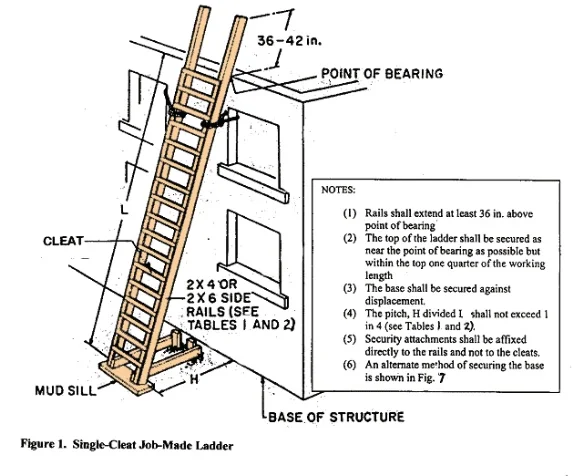

Job-made wooden ladders are custom-made to fit specific job situations during construction or demolition operations. Their primary purpose is to provide access to or egress from a work area. They are not intended to serve as a workstation. They are temporary and serve only until a particular phase of work is completed or until permanent stairways or Fixed Ladders are ready for use (see Fig. 1). They are not to exceed 24 feet in working length. If the required ladder length exceeds 24 feet, then two or more separate Job-Made Ladders are to be used in conjunction with platforms that are protected with railings. ( Read: Portable Ladder Safety )

Introduction to Basic Job-Made Ladder Safety

Ladders are tools where the following basic safety rules apply to the safe use of this kind of ladder:

If you feel tired or dizzy or are prone to losing your balance, stay off the ladder. Users who tire easily or who have physical limitations that inhibit safe climbing such as fainting and/or under medication or prescription drugs which may cause physical impairment are not permitted to use Job-Made Ladders.

Read: Fall Protection and Ladders

Do not use ladders in high winds or storms.

Wear clean slip-resistant shoes. Shoes with leather soles are not appropriate for ladder use since they are not considered sufficiently slip-resistant. Flat-soled shoes are not appropriate, and footwear with heels when climbing Job-Made Ladders is mandatory.

Wearing greasy or slippery gloves and/or footwear is not permitted during climbing.Cleats, gripping surfaces and platforms must be kept free of oil, grease or slippery materials. When ice or frost conditions are present, the ladder must not be used.

Only one person at a time is permitted on a Single-cleat Ladder unless the ladder is specifically designed for more than one climber. No more than two persons (one on either side) are permitted on a Double-cleat Ladder unless the ladder is specifically designed for additional climbers.

Never run, jump or slide down from a ladder or climb more than one cleat at a time.

Climbers must always step through, not around, the rail extensions at the top of the ladder.

Job-made ladders must not be used for guys, braces, hoist supports or structural functions other than those of a ladder.

Read: Demolition Safety: Ensuring a Secure Demolition Process

Inspection and Maintenance

All Job-made ladders, landings, and security attachments must be inspected at least once each week. Any defects that have developed must be corrected immediately, or the ladder must be taken out of service. ( use Portable Ladder Self Inspection checklist )

Inspection records must be maintained. The records must reflect the date of inspection, the identification or location of the ladder and any remedial action required.

Testing of Job-made ladders with loads or impacts is not permitted since this type of testing can weaken lumber components or fasteners causing hidden damage that may lead to sudden failure during use.

Routine maintenance must be carried out each day the Job-made Ladder is in use. Slippery substances such as oil, grease, ice or mud must be wiped from the Cleats. If excessively worn, broken or missing cleats, broken or split side rails, or other defective parts are found, the condition must be reported immediately and the ladder withdrawn from service until replaced or repaired. The bolted connections in spliced ladders must be checked to ensure that the nuts are tight.

Good housekeeping must be maintained in the areas around the tops and the bottoms of ladders. These areas must be maintained level with any drainage slope not to exceed 1 in 24. Accumulated materials or debris is to be removed to help ensure safe mounting and dismounting of ladders.

Protective coatings on Job-made ladders must not include any opaque material that obscures the structural integrity of the wood from visual inspection. Only transparent coatings or wood preservatives may be used.