before they suffer injury . His fourth axiom was the first recorded theory that fortune or luck may play a part in determining not only the outcome of an undesired event, but also the severity of consequent injury.

The severity of an injury is largely fortuitous the occurrence of the accident that results in injury is largely preventable .

Despite these major findings, near miss incidents have mostly been overlooked in industry despite history of major-loss events confirming the theory that there are many near misses or warnings before the occurrence of major accidental losses. Near miss incidents are truly the foundation of major injuries, the building blocks of accidents, and warning signs that loss is imminent.

According to the National Safety Council (USA), and other safety researchers and pioneers, a large percentage of all accidents are preceded by one or more near miss incidents. In other words, close calls should be wake-up calls for employers and employees to realize that something is wrong in the system and needs to be corrected.

TRACKING NEAR MISS INCIDENTS

Near-miss investigations war with the tradition of using an accident to trigger a thorough look at safety conditions and training. Williams, project manager for safety at Raytheon services in Nevada, suggested that if the purpose of safety programs is to prevent accidents, then tracking near-misses offers organizations a better opportunity to lever their preventive efforts. Near-misses can help employers pinpoint trouble areas and focus their safety efforts and training . Most organizations do not encourage employees to report near miss incidents.

Because there has been no injury, little importance is placed on the seemingly trivial event. Most near miss incidents have some form of potential for injury and loss, no matter how trivial they may seem. Although there may not have been a serious outcome, these near miss incidents could result in future accidents.

NEAR MISS—OR NEAR HIT?

Many argue that the event should be called a near hit as this will get management’s attention quicker than near miss. Both descriptions are true as: “If it didn’t miss, it

would have hit.” The American Society of Safety Engineers (ASSE) refers to near miss in their dictionary of technical terms, so this will be the preferred term in this book.

BENEFITS

The main benefit of a near miss recognition, reporting, investigation, and remedy (NEMIRR) system is the fact that by recognizing near miss incidents and taking action to correct the underlying problems, an organization will not only reduce the number of near miss incidents, but, more importantly, will reduce the number of actual accidents in the future. Reducing the number of near miss incidents will fix the problems before they can cause accidents. Another major benefit of near miss reporting is that it is easier to get to the root causes of the event because nobody has been injured or killed, which means there is no pressing need for a cover-up.

Near miss incidents also can be defined as: “close calls that have the potential for injury or property loss.” Most accidents can be predicted by close calls. These are accidents that almost happened or possibly did happen, but simply didn’t result in an injury this time around. In fact, all the stages of the accident were present in the correct sequence except for the exchange of the energy segment that would have caused the injury, damage, loss, or a combination thereof.

EXAMPLES OF NEAR MISS INCIDENTS

Below are some true-to-life examples of actual near miss incident reports. The reports have been edited to make for easier reading, but the contents have not been changed.

- An employee tripped over an extension cord that lay across the floor, but avoided a fall by grabbing the corner of a desk.

- An outward-opening door nearly hit a worker who jumped back just in time to avoid a collision with the door.

- Instead of using a ladder, an employee put a box on top of a drum, lost balance, and stumbled to the ground. Although the employee was shaken, there was no injury.

- A pry bar that was left on the bottom of a mill under repair flew through the air like a missile when a loosened liner fell onto it while the mill was being rotated. The heavy bar missed workers in the immediate vicinity and neither injury nor damage was sustained.

- An employee tested the brakes at the beginning of the shift and they checked out okay. As he approached another vehicle, he hit the brakes and they did not work and he narrowly missed the other vehicle.

- While walking from his car to the stairs, an employee was almost struck by a fast-moving pickup.

- A miner was pulling out hoses to set up the jack leg and the hoses hung up making the miner mad. He pulled really hard and lost his balance and fell down.

- After changing the engine oil on a vehicle, the employee left the discharge gun in the fill tube of the tank and the air purged in the line and spat oil out the tube nearly striking him in the eyes.

- Two welders received minor shocks when they touched a welding machine. On inspection, a loose wire was discovered in the plug of an extension lead that was

- connected to the welding machine.

- While the employee was in the process of lowering a side plate of a bulkhead, the safety catch on the hook opened and the grab that held the plate almost unhooked

- An employee was walking toward his job on the demarcated walkway inside the big workshop. The forklift driver rode toward the workshop. At the corner, the forklift driver nearly knocked the employee over because he was unaware that the forklift was approaching.

RED FLAGS

When near miss incidents like these happen, most workers are simply relieved they were not injured and then forget about what happened moments later. However, when employees narrowly avoid injury like this, they may have just been lucky (the three “luck factors”). Because there was no injury, the event is not reported, therefore, the accident causes will not be identified or rectified. Another person is very likely to be injured by that very same hazard or practice in the future. In fact, the difference between a near miss incident and a serious injury (contact or no contact with a source of energy) is often a fraction of an inch or a split second of time. This can be defined as being lucky. These are red flags waving at employees to let them know something is unsafe and requires immediate attention.

A GIFT

As one safety practitioner put it:

Near miss incident reports are a gift. They allow an organization to analyze potential accidents, such as fatal accidents, collisions, fires, and explosions, enabling them to take corrective action to improve and rectify processes and procedures before loss-producing accidents happen. Safety is traditionally taken seriously, but only for a short period of time after an accident. Proactive safety is when serious attempts are made to predict when the next accident may happen by identifying and reducing risks and fixing things before the event may occur. Near miss incidents offer such an opportunity and will involve a change in safety culture.

PRECURSORS TO ACCIDENTS

Near miss incidents are the precursors to accidents that lead to an exchange of energy and subsequent loss. Literally, fractions of an inch or a split second may be the difference between a serious loss-producing accident and a near miss incident. For example, an individual may be on a ladder and the ladder starts slipping sideways, but fortunately catches on a protruding nail or bolt. This should be reported and investigated so that ladder safety could be addressed throughout the organization and the need for tying off ladders emphasized. As mentioned by Phimister, Bier, and Kunreuther (2004) in “Appendix D: A Note on Definitions,” they define the use of the term accident precursors:

Near miss and its analogs, near hit and close call, are other terms that are likely to arise frequently during workshop discussions. Although near misses are clearly related to precursors, we have tried to distinguish them from precursors, and we encourage you not to use them interchangeably. One way to define a near miss (or, equivalently, a near hit or close call) is as an almost complete progression of events—a progression that, if one other event had occurred, would have resulted in an accident. A near miss might consist of one or more precursors that did occur, and one that did not. A near miss can be considered a particularly severe precursor

HIGH POTENTIAL FOR LOSS

The next near miss incident not only indicates the luck factor, but also the high potential for loss. An underground miner related this event:

We were trying to open the man-way doors to go to the surface. We could not open the door because the door to the shaft and the door to the station were open causing a temporary vacuum. We finally got the door open and the pressure of the air pulled me in toward the shaft. I almost ended up falling down the mine shaft had it not been for the retainer wire.

Boylston (1990) refers to near miss incidents as potential problems. He also quotes the luck factors by saying that failure by an organization to recognize, evaluate,and implement controls for early warnings of potential problems usually results in a system of reactive approaches.

Consequently, there is little if any way to control the magnitude of the problem. Such organizations are “lucky” or “unlucky,” depending on the situation. This is no way to manage an organization.

FACTS ABOUT NEAR MISS INCIDENTS

- Many near miss incidents have the potential to cause injury to people.

- Near miss incidents are largely ignored because they do not result in any loss.

- Most near miss incidents aren’t investigated because a loss did not occur.

- They have often been called near hits, near misses, or near accidents, as they are warnings of potential accidents.

- All high potential, near miss incidents should be reported and investigated to determine and rectify root causes.

- Luck plays a major factor in determining whether the events become accidents (contact) or near miss incidents (no contact).

- Near miss incidents are caused by system failures and can be prevented.

- Reporting, investigating, and eliminating near miss incidents will lead to a reduction in property damage and injury causing accidents.

- Multiple causes are also evident in near miss incidents.

Near miss incidents are warnings and, if an organization eliminates the near miss incidents, the accidents causing damage and injury will look after themselves.