Biological safety cabinets are crucial tools in maintaining a safe working environment in laboratories and healthcare facilities. These cabinets provide a contained space that helps protect both the user and the environment from potentially hazardous materials, such as pathogens and other biological agents. In this article, we will delve into the importance of biological safety cabinets, their classifications, proper usage, maintenance practices, and the critical role they play in ensuring the safety of personnel and the integrity of research outcomes.(Read: hazardous-chemical-storage/)

Introduction to Biological Safety Cabinets (BSC)

Biological Safety Cabinets (BSCs) are designed to protect laboratory personnel, the environment, and the work being performed within the cabinet from exposure to biological agents and cross-contamination. These enclosed, ventilated laboratory workspaces are essential tools in microbiology, virology, genetics, tissue culture, and other biological research and clinical activities.

Key Functions

- Personnel Protection: BSCs prevent exposure of laboratory personnel to infectious agents.

- Product Protection: BSCs protect the work being performed from external contamination.

- Environmental Protection: BSCs ensure that harmful agents are not released into the surrounding environment.

Types of Biological Safety Cabinets

The different types of BSCs are classified into three main categories:

- Class I BSCs:

- Provide personnel and environmental protection.

- Draw in unfiltered air from the laboratory to prevent contamination of the personnel.

- Typically used for working with low to moderate-risk biological agents.

- Class II BSCs:

- Provide personnel, product, and environmental protection.

- Use a combination of HEPA filters to filter both supply and exhaust air.

- Commonly used for clinical, hospital, and research laboratories working with biological agents.

- Class III BSCs:

- Offer the highest level of protection.

- Designed for work with highly infectious or hazardous material.

- Completely enclosed and gas-tight, requiring materials to be passed in and out through a double-door system.

Read: biological-hazard-control/

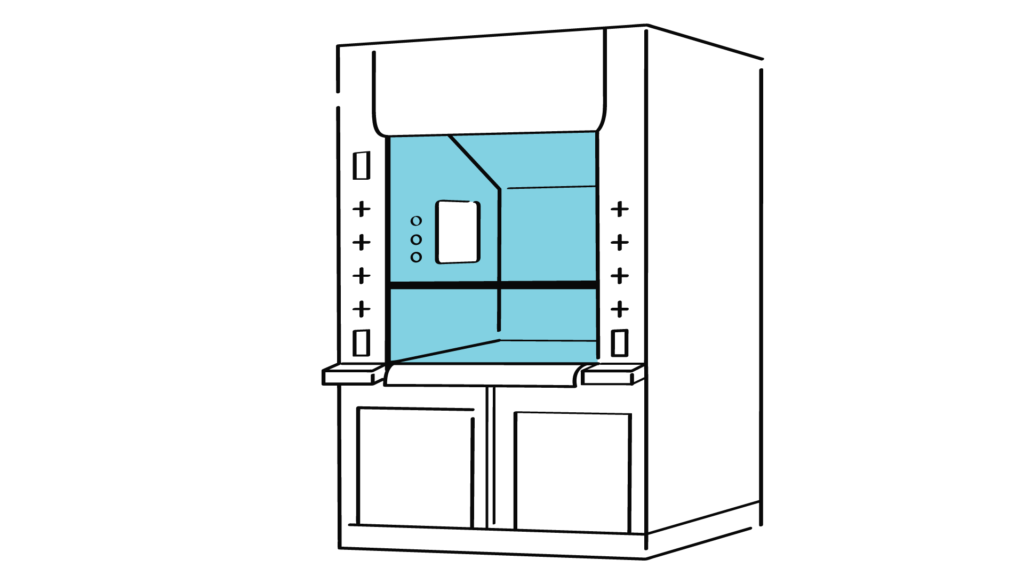

Components

- HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are vital for trapping airborne particles and ensuring the air within the cabinet is clean.

- Airflow Pattern: The airflow system in BSCs maintains a directional flow to minimize contamination. Class II BSCs have a vertical flow, while Class I BSCs operate with a horizontal flow.

- Sash: The protective glass sash provides a barrier between the user and the work area.

Usage and Applications

Biological Safety Cabinets are pivotal in a wide array of settings:

- Experimental Research: Utilized in manipulating cell cultures, bacteria, viruses, and other agents.

- Clinical Laboratories: Essential for diagnosing infectious agents.

- Pharmaceutical Industry: Applied for product testing and quality control to ensure contamination-free environments.

History and Development of BSCs

The development of Biological Safety Cabinets (BSCs) is closely intertwined with advancements in microbiology and biosafety. In the early 20th century, the need for a controlled environment to handle infectious agents became apparent. The first notable design was the laminar airflow cabinet, which emerged in the 1940s. These early iterations aimed to restrict the movement of airborne contaminants, thereby protecting laboratory personnel.

Understanding the critical functions and proper usage of BSCs is essential for laboratory safety and efficiency. It allows researchers to work safely while minimizing the risk of contamination.

Initial Innovations

- 1940s: Introduction of laminar flow cabinets.

- 1960s: Refinements led to the creation of the first Class I BSCs. This type protected the user but did not offer product protection.

- 1970s: The evolution of Class II BSCs, which provided both personnel and product protection by incorporating high-efficiency particulate air (HEPA) filters. Class III cabinets also emerged, which were completely enclosed for handling highly infectious agents.

Technological Improvements

- HEPA Filters: Integral to the success of BSCs, these filters became more efficient in capturing particulates down to 0.3 microns.

- Airflow Design: Enhanced designs improved laminar airflow, which is crucial for preventing contamination.

- Material Science: Use of stainless steel and other non-porous materials improved cleanability and durability.

Regulatory Milestones

- NSF International: Established standards for BSCs, ensuring uniformity and safety. Standards like NSF/ANSI 49 became benchmarks.

- CDC Guidelines: The Centers for Disease Control and Prevention (CDC) released guidelines defining BSC classes and usage protocols, thereby standardizing safety procedures.

- ISO Standards: Introduction of international standards such as ISO 14644 expanded the safety and performance criteria for BSCs globally.

Today, BSCs are indispensable in laboratories dealing with pathogenic organisms. Constant innovations in technology, material science, and regulatory standards have made them more effective and user-friendly. From laminar flow cabinets to highly sophisticated Class III cabinets, these devices have come a long way, ensuring both personnel safety and sample integrity in various research and clinical settings.

Types of Biological Safety Cabinets

Biological Safety Cabinets (BSCs) are classified into three main types: Class I, Class II, and Class III. Each type offers different levels of protection and is suited for various applications and biological research needs.

Class I Biological Safety Cabinets

Class I BSCs offer personnel and environmental protection but do not provide product protection. They are primarily used when the containment of potentially hazardous material is vital.

- Air Supply: Draws unfiltered air from the laboratory.

- Air Flow: Operates with negative pressure airflow to prevent contaminants from escaping.

- Application: Effective for procedures that generate aerosols, such as those involved in handling low to moderate risk biological agents.

Class II Biological Safety Cabinets

Class II BSCs are subdivided into several types (A1, A2, B1, and B2) and provide protection for personnel, the environment, and the product. They are commonly used in clinical, diagnostic, pharmaceutical, and research laboratories.

- Air Supply: Infuses filtered air into the work area.

- Air Flow: Uses a combination of inflow and downflow air to create a barrier that prevents contaminants from entering or exiting the cabinet.

- Types:

- Type A1: Offers moderate protection; recirculates around 70% of air.

- Type A2: Provides similar protection to Type A1 but uses a higher inflow velocity.

- Type B1: Recirculates about 30% of the air; more suited for handling trace amounts of chemical vapors.

- Type B2: 100% exhaust; ideal for working with hazardous chemicals and toxic agents.

Class III Biological Safety Cabinets

Class III BSCs, also known as glove boxes, offer the highest level of protection. They are gas-tight and provide maximum containment for working with high-risk biological agents.

- Air Supply: Provides HEPA-filtered supply air.

- Air Flow: Operates under negative pressure with 100% exhaust air filtered through two HEPA filters.

- Application: Essential for the highest risk agents (Biosafety Level 4), such as those used in virology and high-containment laboratories.

Understanding the different types of Biological Safety Cabinets is critical for ensuring safety in environments where handling hazardous biological materials is necessary. Use of the correct BSC type aligns with specific operational requirements and biosafety levels.

How BSCs Work: Key Components and Mechanisms

Biological Safety Cabinets (BSCs) are essential tools in laboratories that handle infectious or potentially infectious materials. They protect workers, products, and the environment. Understanding the key components and mechanisms of BSCs is crucial for their effective use.

Key Components

- HEPA Filters

- High-Efficiency Particulate Air (HEPA) filters are a critical component. They trap airborne particles as small as 0.3 microns with an efficiency of 99.97%. This keeps contaminants from escaping and ensures a sterile environment inside the cabinet.

- Laminar Airflow

- BSCs utilize unidirectional airflow to minimize cross-contamination. Air moves in parallel streams under constant velocity, providing a clean work area. Vertical laminar flow is common in most BSCs.

- Sash

- The sash serves as a physical barrier between the operator and the inside of the cabinet. It is usually made of transparent material, allowing visibility while offering protection. The sash height must be adjustable to optimize airflow and safety.

- Exhaust System

- The exhaust system in a BSC captures contaminated air and directs it through HEPA filters before it is released back into the environment. Class II BSCs often feature a dedicated exhaust blower.

- Interior Work Surface

- The work surface should be easy to clean and resistant to chemicals. It is strategically designed to prevent spills and accommodate laboratory equipment.

Mechanisms

Airflow Patterns

- Inflow Air

- Air is drawn into the cabinet from the room, creating a barrier that prevents contaminants from entering the work area. This air is immediately directed to the HEPA filters.

- Downflow Air

- Clean filtered air is blown downward from the top of the cabinet, ensuring a sterile environment over the work surface. This downward flow helps protect the material being worked on.

Recirculation

- Many BSCs recirculate a portion of filtered air within the cabinet. For example, in Class II BSCs, approximately 70% of the air is recirculated, while 30% is exhausted after passing through HEPA filters. This mechanism helps maintain a consistent sterile airflow.

Containment

- BSCs ensure containment through negative pressure within the cabinet. The negative pressure prevents contaminated air from leaking out. In case of any air leakage, the contaminated air is directed towards the HEPA filters, thereby containing any potential hazards.

The synergy between these components and mechanisms ensures that Biological Safety Cabinets are reliable in providing protection and maintaining a contaminant-free environment.

Installation and Setup of BSCs in Your Lab

Installing a Biological Safety Cabinet (BSC) in a laboratory involves several critical steps to ensure safety and compliance with regulatory standards. Proper placement, ventilation, and certification are pivotal to effective installation and ongoing operation.

Preparing the Lab

- Select an Appropriate Location:

- BSCs should be placed away from high-traffic areas, doors, windows, and air vents.

- Ensure sufficient clearance from walls and other barriers.

- Plan for Utilities:

- Verify that electrical outlets are accessible and meet the power requirements of the BSC.

- Ensure availability of any necessary plumbing, vacuum, or gas connections as specified by the BSC model.

Setting Up the BSC

- Unpack and Inspect:

- Carefully unpack the BSC, checking for any shipping damage.

- Confirm that all components and accessories are present.

- Level and Position the Cabinet:

- Use a level to ensure the BSC stands evenly.

- Position the cabinet in the designated location, ensuring all guidelines for clearance and airflow are met.

- Connect Utilities:

- Plug in and secure all required electrical and utility connections.

- Ensure the exhaust and supply systems are correctly linked if the BSC requires external venting.

Certification and Testing

- Initial Certification:

- Schedule certification by a qualified professional to confirm that the BSC functions according to safety standards.

- Perform airflow and HEPA filter tests.

- Training Lab Personnel:

- Train staff on proper usage, maintenance, and emergency procedures related to the BSC.

- Establish protocols for cleaning and decontaminating the cabinet.

Maintenance and Compliance

- Regular Maintenance:

- Conduct routine inspections to check for wear and tear.

- Perform periodic maintenance as recommended by the manufacturer, including filter replacements.

- Re-certification:

- Schedule re-certifications annually or as specified by regulatory requirements.

- Re-certify after relocation, significant maintenance, or after major incidents involving the BSC.

Proper installation and setup of a Biological Safety Cabinet ensure both user safety and the integrity of experiments undertaken within the cabinet. Adherence to detailed steps and regular maintenance enhances the efficiency and longevity of BSCs in laboratory settings.

Best Practices for Operating a BSC

Proper operation of a Biological Safety Cabinet (BSC) is essential for maintaining a sterile environment and ensuring user safety. Follow these best practices to optimize BSC performance:

- Preparation and Setup:

- Thoroughly disinfect the BSC work surface and interior walls with an appropriate disinfectant before and after use.

- Remove any unnecessary items from the work area to minimize clutter and airflow disruption.

- Allow the BSC to run for at least 5-10 minutes before beginning work to ensure proper airflow and filtration.

- Personal Protective Equipment (PPE):

- Wear appropriate PPE, including lab coats, gloves, and eye protection, to minimize exposure to hazardous materials.

- Proper Technique:

- Work at least 4 inches inside the front grille to ensure materials are within the air curtain and protected.

- Avoid rapid arm movements and motions that may disrupt airflow, such as sudden opening or closing of the sash.

- Material Placement:

- Place supplies and equipment in the BSC in an organized manner, keeping clean and contaminated items separate.

- Position waste containers toward the rear of the cabinet to minimize airflow disturbances.

- Airflow and Aseptic Techniques:

- Ensure that nothing obstructs the front grille, as it is critical to maintaining proper airflow patterns.

- Utilize aseptic techniques by working from clean to contaminated areas to reduce the risk of cross-contamination.

- Handling Spills and Accidents:

- Immediately clean any spills with appropriate disinfectants and follow institutional spill response protocols.

- Pause work if any disruption occurs that may compromise the cabinet’s efficacy, such as power outages or airflow alarms.

- Maintenance and Certification:

- Regularly inspect and maintain the BSC, including filter changes and decontamination as recommended by the manufacturer.

- Ensure the BSC is certified annually or as required by local regulations to verify proper operation and containment efficacy.

- Training and Protocol Adherence:

- Ensure all users are adequately trained and familiar with the institutional SOPs for BSC use.

- Adhere strictly to established protocols for handling infectious agents and hazardous materials within the BSC.

By adhering to these best practices, users can maximize safety and efficiency while operating a Biological Safety Cabinet.

Maintenance and Certification of BSCs

Regular maintenance and certification are crucial for ensuring the optimal performance of Biological Safety Cabinets (BSCs). These practices not only sustain the safety of the laboratory environment but also protect users from exposure to hazardous materials.

Scheduled Maintenance

Maintenance activities are usually performed based on a routine schedule:

- Daily: Users should clean the interior and exterior surfaces, check the airflows, and ensure that the cabinet is free from any obstructions.

- Monthly: Filter checks, inspection of seals and gaskets, and functional verification of alarms and gauges.

- Annually: Comprehensive inspections by qualified personnel to assess the overall condition and performance of the BSC.

Certification Requirements

Proper certification follows specific guidelines:

- Frequency: Certification should occur annually or biannually, but additional checks are recommended following any significant changes, such as filter replacements or relocations.

- Standards Compliance: Compliance with standards set by organizations like NSF International (formerly known as National Sanitation Foundation), NIH (National Institutes of Health), and CDC (Centers for Disease Control and Prevention) is imperative.

- Procedure: Certification involves rigorous testing of airflow patterns, HEPA filter integrity, and containment efficiency. These tests ensure that the BSC meets the required performance standards.

Common Procedures

Certification procedures typically include:

- Downflow and Inflow Velocity: Verification of air circulation within the cabinet to maintain a sterile environment.

- HEPA Filter Leak Test: Ensuring that the filters are functional and contain no leaks.

- Smoke Pattern Test: Evaluation of airflow patterns to confirm containment capability and user protection.

- Alarm System Check: Testing of all visual and auditory alarms for proper functionality.

Importance of Professional Services

Using certified professionals equipped with the necessary tools and expertise is critical. Professional maintenance services ensure:

Optimal performance and compliance with regulatory standards, reducing the risk of contamination and exposure to hazardous substances.

Record Keeping

Documentation of all maintenance and certification activities is essential:

- Logs: Detailed records should be kept for each inspection, including findings, corrective actions, and dates.

- Verification Certificates: Official certificates of compliance should be stored and readily available for audits.

In summary, maintaining and certifying a Biological Safety Cabinet is not just a recommended practice but an essential one, ensuring safety and compliance within laboratory environments.

Common Issues and Troubleshooting Tips

Contaminated Samples

One of the prevalent issues is the contamination of samples. Contamination can occur due to improper handling or malfunctioning equipment.

- Regular Cleaning: Clean the BSC with a suitable disinfectant before and after use.

- Proper Technique: Always use proper aseptic techniques to handle samples within the cabinet.

- Airflow Monitoring: Regularly check the airflow to ensure it is functioning correctly.

Inadequate Airflow

Inadequate airflow can compromise the safety and efficiency of the BSC.

- Filter Maintenance: Replace the HEPA filters periodically as recommended by the manufacturer.

- Grille Obstruction: Ensure that the grilles are not obstructed by equipment or materials.

- Scheduled Inspections: Regular airflow inspections can preempt serious issues.

Alarm Activation

Sometimes, the BSC alarms may activate unexpectedly, causing disruption in work.

- User Manual: Always refer to the user manual for the specific cause of the alarm.

- Calibration Checks: Ensure that the cabinet is calibrated correctly.

- Regular Maintenance: Routine maintenance can often prevent such alarms from triggering unnecessarily.

Fan Malfunction

The fan system is crucial for maintaining the appropriate environment within the BSC.

- Visual Inspection: Regularly inspect the fan for any visible wear and tear.

- Professional Service: Employ professional services for fan repair or replacement.

- Monitor Noise Levels: An increase in noise levels from the fan can indicate a potential issue.

UV Lamp Burnout

Many BSCs use UV lamps for decontamination purposes, which may burn out over time.

- Lamp Replacement: Follow the manufacturer’s guidelines for replacing UV lamps.

- Operating Hours: Keep track of the operating hours to preemptively change the lamp before it burns out.

- Regular Testing: Conduct periodic tests to ensure that the UV lamp is working correctly.

Electrical Issues

Electrical problems can cause significant disruptions and dangers.

- Proper Wiring: Ensure all electrical components are correctly wired.

- Inspection and Testing: Regularly inspect and test the electrical system.

- Certified Technicians: Only use certified technicians for electrical repairs.

By addressing these common issues and adhering to proper maintenance protocols, one can sustain the optimal functionality and safety of Biological Safety Cabinets (BSC).

Benefits of Using a BSC in Laboratory Environments

Biological Safety Cabinets (BSC) offer numerous benefits for laboratory environments, enhancing safety, efficiency, and research integrity.

Protection from Contaminants

- Personnel Protection: BSCs safeguard laboratory personnel by containing harmful biological agents, minimizing the risk of exposure to infectious microbes.

- Environment Protection: These cabinets also prevent the release of dangerous organisms into the surroundings, thereby protecting the general environment.

Product Protection

- Sample Integrity: BSCs ensure that samples remain uncontaminated during experiments, preserving the integrity and reliability of research results.

- Cross-Contamination Reduction: By maintaining a controlled atmosphere, BSCs significantly reduce the risk of cross-contamination between different samples.

Regulatory Compliance

- Alignment with Standards: Utilizing BSCs helps laboratories comply with national and international biosafety standards, such as those set by the CDC and WHO.

- Inspection Passing: Proper usage of BSCs can aid in passing safety inspections and avoiding potential fines or sanctions.

Improved Workflow Efficiency

- Ergonomic Design: Modern BSCs are designed with ergonomic features, enhancing comfort and reducing strain for technicians performing extended procedures.

- Integrated Technology: Many BSCs come with advanced technological integrations, such as alarms and monitoring systems, streamlining lab operations.

Energy Efficiency

- Eco-Friendly Options: Some BSC models boast energy-efficient features, reducing operational costs and aligning with sustainable practices.

- Reduced HVAC Load: By containing contaminants within the cabinet, BSCs can reduce the load on the building’s HVAC system, contributing to energy savings.

Customization and Versatility

- Flexible Designs: BSCs come in various sizes and configurations, allowing customization to meet specific laboratory needs and space constraints.

- Adaptability: They can accommodate a wide range of laboratory practices, from microbiology and virology to cell culture and molecular biology.

Health and Safety Advancement

- Enhanced Sterilization: BSCs often include built-in UV lights for sterilization, ensuring a sterile workspace before and after experiments.

- Reduced Accident Risk: By containing hazardous materials, BSCs lower the risk of accidental spills and exposure, protecting both personnel and environment.

Economic Benefits

- Cost Savings: Preventing contamination incidents can lead to substantial cost savings by avoiding the need to repeat experiments or dispose of compromised batches.

- Investment in Safety: Investing in high-quality BSCs often results in long-term savings by reducing the likelihood of laboratory-acquired infections and associated costs.

By understanding and leveraging these benefits, laboratories can maximize safety, maintain research integrity, and optimize operational efficiency.

Comparison of BSCs with Other Laboratory Safety Equipment

Biological Safety Cabinets (BSCs) are crucial for protecting laboratory personnel, the environment, and research material. However, other laboratory safety equipment also offers unique protective features and functions. Comparing BSCs with these alternatives provides a deeper understanding of their respective advantages and limitations.

Chemical Fume Hoods (CFHs)

- Purpose: CFHs primarily protect personnel from hazardous chemical fumes and vapors.

- Airflow: CFHs mainly involve negative airflow, drawing air away from the user and venting it outside the building or through a filtration system.

- Usage: Ideal for procedures involving volatile chemicals but do not provide protection against biological agents.

Laminar Flow Cabinets (LFCs)

- Purpose: LFCs, also known as clean benches, offer a sterile environment by directing HEPA-filtered air across the work surface.

- Airflow: Typically unidirectional airflow protecting the specimen from contamination but not the user.

- Usage: Used for non-hazardous materials requiring sterility, such as in electronics and some medical settings.

HEPA-Filtered Enclosures

- Purpose: Utilize HEPA filters to remove particulates from the air, creating a contaminant-free environment.

- Airflow: Varies; can be incorporated into CFHs, BSCs, or standalone units.

- Usage: Applicable in various settings requiring particulate control, from general laboratory environments to specialized production facilities.

Safety Features

- Containment: BSCs provide both containment of biological agents and protection of procedures from environmental contamination.

- Engineering Controls: CFHs are designed for chemical safety, LFCs focus on product sterility, while BSCs balance both to provide biosafety.

- Filtration: Both BSCs and LFCs utilize HEPA filters, but only BSCs incorporate additional airflow dynamics for biosafety levels.

Maintenance and Certification

- Routine Checks: All equipment requires regular maintenance, but BSCs require specific certification for proper functioning.

- Decontamination: BSCs need frequent decontamination to ensure safety, compared to CFHs which may require special decontamination procedures after chemical usage.

Efficiency

- Operational Efficiency: The airflow design in BSCs ensures continuous protection, making them efficient for biological work.

- Energy Consumption: BSCs may consume more power due to their complex airflow and filtration systems compared to some simpler safety equipment.

Understanding the distinctions and applications of BSCs versus other laboratory safety equipment enhances safety management and ensures selecting the right protective measures for specific laboratory tasks.

Emerging Trends and Technologies in Biological Safety Cabinets

Advancements in Biological Safety Cabinets (BSCs) are continuously shaping the landscape of laboratory safety. These developments aim to augment both functionality and user experience, ensuring increased protection and efficiency. Here are some of the most notable emerging trends and technologies:

Smart Technology Integration

- Connected Systems

- Modern BSCs are increasingly being integrated with IoT (Internet of Things) systems.

- Real-time monitoring and remote control capabilities allow for better oversight of environmental conditions and safety compliance.

- Digital Interfaces

- Touch screen panels provide user-friendly interfaces, displaying real-time data on airflow, filter status, and cabinet performance.

- Alarms and notifications can be sent directly to smartphones or other devices, ensuring immediate awareness of any issues.

Energy Efficiency

- Variable Air Volume (VAV) Systems

- BSCs are incorporating VAV systems that adjust airflow based on real-time conditions, reducing energy consumption.

- These systems optimize airflow without compromising safety.

- LED Lighting

- The use of LED lighting instead of traditional fluorescent lighting not only reduces energy use but also prolongs the life of lighting fixtures.

Advanced Filtration Technologies

- HEPA Filters

- High-Efficiency Particulate Air (HEPA) filters are standard, but advancements are improving their efficiency and lifespan.

- ULPA Filters

- Ultra-Low Penetration Air (ULPA) filters are being introduced, trapping particles more effectively than traditional HEPA filters.

Enhanced Ergonomics

- Adjustable Workstations

- Height-adjustable work surfaces are becoming standard, accommodating users of different physical statures.

- User Comfort

- Incorporating anti-fatigue mats and ergonomic seating options to improve comfort during long hours of work.

Safety Enhancements

- UV-C Decontamination

- Some BSCs are now equipped with UV-C lighting, providing an automated method for decontamination.

- Improved Containment

- Advances in structural design enhance containment, reducing the risk of exposure to harmful agents.

Green Building Standards

- Certification

- BSCs are being designed to comply with green building standards like LEED, promoting environmental sustainability.

- Materials

- Use of recyclable and sustainable materials in the construction of BSCs.

Customization and Modularity

- Tailored Solutions

- Manufacturers are offering customization options to meet specific research needs and laboratory layouts.

- Modular Components

- BSCs with modular components allow for easy upgrades and repairs, extending the life of the equipment.

These emerging trends and technologies highlight an ongoing commitment to advancing biological safety and operational efficiency within laboratory settings. As these innovations evolve, they bring about significant improvements in safeguarding researchers and ensuring the integrity of scientific research.

Conclusion: Ensuring Safety and Efficiency with BSCs

Biological Safety Cabinets (BSCs) play a pivotal role in safeguarding technicians, researchers, and the environment from biohazardous materials. Their proper use and maintenance are critical to maintaining safety and efficacy in various laboratory settings.

Key components of ensuring safety and efficiency with BSCs include:

- Proper Selection:

- Class I: Protects user and environment only.

- Class II: Provides protection to user, environment, and the product.

- Class III: Offers the highest level of containment, used for high-risk biological agents.

- Routine Maintenance:

- HEPA Filter Replacement: Replace filters at regular intervals to ensure continued efficacy.

- UV Lamp Maintenance: Regularly check and replace UV lamps to maintain sterility.

- Surface Decontamination: Clean internal surfaces daily with appropriate disinfectants.

- Correct Usage:

- Pre-Use Check: Verify airflow, HEPA filter integrity, and general condition before each use.

- Proper Technique: Minimize disruptions to the airflow by avoiding rapid arm movements inside the cabinet.

- Contamination Prevention: Limit the number of materials and equip necessary for the task, reducing clutter within the BSC.

- Training and Guidelines:

- User Training: Comprehensive training sessions for all users, focusing on proper techniques and safety protocols.

- Standard Operating Procedures (SOPs): Maintain and follow SOPs tailored to the specific BSC being used.

- Emergency Procedures: Establish clear procedures for dealing with spills or accidents inside the BSC.

- Monitoring and Certification:

- Regular Certification: Annual or biannual certification by accredited professionals ensures the BSC remains compliant with safety standards.

- Performance Monitoring: Implement continuous monitoring systems to track airflow patterns and filter integrity in real-time.

By focusing on these aspects, laboratories can maximize the safety and efficiency of BSCs, ensuring a secure working environment for all personnel involved and reducing the risk of contamination. Properly maintained and correctly used, BSCs remain an indispensable tool in biological research and clinical applications. Download: Laboratory Inspection Checklist Form

For many safety resources click here